English

8

conductive nature such as, but not limited to, steel wool, aluminum

foil, or any buildup of metallic particles should be kept away from

charger cavities. Always unplug the charger from the power supply

when there is no battery pack in the cavity. Unplug charger before

attempting to clean.

•DO NOT attempt to charge the battery pack with any

chargers other than the ones in this manual. The charger

and batter y pack are specifically designed to work together.

• These chargers are not intended for any uses other than

charging DEWALT rechargeable batteries. Any other uses

may result in risk of fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• Pull by plug rather than cord when disconnecting charger.

This will reduce risk of damage to electric plug and cord.

• Make sure that cord is located so that it will not be stepped

on, tripped over, or otherwise subjected to damage or

stress.

• Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result in risk

of fire, electric shock, or electrocution.

• When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

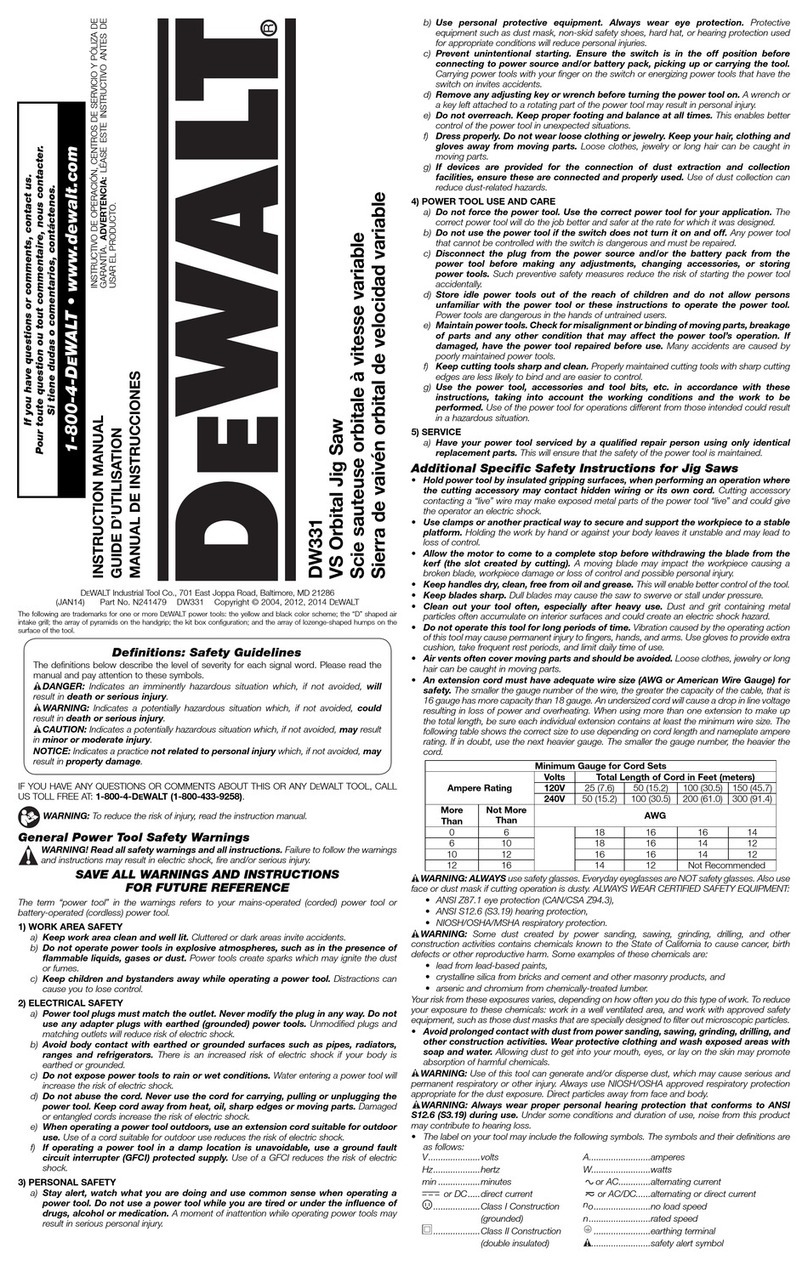

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the gauge

number of the wire, the greater the capacity of the cable, that

is 16 gauge has more capacity than 18 gauge. An undersized

cord will cause a drop in line voltage resulting in loss of power

and overheating. When using more than one extension to make

up the total length, be sure each individual extension contains

at least the minimum wire size. The following table shows the

correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size AWG

18 18 16 16 14 14 12

• Do not place any object on top of charger or place the

charger on a soft surface that might block the ventilation

slots and result in excessive internal heat. Place the charger

in a position away from any heat source. The charger is ventilated

through slots in the top and the bottom of the housing.

• Do not operate charger with damaged cord or plug.

• Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way. Take it to an

authorized service center.

• Do not disassemble charger; take it to an authorized service

center when service or repair is required. Incorrect reassembly

may result in a risk of electric shock, electrocution or fire.

• Disconnect the charger from the outlet before attempting

any cleaning. This will reduce the risk of electric shock.

Removing the battery pack will not reduce this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard 120V

household electrical power. Do not attempt to use it on any

other voltage. This does not apply to the vehicular charger.

Using Automatic Tune-Up™ Mode

The Automatic Tune-Up™ Mode equalizes or balances the

individual cells in the battery pack allowing it to function at peak

capacity. Battery packs should be tuned up weekly or after 10

charge/discharge cycles or whenever the pack no longer delivers

the same amount of work. To use the Automatic Tune-Up™, place

the battery pack in the charger and leave it for at least 8 hours. The

charger will cycle through the following modes.