elco EK 4.100 L-ZA User manual

This manual suits for next models

1

Other elco Burner manuals

elco

elco VECTRON G 1.40 User manual

elco

elco VG 1.40 User manual

elco

elco N6 G-EF3/BT3 Series Quick start guide

elco

elco N6.2400 GL-RZ3/LFL User manual

elco

elco N8 GL-E/BT3 Series Quick start guide

elco

elco EKEVO 6/N6.2400 GL-EZ3 User manual

elco

elco VG 2.120 D User manual

elco

elco VG2.120 M E /TC User manual

elco

elco VECTRON ECO 1.34 User manual

elco

elco Firebird FB 2 K LN User manual

elco

elco VGL 06.1600 DP User manual

elco

elco Low-NOx N10.12000.30 G-EU2 User manual

elco

elco VG3.290 D User manual

elco

elco VL 4.460 D User manual

elco

elco Firebird FB 4 R LN User manual

elco

elco P2.190 L-Z/LMO User manual

elco

elco VECTRON L1.40 User manual

elco

elco L 03.240 DUO User manual

elco

elco N6.2400 G-V User manual

elco

elco VL3.360 D User manual

Popular Burner manuals by other brands

baltur

baltur TBML 350 ME INSTALLATION, USE AND MAINTENANCE INSTRUCTION MANUAL

Enertech

Enertech Bentone BFG1 Installation and maintenance instruction

Carlin

Carlin 801GAS instruction manual

KitchenAid

KitchenAid LP instructions

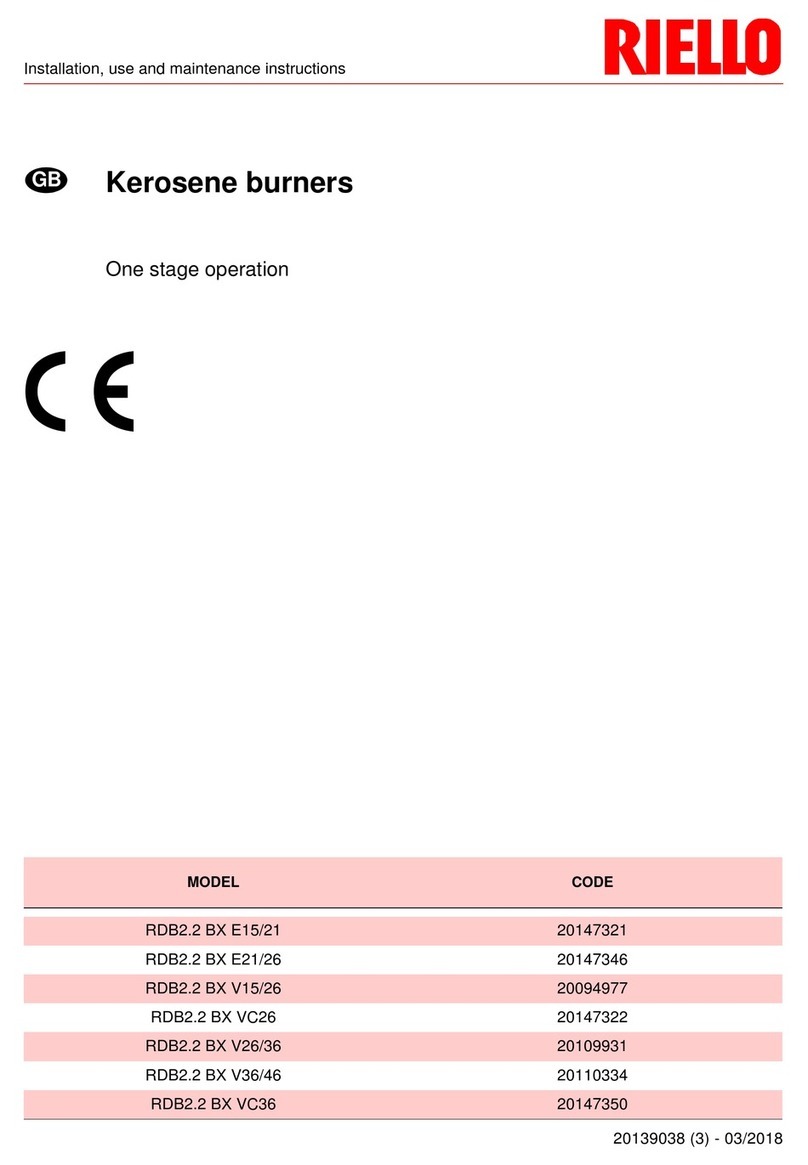

Riello

Riello RS 160/M BLU Installation, use and maintenance instructions

Ecoflam

Ecoflam BLU 700.1 P manual

Riello

Riello RX 70 S/PV Installation, use and maintenance instructions

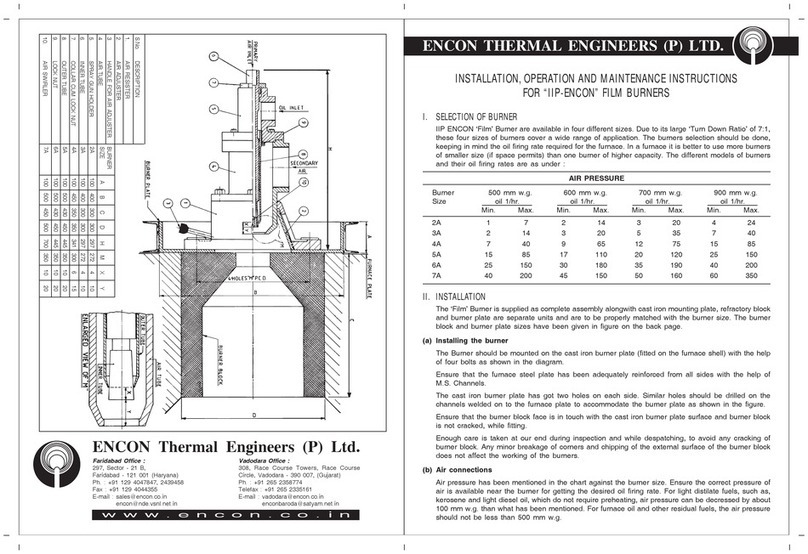

ENCON

ENCON IIP-ENCON Installation, operation and maintenance instructions

baltur

baltur GI 350 DSPGN Instruction

Bentone

Bentone BG 450-2 Installation and maintenance instruction

Gozney

Gozney Dome S1 Technical manual

Riello

Riello G5 444T50 Operation guide