ELEC-MECH SAFE-AID TS7000 User manual

TS7000

TELESCOPICCRANESOPERATORS’MANUAL

VERSIONVIII

October21

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII

Page 2

The purpose of this manual is to provide the customer with the operating

procedures essential for the promotion of proper machine operation for its

intended use. The importance of proper usage cannot be overstressed. All

information in this manual should be read and understood before any attempt is

made to operate the machine.

Since the manufacturer has no direct control over machine application and

operation, conformance with good safety practice in this area is the

responsibility of the user and his operating personnel.

All procedures are based on the use of the system under proper operating

conditions, with no deviations from the original design. Alteration and or

modification of the equipment is strictly forbidden without prior written approval

from Elec-Mech (Pty) Ltd.

The Safe-Aid TS7000 (rated capacity indicator (RCI) / Load Moment Indicator

(LMI)) is only to be regarded as an aid to the operator. When the parameters

are set correctly, the indicator will warn the crane operator of an approaching

overload condition or a condition that could cause damage to equipment,

property, and/or injury to the operator or the site workers in the vicinity of the

crane and its load.

This system under no circumstances must be used as a substitute for the good

judgement of a crane operator when carrying out approved crane-operating

procedures, therefore the responsibility for the safe operation of the crane lies

with the crane operator. The system will not necessarily prevent damage due to

overloading and related causes, if not set properly.

Before operating a crane equipped with a Safe-Aid TS7000 RCI the operator

must read the information in this manual carefully. Correct functioning of the

system depends upon routine daily inspection and any suspected faults or

apparent damage should be immediately reported to the responsible person

before using the crane.

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 3

Contents

SYSTEMUSE–FIGURE1......................................................................................................................................4

SYSTEMSTARTUP–FIGURE2&3........................................................................................................................5

TILTORLEVELSET‐UP–FIGURE4........................................................................................................................6

CRANECONFIGURATIONSELECTION..................................................................................................................7

COUNTERWEIGHT–FIGURE5..........................................................................................................................7

OUTRIGGERBASE–FIGURE6...........................................................................................................................8

BOOMCONFIGURATION–FIGURE7...............................................................................................................9

FIFTHOUTRIGGER–FIGURE8.......................................................................................................................10

WINCH–FIGURE9.........................................................................................................................................11

REEVING–FIGURE10....................................................................................................................................12

DEDUCTIONS–FIGURE11.............................................................................................................................13

PROGRAMCONFIRMATION–FIGURE12......................................................................................................14

OPERATINGSCREENS–FIGURE13,14,15&16...............................................................................................15

ERRORMESSAGES‐FIGURE17ANDTABLE#1.................................................................................................19

SAFE‐AIDTS7000SYSTEMERRORTABLE–TABLE#1........................................................................................20

WORKINGOPERATIONS–FIGURE18&19.......................................................................................................24

INDICATINGSTATUSLIGHTS‐DUMPOUTPUT(LEVERCUT‐OFF)–TABLE#2..................................................27

TOUCHSCREENCALIBRATION–FIGURES20,21&22......................................................................................30

WINDSPEEDSETUP–FIGURES23,24&25–OPTIONAL.................................................................................32

PROGRAM&REEVINGLOCKOUT–FIGURES26,27,28&29...........................................................................33

SCREENBRIGHTNESS–FIGURES30&31..........................................................................................................35

SETDATE&TIME–FIGURES32&33................................................................................................................36

QUICKUSEFLOWCHART...................................................................................................................................37

INSTALLATIONDETAILS.....................................................................................................................................38

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 4

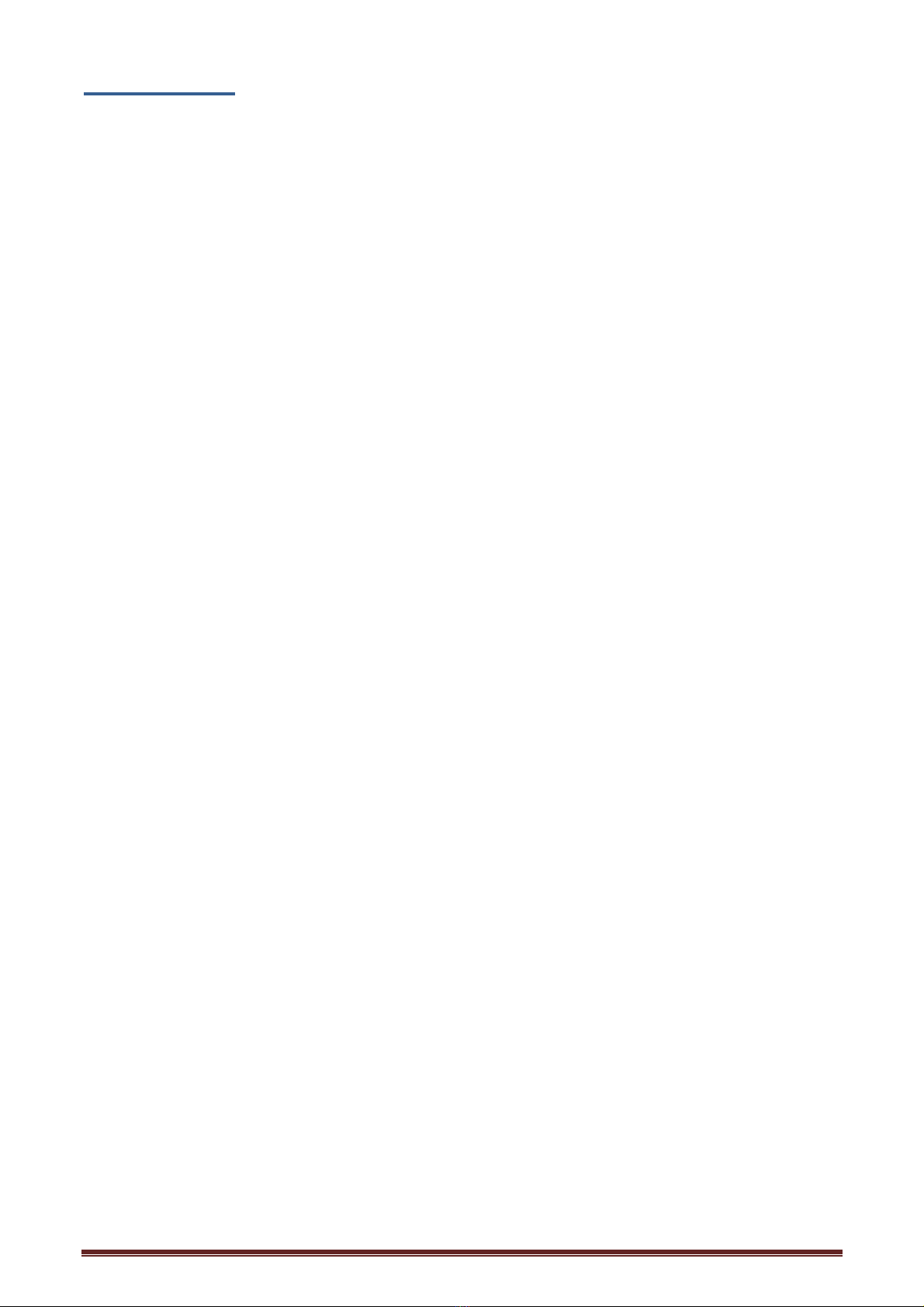

SYSTEMUSE–FIGURE1

The TS7000 unit is designed with ease of operation in mind. The crane configuration is

selected and confirmed by the operator before the system goes into its operating/monitoring

screen requiring no further input from the operator unless the crane configuration is changed.

Before this is done the crane will remain in safe mode, i.e., the dump circuit (cut-off) will be

operational (if the crane has a dump system fitted). All inputs to the system are done by the

operator via the touch screen including the buzzer override function and momentary bypass.

The touch screen is sensitive to touch therefore it is not necessary to push hard on the

screen (if touch screen does not work or selects incorrectly see Touch Screen Calibration).

Figure 1

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII

Page 5

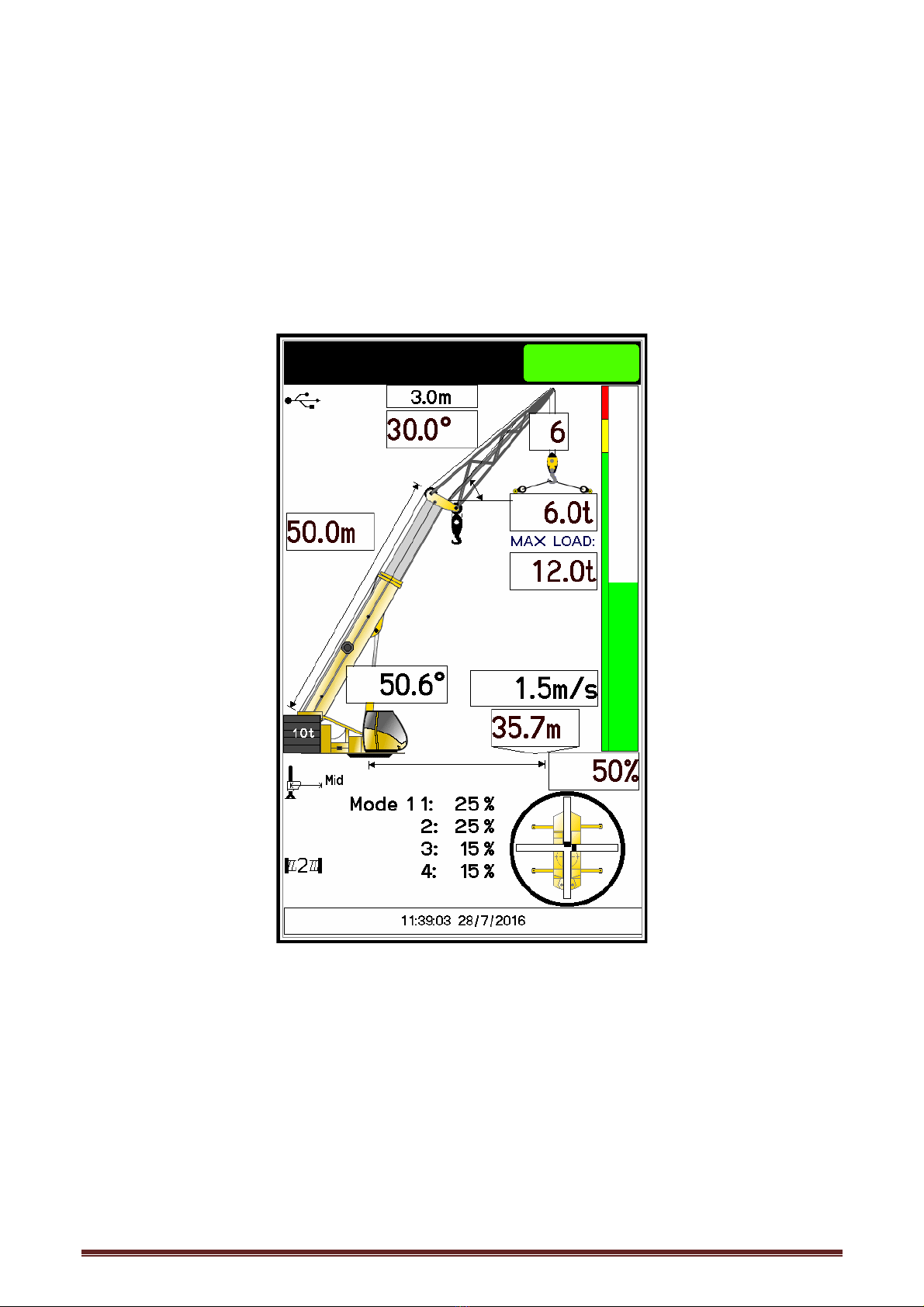

SYSTEMSTARTUP–FIGURE2&3

The TS7000 display (LMI) will automatically come on when the crane is powered up, the

buzzer will sound once then the system will run a CRC (cyclic redundancy check) to make

sure that all raw data is correct.

Once the system has completed the CRC the buzzer will sound again, and a set of internal

diagnostics (watchdogs) will be utilised to verify that all inputs and outputs are working

correctly.

Figure 2 Figure 3

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 6

TILTORLEVELSET‐UP–FIGURE4

This step will be skipped in the following conditions:

No tilt board is fitted

Tilt board is fitted but no tilt values have been entered

The following option is to determine whether the crane is level along the X & Y axis. Level

the machine using the dark black lines running along the axis lines. The machine will be level

once the lines are as close to the centre forming a cross. Press the Exit button to continue.

Figure 4

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 7

CRANECONFIGURATIONSELECTION

The system will now run through a series of selections to establish the current crane configuration.

These selections are setup by the crane manufacturer and correspond to the relevant load chart and

may not be displayed or in the same order as laid out in the manual.

Use the back button to start the complete selection from the beginning at any time.

Once the selection has been done the system will memorize the last selection and when powered up

again will show the program confirmation screen. See Program Confirmation.

Some manufacturers have telescoping monitoring conditions that may require the boom to be fully

retracted before changing the configuration, in this case a Retract Boom message will be displayed

when trying to change the configuration with the boom extended.

Laid out below are the most common selections available

COUNTERWEIGHT–FIGURE5

Select the counterweight that is currently in use.

Figure 5

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII

Page 8

OUTRIGGERBASE–FIGURE6

Select the configuration of the carrier that is currently in use.

Figure 6

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 9

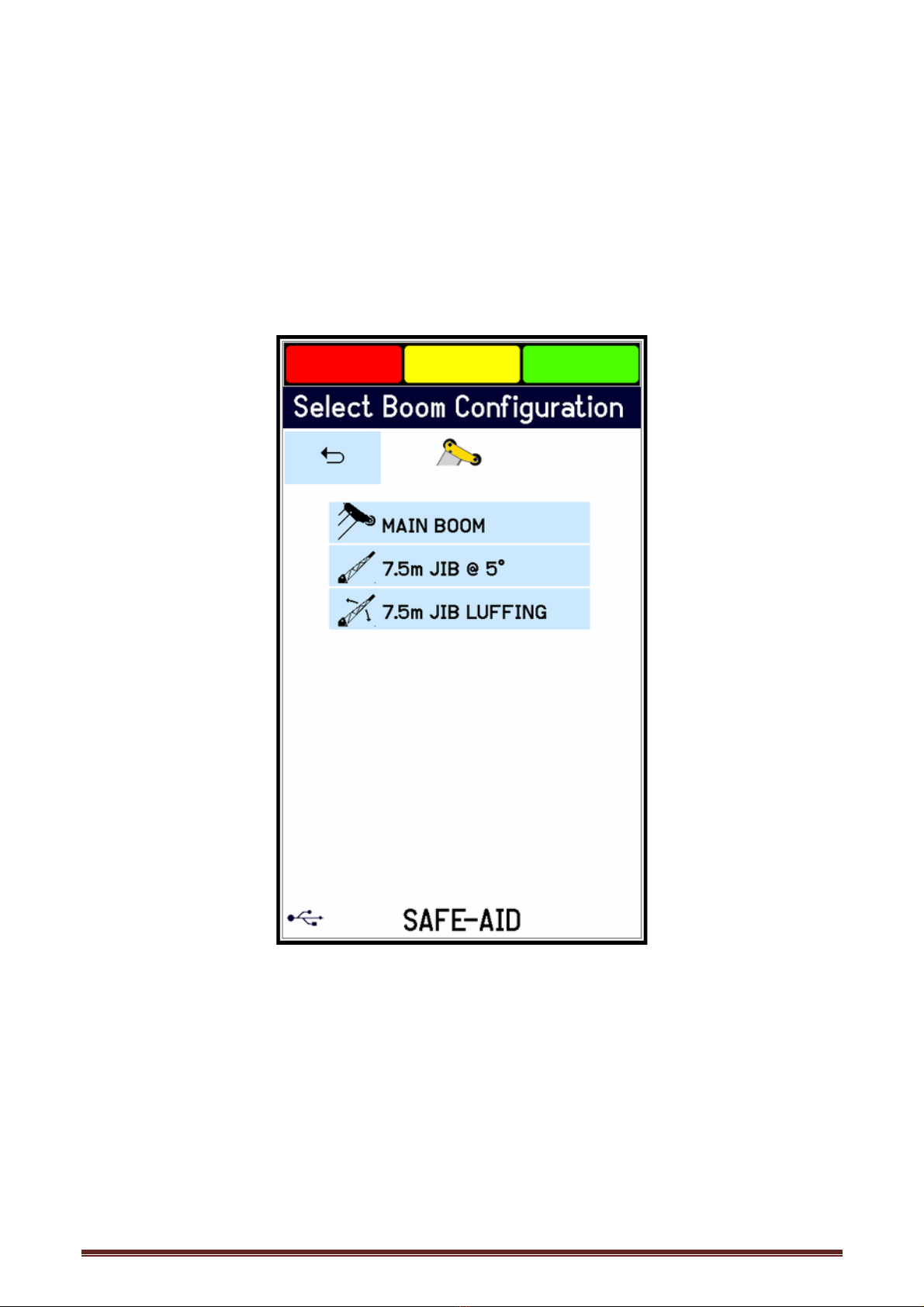

BOOMCONFIGURATION–FIGURE7

Each boom configuration can be selected by pushing on the configuration that is required.

Some manufacturers have telescoping monitoring conditions that may require the boom to

be fully retracted before changing configuration, in this case a Retract Boom message will

be displayed when trying to change the program with the boom extended.

The correct selection of the configuration is imperative as this determines the correct

rated capacities and work areas. If selected incorrectly, a higher rated capacity than

allowed could be selected for that crane configuration, this is very dangerous as it can

cause the boom to bend / break or the crane to tip / fall over.

Figure 7

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII

Page 10

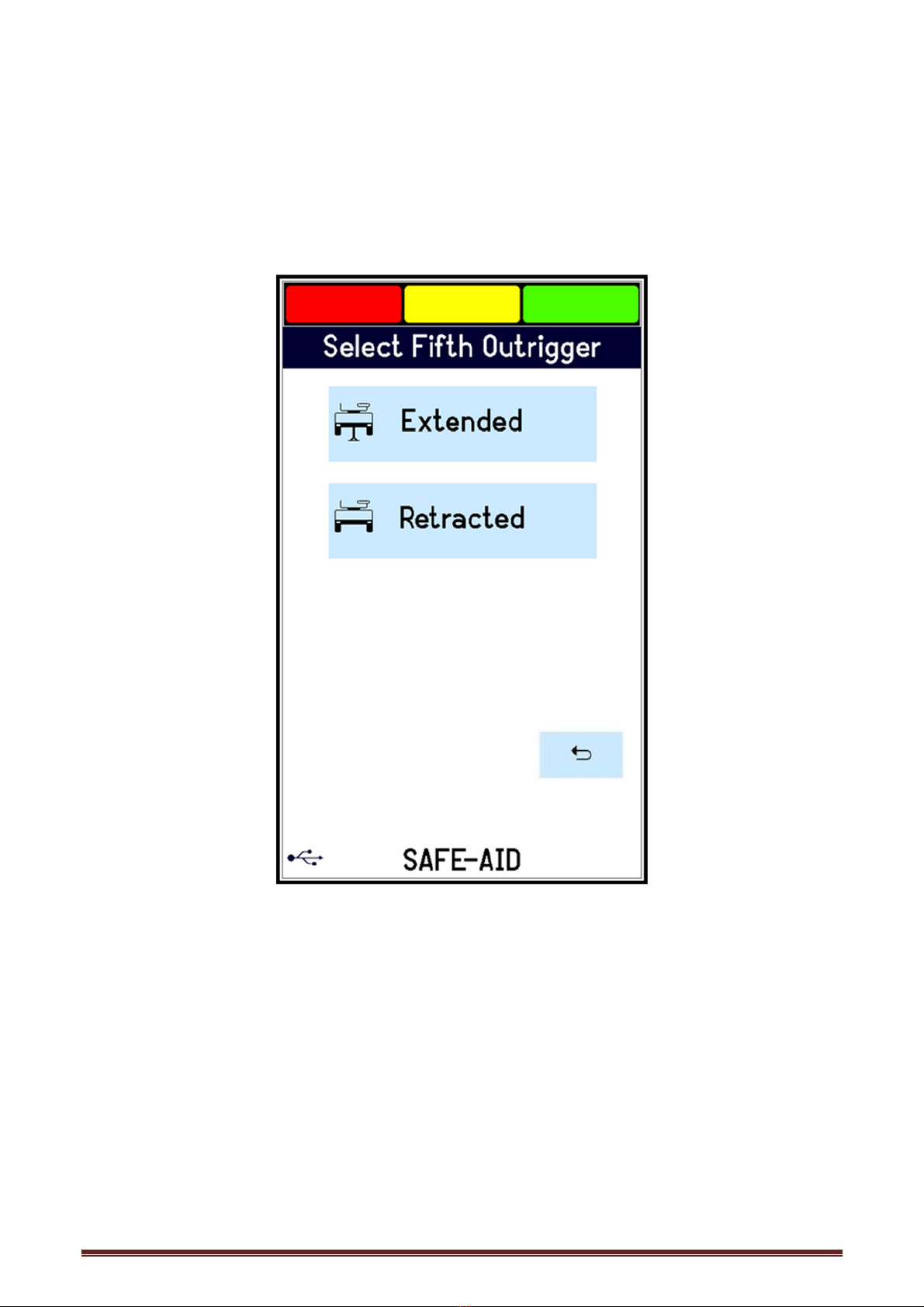

FIFTHOUTRIGGER–FIGURE8

Truck mount cranes may be fitted with additional outriggers (front jack / rear jack or both)

which can be extended (down) or retracted (up). This influences the rated capacities when

working over the front or rear of the crane either by decreasing the capacities or giving a slew

error when the 5th outrigger is retracted (Figure 3). Simply key the option required - if the

5th outrigger is down then select extended if it is up select retracted.

Figure 8

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 11

WINCH–FIGURE9

This step will be skipped in the following conditions:

The system has been programmed with only one winch.

The reeving has been fixed in rigging mode.

The following option is to determine the winch being used for lifting. Simply select the option

required. Select the relevant winch.

Winch 1 – Main Winch

Winch 2 – Auxiliary Winch

Figure 9

While working in the main running screen and the winch needs to be changed or if

an error has been made, press the picture of Winch 1 (main winch) or Winch 2

(auxiliary winch). Select the required winch followed by the correct reeving.

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 12

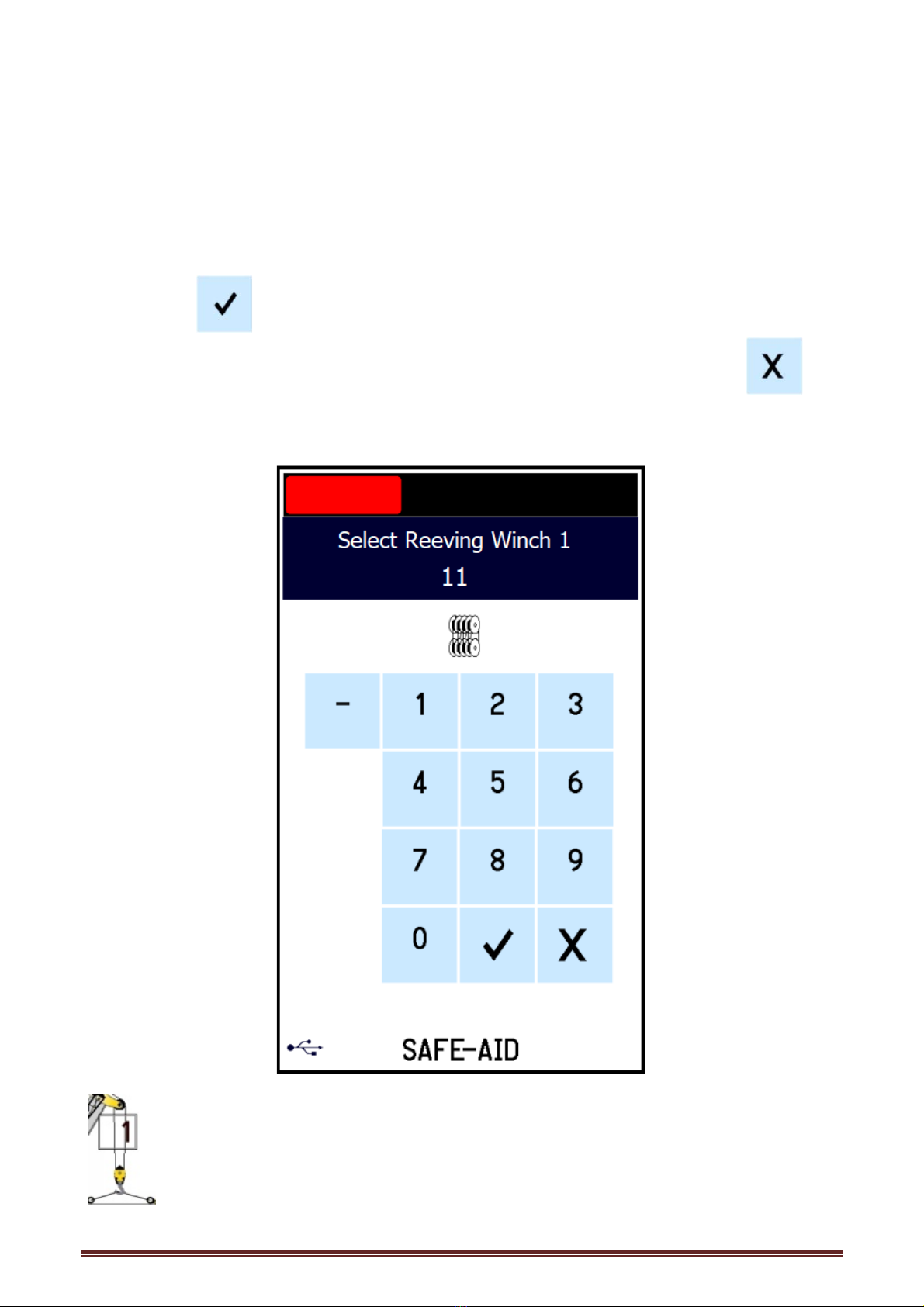

REEVING–FIGURE10

This step will be skipped in the following conditions:

The system has been programmed with fixed reeving.

The reeving has been fixed in rigging mode.

A fixed hook has been selected (cannot be reeved).

After winch selection, how many reeves (falls) the hook is reeved to (total parts of line

between hook block and sheave wheels) must be selected. A numerical keypad will be

displayed, key in the number of reeves on the winch (i.e. Winch #1 or Winch #2), followed by

the enter key (e.g. if Winch #1 (main winch) was selected Select Reeving Winch 1will

be displayed). If the incorrect number is keyed in simply press the clear button and

start again. Once the enter button is pressed the next selectable option or the operating

screen will appear.

Figure 10

While working in the main running screen or if an error has been made and the

reeving needs to be changed, press the block on the main running screen where

the winch rope goes down to the lifted load and the system will respond by

changing to the Reeving entry screen.

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 13

DEDUCTIONS–FIGURE11

This step will be skipped in the following conditions:

No deductions for the relevant program are available.

On cranes where the main boom can be used with the fly jib erected or the main hook block

is on while the fly jib is being used, the crane manufacturer may give deductions that must

be taken off the rated load when using that configuration. The total of all the selected

deductions will be automatically deducted from the rated capacity, this is done by the TS7000

once the correct options have been selected when prompted (figure 9). Press the deduction

required and a will be displayed on the right of the selected deduction, if more than one

deduction is required select all the deductions (figure 10). Once all the deductions have been

selected press to continue.

Figure 11

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 14

PROGRAMCONFIRMATION–FIGURE12

This screen will only be displayed if the system has been programmed to allow this, if

this is not programmed the system will go through all the selections again on power

up.

If none of the configuration settings have changed when powering up to the confirmation

screen confirm by pressing the to continue to the working screen. If any of

the configurations have changed then press the and the system will

automatically go to the first configuration selection. Select the correct configuration step by

step and the system will automatically save the configuration for the next start up.

Figure 12

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 15

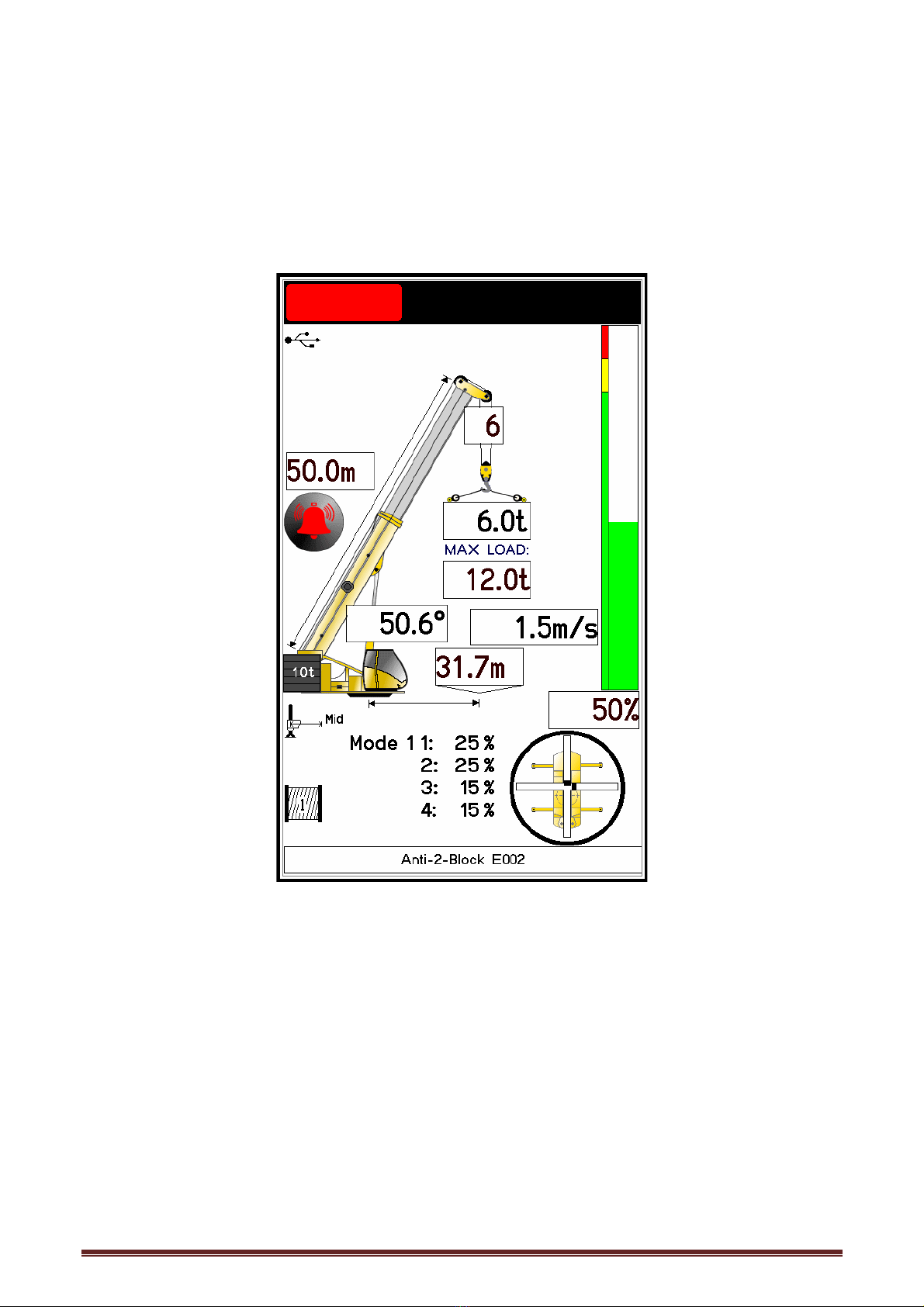

OPERATINGSCREENS–FIGURE13,14,15&16

All the crane and system information can be viewed from here including all the parameters

selected from power up. Should a different program need to be selected, press the crane

graphic on the screen, the system will go back to the beginning as on system start up. Repeat

the steps above.

Figure 13 Figure 14

Figure 15 Figure 16

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 16

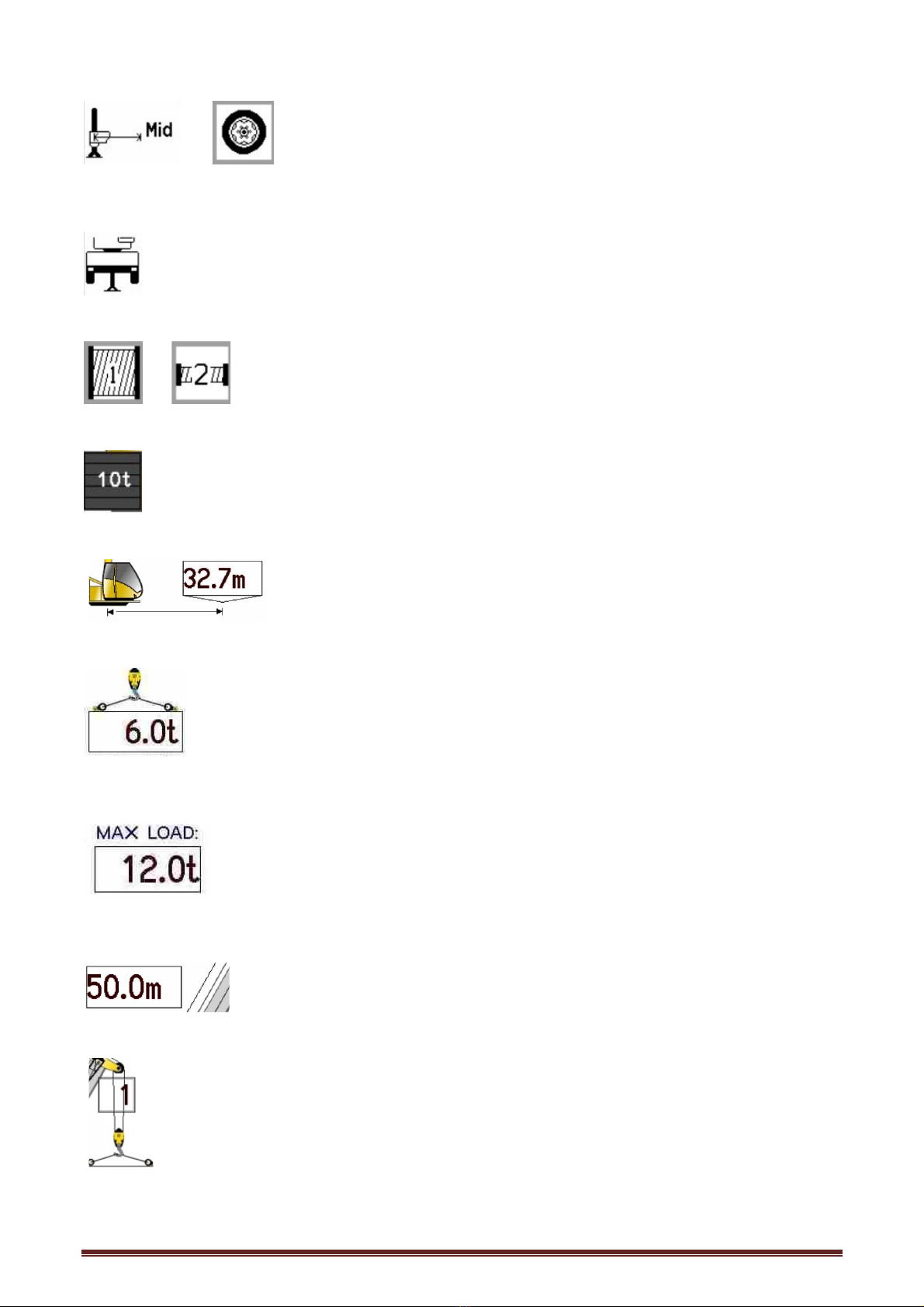

In operating mode, you can see all the current parameters of the crane.

or Outrigger Base: This is the current outrigger base – can be

represented by the outrigger picture with outrigger length or a picture of a tyre with the crane

travel speed.

Fifth Outrigger: This is the fifth outrigger position

or Winch: This is the winch selected

Counterweight: This is the total weight of counterweights fitted

Radius: This is the current radius from centre line of rotation to the

centre of the hook block (load) if the hook block (load) is suspended and hanging vertical.

Lifted Load: This is the load on the hook at the present time, if the green light

and the load are flashing it is a tare load (the tare has been pressed).

Rated Capacity: This is the load allowed to be picked up with the selected

configuration at that current radius as specified by the manufacturer.

Main Boom Length: This displays the current total main boom length.

Reeving: This is the current reeving (number of falls) selected.

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 17

Main Angle: This displays the main boom angle.

Fly Length: This displays the selected or measured

fly length.

Fly Angle:A fixed angle will be shown for a fixed fly and for a

monitored fixed fly the angle will change as the fly angle changes. The fixed fly angle is

measured relative to the main boom i.e. 0° being straight with the main boom and

increasing as the offset to the main boom increases.

Luffing Fly Angle:If a luffing fly is fitted, the luffing fly angle will be shown in

the fly angle box. The luffing fly angle is measured relative to ground level i.e. 0° is the fly jib

parallel to the level ground.

Utilisation: Percentage utilisation is the percentage of rated load used by the

current lifted load.

Utilisation Bar: The percentage utilisation is also displayed graphically by a bar graph,

going from green (0% - 89%), then amber (90% - 99%) and finally red (100% and above)

increasing incrementally with the percentage utilisation.

Date & Time: This is the current date and time.

Wind Speed: This is the current windspeed (live value) in the units of

measure selected.

Boom Telescope Percentages – This shows the current mode and the

boom section percentages.

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 18

Area Selection: This is not user selectable and shows the current area the crane is

working in:

360 Degrees Over Side & Rear Direct Over front

Direct Over Rear Direct Over Front & Rear Over Side

Over Front and Side Over Front Outrigger Over Rear Outrigger

To Outrigger To Outrigger

Level/Tilt: The cross through the area selection represents the X & Y axis

while the two lines in the axis are the positioning of the crane (see Tilt or Level setup).

Area Selection Potentiometer: The black segment in the perimeter circle

represents the position of the boom relative to the carrier.

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 19

ERRORMESSAGES‐FIGURE17ANDTABLE#1

The TS7000 will sound a buzzer and the green block will be replaced by an orange or red

block at the top of the screen if any error occurs on the system. These errors are displayed

at the bottom of the screen as either an error code only or the error description with the error

code e.g., Anti-2-Block E002 where program selection is normally displayed. If more than

one error occurs the errors will scroll on the bottom until rectified.

Figure 17

For all the errors, we have given indication of the problem and the common

solutions, these can be done by the operator or an individual who has some

basic crane knowledge. If the given solution does not work, please contact the

original installer or someone from our service network.

TS7000 TELECSOPIC CRANE OPERATORS MANUAL - VERSION VIII Page 20

SAFE‐AIDTS7000SYSTEMERRORTABLE–TABLE#1

CODE SCREEN DISPLAY INDICATION OPERATOR SOLUTION

E001 Slew Error Boom is not over an area covered by the current

configuration selected. Slew the boom into a safe working area.

E002 Anti-2-Block The main or auxiliary hook has been pulled up too close

to the boom head sheave wheels. Lower Winch 1 or 2.

E003 Anti-2-Block Fly The hook has been pulled up to close to the fly jib tip

sheave wheel. Lower Winch

E004 90% Overload The lifted load is greater than or equal to 90% of the

rated capacity

Move load into safe working position -

winch down, boom up or retract boom.

E005 Overload The lifted load is greater than or equal to 100% of the

rated capacity

Move load into safe working position -

winch down, boom up or retract boom.

E007 Length Exceeded

The length allowed for the selected configuration has

been exceeded or the length is greater than maximum

manufacturer's specified len

g

th.

Retract boom & check configuration

selection is correct.

E008 Low Angle The angle of the boom is below the crane manufacturer's

minimum specification. Raise boom.

E009 Extend Boom You are working below the specified working length for

the selected boom configuration.

Extend boom to the correct working length

& check program selection.

E010 Rope Overload The maximum line pull specified by the manufacturer has

been exceeded.

Put Load down – check correct reeving

selected.

E025 Telesequence Error The boom has been telescoped incorrectly NOT

according to the manufacturer's specifications.

Retract boom fully and telescope according

to the manufacturer's specifications.

E027 Main A400 No Coms No communication between main angle board and

motherboard/display. Call installer or service technician.

E028 Aux A400 No Coms No communication between auxiliary angle board and

motherboard/display. Call installer or service technician.

E029 M400 No Coms

No communication between mother board and display.

Call installer or service technician.

Table of contents