ELCOS DIP-804/00 Instruction Manual

ENGINE PROTECTION DEVICE

TYPE

THE ENGINE IS STOPPED (VIA ELECTROMAGNET

OR SOLENOID) IN CASES OF ANOMALY FOR:

• INEFFICIENT BATTERY CHARGE ALTERNATOR (BELT BREAKAGE)

• LOW OIL PRESSURE

• OVERHEATING

• FUEL RESERVE (without stopping engine)

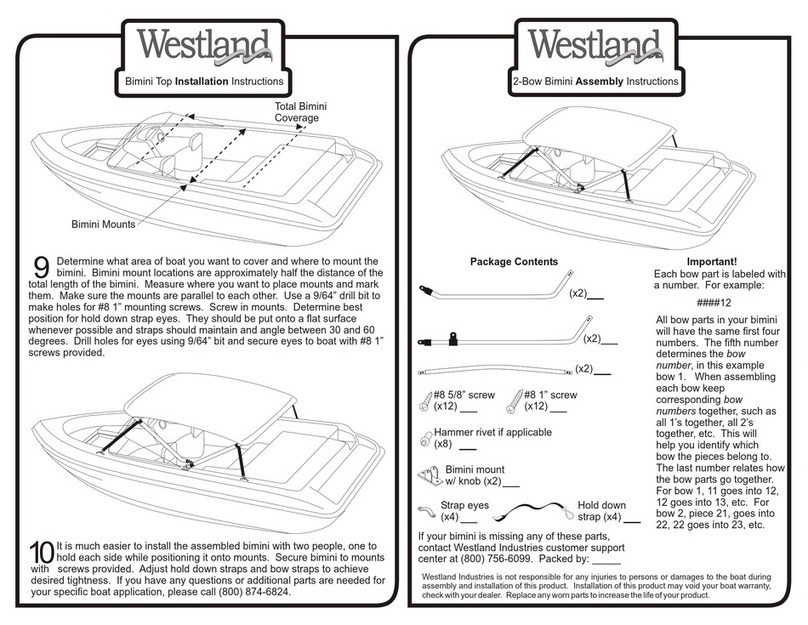

OIL AND BATTERY INDICATORS INTEGRATED INTO THE DEVICE

GB DIP-804/00/2 1

DIP-804/00

INSTRUCTION AND USER MANUAL

®

PARMA ITALY

Fax +39 0521/270218

Tel. +39 0521/772021

This surveys the fonctioning of the diesel engine and stops it if there are anomalies in the parts controlled by

probes.

It has been designed to be installed in cavities in dashboards, electric panels, etc.

NOTICES

Warning:

adhere closely to the following advice

- Always install under other equipment which produces or spreads heat.

- Always follow the circuit diagram when making connections.

- Check that the line loading and the consumption of the connected equipment are compatible with the

enclosed technical characteristics.

- All technical interventions must be performed with the engine stationary and terminal 50 of the starter

motor disconnected.

- Never use a battery charger for the emergency start-up, this could damage the equipment.

- To protect the safety of persons and the equipment, before connecting an external battery charger,

disconnect the electrical plant terminals from the battery poles.

NOTE: THE HOLE IN THE CASING USED TO INSTALL THE EQUIPMENT, COULD INFLUENCE THE LEVEL OF

PROTECTION OF BOTH. STEPS MUST BE TAKEN TO MAINTAIN THE ORIGINAL LEVEL OF

PROTECTION.

THIS DEVICE IS NOT SUITABLE FOR OPERATING IN THE FOLLOWING CONDITIONS:

- Where the environmental temperature is outside the limits indicated in the enclosed technical sheet.

- Where there are high levels or heat from radiation caused by the sun, ovens or the like.

- Where there is the risk of fire or explosions.

- Where the device can receive strong vibrations or knocks.

The following maintenance operations should be performed every week:

- check that the indicators function;

- check the batteries;

- check that the conductors are tight, check the condition of the terminals.

CONDUCTION AND MAINTENANCE

ELECTROMAGNETIC COMPATIBILITY

This device functions correctly only if inserted in plants which conform with the CE marking standards; it meets the

exemption requirements of the standard EN50082-2 but it cannot be excluded that malfunctions could occur in

extreme cases due to particular situations.

The installer has the task of checking that the disturbance levels are within the requirements of the standards.

YOUR ELECTRICAL TECHNICIAN CAN ASK US ANYTHING ABOUT THIS

PRODUCT BY TELEPHONING ONE OF OUR TECHNICIANS

UNLESS WE MAKE A WRITTEN DECLARATION STATING THE CONTRARY, THIS PANEL IS NOT SUITABLE

FOR USE AS A CRITICAL IN EQUIPMENT OR PLANTS RESPONSIBLE FOR KEEPING PERSONS OR OTHER

LIVING BEINGS ALIVE

2 GB DIP-804/00 /2

ENGINE PROTECTION DEVICE TYPE DIP-804/00

GB DIP-804/00 /2 3

IGNITION KEY TWIN-FUNCTION INDICATORS

ENGINE PROTECTIONS

- REST

- MANUAL STOP

- RESET PROTECTION

- DEVICE SUPPLY

- START ENGINE

0

AUT.

START

These are on when the key is turned to "AUT".

They switch off when the engine is running and

the oil pressure and battery recharger are

regular.

The engine protections are enabled when the ENGINE PROTECTIONS ACTIVE indicator is

on (20 seconds after turning the key to "AUT" or, in any case 20 seconds after the end of the start

impulse).

The interventions of the protection probes (mounted on the engine), shown by the relevant visual

indicators, stop the engine and can be divided into two groups:

These are enabled after the PROTECTIONS

ACTIVE indicator switches on, and they

switch on when the relevant anomaly is

detected.

- OIL AND BATTERY INDICATORS

- ANOMALY INDICATORS

After a 3 second delay for:Immediately for:

- OIL PRESSURE SWITCH

- OVERHEATING THERMOSTAT

- BATTERY CHARGE ALTERNATOR

(ALTERNATOR BELT BREAKAGE)

MAIN ALARM

This is obtained in three ways:

By turning the ignition key to zero

Because of protections intervention

-

-

The protection device uses two different types of stoppage:

- activating the ELECTROMAGNET which pulled the STOP lever for 20 seconds

- disconnecting the supply to the SOLENOID which closes the gasoline passage.

Enabled when the ignition key is turned to "AUT", without stopping the engine.

This can be obtained by mounting a visual and/or acoustic indicator externally connected to the

relevant output.

This is continuously activated if the protections or fuel reserve alarm intervene.

RESET: This is obtained by turning the ignition key to zero.

(MOUNTED EXTERNALLY)

STOPPING

ALARM

(FUEL RESERVE )

FUNCTIONING

4 GB DIP-804/00 /2

1235678293031373940

B+

D+

YELLOW

RED

YELLOW

GRGB LC

R

LE

+~~

39 40

DIP-804/00

h

1

48 3

416

41

40

28

26

27

30

50

30

15/54

50

W

157

3W

MAX

(BELT BREAKAGE)

WARNING DO NOT CONNECT THE CHARGE CONTROL BULB INTO THE PLANT

SEE "TWIN FUNCTION INDICATIONS" ON PAGE 3

FUSE

5A

FUSE

5A

CIRCUIT DIAGRAM

85

30

86

87

2/7

GB DIP-804/00 /2 5

(1) IGNITION KEY

(2/7) DRIVE-EXCITED MAGNET OR SOLENOID

(3) OIL PRESSURE SWITCH

(4) THERMOSTAT

(16) FUEL FLOAT

(48) HOUR COUNTER

(157) INDICATOR (GENERAL ALARM)

(26) PERMANENT MAGNET CHARGE

ALTERNATOR REGULATOR

(27) ALTERNATOR REGULATOR

(28) PRE-EXCITATION CHARGE

ALTERNATOR

(40) STARTER MOTOR

(41) BATTERY

ON REQUEST

ACCESSORIES

MOUNTED ON THE ENGINE

The system is arranged to command

the stopping with SOLENOID.

For ELECTROMAGNET stopping,

connect terminals 39 and 40.

STOP SYSTEMS SET UP DRIVE

EXCITATION

STOP

EXCITATION

SOLENOID

for closing

diesel

ELECTROMAGNET

for pulling

STOP lever

39 40

6 GB DIP-804/00 /2

(SIMULATION)

FUNCTION PERFORMED INTERVENTION SIMULATION

(WITH INDICATOR ON

PROTECTIONS ARE ACTIVE)

FUNCTIONS INTERVENTION

(STOP, GENERAL ALARM

AND VISUAL INDICATOR ON)

RECHARGE

ALTERNATOR

(BELT BREAKAGE)

LOW OIL

PRESSURE

OVERHEATING

FUEL RESERVE

AFTER 3 SECONDS

IMMEDIATELY

IMMEDIATELY

AFTER 3 SECONDS

THE RELEVANT INDICATOR

WILL LIGHT UP WITHOUT

STOPPING THE ENGINE

DISCONNECT THE WIRE FROM

TERMINAL [8] OF THE DEVICE AND

CONNECT TERMINAL [8] TO EARTH

DISCONNECT THE WIRE FROM THE

OIL PRESSURE SWITCH TERMINAL

AND CONNECT IT TO EARTH

DISCONNECT THE WIRE FROM THE

THERMOSTAT AND CONNECT IT

TO EARTH

DISCONNECT THE WIRE FROM THE

W TERMINAL OF THE FLOAT AND

CONNECT IT TO EARTH

NOTE

WHEN THE SIMULATION HAS BEEN COMPLETED ENSURE THAT ALL OF THE CONNECTIONS

ARE RETURNED TO THEIR ORIGINAL POSITIONS

DEVICE TEST

(WITH PROBES DISCONNECTED)

NOTE: WHEN THE TEST HAS BEEN COMPLETED RECONNECT THE PROBES

FUNCTION PERFORMED TEST

RECHARGE

ALTERNATOR

(BELT BREAKAGE)

LOW OIL

PRESSURE

OVERHEATING

FUEL RESERVE

ENGINE

STATIONARY

ENGINE

STATIONARY

ENGINE RUNNING

WITH REGULAR

BELT

ENGINE RUNNING

WITH REGULAR

PRESSURE

ENGINE WITH

NORMAL

TEMPERATURE

SUFFICIENT FUEL

ENGINE RUNNING

WITH BROKEN

BELT

ENGINE RUNNING

WITH INSUFFI-

CIENT PRESSURE

ENGINE

OVERHEATING

INSUFFICIENT

FUEL

NORMALLY THE

RELEVANT

TERMINAL OF THE

BATTERY CHARGE

ALTERNATOR IS

NEGATIVE WITH

THE ENGINE

STATIONARY

NORMALLY THE

TERMINAL OF THE

OIL PRESSURE

SWITCH IS

NEGATIVE WITH

THE ENGINE

STATIONARY

NORMALLY THE

TERMINAL OF THE

THERMOSTAT IS

NEGATIVE WHEN

THE ENGINE IS

TOO HOT

NORMALLY THE W

TERMINAL OF THE

FLOAT IS

NEGATIVE WHEN

THE FUEL IS

RUNNING OUT

D+

B+

GRGB LC

R

LE

+~~

YELLOW

YELLOW

RED

PERMANENT

MAGNET

ALTERNATOR

PRE-EXCITATION

ALTERNATOR

OIL PRESSURE

SWITCH

THERMOSTAT

FLOAT

W

3W

3W

3W

3W

GB DIP-804/00 /2 7

ENGINE PROBES TEST

8 GB DIP-804/00 /2

TYPE OF PROBLEM PROBABLE CAUSES REMEDIAL INTERVENTIONS

THE STARTER MOTOR

FUNCTIONS BUT THE

ENGINE DOES NOT

START

- Lack of fuel

- Fuel supply circuit defect

- Low temperature

- Fill the tank

- Check that the stop system (solenoid or

electromagnet) functions

Consult the engine instruction manual

- Check that the preheating functions

- The belt breakage

indicator lights up after

the PROTECTIONS

ACTIVE indicator

lights up

- The low oil pressure

indicator lights up after

the PROTECTIONS

ACTIVE indicator

lights up

- The overheating

indicator lights up

ENGINE STOPS FOR

ANOMALY

ENGINE DOES NOT

STOP UNDER ANY

CONDITIONS

- Stop system

(electromagnet or

solenoid) does not

function

- Defective engine

probes

- Defective device

- Check the condition of the alternator belt

- Check the engine oil level

- Check the engine cooling system

- Check the correct mechanical or electrical

functioning of the stop system. If the

problem persists, check the stop

servo-relay.

- Test the probes (see ENGINE PROBES

TEST on page 3) and if necessary replace

them.

- Check that during the stop phase there is

voltage on terminal (5) (see STOP on

page 3), simulate the function (see DEVICE

TEST on page 5 and if necessary replace

the device (*)

TROUBLE SHOOTING

GB DIP-804/00 /2 9

- The belt breakage

indicator lights up after

the PROTECTIONS

ACTIVE indicator

lights up

- The low oil pressure

indicator lights up after

the PROTECTIONS

ACTIVE indicator

lights up

- The overheating

indicator lights up

- Defective device

TYPE OF PROBLEM PROBABLE CAUSES REMEDIAL INTERVENTIONS

ENGINE STOPS FOR

ANOMALLY THOUGH

ALL APPEARS TO BE

REGULAR

- Check the function of the charge alternator

- Test and, if necessary, replace the oil

pressure switch

- Test and, if necessary, replace the

thermostat

- Simulate the functioning of the device (see

DEVICE TEST on page 5) and if necessary

replace it (*)

Turn the key to zero to reset the functioning

Before replacing the device, we suggest that you telephone one of our technicians for advice.

When your technician-electrician phones he must have the scheme on page 5 available together with the

following information:

- Type of equipment installed

- Problem encountered

- Condition of the indicators on the dashboard when the problem occurred

- Any remedial interventions performed

[*] DEVICE REPLACEMENT

TROUBLE SHOOTING

10 GB DIP-804/00 /2

SEE PAGE 5

ACCESSORIES DATA FOR ORDERING

MOBILE SOCKETS

type PMO-134/00 code 40804234

ENGINE PROTECTION DEVICE

type code

type code

DIP-804/00 12 V

DIP-804/00 24 V

00030201

00030202

ACCESSORIES AVAILABLE ON REQUEST

11GB DIP-804/00 /2

Ø86

Ø80

67

57

49.5 7.5

- BATTERY SUPPLY 12 VDC (MAX 16 VDC)

VOLTAGE or 24 VDC (MAX 32 VDC)

- CIRCUIT LOADING WITH KEY

TURNED TO ZERO 8 mA

- MAXIMUM LOAD ON OUTPUT [5] 3 A

(STOP)

- MAXIMUM LOAD ON OUTPUT [7] 3 W

(GENERAL ALARM)

- TEMPERATURE RANGE -10 ÷ +60 °C

- TERMINAL BOARD FASTON 6.35 × 0.8

- DEGREE OF PROTECTION:

FOR THE ELECTRONICS IP 65

FOR THE TERMINAL BOARD IP 00

- WEIGHT 450 g

TECHNICAL DATADIMENSIONS

Remarks

12 GB DIP-804/00 /2

Table of contents

Other ELCOS Protection Device manuals