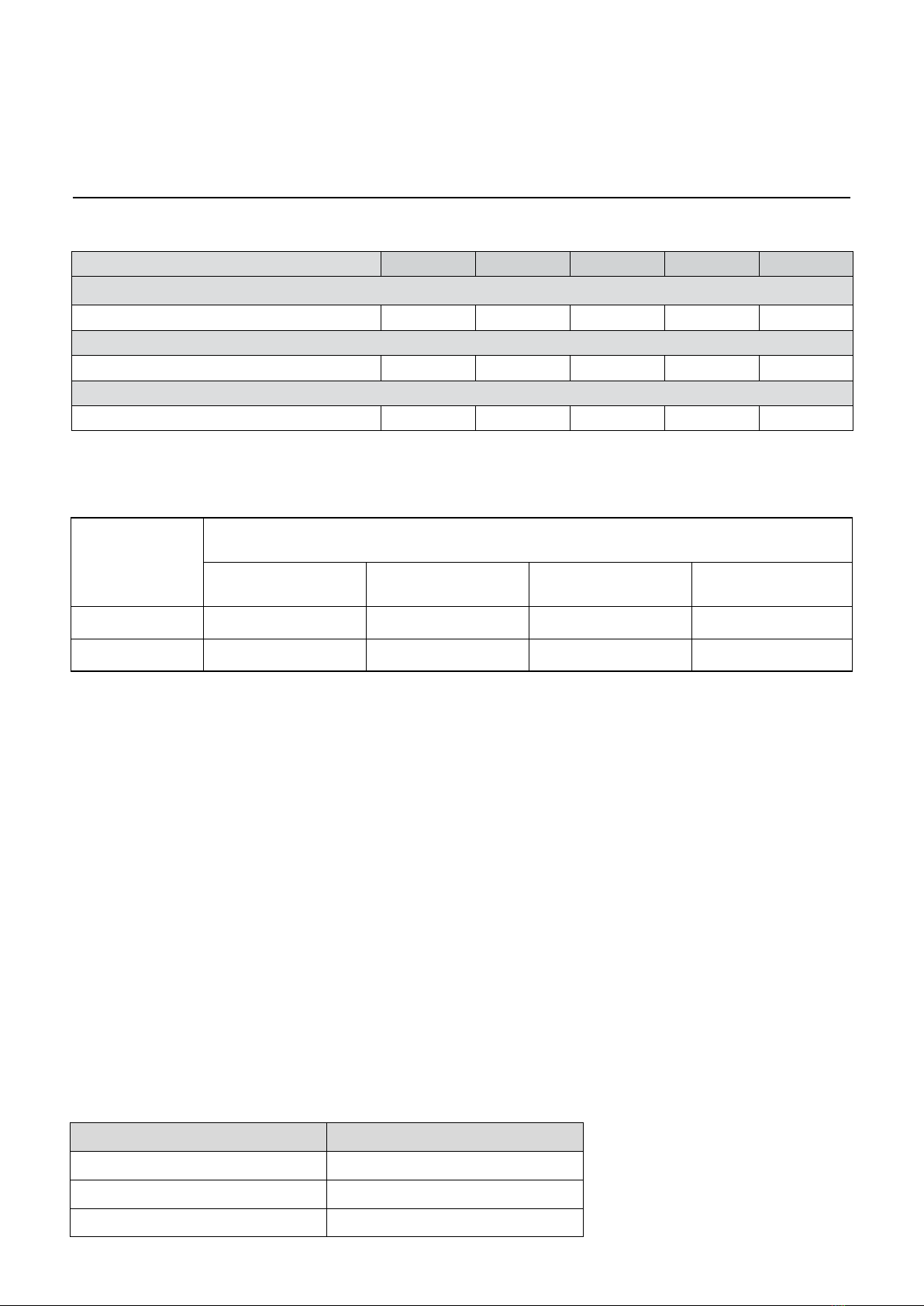

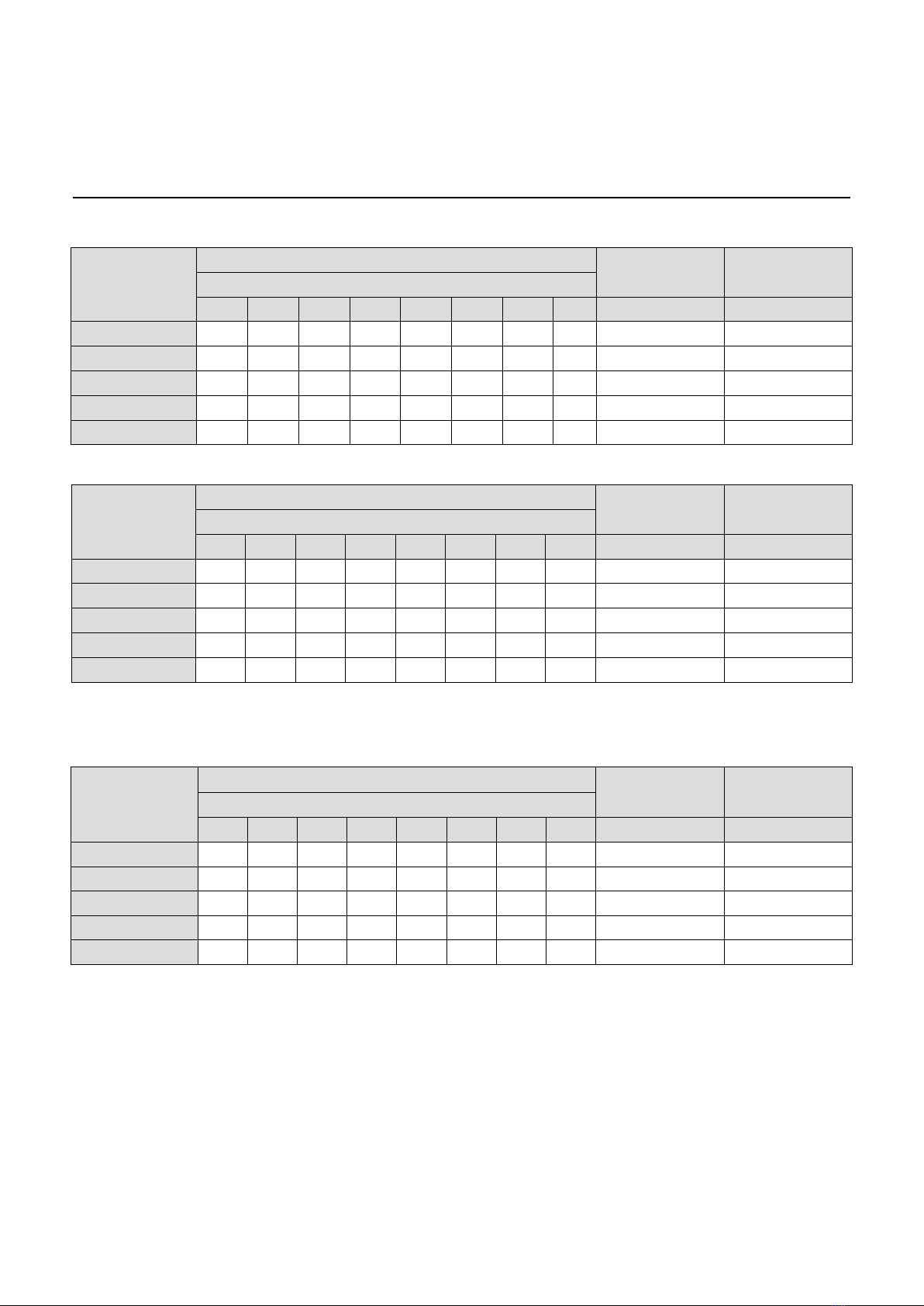

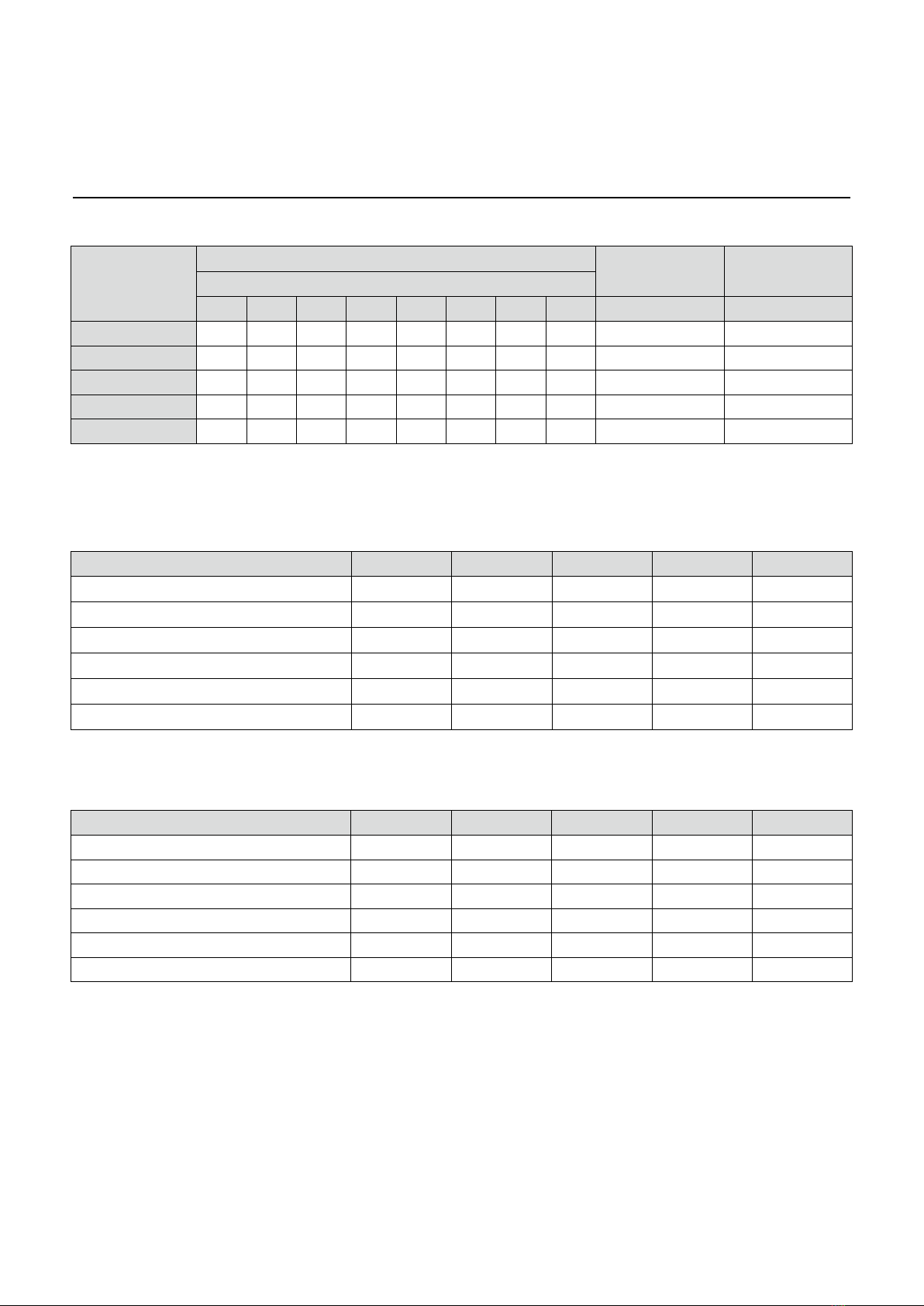

General information

Standard unit technical specifications

Compressor Range 54–61kW

Inverter controlled rotary-type hermet-

ic compressor equipped with a motor

protection device for overheating,

overcurrents and excessive tempera-

tures of the supply gas. It is installed

on anti-vibration mounts and it is

equipped with oil charge. The com-

pressor is wrapped in a sound-

absorbing hood, that reduces its

sound emissions and it thermally insu-

lates it. A crankcase heater, which

starts automatically, keeps the oil

from being diluted by the refrigerant

when the compressor stops.

Compressors are connected in tan-

dem on a single refrigerating circuit

with a dedicated system for the oil

recovery

Range 65–88 kW

Direct expansion heat exchanger

Scroll hermetic compressor with

steam injection controlled by inverter,

complete with motor over-temperature

and over-current devices and protec-

tion against excessive gas discharge

temperature. It is installed on anti-

vibration mounts and it is equipped

with oil charge. The compressor is

wrapped in a sound-absorbing hood,

that reduces its sound emissions and

it thermally insulates it.

A crankcase heater, which starts au-

tomatically, keeps the oil from being

diluted by the refrigerant when the

compressor stops.

Compressors are connected in tan-

dem on a single refrigerating circuit

with a dedicated system for the oil

recovery .

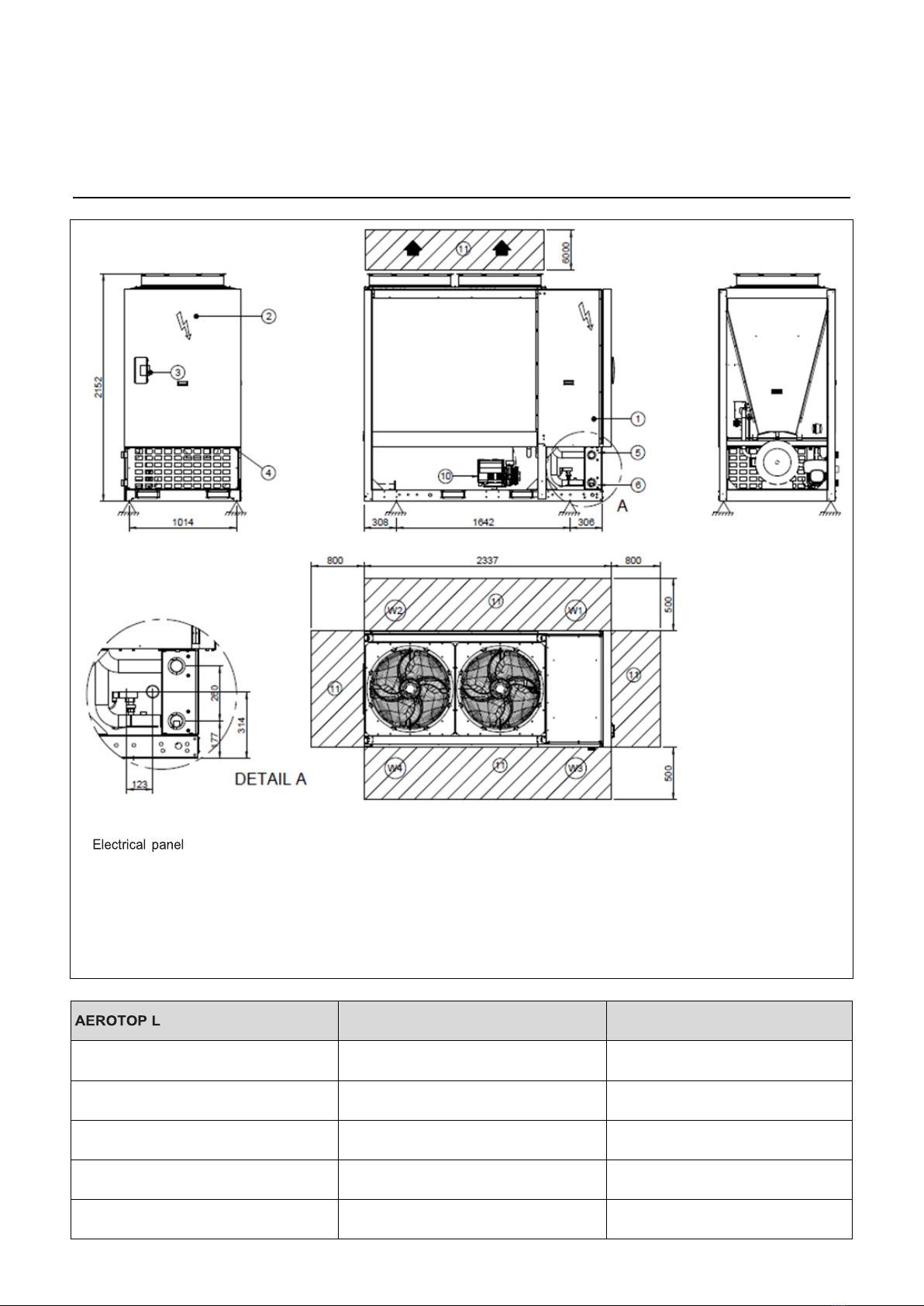

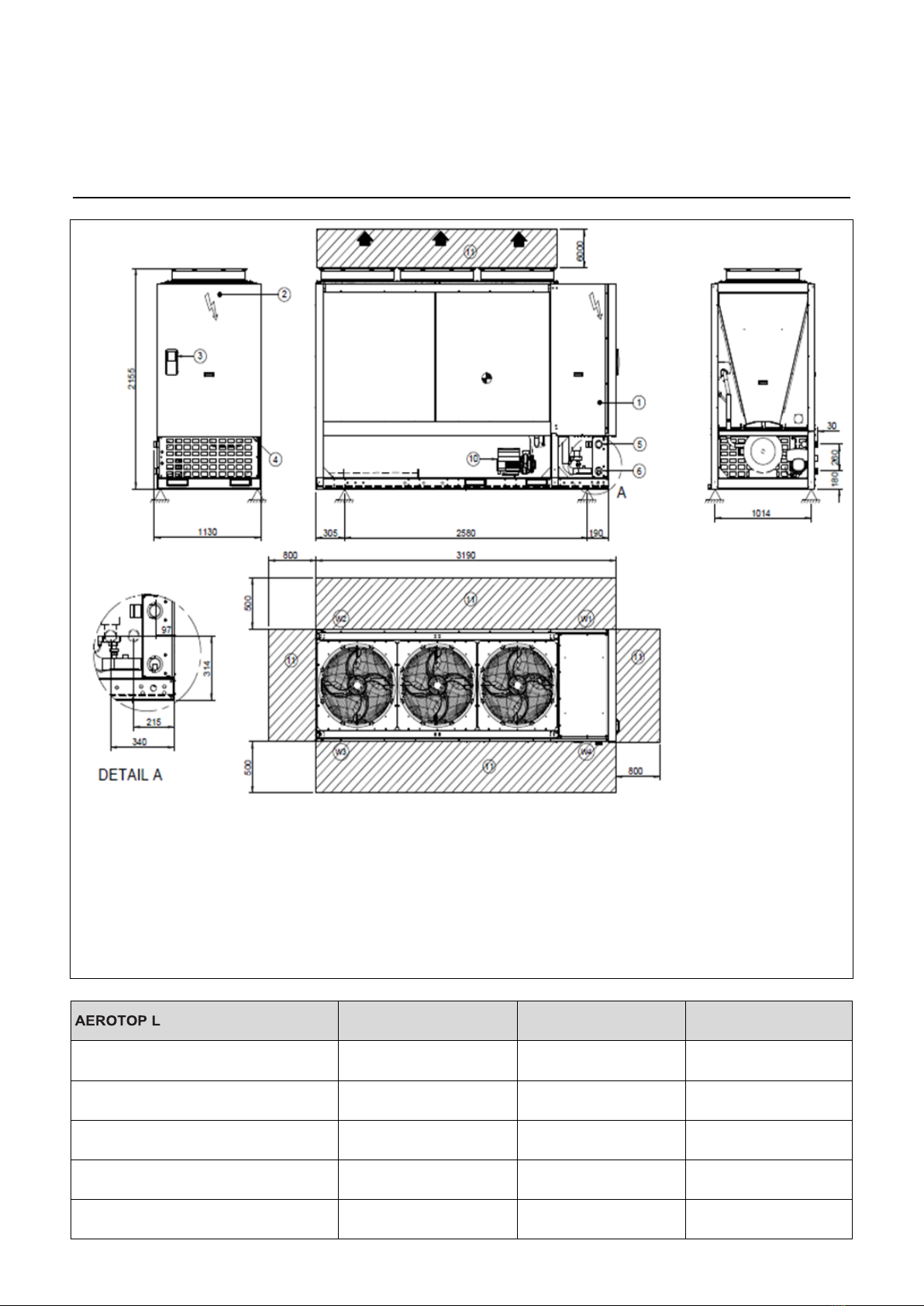

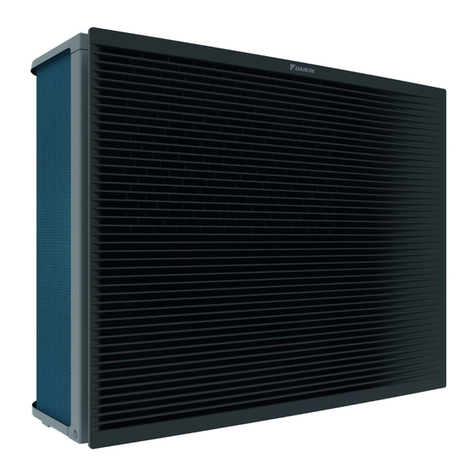

Structure

Supporting structure realized with

steel with zinc-magnesium superficial

traitment painted with polyester pow-

der RAL 9001, that ensures excellent

mechanical features and high long-

term resilience against corrosion.

Paneling

External RAL 9001 painted zinc-

magnesium sheet metal panelling that

ensures superior resistance to corro-

sion for outdoor installation and elimi-

nates the need for periodic painting.

Each panel can be easily removed to

allow full access to internal compo-

nents.

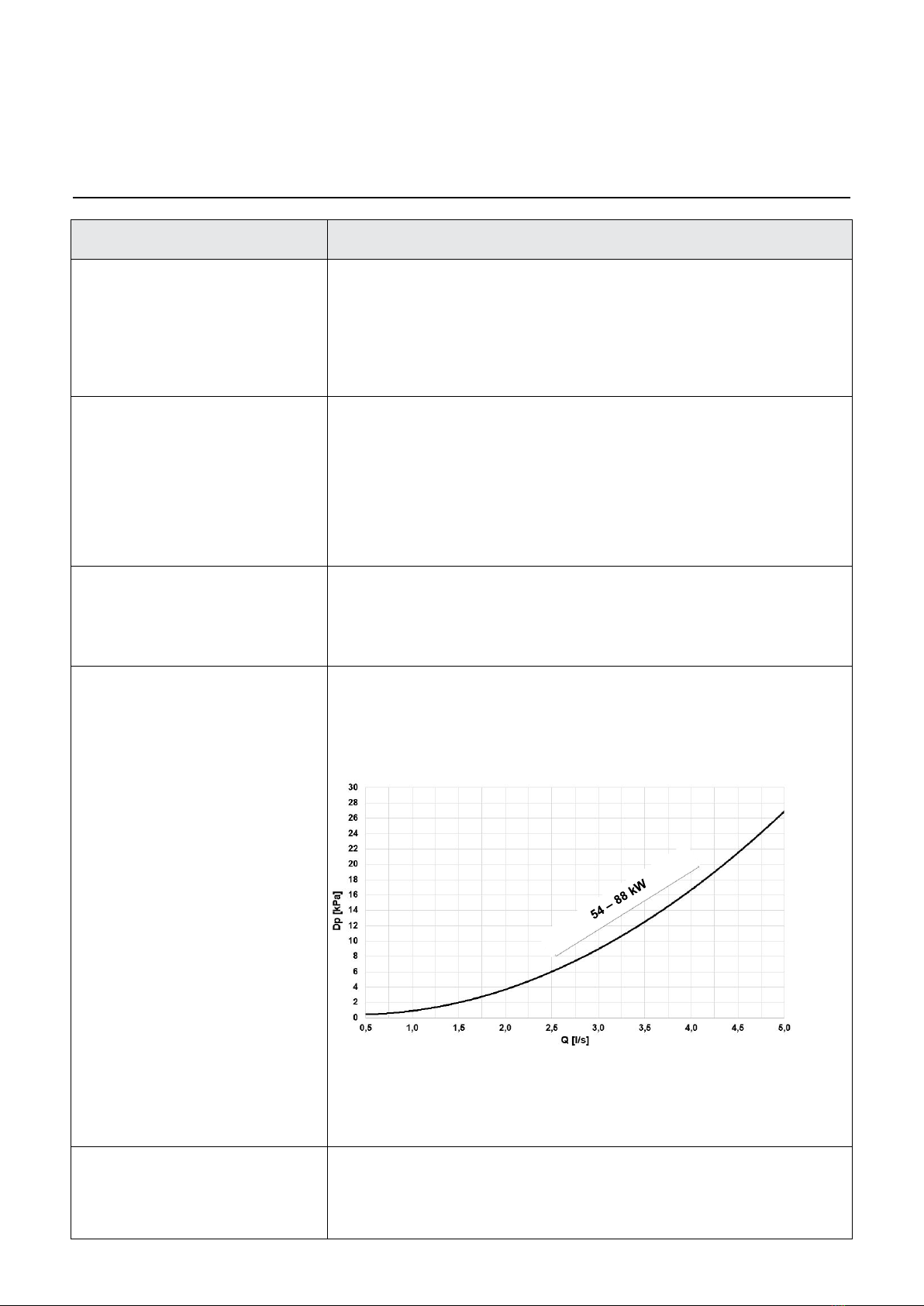

Internal exchanger

Direct expansion heat exchanger,

brazed AISI 316 stainless steel

plates, in pack without seals using

copper as the brazing material, with

low refrigerant charge and large

exchange surface.

The exchanger comes complete

with:

external thermal insulation no-

condensation, thickness 17 mm, in

expanded polypropylene (EPP)

antifreeze heater to protect the wa-

ter side exchanger, preventing the

formation of frost if the water tem-

perature falls below a set value.

flow switch

anti-ice probe

External exchanger

c coil exchanger made with copper

pipes placed on staggered rows me-

chanically expanded to better adhere

to the fin collar.

Fins are made from aluminum with

hydrophic treatment that allows the

correct evacuation of condensing wa-

ter and optimizes defrosting.

Fins have a special corrugated sur-

face and they are appropriately dis-

tanced to ensure the maximum heat

exchange efficiency. n.

Fan

Helical fans with 4 profiled blades

made of reinfoced plastic, directly

coupled to the DC brushless motor

with electronic control, IP 54 execu-

tion.

Fans are located in aerodynamically

shaped structures to increase efficien-

cy and minimize noise level, equipped

with accident prevention steel guards.

Refrigeration circuit

Refrigeration circuit with: Direct ex-

pansion heat exchanger

filter dryer

liquid receiver

pressure transducer (high/low)

refrigerant temperature probe

electronic expansion valves

non return valve4-way reverse-cycle

valve

high pressure safety pressure

switch

low pressure safety pressure switch

low pressure safety valve

return liquid separator

oil separator

Refrigeration circuit

cooling system of the of the electri-

cal control panel using undercooled

liquid

Only for range 65–88 kW:

economizer exchanger

Electrical panel

main door lock isolator switch

phase monitor

auxiliary components protection fuse

compressor protection fuse

fan motor thermal protections

interface terminal with graphic dis-

play

intuitive graphical interface retro

lighted

display of operating status

Unit On/Off and overload reset

manual changing of the operating

mode (hot or cold)

management of the operating pa-

rameters

daily, weekly programmer of temper-

ature set-point and unit on/off

self-diagnosis system with immedi-

ate display of the fault code

compressor overload protection and

timer

relay for remote cumulative fault

signal

potential-free contact for remote on-

off control

potential-free contact for summer /

winter change

potential-free contacts for compres-

sor status

serial port with modbus port (RS485)

for remote communication

Test

Unit subjected to factory-tested in

specific steps and test pressure of the

piping of the refrigerant circuit (with

nitrogen and hydrogen), before ship-

ping them