General information

Legal guidelines, warranty conditions,

checks on delivery

General indications

The sizing, installation, com-

missioning and maintenance of

the products described in this

document can only be carried

out by qualified specialists.

Please comply with local legal

instructions, which may differ

from the directions given in this

document.

These instructions are necessary to

correctly install, adjust and maintain

the appliance. It is therefore essential

to read the following instructions care-

fully and to have the heat pump in-

stalled, tested and maintained by

qualified technicians with specific

training.

At the end of the period of warranty,

the manufacturer declines all respon-

sibility for mechanical, hydraulic or

electrical modifications. In the event

of explicitly unauthorised interven-

tions, carried out in breach of these

instructions, the warranty shall be

forfeit with immediate effect.

During installation, the specific operat-

ing safety regulations must be com-

plied with. Please check that the prop-

erties of the power supply match the

heat pump details (identification tag).

These instructions and the heat

pump's electrical system must be

stored with due care and attention

and, if necessary, made available to

the relevant personnel.

The manufacturer declines all

responsibility for damages to

individuals and property

caused, directly or indirectly, by

failure to comply with these

instructions.

The appliance body can only be

opened by a qualified techni-

cian.

Binding indications and directives

The construction and manufacture of

the heat pump complies with all Euro-

pean regulation directives (see EC

declaration of conformity).

The power connection of the

heat pump must be carried out

in compliance with national

appliance regulations. In addi-

tion, it is necessary to comply

with the connection conditions

of the local energy provider.

Additional indications and instruc-

tions.

Functional or surface-ready heating

with the heat pump according to DIN

EN 1264 is only possible if taking into

account the aforementioned condi-

tions.

After sizing the heat pump for nor-

mal operations, it may not be possi-

ble to generate all heating neces-

sary.

Please comply also with the following

instructions:

•

Comply with regulations and in-

structions issued by the screed

manufacturer of the screed mortar!

•

Correct operations are possible

only with a system that has been

installed up to standards

(hydraulics, electrical components,

settings)!

Otherwise the screed

could be damaged!

Because overloading could

cause serious damages, it is

forbidden to activate the heat

pump if the following conditions

apply:

•

construction drying out;

•

System temperature < 25 °

C . It is recommended to

heat with the use of electrical

resistance installed

•

unfinished system

(raw construction);

•

external doors and windows

not completed and closed.

In these cases, it is necessary

to make provisions for site

heating.

Warranty terms

The warranty for heat pumps is valid

for 24 months from the day of deliv-

ery. For everything else, the sale,

provision and warranty conditions

apply on the basis of the order con-

firmation.

Our warranty provisions shall be for-

feit for damages as a result of:

•

improper use, misuse or non-

compliant use

•

incorrect installation or commis-

sioning by the purchaser or

third

parties

•

addition of parts from other manu-

facturers

•

usage of the system with exces-

sive pressure or pressure outside

the indicated factory levels

•

failure to comply with the instruc-

tions contained in the manual

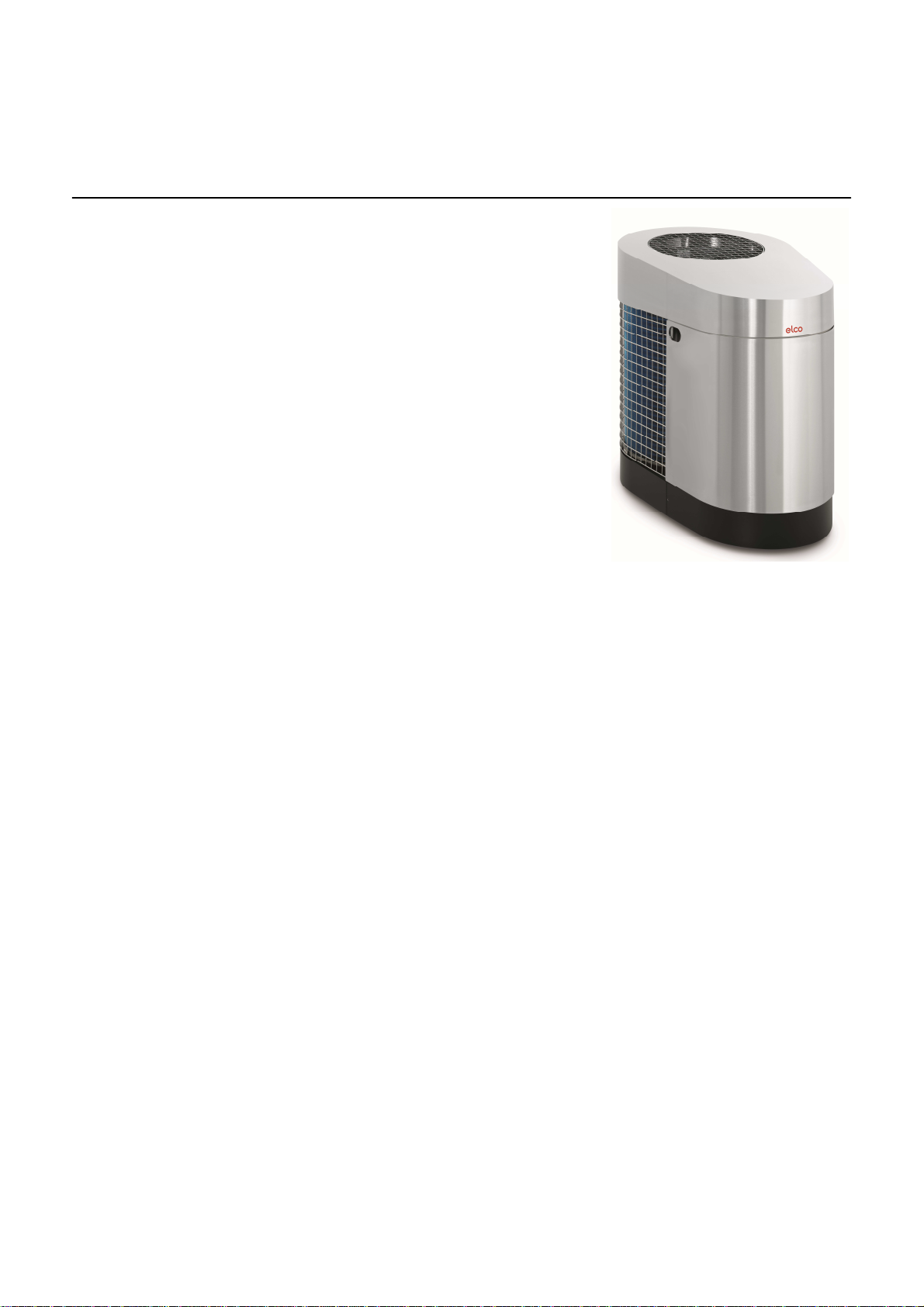

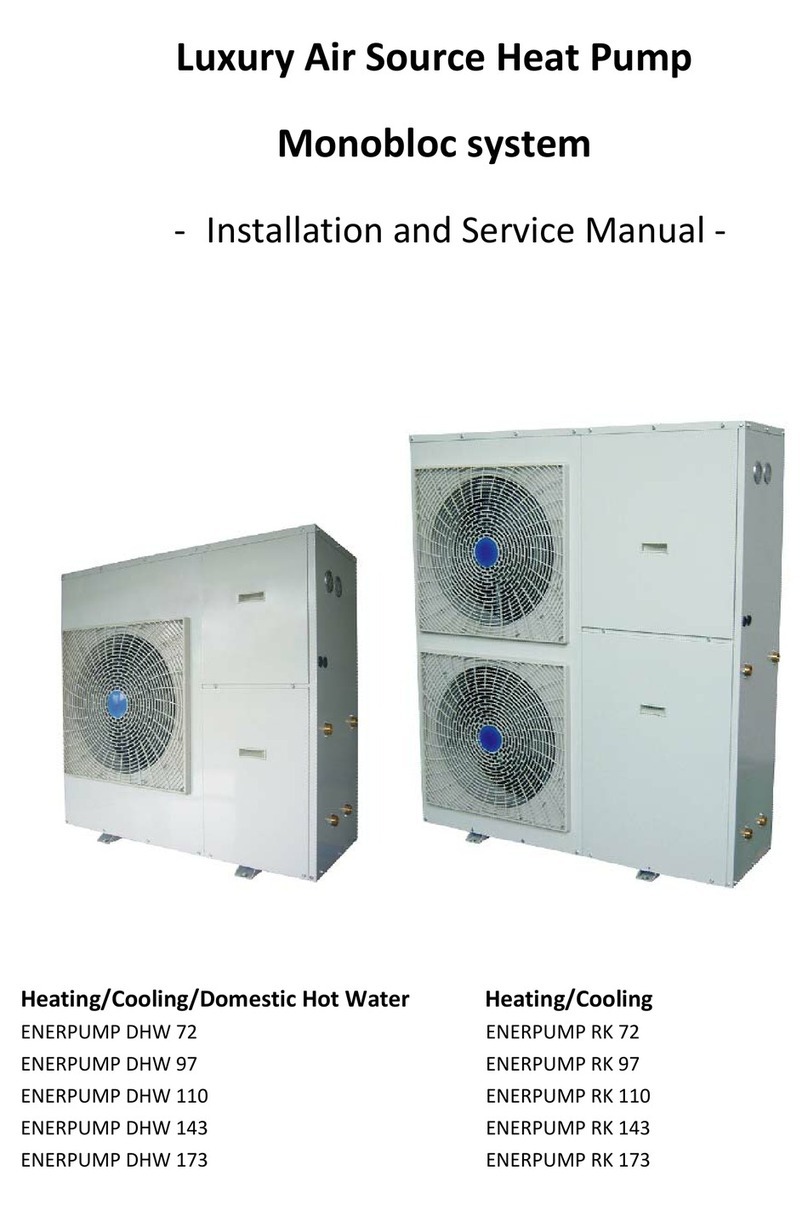

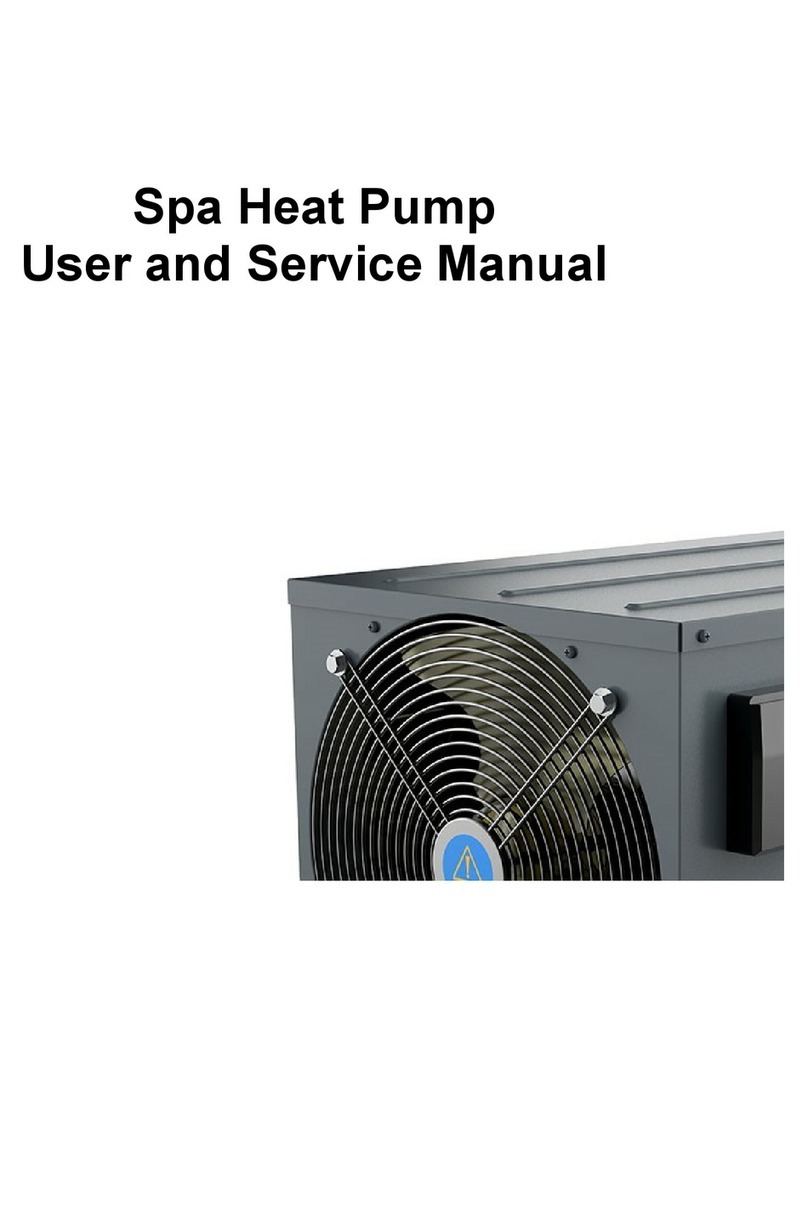

Checks on delivery

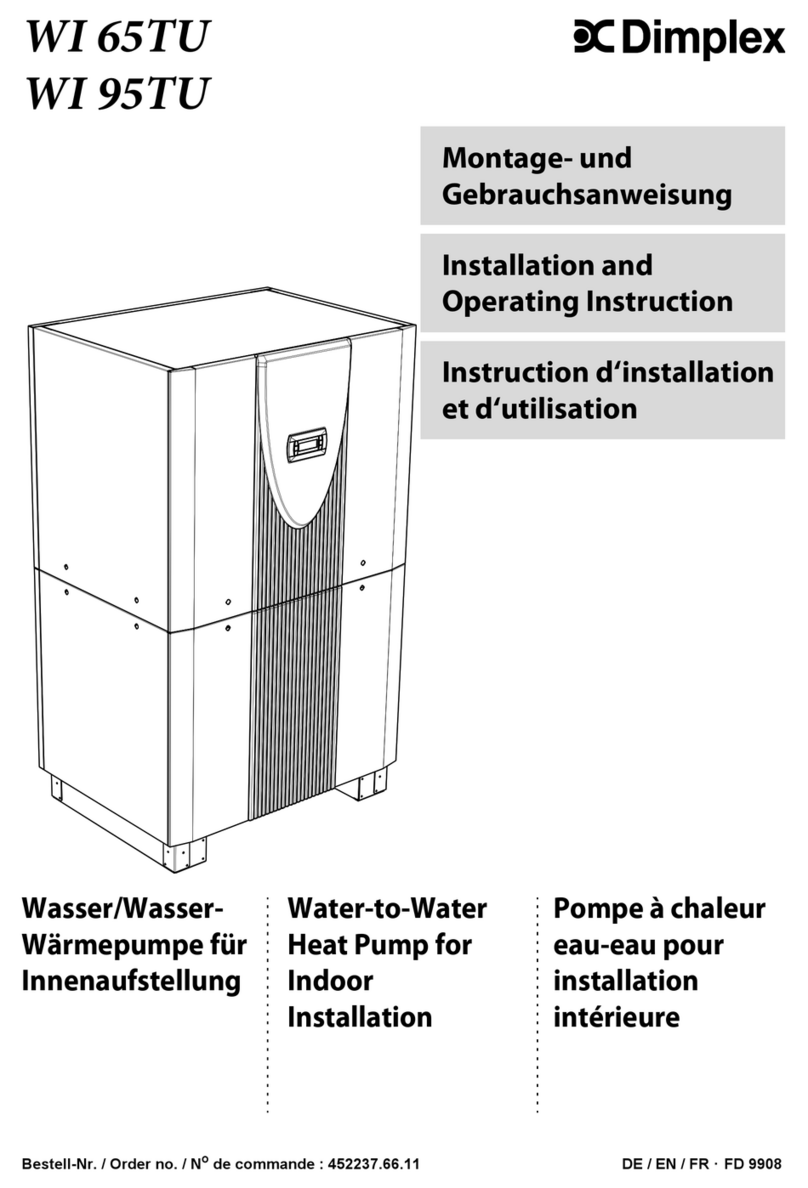

The appliances are delivered on a

wooden pallet, packed in cardboard.

At the time of delivery, please check

that the appliance wasn't damaged in

transport and that the equipment is

complete.

If you do find any damage, this

must be reported immediately on

the transport document with the

following wording: «Delivery ac-

cepted with reserved due to obvi-

ous damages».

The utmost care has been used in

manufacturing the heat pump.

However, during the manipulation of

the evaporator, it isn't possible to ex-

clude a slight bending of the single

blades during production. This does

not constitute a defect in the product.

For more information, please see

product description: high-efficiency

visible evaporator.

6