Omron CP1L-E User manual

Other Omron Computer Hardware manuals

Omron

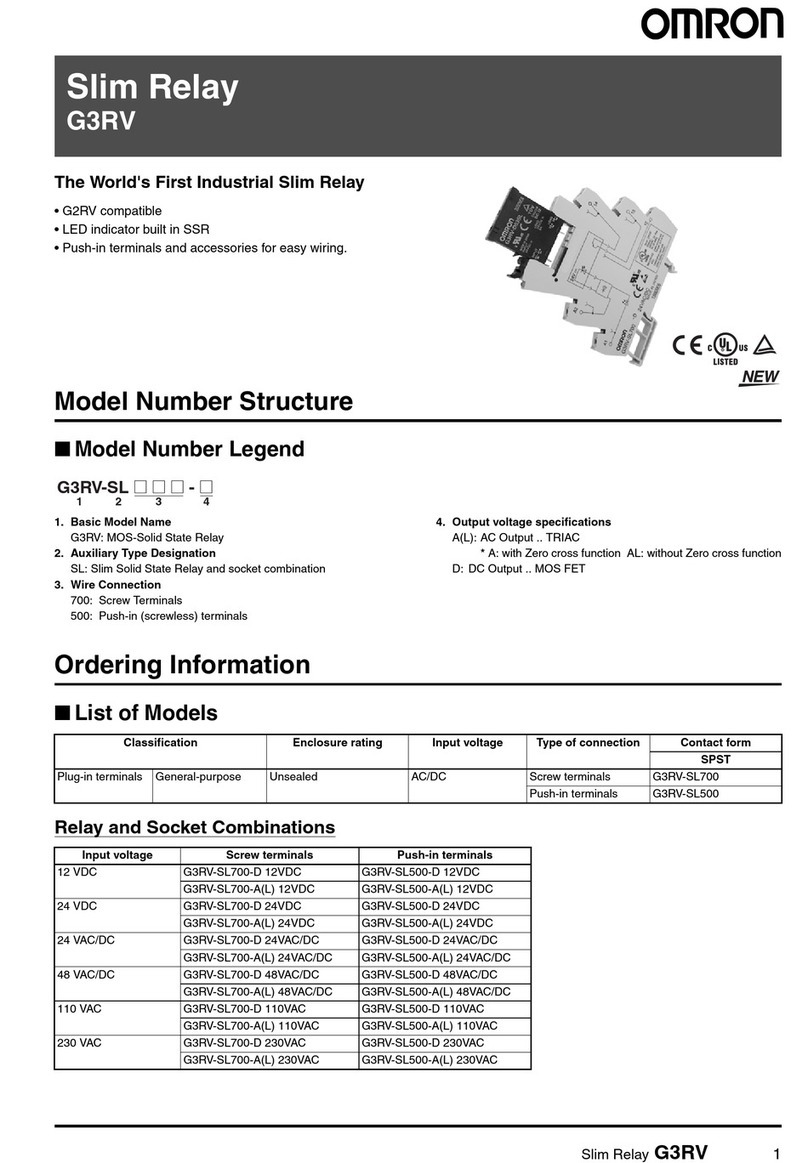

Omron G3RV User manual

Omron

Omron NX Series User manual

Omron

Omron CJ2H-CPU64 - User manual

Omron

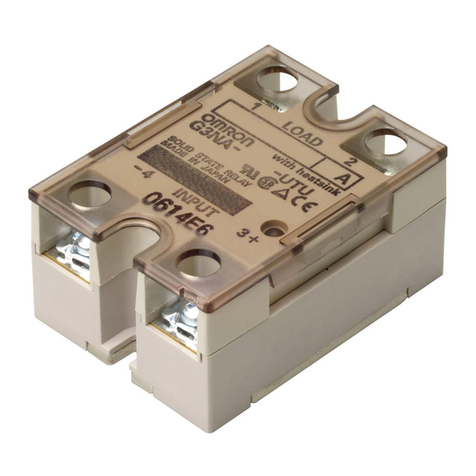

Omron G3NA User manual

Omron

Omron CS1W-CRM21 User manual

Omron

Omron G2RS User manual

Omron

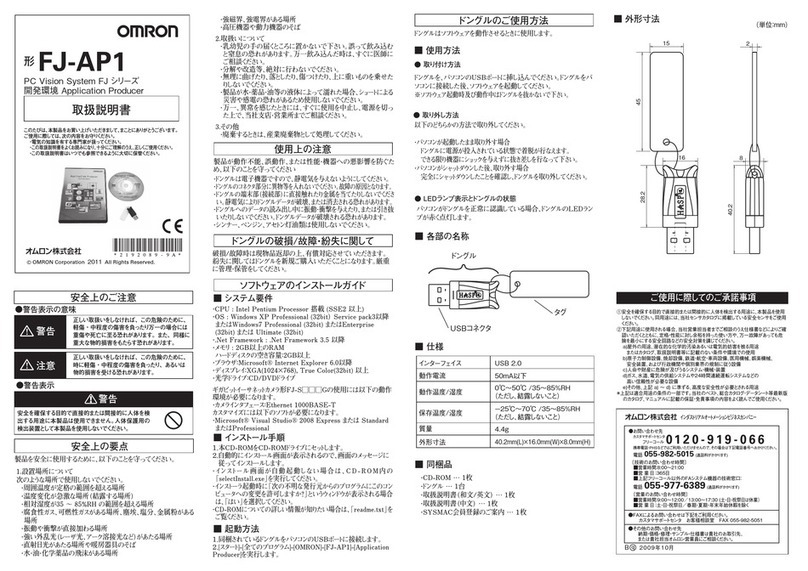

Omron FJ-AP1 User manual

Omron

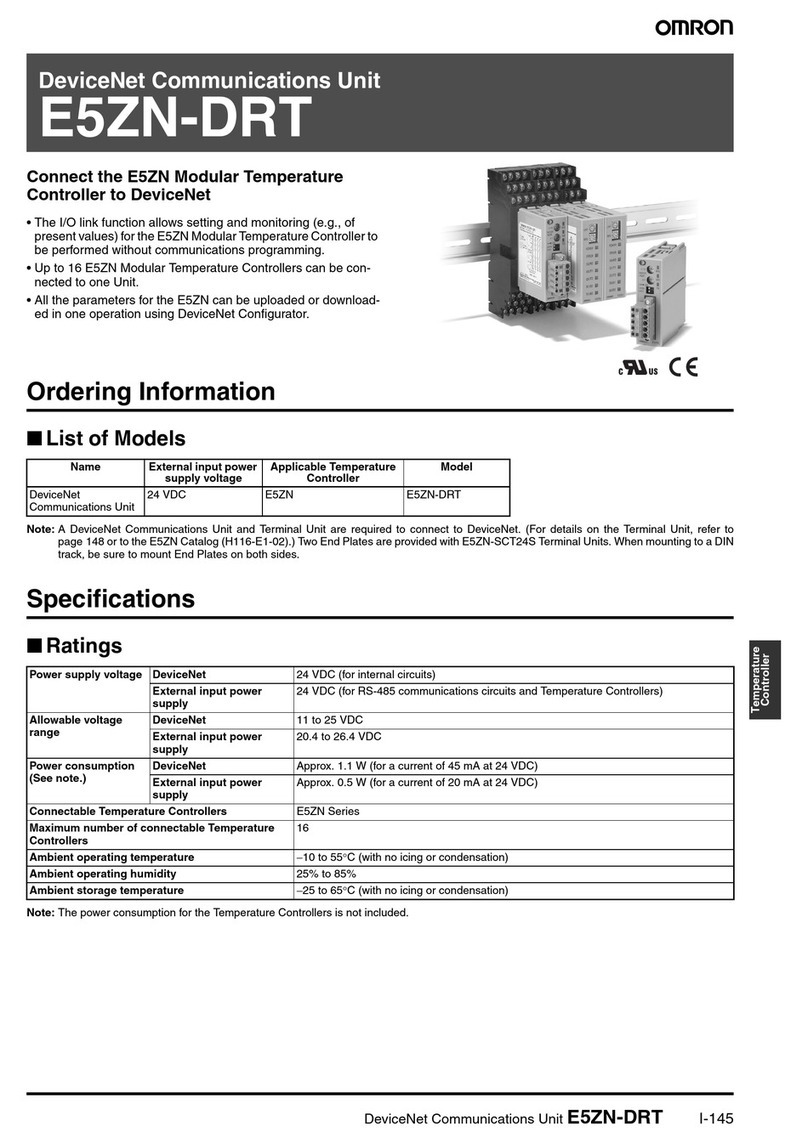

Omron E5ZN-DRT User manual

Omron

Omron CJ Series Instruction Manual

Omron

Omron NJ501-1400 User manual

Omron

Omron G3PA User manual

Omron

Omron CP1H CPU UNITS - PROGRAMMING 05-2007 User manual

Omron

Omron G3PE Series User manual

Omron

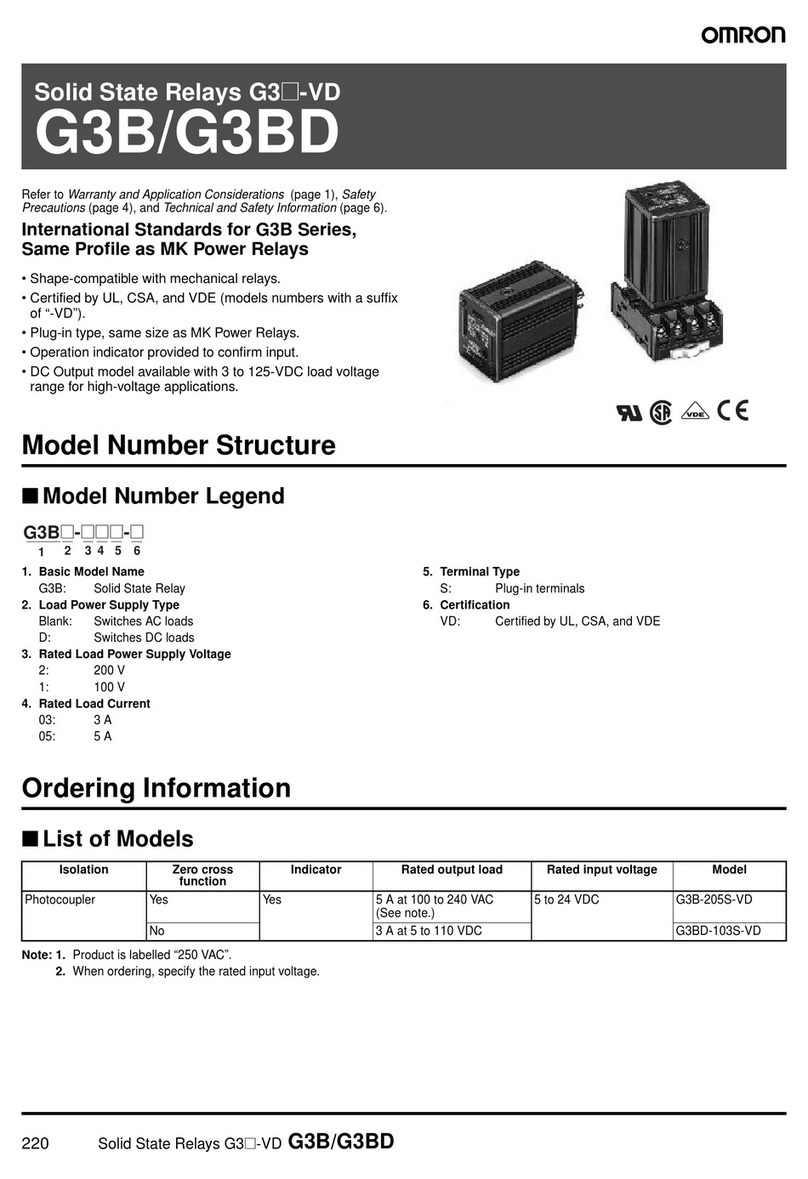

Omron G3B User manual

Omron

Omron 3G8F5-DRM21 User manual

Omron

Omron R88A-MCW151-DRT-E User manual

Omron

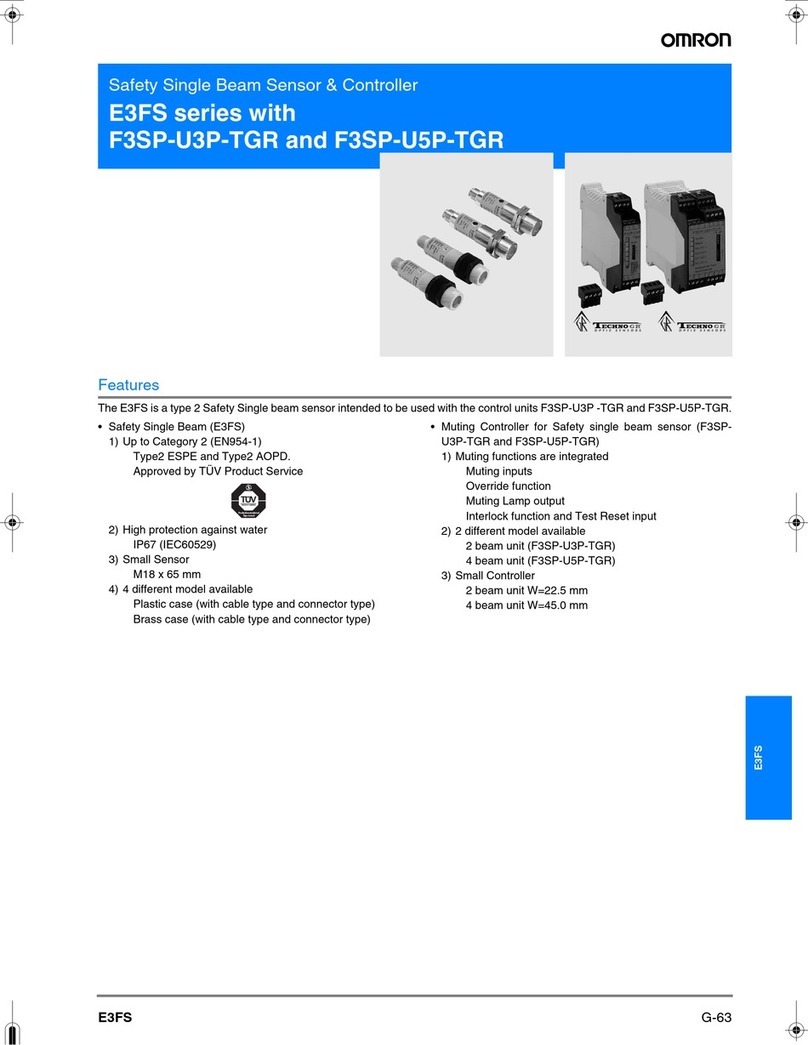

Omron F3SP-U3P-TGR User manual

Omron

Omron New H7E Series User manual

Omron

Omron NX701-1720 User manual

Omron

Omron 3G3AX-MX2-PRT-E User manual

Popular Computer Hardware manuals by other brands

Toshiba

Toshiba TOSVERT VF-MB1/S15 IPE002Z Function manual

Shenzhen

Shenzhen MEITRACK MVT380 user guide

TRENDnet

TRENDnet TEW-601PC - SUPER G MIMO WRLS PC CARD user guide

StarTech.com

StarTech.com CF2IDE18 instruction manual

Texas Instruments

Texas Instruments LMH0318 Programmer's guide

Gateway

Gateway 8510946 user guide

Sierra Wireless

Sierra Wireless Sierra Wireless AirCard 890 quick start guide

Leadtek

Leadtek Killer Xeno Pro Quick installation guide

Star Cooperation

Star Cooperation FlexTiny 3 Series Instructions for use

Hotone

Hotone Ampero user manual

Connect Tech

Connect Tech Xtreme/104-Express user manual

Yealink

Yealink WF50 user guide