elco ELK22MP User manual

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 1

MICROPROCESSOR DIGITAL

ELECTRONIC REGULATOR

INSTRUCTIONS FOR USE

Ver. 04 (EN) – 02/22

EL.CO. S.r.l.

Via Lago di Molveno, 20

36015 SCHIO (VI) ITALY

TEL.: +39 0445 661722

FAX: +39 0445 661792

internet : http://www.elco-italy.com

INTRODUCTION

This manual contains the information required

for proper installation and the instructions for

use and maintenance of the product. It is

therefore recommended to read it carefully and

to preserve it.

This publication is the exclusive property of

EL.CO. S.R.L. that places the absolute

prohibition of reproduction and disclosure, even partial, if not

expressly authorized.

EL.CO. S.R.L. reserves the right to make aesthetic and

functional changes at any time and without notice.

If a malfunction or failure of the device can create hazardous or

dangerous situations for people, animals or property, the

system must be equipped with additional security devices.

EL.CO. S.R.L. and its legal representatives do not assume any

responsibility for any damage to people, things or animals

deriving from tampering, improper use, incorrect use or

otherwise not complying with the device's features.

1

–

DIMENSION

(mm)

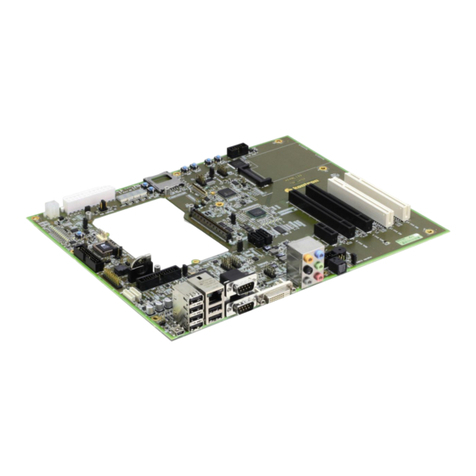

1.1 – ELK22MP MODULE FOR DIN RAIL ASSEMBLY

SCRIZIONE STRUMENTO

2

-

DEVICE DESCRIPTION

2.1 - GENERAL DESCRIPTION

The ELK22MP series is made up of digital microprocessor

controllers, with ON / OFF, ON / OFF neutral zone, PID and with

AUTOTUNING function for PID regulation.

The instrument can have up to 3 outputs, for settingstatic relays

(SSR) or 2 relays. It is compatible with TC, J, K - RTD Pt 100

temperature probes; PTC KTY8 1-121; NTC 103AT-1 - For

normalized signals 4… 20mA, 0… 10V.

It is designed for mounting on a din rail.

The ELK22MP series consists of 4 models. 3 of these act as a

centralizer and one of them as a slave. The models of the

ELK22MP series are:

- ELK22MP: Control unit equipped with programmable inputs and

outputs with the ELK22DKP keyboard

- ELK22MPM: Centralizer equipped with programmable inputs and

outputs via ELK22DKP keyboard andRS485

- ELK22MPE: Centralizer equipped with programmable inputs and

outputs via RJ45 (Ethernet).

- ELK22MPS: Slave equipped with inputs and outputs, controlled

via bus by ELK22MP or ELK22MPM or ELK22MPE

The configuration of the instrument foresees the connection of 1

centraliser product (ELK22MP, ELK22MPM) connected to 15

ELK22MPS via bus located on the back of the product, sold as an

accessory (see Paragraph 10.6). Using the ELK22MPE centralizer it

is possible to connect 31 ELK22MPS devices, again via the bus

located on the back of the product, which can be sold as an

accessory (see Paragraph 10.6).

Using an external device (for example ELK22DKP (see Paragraph

3.2), PLC, PC ...) it is possible to program the centralizer and the

slave devices connected to it via the bus on the back (see

Paragraph 4.6).

Throughout the manual we consider ELK22MP, ELK22MPM or

ELK22MPE devices as “centralizing devices” and ELK22MPS

devices as “slave devices”. If there are any particular functions then

we will refer to the particular model.

3

-

PROGRAMM

ING

3.1 – PROGRAMMABLE MODELS

The programming phase must take place when the product is

switched on. According to what has been described, the

configuration of a series of ELK22MP foresees the installation of a

centralizing device with n slave devices connected through the bus

(see Paragraph 4.6).

The various programming modes are:

- Via keypad ELK22DKP (only for ELK22MP and

ELK22MPM)

ELK22MP

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 2

- Via RS485 (only for ELK22MPM)

- Via Ethernet (only for ELK22MPE)

Programming with RS485 or Ethernet can be done via, for example,

operator panel, PLC or computer.

We will indicate "external instrument" the set of all the instruments

that can connect to the centralizing devices.

The programming phases must reflect these steps:

- Only one centralizing device

oPower on the device

oProgramming the centralizing device with the

external device

oUse the device

- One centralizing devica with N slave device

oPower on the centralizing deivce

oProgramming the centralizing device with the

external device

oConnect a slave to the centralizer via bus (, see

Paragraph 4.6). Turn on the product and program

it with the external device connected to the

centralizer.

The external device cannot be

connected to a slave device.

oRepeat the previous step for each slave in

possession.

oUse the devices

After having programmed the various devices, it is possible to

control them with the external device connected only to the

centralizing device. The slave devices are connected with the bus

(see Paragraph 4.6) to the centralizing device but are controlled by

the external device.

The devices, if more than one, must be connected one by

one and programmed one by one. Each device has the same

default address. (see Paragraphs 3.2.1, 3.3.2 and 3.4.2)

3.2 – PROGRAMMING BY ELK22DKP KEYBOARD (only for

ELK22MP e ELK22MPM)

3.2.1 – DESCRIPTION

Only the ELK22MP and ELK22MPM models can be programmed

via the ELK22DKP keypad. Through the bus connection (see

Paragraph 4.6) it is possible to program the slave products

ELK22MPS. The keyboard connected to the ELK22MP or

ELK22MPM model can program and set the parameters of each

ELK22MPS connected via bus.

The default MODBUS address is 100.

3.2.2

-

FRONT PANEL DESCRIPTION (ELK22DKP)

1 – Key : Used to access programming of the operating

parameters and to confirm the selection.

2 - Key ▼: Used for decreasing setpoint setting, values to be set,

and for parameter or module selection. Long pressed in full menu

programming, it changes the access level of the selected

parameter. (See para. 3.1, 3.3). Long pressed in the menu for the

module selection performs the download of the parameters from the

module to the programming keypad. (See para. 3.5).

3 - Key ▼: Used for increasing setpoint setting, values to be set,

and for parameter or module selection. Long pressed in full menu

programming, it changes the access level of the selected

parameter. (See para. 3.1, 3.3). Long pressed in the menu for the

module selection performs the upload of the parameters from the

programming keypad to the module. (See para. 3.5).

4 – Key : When in programming mode, you can use it to quit

programming or to cancel the change of a parameter. During

normal operation, it enables the menu to select a module.

5 – 4 red digits: Process value during operation, parameter

selected during programming.

6– 4 green digits: Setpoint value during operation, value of the

parameter selected during programming.

7 – LED 1 : It indicates OUT1 output status. LED 2 : It indicates

OUT2 output status.

8 – LED AL : It indicates the state of the alarm.

9 – LED B1 : In full programming mode, it indicates that the

parameter is not visible in the operator menu. LED B2 : In full

programming mode, it indicates that the parameter is visible in the

operator menu.

10 – LED °C : It indicates unit of measure in degrees centigrade.

11 – LED °F : It indicates measurement units in degrees

Fahrenheit.

12 – LED REM : In parameters programming mode, it indicates that

you are changing the selected parameter. In module selection

programming mode, it indicates that you are selecting a remote

module.

13 – Led MAN : In module programming mode, it indicates the

download of a setting.

3.2.3- MODULE SELECTION

Pressing the button lights up the REM LED to indicate that you

can select on which ELK22MP you want to connect to and interact

with the programming keypad.. The 4-color display displays the

read temperature while the 4-screen green display shows the

address of the ELK22MP you are currently selecting. Use the ▲

and ▼keys to select the desired ELK22MP depending on the

address you set. Pressing the key confirms the selection of the

ELK22MP with the displayed address.

3.2.4 - SETPOINTS FAST SETTING

The 4 green displays display always displays the setpoint set.

Pressing the ▲key increases the value and pressing the ▼key

decreases the value. These keys act at one-digit steps, but if

pressed for more than half a second, the value increases or

decreases rapidly to allow quick access to the desired value. The

setpoint can be set with a value between the value programmed in

para. “SSP” and the value programmed in para. “FSP”.

3.2.5 - PROGRAMMING THE PARAMETERS

To have access to the operating parameters of the device in the

installer mode, you must press the key and hold it for about 2

seconds, while pressing the key for user mode access. The

display will show “SET” and then “PASS” if a password for the

installer access is set. Use the ▲and ▼keys to enter the

password and confirm with . The red display shows the code that

identifies the parameter, the green display shows the value set and

with the ▲and ▼keys you can select the parameter you want to

edit. Once the desired parameter is selected by pressing the key

, the “REM” LED lights up to indicate that you are changing the

parameter setting using the ▲and ▼keys. After setting the desired

value, press again the key ; the new value will be stored while,

pressing the key , the new value will not be stored, then the

“REM” LED will switch off. By using the ▲and ▼keys, you can

select another parameter and change it as described. To exit the

programming mode, do not press any key for about 10 seconds if in

user mode or 20 seconds if in the installer mode, or hold down the

key until you exit the programming mode.

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 3

3.2.6 - PROTECTION OF PARAMETERS WITH PASSWORD

The device has two levels of access to the programming, installer,

and user menu. The password can be customized via the “PASS”

parameter.If you want to have this protection, set the “PASS”

parameter with the desired password number and exit the

parameter programming. If you do not want to protect the installer

menu, set the parameter “PASS” on “0000'. By accessing the

installer mode, each parameter will have the B1 or B2 LED on. B1

indicates that the parameter is visible only in the installer menu;

otherwise, B2 indicates that it is also visible in the user menu. To

enable a parameter to be visible on the user menu, hold down the

▲key until B1 turns off and B2 lights up. To hide a parameter from

the user menu, hold down the ▼key until B2 turns off and B1 lights

up.

Is possible from this parameter set the default factory default. From

password value 0000 hold down the key ▼two times. Display show

rSt dEF, premere il tasto , display show rSt SurE, at this time

hold down the key ▲for three seconds. In any time is possible

cancel the reset request by hold down the key .

3.2.7 - COPY OF PARAMETERS FROM AN ELK22MP TO

ANOTHER

From the ELK22MP selection menu, you can copy the programming

parameters of an ELK22MP to other ELK22MP.

You must download the parameters by pressing the ▼button for a

long time until the MAN LED lights up. The MAN LED indicates that

you have a loaded configuration that can be copied to other

ELK22MP. Use the ▲and ▼keys to select ELK22MP on which

you want to copy the configuration and start uploading the

parameters by pressing the ▲key for a long time.. The 4-color

display displays “UP_C”; confirm by pressing the key or cancel

the copy by pressing the key . To erase the parameters from the

download zone, press and hold the key until the MAN LED turns

off.

3.2.8 – DATA EXCHANGE

Data is exchanged via the bus commanded from the keyboard.

Communication via bus takes place via an RS485 line.

The configurable parameters are found in Paragraph 6.

3.3 – PROGRAMMING BY RS485 MODBUS (only for

ELK22MPM)

3.3.1 – DESCRIPTION

The ELK22MPM devices are equipped with an RS485 serial

communication interface.

At rest, the module is in receiving condition and transmits after

receiving and decoding a correct message addressed to it.

The connection between the ELK22MPM accelerator and the

ELK22MPS slaves is via bus, which can be purchased as an

accessory. (see Paragraph 10.6)

To keep the line at rest it is necessary to use a 120 Ohm

termination resistor. The device does not mount this

resistance. The termination of the RS485 line with the 120 Ohm

resistor can be done using the terminal supplied as an

accessory. (see Paragraph 10.6)

The communication speeds adopted range from 1200 to 38400

baudrates and allow very satisfactory performances, while

remaining well below the limits imposed by the RS485 standard.

This allows the line to be wired using a medium quality shielded

twisted pair - the total line capacity should not exceed 200 nF.

The poll rate during programming and in use must not be

less than 50ms.

In case of using a number greater than 8 ELK22MPS the

recommended poll speed is greater than or equal to 80ms.

The maximum length of an RS485 transmission is 400

meters.

3.3.2 – COMMUNICATION PROTOCOL DESCRIPTION

The protocol is a subset of the widely used MODBUS RTU protocol.

This choice guarantees ease of connection to many PLCs and to all

commercial supervision programs.

The default MODBUS address is 100.

For those wishing to develop their own application software, all the

necessary tips and information are available.

The MODBUS RTU protocol functions implemented in the

EKL22MPM instruments are:

Function 1 - output status read

Function 3 - n word read

Function 6 - one word write

Function 7 - allarm status read

These functions (see Paragraph 7) allow the supervision program to

read and modify any data of the module. The communication is

based on messages sent from the centralization station

(ELK22MPM) to a slave station (ELK22MPS) and vice versa. The

slave station which recognizes its address in the message,

analyzes its content and, if it finds it formally and semantically

correct, generates a reply message for the master.

The communication process involves four types of messages:

From the centralizer to the slave:

•Function 1: output status read request

•Function 3: n word read request

•Function 6: one word write request

•Function 7: allarm status read request

From the slave to the centralizer:

•Function 1: output status read replay

•Function 3: n word read replay

•Function 6: one word write replay

•Funzione 7: allarm status read replay

Each message contains four fields:

•slave address: the values between 1 and 255 are valid;

address 0 (zero) is reserved by MODBUS RTU for the

diffusion of messages, but is not adopted in the ELK22MP

series due to the implicit unreliability of this type of

communication;

•function code: contains 1 or 3 or 6 or 7 depending on the

specified function;

•information field: contains the addresses or the value of

the words, as required by the function in use;

•control word: contains a Cyclic Redundancy Check (CRC)

calculated according to the rules envisaged for CRC16.

The characteristics of asynchronous communication are: 8 bits, no

parity, one stop bit.

The functions described for the RS485 protocol are found in

Paragraph 7.

3.3.3 – DATA EXCHANGE

The data exchanged consists of a 16-bit word. All readable and

writable data appear as 16-bit words allocated in the instrument's

memory.

The operating and configuration parameters of the instrument can

be read and written via serial communication.

The configurable parameters are found in Paragraph 6.

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 4

3.4 – PROGRAMMING VIA ETHERNET TCP / IP (only for

ELK22MPE models)

3.4.1 – DESCRIPTION

ELK22MPE devices are equipped with an RJ45 Modbus TCP / IP

communication interface. At rest, the module is in receiving

condition and transmits after receiving and decoding a correct

message addressed to it.

The poll rate during programming and in use must not be

less than 50ms.

In case of using a number greater than 8 ELK22MPS the

recommended poll speed is greater than or equal to 80ms.

3.4.2 – COMMUNICATION PROTOCOL DESCRIPTION

The protocol is a subset of the widely used MODBUS RTU protocol.

This choice guarantees ease of connection to many PLCs and to all

commercial supervision programs.

The connection between the ELK22MPE centralizer with the

ELK22MPS slaves is via bus, which can be purchased as an

accessory. (see Paragraph 10.6)

The default IP address is 10.10.10.50.

The default SUBNET MASK address is 255.255.255.0

The default GATEWAY address is 0.0.0.0

For those wishing to develop their own application software, all the

necessary tips and information are available.

The MODBUS TCP / IP protocol functions implemented in the

EKL22MPE instruments are:

Function 1 - output status read

Function 3 - n word read

Function 6 - one word write

Function 7 - allarm status read

These functions (see Paragraph 8) allow the supervision program to

read and modify any data of the module. The communication is

based on messages sent from the centralization station

(ELK22MPE) to a slave station (ELK22MPS) and vice versa. The

slave station which recognizes its address in the message,

analyzes its content and, if it finds it formally and semantically

correct, generates a reply message for the master.

The communication process involves four types of messages:

From the centralizer to the slave:

•Function 1: output status read request

•Function 3: n word read request

•Function 6: one word write request

•Function 7: allarm status read request

From the slave to the centralizer:

•Function 1: output status read replay

•Function 3: n word read replay

•Function 6: one word write replay

•Funzione 7: allarm status read replay

Each message contains six fields:

•header: 2 bytes of unique identification code

•control: 2 bytes always at 0

•length: length of the packet excluding the first 6 bytes

•slave address: the values between 1 and 255 are valid;

address 0 (zero) is reserved by MODBUS RTU for the

diffusion of messages, but is not adopted in the ELK22MP

series due to the implicit unreliability of this type of

communication;

•function code: contains 1 or 3 or 6 or 7 depending on the

specified function;

•information field: contains the addresses or the value of

the words, as required by the function in use;

The functions described for the TCP / IP protocol are found in

Paragraph 8.

3.4.3 – DATA EXCHANGE

The data exchanged consists of a 16-bit word. All readable and

writable data appear as 16-bit words allocated in the instrument's

memory.

The operating and configuration parameters of the instrument can

be read and written via serial communication.

The configurable parameters are found in Paragraph 6.

4

–

WARNINGS

FOR IN

STALLATION

AND U

SE

4.1 – PERMITTED USE

The device has been designed as a measurement and

adjustment device in accordance with EN61010-1 for

operation at altitudes up to 2000 m. The use of the

device in applications not expressly provided for in the

aforementioned standard must include all appropriate protective

measures. The device CANNOT be used in hazardous

(inflammable or explosive) environments without proper protection.

It should be remembered that the installer must ensure that the

electromagnetic compatibility rules are respected even after the

device has been installed, possibly using special filters. If a failure

or malfunction of the device can create hazardous or dangerous

situations for persons, animals or property, the system must be

equipped with additional electromechanical devices to ensure

safety.

4.2 - MECHANICAL ASSEMBLY

The ELK22Mp module must be installed on the DIM rail. Avoid

placing the inside of the device in places subject to high humidity or

dirt that may cause condensation or introduction into the device of

parts or conductive substances. Ensure that the device has

adequate ventilation and avoid installation in containers where

devices are located that can lead the device to operate outside the

declared temperature limits. Install the device as far as possible

from sources that may generate electromagnetic disturbances such

as motors, contactors, relays, solenoid valves etc.

Only the frontal panel will be accessible after the installation.

The programming device, in a 50 x 50 mm container, is designed

for panel-mounted mounting inside housing. Then make a 45 x 45

mm square hole or a 22 mm diameter hole and insert the keypad by

fastening it with the supplied nut. It is recommended to mount the

special gasket to obtain the degree of frontal protection stated.

An installation not complying with these instructions could

compromise the protection declared.

4.3 ELECTRICAL CONNECTIONS

Make the connections by connecting only one conductor for each

clamp and following the diagram shown, checking that the supply

voltage is that indicated on the device and the absorption of the

actuators connected to the device is not higher than the maximum

current allowed. The device, provided for permanent connection

within an equipment, does not have either switch or internal

overcurrent protection devices. It is therefore recommended to

provide for the installation of an overcurrent protection device

(500mA fuse for the 230∿ model or 2A fuse for the 24≂ model) and

a bipolar switch/disconnecting switch, marked as a disconnecting

device, which interrupts the power supply of the device. This switch

must be positioned as close as possible to the device and in a place

easily accessible by the user. It is also recommended to adequately

protect the supply of all circuits connected to the device with

suitable items (i.e. fuses) that are appropriate for circulating

currents. It is recommended to use insulation cables suitable to the

voltages, temperatures and operating conditions and to ensure that

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 5

the cables for the input sensors are kept away from power cords

and other power cables, in order to avoid induction of

electromagnetic disturbances. Output SSRs and inputs are not

electrically insulated. Connect on the input only insulated probes. If

some wiring harness cables are shielded, it is recommended to

connect them to one side on the ground. Finally, it is recommended

to check that the set parameters are the desired ones and that the

application works properly before connecting the outputs to the

actuators in order to avoid system abnormalities that could cause

damage to persons, things or animals.

4.4 – ELECTRICAL SCHEME CONNECTIONS

4.4.1 - ELK22MPS

4.4.2 - ELK22MPE

4.4.3 - ELK22MP e ELK22MPM

4.4 - ELECTRICAL SCHEME CONNECTIONS FOR ELK22DKP

(only for ELK22MP or ELK22MPM)

4.5 – CONNECTION FROM ONE DEVICE TO ANOTHER DEVICE

The ELK22MP series devices can be connected to each other via

the bus connector supplied as an accessory. (see Paragraph 10.6).

Slave devices must be connected to a centralization device to form

a sequence.

A devices sequence that have ELK22MPE as a centralizer

must consist of a centralizer device and a maximum of 1 to 31 slave

devices.

A devices sequence that have ELK22MPM or ELK22MP as a

centralizer must consist of a centralizer device and a maximum of 1

to 15 slave devices.

Two control units cannot be connected to each other via the

bus but must be considered as two distinct devices. Two control

units connected to each other via bus can cause a malfunction of

the product.

Be careful if you change the centralization device. If you switch

from an ELK22MPE to an ELK22MPM or ELK22MP centralizer, pay

attention to the number of ELK22MPS connected via bus.

4.6 – CONNECTION WITH TERMINAL RESISTOR

ELK22MP devices use RS485 via bus to communicate with each

other. In particular, the centralizing device communicates via bus

with the slave devices in order to program them.

The RS485 line requires a termination resistor to avoid

disturbances. This resistance, 120 Ohm, must be placed at the end

of an RS485 line. Through the connector (see paragraph 10.6) it is

possible to mount the termination resistor directly on the bus at the

end of the ELK22MP series device line.

The termination resistor is mandatory for the operation

of any RS485 line.

Terminating a line of ELK22MP series devices with the

connector (see Paragraph 10.6) and the 120 Ohm resistor gives

the possibility to terminate an RS485 serial line. The accessory

is already supplied with a 120Ohm resistor.

Resistor 120 Ohm

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 6

It is possible to continue the serial line using the same

connector (see Paragraph 10.6). In this mode, the termination

resistor will not be placed at the end of the battery of the

ELK22MP devices but it must be the device to which the line is

connected that must have the termination resistor. To do this,

disconnect the resistance from the accessory and continue the

line with the cables for RS485 as below screenshot shwon

4.7 – IMAGE CONNECTION

4.7.1 – ELK22MP Stand Alone

4.7.2 – ELK22MPM Stand Alone

4.7.3 – ELK22MPE Stand Alone

4.7.4 – ELK22MP with at most 15 ELK22MPS

4.7.5 – ELK22MPM with at most 15 ELK22MPS

4.7.6 – ELK22MPE with at most 31 ELK22MPS

7 - pole RX (-)

8 - pole TX (+)

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 7

5

–

OPERATION

5.1 - MEASUREMENT AND DISPLAY

The thermoregulator handles the following sensors that can be set

by the “Sens” parameter: thermocouple type (TCJ), K (TCK), S

(TCS), PTC KTY81-121 (ptc), NTC 103AT-2 (ntc), PT100 (p100), 0-

10V (0-10), 4-20mA (4-20)..

When changing this parameter, it is recommended that you turn the

power off and on again to obtain a correct measurement.

You can set the measurement unit of temperature (°C, °F) by the

“Unit” parameter and the desired measurement resolution (0=1;

1=0,1) by the “dP” parameter (for Pt100, 0-10V, 4-20mA).

The device allows the calibration of the measurement, which can be

used for a new calibration of the device according to the needs of

the application, by par. “CA”. You can set a positive or negative

offset that is simply added to the value read by the probe before the

display and that is constant for all measurements. You can define

the temperature display range by setting the “SSC” and “FSC”

parameters.

Using the “FiL.d” parameter, you can set the display update time..

5.2 - ON/OFF REGULATOR

This adjustment mode can be achieved by setting the "Cont" =

On.F parameter and can act on output 1 or output 2 or output 3

according to the measurement, of the Setpoint "SP1", the operating

mode "O1F”,“O2F”, “O3F”, and the hysteresis "HPOS" and

“HNEG” programmed.

The device performs an ON/OFF adjustment with asymmetric

hysteresis.

The regulators behave as follows: in case of reverse action or

heating (“OxF”=H.REG), they disable the output when the process

value reaches the [SP + HPOS] value and reactivate it when it falls

below the [SP - HNEG] value.

Vice versa, the regulators behave as follows: in case of direct action

or cooling (“OxF”=C.REG), they disable the output when the

process value reaches the [SP - HNEG] value and reactivate it

when it goes over the [SP + POS] value.

5.3 - NEUTRAL ZONE ON/OFF ADJUSTMENT

Neutral Zone operation is used to control systems that have an

element that causes a positive increase (i.e. heating, humidifying,

etc.) and an element that causes a negative increase (i.e. cooling,

dehumidifying, etc.).

This operation can be carried out when there are 2 outputs and it’s

obtained by programming the parameter “Cont” = ON.FN, the

parameter “OxF” = H.REG, the parameter “OyF” = C.REG.

The adjustment operation operates on outputs depending on the

measurement of the setpoint "SP1" and hysteresis "HPOS" and

“HNEG” programmed.

The regulator behaves as follows: it turns off the outputs when the

process value reaches the SP1 setpoint and activates the OUT1

output when the process value is less than [SP1-HNEG],or turns on

the OUT2 output when the process value is greater than

[SP1+HPOS].

Consequently, the element causing the positive increase will be

connected to the OUT1 output while the negative increase element

will be connected to OUT2 output.

5.4 - PID REGULATOR

The PID single action adjustment mode can be implemented by

setting the parameter "Cont" = Pid and acts on OUT1 or OUT2 or

OUT3 output as a function of the “SP1”setpoint.

To obtain a good stability of the variable in fast processes, the “tr1”

cycle time must have a low value with a very frequent intervention

of the adjustment output.

In this case, it is recommended to use a static relay (SSR) for the

actuator control.

The single-action PID adjustment algorithm provides the setting of

the following parameters:

"Pb" - Proportional Band

"tI" - Integral Time

"td" - Derivative time

"tr1" - Output cycle time

5.5 - AUTOTUNING FUNCTION

The AUTOTUNING function calculates the PID parameters through

an OSCILLATORY tuning cycle, after which the parameters are

stored by the device and, during the adjustment, they remain

constant.

Autotuning function automatically calculates the following

parameters:

"Pb" - Proportional Band

"Int" - Integral Time

"dEr" - Derivative time

To enable the AUTOTUNING function, proceed as follows:

1) Set the desired “SP1” setpoint.

2) Set the "Cont" =Pid setpoint.

3) Set the "O1F" parameter depending on the process to be

controlled through OUT1 output.

4) Set the "Auto" parameter as:

= 1 - if you want autotuning to start automatically every time you

turn on the device.

= 2 - if you want autotuning to start automatically at the next power

up of the device and, once tuning is completed, the par.

“Auto”=OFF.

= 3 – manual start-up by hold down the key for 5 seconds

5) Quit programming parameters.

6) Connect the device to the controlled system.

7) Activate autotuning by turning the unit off and on again. At this

point, the Autotuning function is activated and is reported through

the "Auto" display on the green display.

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 8

The regulator then performs a series of connected system

operations to calculate the most suitable PID adjustment

parameters.

The duration of the Autotuning cycle is limited to a maximum of 12

hours.

If the process is not completed within 12 hours, the parameters will

not be changed and display show “Fail Auto”. Holding down the

key return to normal operation.

Is possible stop the autotuning process by hold down the key for

five seconds.

The values calculated by the AutoTuning will be automatically

stored by the device at the end of the proper run of the Autotuning

cycle in the PID adjustment parameters.

5.6 - ALARM FUNCTION

In the control mode, you can activate relative minimum or

maximum, absolute minimum or maximum, relative window with

activation inside or outside window alarms.

You can enter a hysteresis and a delay on the return of the alarm.

Such functions may be useful in order to avoid frequent

interventions of the outputs especially when they command

compressors.

The delay function is deactivated by programming “ALxD” on 0.

The parameter “ALx” sets the alarm setpoint..

Set “O1F” = AL to associate output 1 with the alarm 1.

Set “O2F” = AL to associate output 2 with the alarm 2.

Example of operation with “AL1T” = Loab (minimum alarm)

Example of operation with “AL1T” = HidE (relative maximum)

Example of operation with “AL1T” = LHdi (relative band in)

5.7 – SETTING MODULE ADDRES

ELK22MP have 16 as default addres. At the startup of the system,

ELK22DKP will be in communication with the lowest addres of the

full system. During normal operation will be accepted value from 1

to 16. Connect one ELK22MP at time and set the ADR parameter

before connect the next ELK22MP.

Example: connect and power up the first ELK22MP, program the

ADR parameter to 0, and power off the system. Connect the second

ELK22MP and power up the system (or only the ELK22MP), and

set the ADR parameter at the next or prefer value, but it will be

different of the last ADR set.

6

-

PROGRAMMABL

E PARAMETERS TABLE

Below are all the parameters that the device can be equipped with.

The hex address is only for ELK22MPE and ELK22MPM

The address in decimal is also avaiable for better reading.

Address 512 in decimal (0x200 in hex) is reserved for reading

the product temperature.

Descrizione Range Def. Indirizzo

hex

SP1

SetPoint 1 SSP ÷ FSP

0 0x00-0

SENS In-probe type:

TCJ = Thermocouple

J

TCK = Thermocouple

K

TCS = Thermocouple

S

ntc= Thermistor NTC

103-AT2

Ptc= Thermistor PTC

KTY81-121

P100= Thermal

resistor Pt100

0-10= 0-10V

4-20= 4-20mA

1 = TCJ

2 = TCK

3 = TCS

4 = NTC

5 = PTC

6 = P100

TCJ 0x01-1

DP Number of decimals P100, 0-

10,

4-20:

0 / 1

0 0x02-2

S

SC

Minimum display -999 ÷ 1000

-50 0x03-3

FSC

Maximum display -999 ÷ 1000

1000

0x04-4

UNIT Temperature

measurement unit

0 = °C

1 = °F

°C 0x05-5

CA

Measure offset -100 ÷ 100 0 0x06-6

FIL.D Display adjustment

time

0.5 0x07-7

CONT Adjustment type:

Pid= PID

On.F= ON/OFF

On.Fn= Neutral Zone

(double action

ON/OFF)

0 = Pid

1 = On.F

2 = On.Fn

On.F

0x08-8

AUTO Enabling autotuning:

OFF = Disabled

1 = Start-

up upon

each switching on

2 = Start-

up upon

the first switching

on

= Manual Start-up

OFF /

1 ÷ 3

OFF 0x09-9

BP Proportional band

(PID adj.)

1 ÷ 1000 40 0x0A-10

TD Integral time (PID

adj.)

0 ÷ 100.0

sec.

10.0 0x0B-11

TI Derivative time (PID

adj.)

0 ÷ 100.0

sec.

5.0 0x0C-12

TR1 Output time period 0.5 ÷ 20.0

sec.

20.0 0x0D-13

HPOS Positive adjustment

hysteresis

0 ÷ 100 2 0x0E-14

HNEG Negative adjustment

hysteresis

0 ÷ 100 2 0x0F-15

SSP Setpoint setting lower

limit

SSC ÷ FSC

-50 0x10-16

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 9

FSP Setpoint setting

upper limit

SSC ÷ FSC

1000

0x11-17

O1F Operation mode of

the OUT1 output:

none: unused

H.reg= Heating

C.reg= Cooling

Al= alarm

On= Always on

0 = None

1 = H.reg

2 = C.reg

3 =Al

4 = On

H.reg

0x12-18

O2F Operation mode of

the OUT2 output:

none: unused

H.reg= Heating

C.reg= Cooling

Al= alarm

On= Always on

0 = None

1 = H.reg

2 = C.reg

3 =Al

4 = On

None

0x13 -19

O3F Operation mode of

the OUT1 output:

none: unused

H.reg= Heating

C.reg= Cooling

On= Always on

0 = None

1 = H.reg

2 = C.reg

3 = On

None

0x14 -20

AL1T Operation mode of

the alarm:

none= disabled

LoAb= absolute

minimum

HiAb= absolut

maximum

LodE= relative

minimum

HidE= relative

maximum

LHdi= relative

window in

LHdo= relative

window out

0 = None

1 = Loab

2 = Hiab

3 = LodE

4 = HidE

5 = LHdi

6 = LHdo

None

0x15 -21

AL1

Alarm threshold SSP ÷ FSP

0 0x16 -22

HAL1 Hysteresis of alarm

remedy

0 ÷ 100 1 0x17 –

23

AL1D Delay of alarm

remedy

0 ÷ 100.0

sec.

0 0x18 - 24

AL2T Operation mode of

the alarm:

none= disabled

LoAb= absolute

minimum

HiAb= absolut

maximum

LodE= relative

minimum

HidE= relative

maximum

LHdi= relative

window in

LHdo= relati

ve

window out

0 = None

1 = Loab

2 = Hiab

3 = LodE

4 = HidE

5 = LHdi

6 = LHdo

None

0x19 - 25

AL2 Alarm threshold SSP ÷ FSP

0 0x1A -

26

HAL2

Hysteresis of alarm

remedy

0 ÷ 100 1 0x1B –

27

AL2D Delay of alarm

remedy

0 ÷ 100.0

sec.

0 0x1C –

28

ADR Module address 1 ÷ 16 16 0x1D -

29

For each model the additional parameters are:

Only for ELK22MP:

PASS Menu password 0000 0x1E -

30

REV Firmware revision 0x100 0x1F -

31

Only for ELK22MPM and ELK22MPS:

ADDRM

Modbus address 100 0x1E -

30

VELM Modbus speed 0 =

1200

1 =

2400

2 =

9600

3 =

19200

4 =

38400

9600 0x1F -31

P

ASS

Menu password 0000 0x20 - 32

REV

Firmware revision 0x200 0x21 - 33

Only for ELK22MPE:

ADDRM

Indirizzo Modbus 100 0x1E -

30

VELM Modbus speed 0 =

1200

1 =

2400

2 =

9600

3 =

19200

4 =

38400

9600 0x1F -

31

IP1 First set of 8-

bit IP

address

0-255 10 0x20 -

32

IP2 Second set of 8-

bit IP

address

0-255 10 0x21 -

33

IP3 Third set of 8-

bit IP

address

0-255 10 0x22 -

34

IP4 Fourth set of 8-

bit IP

address

0-255 50 0x23 -

35

SUB1 First set of 8-

bit IP

subnetmask

0-255 255 0x24 -

36

SUB2 Second set of 8-

bit IP

subnetmask

0-255 255 0x25 -

37

SUB3 Third set of 8-

bit IP

subnetmask

0-255 255 0x26 -

38

SUB4 Fourth set of 8-

bit IP

subnetmask

0-255 0 0x27 -

39

GAT1 First set of 8-bit

IP

gateway

0-255 0 0x28 -

40

GAT2 Second set of 8-

bit IP

gateway

0-255 0 0x29 -

41

GAT3 Third set of 8-

bit IP

gateway

0-255 0 0x2A -

42

GAT4 Fourth set of 8-

bit IP

gateway

0-255 0 0x2B –

43

PASS Menu password 0000 0x2C -

44

REV Firmware revision 0x300 0x2D -

45

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 10

7

-

RS

485 PROTOCOL

7.1 – FUNCTION 1 – READ OUTPUT STATUS

The address first word must be less of the number of the output and

the number of the word to read, must be less or equal of the

number of output minus address first word.

The request has the following frame:

Slave

number

Functio

n

number

First word address

MSB LSB

Number of words

MSB LSB

byte 0 byte1=

0x0

1

byte 2 byte 3 byte 4 byte 5

The reply has the following frame:

Slave

number

Functio

n

number

NB Number

of read byte

Status

output

byte

CRC

LSB MSB

byte 0 byte1=

0x01

byte 2 byte 3 byte 4 byte 5

7.2 – FUNCTION 3 – READ N WORD

The number of words to be read must be less or equal twenty-eight.

The request has the following frame:

Slave

number

Functi

on

numb

er

First word

address

MSB LSB

Number of

words

MSB LSB

CRC

LSB MSB

byte 0 byte1=

0x0

3

byte 2 byte 3 byte 4 byte 5 byte 6

byte 7

The reply has the following frame:

Slave

number

Functi

on

numb

er

NB

numer

o di

bytes

letti

Value of first

word

MSB LSB

Followi

ng

words

CRC

LSB MSB

byte 0 byte1

=

0x03

byte 2 byte 3 byte 4 byte 5 byte

NB+2

byte

NB+3

7.3 – FUNCTION 6 – ONE WORD WRITE

The request has the following frame:

Slave

number

Functio

n

number

First word

address

MSB LSB

Value to write

MSB LSB

CRC

LSB MSB

byte 0 byte1=

0x0

6

byte 2 byte 3 byte 4 byte 5

byte 6 byte 7

The normal reply is merely an echo of the request message:

Slave

number

Functio

n

number

First word

address

MSB LSB

Value to write

MSB LSB

CRC

MSB LSB

byte 0 byte1=

0x0

6

byte 2 byte 3

byte 4 byte 5

byte 6 byte 7

7.4 – FUNCTION 7 – READ ALLARM STATUS

The request has the following frame:

Slave number Function

number

CRC

LSB MSB

byte

0

b

yte

1

=

0x0

7

byte 6

byte 7

The reply has the following frame:

Slave

number

Function

number

Alarm Status CRC

LSB MSB

byte 0 byte1=

0x0

7

byte 2 byte 3 byte 4

7.5 – CYCLIC REDUNDANCY CHECK (CRC) (Only for

ELK22MPM)

CRC is a check word that premits to verify the integrity of a

message.

Every message, sent or received, has in the two last characters the

CRC check word.

After receiving a request, the controller checks the validity of the

received message

comparing the received CRC with the calculated one.

When a reply is ready the controller calculates the CRC word and

adds two characters to

the prepared message. CRC calculation is performed on every

character of the message,

excluding the last two.

Being MODBUS RTU (JBUS) protocol compatible, ELK22S and

ELK22MS controllers

adopt an identical algorithm for CRC calculation.

The polinomial adopted by MODBUS RTU (JBUS) is 1010 0000

0000 0001.

Note: the first transmitted character of the CRC word is the least

significant between calculated bytes.

8

-

TCP/

IP

PROT

OCOL

8.1 – PROTOCOL PACKET

The TCP/IP protocol packet must consist of:

•6 bytes di header

•Bytes relating to one of the functions described below

The construction of the packet foresees to append the other bytes

relating to the function to be performed to the 6 header bytes.

For example, if you want to read the status of the outputs, you will

have to create the packet by adding to the header the 6 bytes

relating to the function of reading the status of the outputs. This

would result in a 12-byte packet.

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 11

8.2 – HEADER TCP

The header consists of 6 bytes and is structured as follows:

Byte Univoco

Byte sempre a 0 Packet length without

the length of the

header

byte 0

byte 1

byte 2

byte 3

byte 4

byt

e 5

The first 4 bytes are unique bytes generated by the host and to be

replicated as they are to each function. The first 4 bytes are part of

the standard TCP / IP protocol.

8.3 – FUNCTION 1 – READ OUTPUT STATUS

The address first word must be less of the number of the output and

the number of the word

to read, must be less or equal of the number of output minus

address first word.

The request has the following frame:

Slave

number

Functio

n

number

First word address

MSB LSB

Number of words

MSB LSB

byte 0 byte1=

0x01

byte 2 byte 3 byte 4 byte 5

The reply has the following frame:

Slave

number

Functio

n

number

NB Number

of read byte

Status

output

byte

byte 0 byte1=

0x01

byte 2 byte 3

8.4 – FUNCTION 3 – READ N WORD

The number of words to be read must be less or equal twenty-eight.

The request has the following frame:

Slave

number

Functio

n

number

First word address

MSB LSB

Number of words

MSB LSB

byte 0 byte1=

0x0

3

byte 2 byte 3 byte 4 byte 5

The reply has the following frame:

Slave

number

Functio

n

number

NB

numero

di bytes

letti

Value of first word

MSB LSB

Following

words

byte 0 byte1=

0x0

3

byte 2 byte 3 byte 4 byte 5

8.5 – FUNCTION 6 – ONE WORD WRITE

The request has the following frame:

Slave

number

Function

number

First word address

MSB LSB

Value to write

MSB LSB

byte 0 byte1=

0x0

6

byte 2 byte 3 byte 4 byte 5

The normal reply is merely an echo of the request message:

Slave

number

Function

number

First word address

MSB LSB

Value to write

MSB LSB

byte 0 byte1=

0x0

6

byte 2 byte 3 byte 4 byte 5

8.6 – FUNCTION 7 – READ ALLARM STATUS

The request has the following frame:

Slave number Function number

byte 0

b

yte1

=

0x0

7

The reply has the following frame:

Slave number Function

number

Alarm Status

byte 0 byte1= 0x07 byte 2

9

-

LED TABLE

PR

Thanks to the LEDs placed in front of the ELK22MP series products

it is possible to observe if the product is powered, if the outputs are

present and if the ethernet communication works.

(ethernet communication only for ELK22MPE).

Explanation: A = LED off, E = LED on steady, B = LED flashing

State Description

PWS

OUT1

OUT2

OUT3

Link / Active

(Only for

ELK22MPE)

OFF

Device off A A A A A

ON

Device on E A A A A

ON,

OUT1

Device on

with output

1

connected

E E A A A

ON,

OUT2

Device on

with output

2

connected

E A E A A

ON,

OUT3

Device on

with outpu

t

3

connected

E A A E A

ON,

OUT1,

OUT2

Device on

with output

1 and

2

connected

E E E A A

ON,

OUT1,

OUT3

Device on

with output

1 and 3

connected

E E A E A

ON,

OUT2,

OUT3

Device on

w

ith output

2 and 3

connected

E A E E A

ON,

OUT1,

OUT2,

OUT

3

Device on

w

ith output

1,2 and 3

connected

E E E E A

ON,

Link/Act

ive

Device on

with

ethernet

communica

tion

E A A A E = Cable

connected

B =

Comunicatio

n active

ON,

Link/Act

ive,

OUT1

Device on

with

ethernet

communica

tion an

d

output 1

connected

E E A A E = Cable

connected

B =

Comunicatio

n active

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 12

ON,

Link/Act

ive,

OUT2

Device on

with

ethernet

communica

tion an

d

output 2

connected

E A E A E = Cable

connected

B =

Comunicatio

n active

ON,

Link/Act

ive,

OUT3

Device on

with

ethernet

communica

tion an

d

output 3

connected

E A A E E = Cable

connected

B =

Comunicatio

n active

ON,

Link/Act

ive,

OUT1,

OUT2

Device on

with

ethernet

communica

tion an

d

output 1

and 2

connected

E E E A E = Cable

connected

B =

Comunicatio

n active

ON,

Link/Act

ive,

OUT1,

OUT3

Device on

with

ethernet

communica

tion an

d

output 1

and 3

connected

E E A E E = Cable

connected

B =

Comunicatio

n active

ON,

Link/Act

ive,

OUT2,

OUT3

Device on

with

ethernet

communica

tion an

d

output 2

and 3

connected

E A E E E = Cable

connected

B =

Comunicatio

n active

ON,

Link/Act

ive,

OUT1,

OUT2,

OUT3

Device on

with

ethernet

communica

tion an

d

output 1,2

and 3

connected

E E E E E = Cable

connected

B =

Comunicatio

n active

OBLEMS, MAINTENANCE AND WARRANTY

1

0

–

TECHN

ICA

L DATA

10.1 - ELECTRICAL CHARACTERISTICS

Power supply: 24V≂, 100…240V∿+/- 10%

AC frequency: 50/60 Hz

Absorption: Approx. 4 VA

Input/s: 1 input for temperature probes: tc J, K, S ; RTD Pt 100 IEC;

PTC KTY 81-121 (990 W @ 25 °C); NTC 103AT-2 (10KW @ 25

°C); 0-10V; 4-20mA.

Output/s: Up to 3 outputs. 2x Relay SPDT (6A-AC1, 3A-AC3 250

V∿, 1/2HP 250 V∿, 1/3HP 125V∿) or voltage output for piloting

SSR (25mA/ 16V ), 1x voltage output for piloting SSR (25mA/

16V ).

Auxiliary power output: 15 V not stab. / 20 mA Max

Electrical relay output life: 100000 operat.

Overtension category: II

Measurement category: I

Protection class against electric shock: Class II front

Isolation: Reinforced between low voltage parts (“24” and “240”

power supply and relay outputs) and front; reinforced between low

voltage parts (“24” and “240” power supply and relay outputs) and

low voltage parts (static inputs and outputs); reinforced between

power supply and relay outputs; reinforced between low voltage

parts (“24” and “240” power supply and relay outputs) and ethernet

port.

No insulation between the input and the static outputs.

10.2 - MECHANICAL CHARACTERISTICS

Container: Self-extinguishing plastic UL 94 V0

Dimensions: 50 x 50 mm, depth 118 mm

Weight ELK22MP: approx.. 150 g

Weight ELK22DKP: approx.. 60 g

Installation ELK22DKP: Panel mounting in 49,5 x 49,5 mm hole or

22 mm diameter hole

Installation ELK22MS: Omega DIN guide

Connections: 2,5 mm

2

screw terminal block

Front protection degree: IP 65 (ELK22DKP with gasket)

Pollution degree: 2

Ambience of usage: internal

Working ambient temperature: 0 ... 50 °C

Working ambient humidity: 30 ... 95 RH% with no condensation

Temperature for the transportation and storage -10 ... 60 °C

10.3 - OPERATING CHARACTERISTICS

Adjustment: ON/OFF, neutral zone ON/OFF, single action PID.

Measurement range: According to the probe used (see table)

Display resolution: According to the probe used. 1/0.1.

Total accuracy: +/- (0,5 % fs + 1 digit) ; tc S: +/- (1 % fs + 1 digit)

Measurement sampling time: 170 ms

Maximum cold joint compensation error (in tc): 0.1°C/°C at room

temperature 0 ... 50°C after a warm-up time of 20 min.

Display: 4 red digits h 12 mm, 4 green digits h 7 mm

Conformity: Directive EEC EMC 89/336 (EN 61326), Directive EEC

BT 73/23 and 93/68 (EN 61010-1).

10.4 - MEASUREMENT RANGE TABLE

INPUT

“dP

” = 0

“dP”= 1

tc J

“SEnS” = J

-50 ... 1000 °C

-58 ... 1832 °F

- - - -

tc K

“SEnS” = CrAl

-50 ... 1000 °C

-58 ... 1832 °F

- - - -

tc S

“SEnS” = PtRh10%

-

Pt

0... 1000 °C

32 ... 1832 °F

- - - -

Pt100 (IEC)

“SEnS” = Pt1

-100 ... 400 °C

-148 ... 752 °F

-100.0 ... 400.0 °C

-148.0 ... 752.0 °F

PTC (KTY81-121)

“SEnS” = Ptc

-50 ... 150 °C

-58 ... 302 °F

NTC (103-AT2)

“SEnS” = ntc

-30 ... 110 °C

-22 ... 230 °F

0-10V

“SEnS” =

0

-

10

-1000 … 1000 -100.0 … 100.0

4-20mA

“SEnS” = 4

-

2

0

-1000 … 1000 -100.0 … 100.0

EL.CO. S.R.L. – ELK22MP - INSTRUCTIONS FOR USE - Ver.05 - 03/22 - PAG. 13

10.5 - DEVICE CODING

ELK22MP-A-B-C

ELK22MPS-A-B-C

ELK22MPM-A-B-C

ELK22MPE-A-B-C

A : SUPPLY

24 = 24 ≂ (VAC/VDC)

240 = 100... 240∿(VAC)

B : OUTPUT OUT1

R= Relay

C : OUTPUT OUT2

2R = Relay

2S = Voltage output for SSR

OUTPUT OUT3

For all models

MODBUS COMMUNICATION

Only for ELK22MPM

MODBUS TCP COMMUNICATION

Only for ELK22MPE

10.6 – ACCESSORIES (Not supplied)

ELK22DKP = Keyboard

BC-8P = Connection cable for ELK22MP

TC-8P = Connector for RS485 line terminal resistor. This connector

has the termination resistor already integrated

11

-

PROBLEMS, MAINTE

N

AN

CE AND WARRANTY

11.1 - ERROR REPORTING

Error

Reason

Action

Fail

Auto

Autotuning not comp

leted

within 12 hours

Check connecti

on

probe and a

ctuator,

then restart autotuning

- - - - Interruption of the probe

Check that t

he probe is

correctly connected t

o

the device, and then

verify that the probe is

working properly

11.2 - CLEANING

It is recommended to clean the device only with a slightly soaked

cloth of water or non-abrasive detergent and not containing

solvents.

11.3 - WARRANTY AND REPAIR

The device is guaranteed by manufacture defects or defects in

material found within 12 months from the date of delivery.

Warranty is limited to repair or replacement of the product.

Possible opening of the container, tampering with the device, or

improper use and installation of the product will automatically result

in the warranty being decayed.

In case of defective product during warranty period or out of

warranty period, contact the EL.CO. sales office. To get permission

to ship.

The defective product, therefore, accompanied by the indications of

the defect found, must be delivered by freight forwarding at the

EL.CO. factory, unless otherwise agreed.

Table of contents