Elcometer 8400 User manual

English

Elcometer 8400

Heated Press

Operating Instructions

8400 - TMA-0357 Issue 01 A5.fm Page -1 Tuesday, October 2, 2007 3:33 PM

English

The Elcometer 8400 Heated Press has been tested in accordance

with EU regulations governing Electro-magnetic compliance and it

meets the required directives.

Note: Readings on the control panel may be affected if the unit is operated

within a radio frequency electromagnetic strength of greater than 3 V/m.

is a registered trademark of Elcometer Instruments Ltd.

All other trademarks acknowledged.

© Copyright Elcometer Instruments Ltd. 2007.

All rights reserved. No part of this Document may be reproduced, transmitted,

transcribed, stored (in a retrieval system or otherwise) or translated into any

language, in any form or by any means (electronic, mechanical, magnetic,

optical, manual or otherwise) without the prior written permission of

Elcometer Instruments Ltd.

A copy of this Instruction Manual is available for download on our Website via

www.elcometer.com/downloads.

Doc.No. TMA-0357 Issue 01

Text with Cover No: 20519

8400 - TMA-0357 Issue 01 A5.fm Page 0 Tuesday, October 2, 2007 3:33 PM

1

CONTENTS

Section Page

1 About this instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 These instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 What the box contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 The parts of the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 The controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Zeroing the load display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Adjusting the pressing force. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6 Caution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Testing a specimen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Pressing force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Technical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 Related equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8400 - TMA-0357 Issue 01 A5.fm Page 1 Tuesday, October 2, 2007 3:33 PM

2

hank you for purchasing this Elcometer 8400 Heated Press. Welcome to

Elcometer.

Elcometer are world leaders in the design, manufacture and supply of

inspection equipment for coatings and concrete. Our products cover all aspects

of coating inspection, from development through application to post application

inspection.

Your Elcometer 8400 Heated Press is a world beating product. With the

purchase of this product you now have access to the worldwide service and

support network of Elcometer. For more information visit our website at

www.elcometer.com

1 ABOUT THIS INSTRUMENT

The Elcometer 8400 Heated Press is an instrument which applies a known

pressing force and temperature to flat specimens compressed between two

plates within the instrument.

The press is used to simulate the conditions of pressure and heat commonly

found in a wide variety of production processes. The effects of stacking and

storage at elevated temperatures may also be assessed using this instrument.

Your Elcometer 8400 Heated Press has two horizontal parallel plates mounted

on a frame. The vertical position of the upper plate is adjustable and is used to

apply a force on the specimens placed between the plates, simulating the effect

of stacking.

Each plate can be electrically heated and regulated up to 250°C (482°F), thus

simulating changes in environmental temperature.

Specimens are stacked horizontally between the two plates, the force is applied

and a temperature selected.

The operator determines the length of time the simulation is to run and once

complete, observes the effect of the pressure and temperature on the

specimens.

1.1 These instructions

These instructions describe the operation of the following Elcometer 8400

Heated Presses:

• Elcometer 8400/1, 0 N to 10 000 N (0 lbf to 2248 lbf)

• Elcometer 8400/2, 0 N to 20 000 N (0 lbf to 4496 lbf)

• Elcometer 8400/3, 0 N to 30 000 N (0 lbf to 6744 lbf)

T

8400 - TMA-0357 Issue 01 A5.fm Page 2 Tuesday, October 2, 2007 3:33 PM

3

1.2 Standards

Your Elcometer 8400 Heated Press can be used in accordance with the

following International standard:

EN ISO DIN NF 4622

1.3 What the box contains

• Elcometer 8400 Heated Press

• Operating instructions

The Elcometer 8400 Heated Press is packed in a cardboard, wood and foam

package. It is recommended that this packaging is retained and reused in the

event that the instrument needs to be transported.

If the packaging materials are disposed of, please ensure that this is done in an

environmentally sensitive manner. Consult your local Environmental Authority

for further guidance.

To maximise the benefits of your new Elcometer 8400 Heated Press

please take some time to read these Operating Instructions. Do not

hesitate to contact Elcometer or your Elcometer supplier if you have any

questions.

2 GETTING STARTED

This section of the instructions is intended for first-time users of the Elcometer

8400 Heated Press. It contains information on the parts and controls of the

instrument and advice on safe use of the equipment. When you have finished

reading this section you will be ready to start using your Elcometer 8400 Heated

Press.

2.1 Installation

Your Heated Press is heavy - approximately 120 kg (264 lb); mount the

instrument on a sturdy table.

For safety reasons it is advisable to position the instrument in such a way that

the back of the instrument is not accessible (close

a

to a wall for example).

Protective guards may be placed around the instrument to reduce the risk of

accidental contact with hot surfaces.

Fasten in place using the mounting holes in the base plate of the instrument.

a. Leave a gap of least 300 mm (12") to allow for ventillation.

8400 - TMA-0357 Issue 01 A5.fm Page 3 Tuesday, October 2, 2007 3:33 PM

4

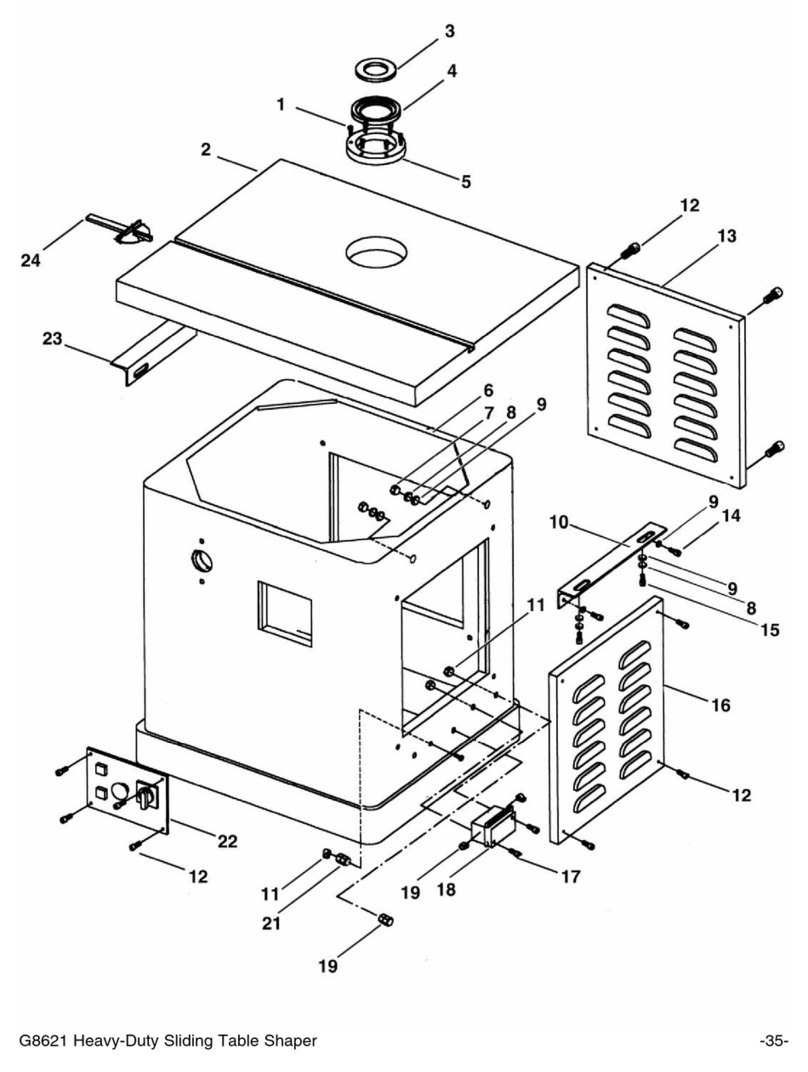

2.2 The parts of the instrument

The main parts of your Elcometer 8400 Heated Press are shown in Figure 1.

Figure 1. Parts of the Elcometer 8400 Heated Press

LOW

HIGH

ST

SP

o

C

ST

OUT

ALM

FN

LOW

HIGH

ST

SP

o

C

ST

OUT

ALM

FN

ON

HEATING

OFF

Upp erTabl e

ON

HEATING

OFF

Lower Table

ON

OFF

Lower Table

R

K8400

Heating P ress

Top plate

Bottom plate

Specimens

Press

adjusting

wheel

Control

panel

Base plate

Screw plate

8400 - TMA-0357 Issue 01 A5.fm Page 4 Tuesday, October 2, 2007 3:33 PM

5

2.3 The controls

Your Elcometer 8400 Heated Press includes a control panel (Figure 2/Figure 3)

which is used to display and control plate temperature and display the force

applied to the specimens.

Figure 2. Control panel (220 V and 240 V models)

Figure 3. Control panel (110 V models)

LOW HIGH ST

SP

o

C

ST

OUT

ALM

FN

LOW HIGH ST

SP

o

C

ST

OUT

ALM

FN

ON

HEATING

OFF

Upper Table

ON

HEATING

OFF

Lower Table

ON

OFF

Lower Table

R

K8400

Heating Press

Load

display

Temperature

display/control

and heating on/off:

Upper plate (table)

Lower plate (table) Power on/off

POWER ON

MAIN SWITCH

LOW

HIGH

ST

SP

o

C

ST

OUT

ALM

FN

LOW HIGH ST

SP

o

C

ST

OUT

ALM

FN

ON

HEATING

OFF

Upper Table

ON

HEATING

OFF

Lower Table

R

K8400

Heating Press

Power on/off

Temperature

display/control

and heating on/off:

Load

display

Power on/off

indicator

Upper plate (table)

Lower plate (table)

8400 - TMA-0357 Issue 01 A5.fm Page 5 Tuesday, October 2, 2007 3:33 PM

6

2.3.1 Power on/off

To switch the instrument on or off, rotate the main switch mounted on the control

panel. An indicator light on the control panel illuminates when the power is on.

2.3.2 Plate temperature

The temperature of the top and bottom plates is displayed on two temperature

controllers on the control panel.

Figure 4. Temperature controller

To adjust the temperature:

• Press and hold either the (increase) or (decrease) button for 3

seconds. The SP LED will start to flash and the set-point temperature will

be displayed and will start to change.

• Use the and buttons to adjust the set-point temperature.

• When the desired set-point temperature is displayed, do not push any

buttons for 3 seconds. The controller will fix the set-point temperature to the

value shown on the display and will then return automatically to the normal

display mode.

2.4 Zeroing the load display

After placing the specimens on the bottom plate and before applying a pressing

force, the load display on the control panel must be set to zero. To zero the

display, press the TARE button (Figure 5).

Figure 5. Press TARE button to zero the load display

LOW

HIGH

ST

SP

o

C

ST

OUT

ALM

FN

8400 - TMA-0357 Issue 01 A5.fm Page 6 Tuesday, October 2, 2007 3:33 PM

7

2.5 Adjusting the pressing force

The force applied to the specimen by the plates is adjusted by rotating the press

adjusting wheel. The force is displayed on the control panel. Always remember

to zero the display after placing the specimens on the bottom plate and before

applying force using the top plate.

Never exceed the maximum working force of your instrument:

• Elcometer 8400/1: 10 000 N (2248 lbf)

• Elcometer 8400/2: 20 000 N (4496 lbf)

• Elcometer 8400/3: 30 000 N (6744 lbf)

2.6 Caution

The Elcometer 8400 Heated Press has been manufactured with your safety in

mind. However, improper use can result in damage to the machine.

Please observe the precautions discussed in these operating instructions.

To reduce the risk of electric shock, do not open the control panel of

the Heated Press. There are no user-serviceable parts inside.

To reduce the risk of fire or electric shock, do not expose the Heated

Press to rain or excess moisture.

The mains plug on your Heated Press may be fitted with a fuse. When replacing

this fuse, ensure a fuse of the correct rating is used.

Take care when using your Heated Press - all surfaces of the top and

bottom plates and the screw plate can reach 250°C (482°F) and can

cause serious burns on contact with skin.

All personnel using this Heated Press must read these instructions and should

take great care to avoid touching the plates when they are at high temperature.

The press can produce a very high load between the top plate and

the bottom plate. When adjusting the press take care to avoid

trapping fingers or hands between the two plates.

8400 - TMA-0357 Issue 01 A5.fm Page 7 Tuesday, October 2, 2007 3:33 PM

8

3 TESTING A SPECIMEN

1. Connect the Elcometer 8400 Heated Press to the mains supply.

2. Switch on the instrument.

The temperature displays, load display and load sensor cooling fan will

operate.

3. Place the specimens in the centre of the bottom plate.

4. Press the TARE button on the load display to zero the display.

5. Rotate the press adjusting wheel to bring the top plate down onto the

specimens and then continue rotating until the required force is indicated

on the load display.

Never exceed the maximum force - see “Adjusting the pressing force” on

page 7.

During the test the pressing force will change due to thermal expansion of

materials - see “Pressing force” on page 9.

6. Set the required temperature for the top and bottom plates - see 2.3.2.

7. Switch on the top and bottom plates and start a stop watch to time the test.

The temperature will increase until it stabilises at the set point of each

temperature controller; from ambient temperature it takes approximately 60

minutes for the plates to reach 200°C (392°F).

Do not touch the plates when they are hot.

8. During the test, confirm that the load sensor cooling fan located under the

bottom plate is rotating. It is important that this fan operates correctly

because it keeps the sensor below its maximum working temperature of

65°C (149°F).

9. At the end of the test release the pressing force and remove the specimens

taking care to avoid contact with all hot surfaces.

10.Inspect the specimens in accordance with the requirements of the test

standard.

8400 - TMA-0357 Issue 01 A5.fm Page 8 Tuesday, October 2, 2007 3:33 PM

9

4 PRESSING FORCE

During the test the pressing force will change due to thermal expansion of

materials. Tests have been carried out to illustrate this and the results are given

below.

All tests were conducted on a stack of specimens 70 mm (2.8") high with an

initial force of 5000 N (1124 lbf) at an ambient temperature of 20°C (68°F).

5 MAINTENANCE

The Elcometer 8400 Heated Press is designed to give many years reliable

service under normal operating and storage conditions.

Every six months, or sooner when used intensively, lubricate the helical screw

of the press adjustment mechanism using machine oil.

The Elcometer 8400 Heated Press does not contain any internal user-

serviceable components. In the unlikely event of a fault, the instrument should

be returned to your local Elcometer supplier or directly to Elcometer.

Details of Elcometer offices around the world are given on the outside cover of

these Operating Instructions. Alternatively visit the Elcometer website,

www.elcometer.com

Material Temperature Force

Set point

(°C) Bottom plate

(°C) Top plate

(°C) (N) (lbf)

Steel 50 48.4 48.8 4870 1095

Steel 100 100.9 99.9 4870 1095

Steel 200 200.4 197.8 4590 1032

Aluminium 50 50.3 50.2 4970 1117

Aluminium 100 100.5 99.2 4920 1106

Aluminium 200 200.3 196.8 4890 1099

8400 - TMA-0357 Issue 01 A5.fm Page 9 Tuesday, October 2, 2007 3:33 PM

10

6 TECHNICAL SPECIFICATION

Maximum specimen dimensions: 250 mm x 250 mm (9.8" x 9.8")

Maximum specimen height: 140 mm (5.5")

Force on specimen; Model 8400/1: 0 N to 10 000 N (0 lbf to 2248 lbf)

Model 8400/2: 0 N to 20 000 N (0 lbf to 4496 lbf)

Model 8400/3: 0 N to 30 000 N (0 lbf to 6744 lbf)

Press temperature: Ambient to 250°C (482°F)

Temperature accuracy: ± 4 %, with minimum ± 2°C (3.6°F) in

the centre of the plate

Operating voltage: UK, 240 V AC 50 Hz

EUR, 220 V AC 50 Hz

US, 110 V AC 60 Hz

Power consumption: 2500 W

Fuse rating - plug (if fitted): 10 A

Fuse rating - machine: 10 A (2 off)

Dimensions: 900 mm x 500 mm x 800 mm

(36" x 20" x 31.5")

Weight: 120 kg (264 lb)

7 RELATED EQUIPMENT

In addition to the Elcometer 8400 Heated Press, Elcometer produces a wide

range of other equipment for determining the physical characteristics of surface

coatings.

Users of the Elcometer 8400 Heated Press may also benefit from the following

Elcometer products:

• Elcometer 8300 CoRI Stress Meter

• Elcometer Coating Appearance Meters

• Elcometer Corrosion Testers

• Elcometer Coating Thickness Gauges

For further information contact Elcometer, your local supplier or visit

www.elcometer.com

8400 - TMA-0357 Issue 01 A5.fm Page 10 Tuesday, October 2, 2007 3:33 PM

Table of contents

Other Elcometer Power Tools manuals

Popular Power Tools manuals by other brands

DeWalt

DeWalt SDS MAX D25711 instruction manual

Sieg

Sieg X2.7 instruction manual

Bessey

Bessey Seaming Tool PS55 brochure

Shrinkfast

Shrinkfast 998 UL Operating, field maintenance, and parts manual

Ryobi

Ryobi OES1813 Original instructions

PCB Piezotronics

PCB Piezotronics 027137-07051 Installation and operating manual