19

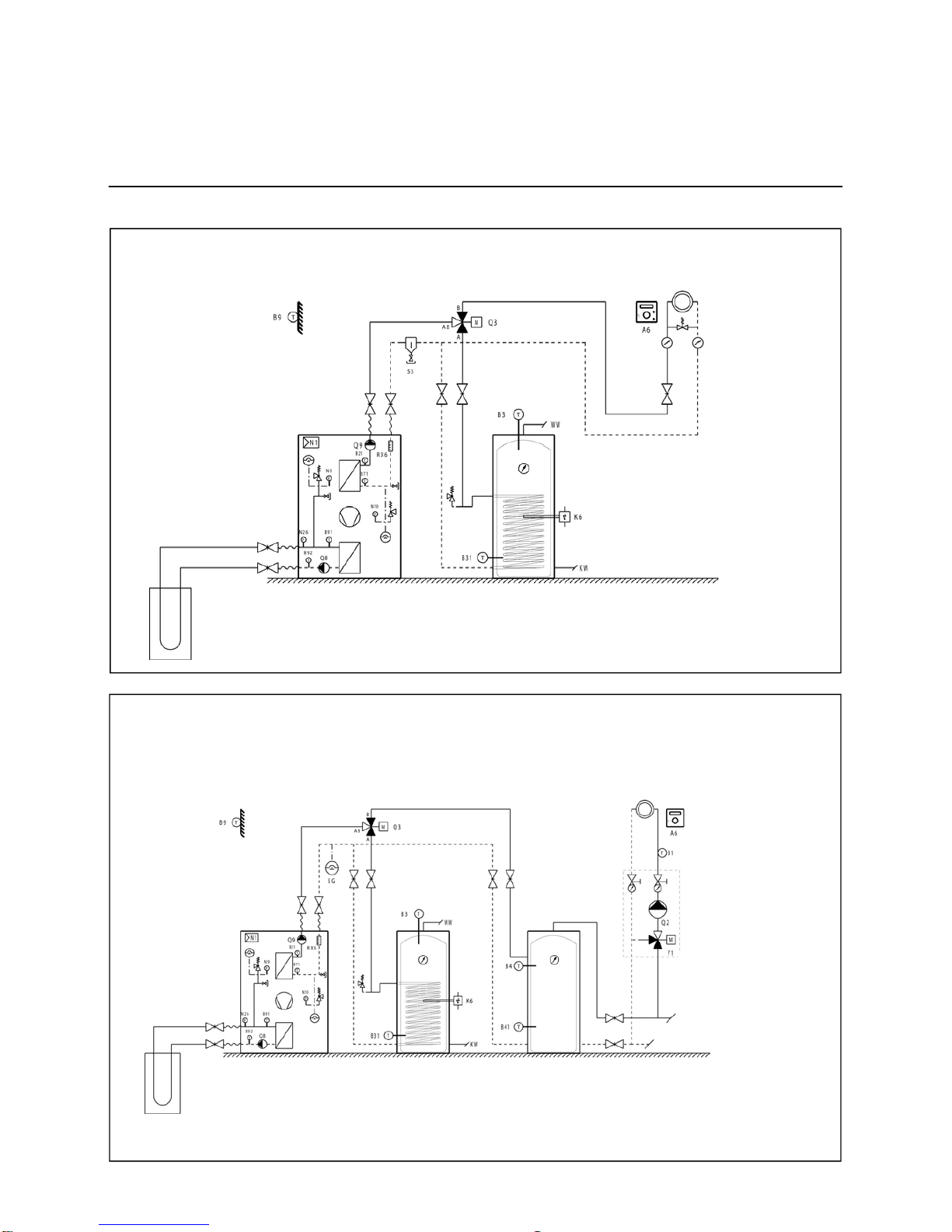

Charging Geothermal Heating Systems

Charging with Antifreeze

Correctly Charging a Geothermal Heating System Circuit

Charging with Antifreeze

After flushing, the entire geothermal

heating system circuit is to be filled

with clean tap water. Follow the steps

below to prepare the required con-

centration of antifreeze with a 100%

concentrate. For example:

The required antifreeze concentration

is 25% (ideal range is 25-30%) with a

140-m Duplex® ø 32 mm BHE.

(Content per meter = 4 pipes x 10 dm,

length x 0.13 dm,

inner radius2x rr = 2.12 l/m.)

Correctly Charging a Geothermal

Heating System in 14 Steps

1. Flush the GHS circuit as described

on page 18.

2. Calculate the probe volume acc. to

table above. One GHS (GHS

ø 32 mm) has 2.12 l/m content per

meter. This yields the following

GHS content for our example:

140 m x 2.12 l/m = 296.8 liters

(297 l). Do not forget the content of

the connection lines up to the heat

pump, 30 liters in our example.

This results in a total system content

of 297 liters + 30 liters = 327 liters.

3. Required volume of 100% anti-

freeze concentrate:

25% of 327 liters = 82 liters.

4. Close the sliders to the heat pump.

Remove the drain hose from the

tank and place in drain.

5. Open the sliders of the GHS – if

several probes have been

installed, one slider after the other

is opened during charging.

6. Fill the mixing tank with an approx.

mixture of 1:1 of antifreeze

concentrate and fresh water.

Depending on tank size, not all of

the 82 liters of concentrate fit into

the tank (see calculation, item 3).

7. Switch the feed pump on.

As soon as the tank begins to

empty, continuously fill in the

remaining antifreeze concentrate

and additional fresh water into the

mixing tank at a ratio of approx.

1:1. Make sure that always at least

40 liters of mixed reserve remains

in the tank. Volume markers can

be attached to the edge of the

tank to help you determine its

volume.

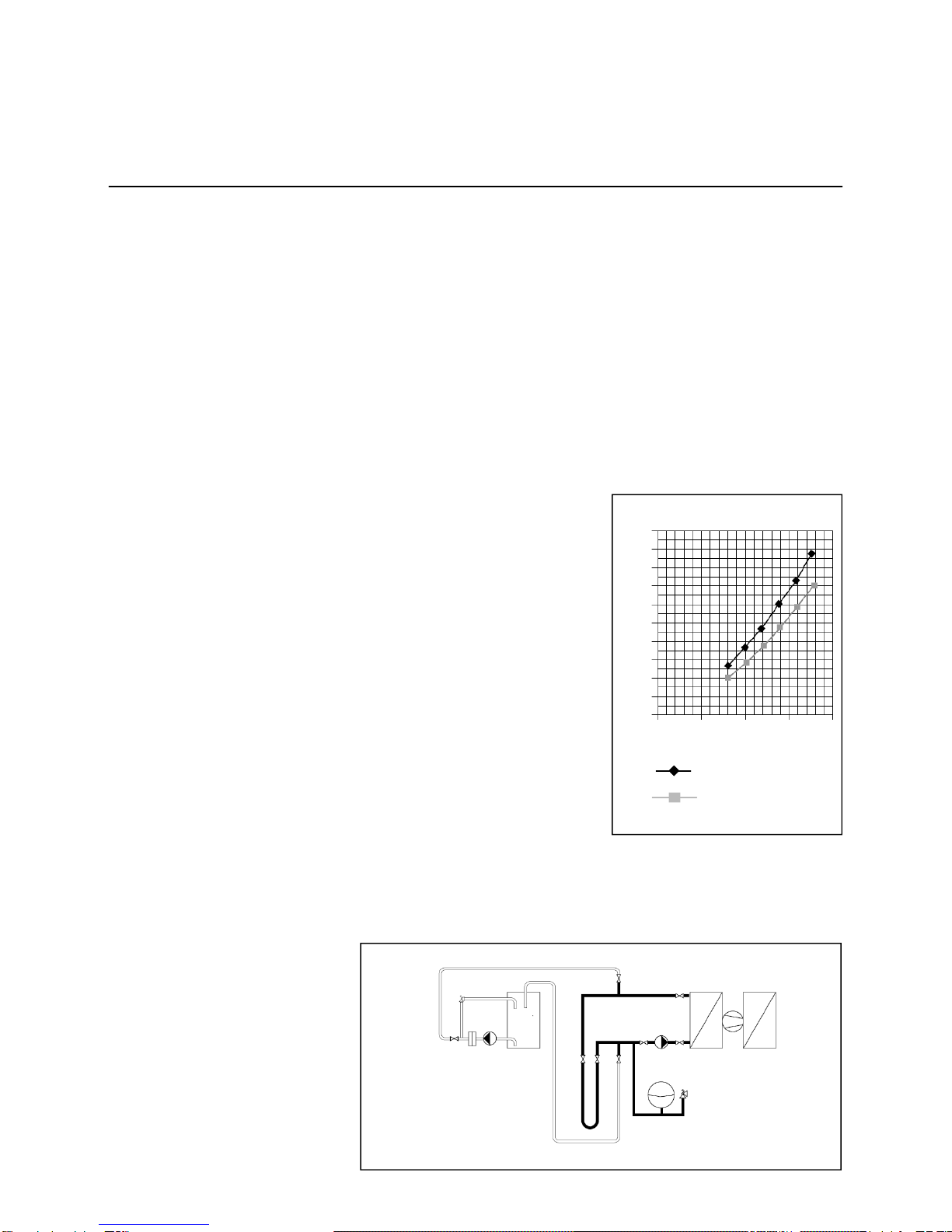

8. The feed pump is allowed to run

until the entire antifreeze

mixture – except for the 40 liters

reserve – are filled in and then is

switched off at once. Excess tap

water drains from the drain hose

into the drain.

9. Now insert the drain hose into the

tank, turn the feed pump back on,

and allow it to run until glycol and

water are thoroughly mixed. This

takes about 6-times to 8-times as

long as it takes for flushing (see

diagram, item flushing).

10. Close charging valves at drain

hose and then those at the

geothermal heating system

distributor. The excess pressure

valve (2.5 bar) routes the excess

mixture back into the tank. Shut off

feed pump. About 40 liters remain

in the tank. Some of the mixture

was absorbed by the expansion

of the geothermal heating system.

11. In case of relatively long geo-

thermal heating systems and

insufficiently mixed mixture, the

excess pressure valve at the tank

is triggered and thereby intensifies

mixing.

12. If several GHSs are combined into

one system, the second, third, etc.

GHS is first flushed and then

charged individually until all have

been processed.

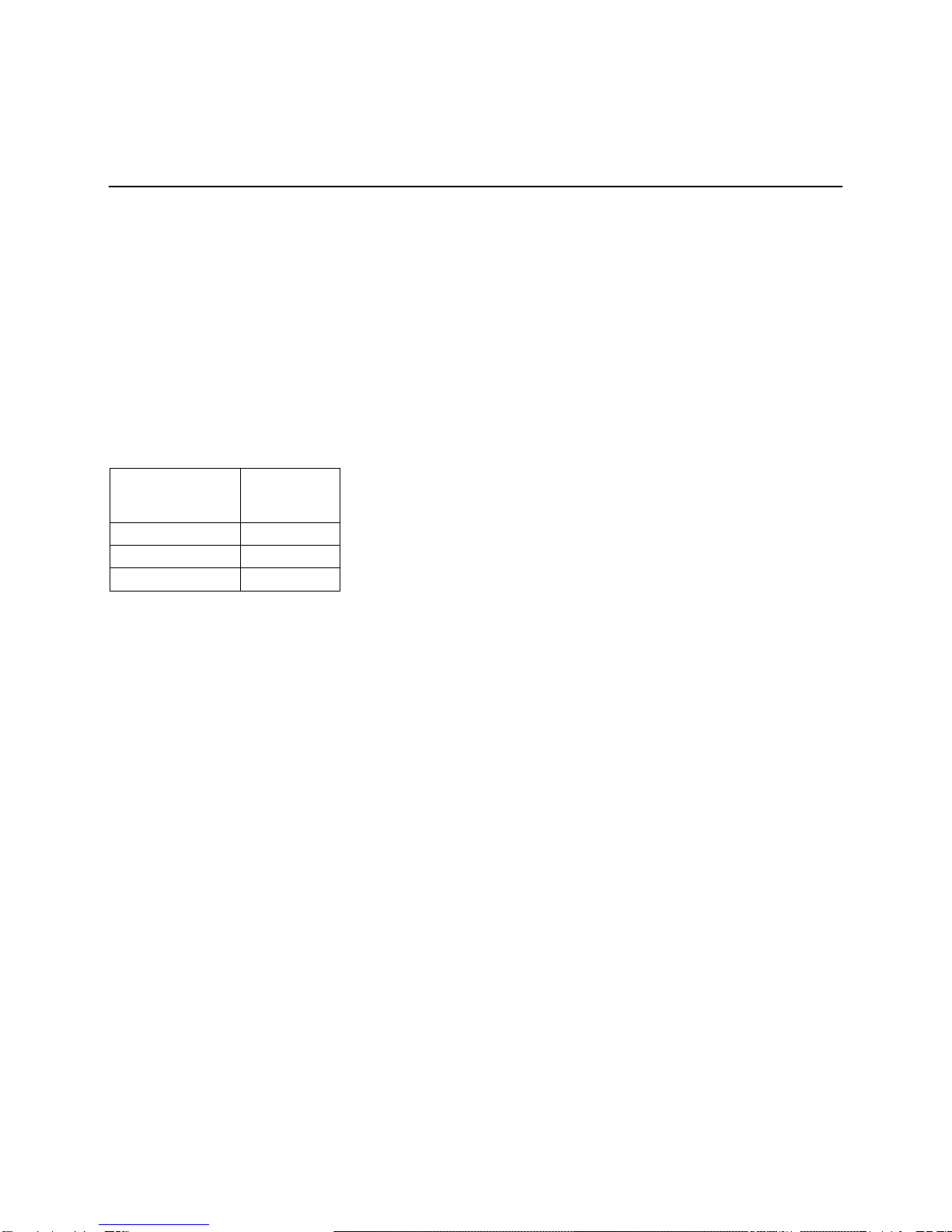

13. Once all geothermal heating

systems are charged, the eva-

porator and the brine circulating

pump must be charged next.

All sliders to the geothermal

heating systems are closed for

this purpose and the sliders to the

evaporator are opened.

The remaining mixture is now

carefully pumped via the slider at

the filling hose. Allow water in the

circuit to escape via the drain

hose. As soon as the glycol

mixture emerges as the drain hose

(color change), close the corre-

sponding valve and allow the

pump pressure to charge the

expansion vessel (2.5 bar). Then

close the valve at the filling hose.

The system is now charged with

the correct concentration and

correct operating pressure without

introducing pollutants to the

system.

14. Now carry out a pressure test.

This test should be performed

over an extended period to avoid

the hassle of finding leaks later on.

Note: Antifreeze mixtures are

more likely to result in leaks earlier

than water alone!

Geothermal heating

system (probe)

diameter

Content per

meter

25 mm 1,31 l/m

32 mm 2,12 l/m

40 mm 3,34 l/m