BMC LD6 User manual

LD6 & MD8 BACKHOES

OPERATOR’S MANUAL for

Back Hoes

Fron End Loaders

Fron Blades

Power S eering

Trenchers

Table of Contents

Page

Safety Precautions 1

General Information 2

LD6 Backhoe

MD8Backhoe 4

LD6 and MD8 Backhoe Box Parts 5

LD6 Backhoe Installation 6-12

MD8 Backhoe Installation 1 -19

LD6 and MD8 Bucket Installation 20

LD6 and MD8 Hose Installation 21-25

Controls 26-27

Operations 28- 4

Backhoe Removal and Storage 5

Backhoe Installation After Storage 5- 6

General Maintenance 6- 8

Torque Charts 9

Hand Signals and Decals 40

Specifications (LD6 and MD8) 41-42

Pre-Delivery Checklist 4

SAFETY PRECAUTIONS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

1

The following precautions are suggested to help

prevent accidents. A careful operator is the best

operator.

BACKHOE SAFETY PRECAUTIONS

1. Read the Operator’s Manual carefully to acquaint

yourself with the backhoe. Working with unfamiliar

equipment can lead to accidents.

2. Use the handholds and steps when getting on and

off the backhoe.

. Replace safety and warning decals when they become

illegible.

4. For safe operation observe proper maintenance

and repair of all pivot points, hydraulic cylinders, hoses

and main attaching bolts prior to each day’s operation.

5. Always be sure of water, gas, sewage and electrical

line location when operating the backhoe.

6. Watch for overhead and underground high voltage

electrical line before you start to dig.

7. Operate the backhoe controls only when properly

seated at the controls.

8. Do not use the backhoe for a hoist.

9. Never allow anyone to get under the backhoe when

the boom or dipper arm is raised or stabilizers are

raised.

10. Always be watchful of bystanders when lowering

the stabilizers or operating the backhoe.

11. To prevent upsets, avoid full reach and swinging a

loaded backhoe bucket to the down hill side when

operating on a slope.

12. Always lower the bucket to the ground, shut off

the engine and apply parking brakes before getting off

the unit.

1 . Never attach pulling devices to the ROPS or

backhoe for pulling purposes, as the unit can tip

rearward.

14. Keep the operator’s platform free of debris.

15. Adequately block up the backhoe when it is

detached from the tractor.

Whenever you see this symbol it means:

TRACTOR SAFETY PRECAUTIONS

1. Do not start the engine while standing beside the

tractor. Always sit in the tractor seat when starting the

engine.

2. Do not get off the tractor while it is in motion.

. Use an approved roll bar and seat belt for safe

operation. If your tractor is not equipped with a roll

bar and seat belt, see your tractor equipment dealer.

4. Always use the seat belt when the roll bar is

installed. Do not use the seat belt if the roll bar is

removed from the tractor.

5. Do not permit anyone but the operator to ride on

the unit. There is no safe place for extra riders.

6. Lower the bucket to the ground, shut off the engine

and apply the parking brake before getting off the

tractor.

7. Do not operate the tractor engine in an enclosed

building without adequate ventilation. Exhaust fumes

can suffocate you.

8. Never leave the unit when it is parked on an

incline. Always park the unit on level ground where

possible. If the unit is parked on an incline, always

lower the bucket so that the cutting lip contacts the

ground, apply the parking brake and securely block the

wheels.

9. Use care when operating on grades to maintain

proper stability. Also drive at speeds compatible with

safety, especially when operating over rough ground,

crossing over ditches, slopes, or when turning.

10. Use SMV warning signs on the tractor when

traveling on public roads both day and night.

11. Use the flasher / turn signal lights when traveling

on public roads both day and night unless prohibited by

law.

12. Never pull from the tractor rear axle or any point

above the axle. Doing so may cause the tractor to upset.

1 . Always check overhead clearance, especially

when transporting the unit.

14. Do not lubricate or make mechanical adjustments

while the unit is in motion or when the engine is

running.

15. Never make repairs or tighten the hydraulic hoses or

fittings when the system is under pressure, when the

engine is running, or when the backhoe cylinders are

under a load.

16. Always wear safety glasses when servicing or

repairing the machine.

GENERAL INFORMATION

2

The BMC Series LD6, Fig 1. and MD8, Fig 2. Backhoes are shipped complete (crated) less mounting kit and

bucket. To mount either of the basic Backhoes to a tractor, a mounting kit (for a specific tractor model) is required.

Also required is one of the three bucket options for the LD6 and one of the four for the MD8. Items unique to each tractor fit

up (pressure / return hoses, seat assemblies, mounting bolts, etc.) are included in the mounting kit for each tractor.

The BMC Series LD6 and MD8 Backhoe can be installed from the crate to the tractor in a matter of a few hours. The

BMC Series Backhoes should be installed on tractors that have a front blade of front loader that will stabilize the

front of the tractor. Installation of the front blade or front loader is covered in the appropriate manual.

The LD6 and MD8 Backhoe general specifications are listed on page 41 and 42. The Backhoes are identified by name

plates as follows:

This manual is divided into five (5) major sections:

Installation of LD6 Backhoe (Page 6)

Installation of MD8 Backhoe (Page 1 )

Installation of Buckets (Page 20)

Hosing of the LD6 and MD8 Backhoe (Page 21)

Operation of the Backhoe (Page 26)

Maintenance of the Backhoe (Page 6)

The mounting frame, seat and backhoe / tractor hydraulic interface is covered in the mounting frame installation

sheet. During assembly and when ordering parts, the right side of the backhoe is the same as the right side of the

tractor, facing forward in the tractor operator’s seat.

Your local tractor and equipment dealer is responsible for the proper assembly and pre-delivery servicing of the

backhoe.

Bran ly Manufac uring Company reserves he righ o make design changes or improvemen s wi hou incurring any

obliga ion o up-da e exis ing equipmen or any obliga ion for no ifica ion o owners of exis ing equipmen of hose

changes.

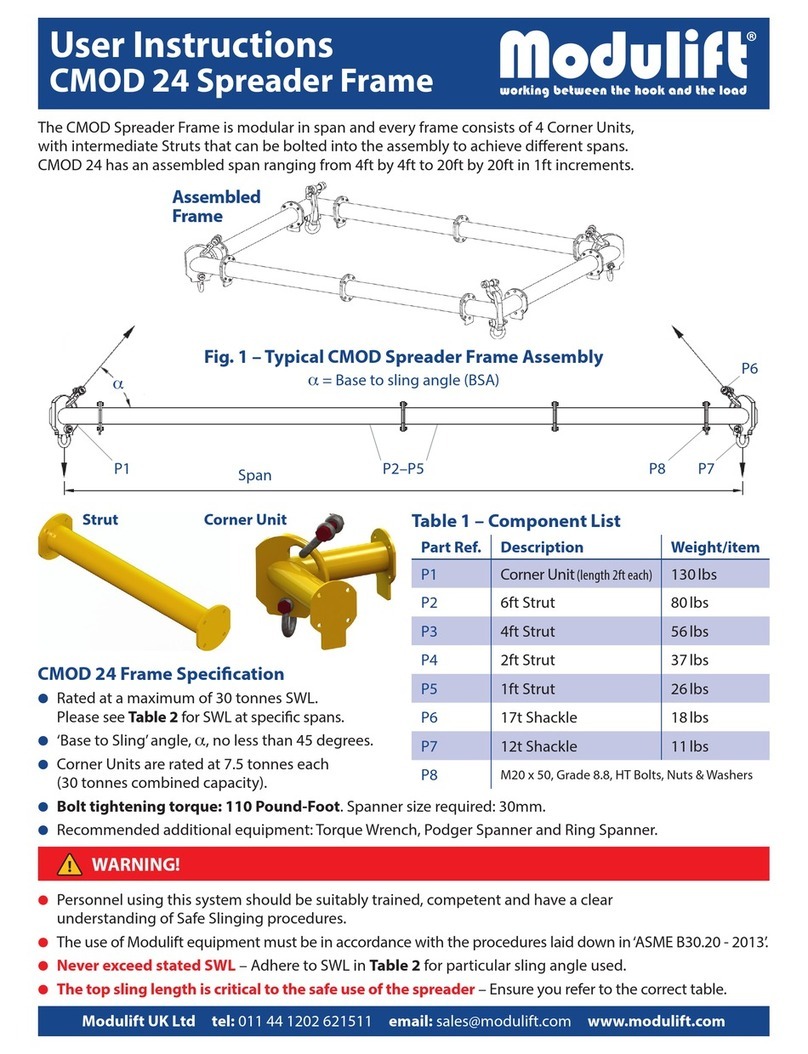

LD6 BACKHOE

3

Fig. 1

SERIES LD6 BACKHOE

1. Main Frame 8. Crowd Cylinder

2. Main Boom 9. Bucket Cylinder

. Dipper Arm 10. Control Valve

4. Bucket 11. Stabilizer Guard

5. Stabilizer Arm 12. Right Step

6. Stabilizer Cylinder 1 . Stabilizer Foot

7. Boom Cylinder 14. Grab Bar

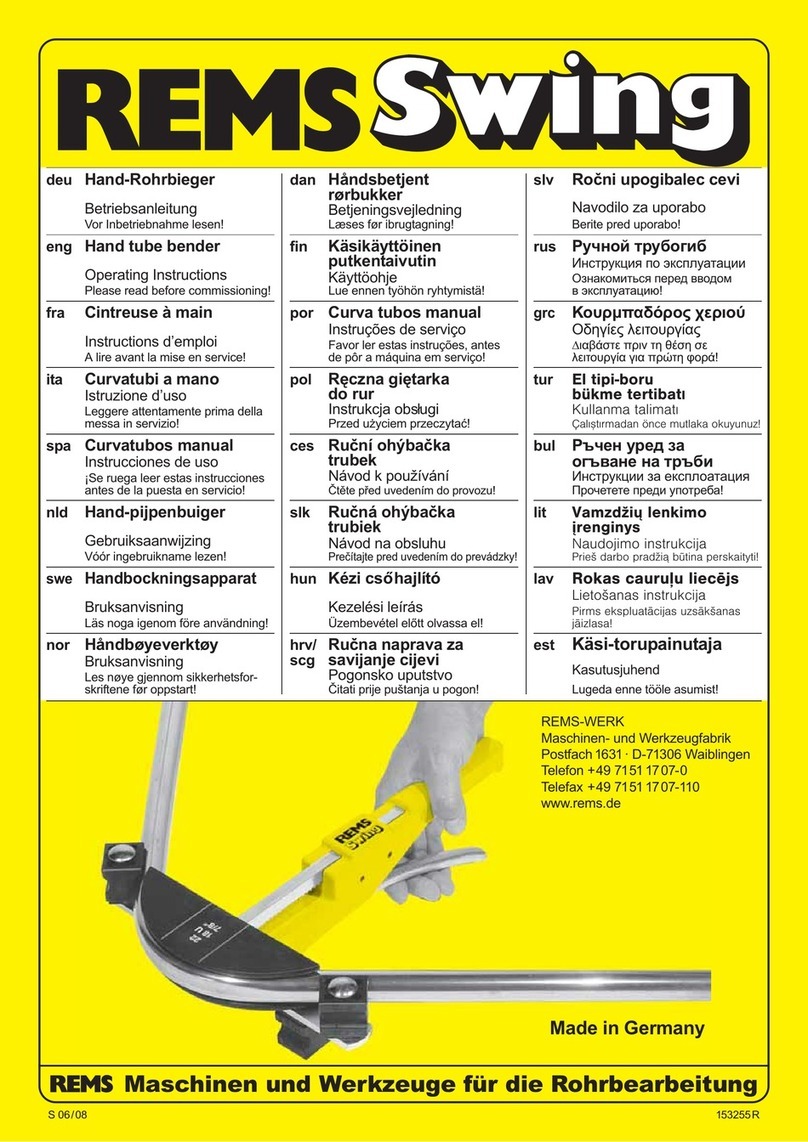

MD8 BACKHOE

4

Fig. 2

SERIES MD8 BACKHOE

1. Main Frame 8. Crowd Cylinder

2. Main Boom 9. Bucket Cylinder

. Dipper Arm 10. Control Valve

4. Bucket 11. Stabilizer Guard

5. Stabilizer Arm 12. Right Step

6. Stabilizer Cylinder 1 . Stabilizer Foot

7. Boom Cylinder 14. Grab Bar

LD6 AND MD8 BACKHOE BOX PARTS

5

The LD6 and MD8 box parts contains items needed to complete the assembling of the LD6 and MD8 Backhoe. Be

sure to check the contents of the box against the packing list in the box or against the parts list in this manual.

Backhoe Box Par s

ITEM DESCRIPTION QUANTITY

1 Step, Right 1

2 Step, Left 1

Grab Bar 1

4 Cotter Pin /16” x 1 ½” 10

5 Cylinder, Stabilizer 2

6 Pin Cylinder 1” x ” 4

7 Guard, Stabilizer 2

8 Ties, Plastic Hose 5

9 Adaptor Fitting, SAE 6 O-Ring to JIC 6 Flare St. 10

10 Clamp, Insulated Hose 1” 6

11 Screw, Machine /16” x ¾” 6

12 Washer, Lock /16” 6

1 Nut, Hex /16” 6

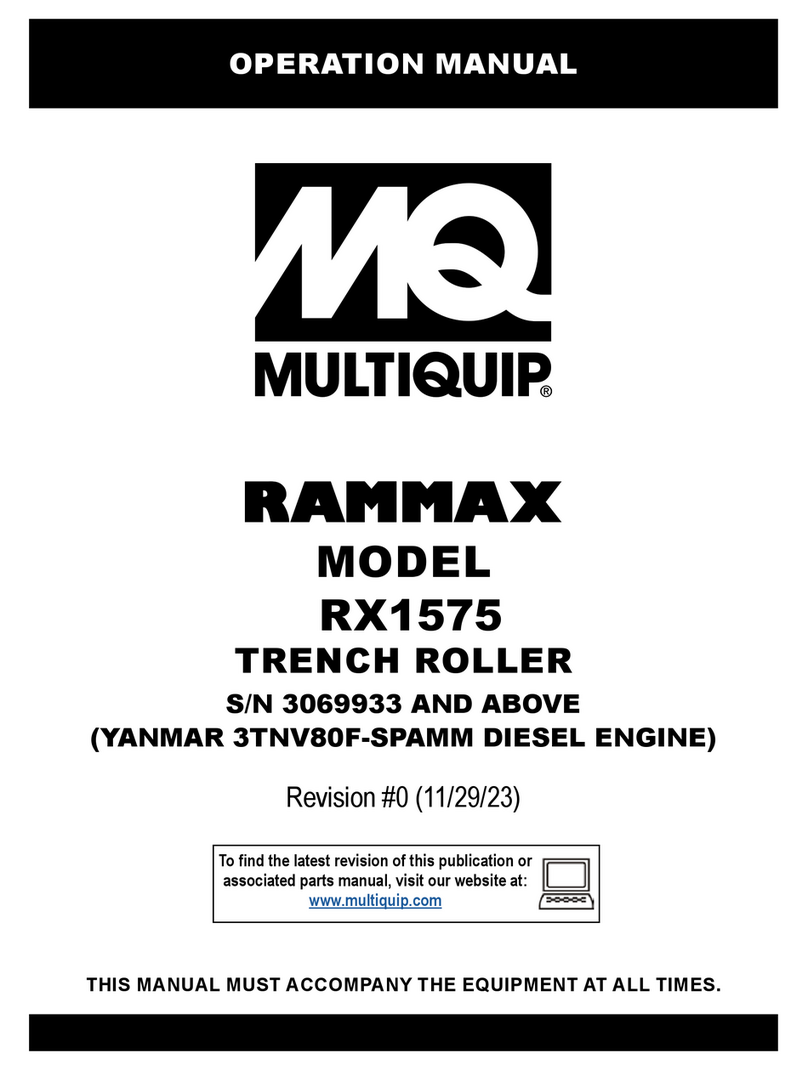

LD6 MAIN FRAME ASSEMBLY

6

Fig. 1

ITEM DESCRIPTION QUANTITY

1 Main Frame 1

2 *Step, Right 1

*Step, Left 1

4 *Grab Bar 1

5 Arm, Stabilizer 2

6 Pin, Stabilizer ¾” x 9 ½” 2

7 *Guard, Stabilizer 2

8 Pin, Stabilizer Guard ½” x 5” 2

9 *Cylinder, Stabilizer 2

10 *Pin, Cylinder 1” x ” 4

11 *Cotter Pin /16” x 1 ½” 14

12 Cotter Pin 1/8” x 1” 4

1 *Adaptor Fitting SAE 6 O-Ring to JIC 6 Flare Straight 4

14 *Ties, Plastic Hose 4

15 Bolt, Machine ¾” x 1 ½” G5P 1

16 Nut, Hex Self Locking ¾” 1

*ITEMS NOTED ARE SHIPPED IN BACKHOE PARTS BOX

LD6 MAIN FRAME INSTALLATION

7

The LD6 main frame assembly, Fig 1, is shipped with

some of the retaining pins and bolts installed. It will be

necessary to remove the pins as the different parts are

assembled on the main frame. The main frame should

be installed on the mounting frame plate as follows:

(1) Position the Backhoe Mainframe (item 1) over the

Mounting plate on the Mounting Frame. Maneuver the

mainframe until the eight holes in the mainframe align

with the eight (8) holes in the mounting plate. Secure

the mainframe with eight (8) each 5/8” x 2” machine

bolts, lockwashers and hex nuts supplied in the

mounting frame kit. Torque the bolts and nuts per

Table 1, Page 9.

Fig. 2

(2) Install the left step (Item ) in the step mounting

receptacle located on the left side of the Backhoe main

frame with orientation of the step as shown in Fig. .

( ) Repeat step two to install the right step (Item 2).

Fig.

(4) Install the grab bar (Item 4) in the grab bar

mounting receptacle located on the inside of the side

plates and just above the top plate. Secure the grab bar

with two (2) /16” x 1 ½” cotter pins (Item 11) as

shown in Fig. 4.

Fig. 4

(5) Attach the left stabilizer arm (Item 5) between

the stabilizer mounting lugs, located on the left side of

the mainframe near lower edge, securing the arm to the

mainframe with one (1) each stabilizer pin (Item 6) and

two (2) each /16” x 1 ½” cotter pins as shown in Fig.

5.

(6) Repeat step 5 for the right side stabilizer arm.

Fig. 5

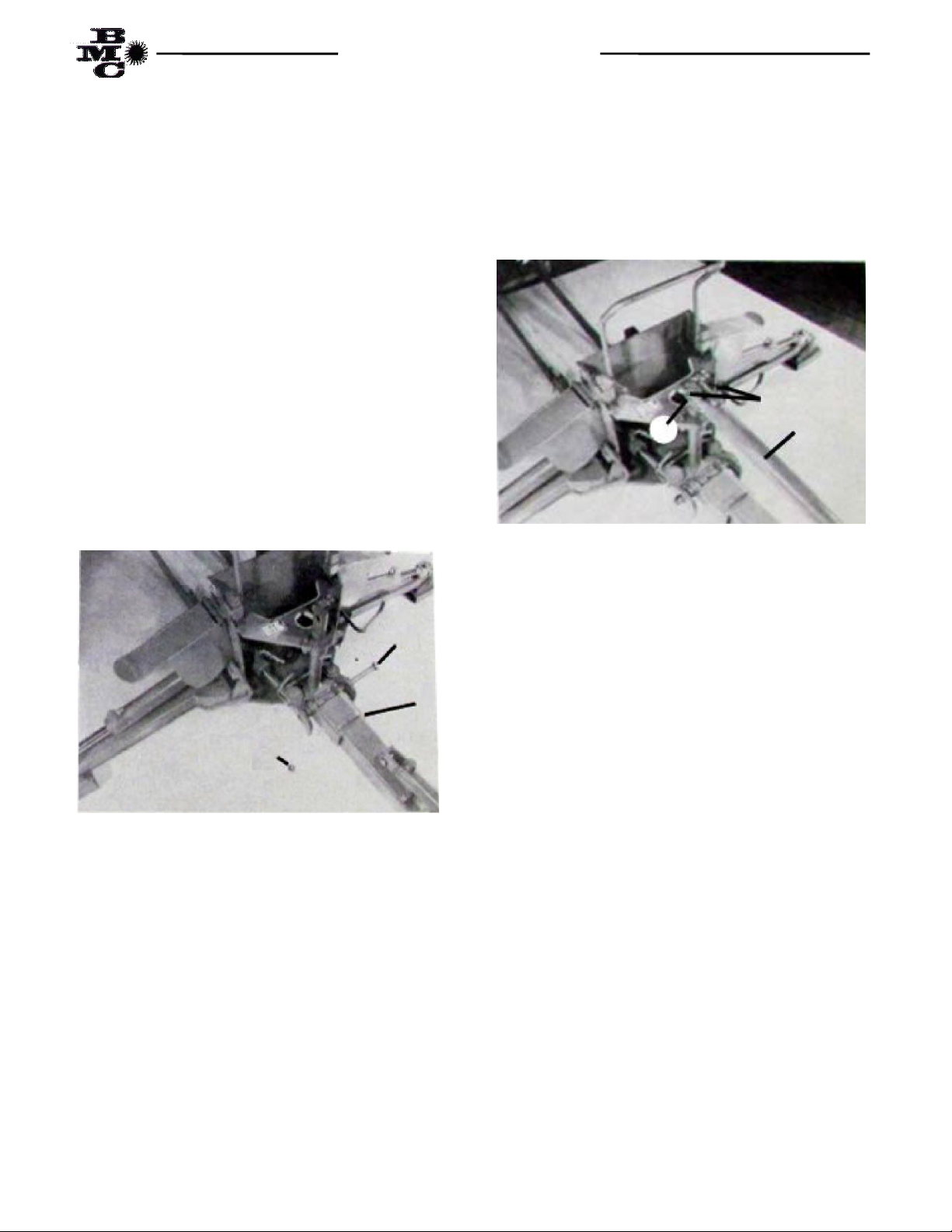

(7) Attach base end of (1) each stabilizer cylinder

(Item 9) to left side of main frame cylinder anchor lug,

located in the center and just above the base end of the

stabilizer arm, using one each cylinder pin (Item 10)

and two each /16” x 1 ½” cotter pins (Item 11) as

shown in Fig. 6.

Bolts Machine 5/8” x 2”

1

2

4

5 6 11

LD6 MAIN FRAME INSTALLATION

8

Fig. 6

(8) Attach the rod end of the stabilizer cylinder to the

anchor lug, located in the center of the stabilizer arm

near the stabilizer foot, using one each cylinder pin

(Item 10) and two each /16” x 1 ½” cotter pins (Item

11) as shown in Fig. 6.

(9) Attach the right side stabilizer cylinder by

repeating steps 7 and 8.

(10) Attach the left stabilizer guard (Item 7) over the

mounting receptacle, located on the upper portion of the

main frame side plate, aligning the two holes in the

stabilizer guard with the mounting receptacle and

inserting the guard pin (Item 8) through the guard and

receptacle. Secure the pin with two each 1/8” x 1”

cotter pins (Item 12) as shown in Fig. 6.

(11) Attach the right stabilizer guard by repeating

step 10.

(12) Install one each of the SAE 6 O-Ring to JIC 6

Flare Straight adapter fittings (Item 1 in box parts list,

page 5) in both ports of the right and left stabilizer

cylinders (four (4) required) as shown in Fig. 6.

NOTE: I is very impor an o check he orque on he eigh 5/8” x 2” machine bol s re aining he mainframe o he

moun ing frame op pla e af er eigh (8) hours of opera ion and every 40 hours of opera ion hereaf er. I is

accep able, once opera ion of backhoe and moun ing frame adap a ion o rac or has proved sa isfac ory, o weld he

mainframe o he moun ing ki .

7

10 10

1

12

8

9

LD6 MAIN BOOM ASSEMBLY

9

6

FIG. 1

ITEM DESCRIPTION QUANTITY

1 Main Boom 1

2 Cylinder, Main Boom 1

Pin, Cylinder ¾” x 2 ¾” 1

4 Cotter Pin 1/8” x 1” 2

5 Cylinder, Crowd 1

6 Pin, Cylinder 1” x ” 1

7 Clip, Bobby Pin 2

8 Bolt, Machine G5P 1” x 6 ½” 1

9 Nut, Self-Locking Hex 1” 2

10 Bolt, Machine 1” x 5 ½” 1

11 Clamp, Hose 4” 2

12 Bolt, Machine ¼” x 1 ¼” 2

1

2

4

9 8

10

9

11

12 7 5

LD6 MAIN BOOM INSTALLATION

10

The LD6 main boom assembly, Fig. 1, is shipped with

the retaining pins and bolts installed. It will be

necessary to remove the pins and bolts as the main

boom is being assembled to the main frame. The main

boom should be attached to the main frame as follows:

(1) Remove the ¾” x 10 ½” plated bolt (Item 15 in

the main frame assembly) and ¾” self-locking hex nut

(Item 16 in the main frame assembly) from the yoke of

the swing shaft. Position the base end of the main boom

(Item 1) between the mounting ears (use two men or

overhead hoist) and secure by re-inserting the ¾” x

10 ½” plated bolt through the yoke ear and boom as

shown in Fig. 2. The bolt should be seated (or

locked) in the locking ring on the outside mounting ear

of the yoke to prevent bolt from turning during

operation. Fasten the bolt in place with the ¾”

self-locking hex nut, tightening for fit but not

sufficiently to warp the yoke mounting ears.

Fig. 2

(2) Mount the base end of the main boom cylinder

(Item 2) with flat top end of the swing shaft between

the ears of the cylinder clevis. Secure the boom cylinder

with a ¾” x 2 ¾” cylinder pin (Item ) and two each

1/8” x 1” cotter pin (Item 4) as show in Fig. .

Fig.

( ) Install one each of the SAE 6 O-Ring to JIC 6 Flare

straight adapter fittings (Item 1 in box parts, Page 5) in

both ports of the crowd cylinder.

16

15

1

2

4

LD6 DIPPER ARM ASSEMBLY

11

FIG. 1

ITEM DESCRIPTION QUANTITY

1 Dipper (Crowd) Arm 1

2 Pin, Bucket Link 1” x 6 ¼” 1

Spacer, Bucket Link 1” I.D. x 1 ¼” O.D. x 2” 2

4 Cotter Pin /16” x 1 ½” 2

5 Cylinder, Bucket 1

1 2

4

5

LD6 DIPPER ARM INSTALLATION

12

The LD6 dipper arm (crowd) assembly, Fig. 1, is

shipped assembled with the exception of the adaptor

fittings and the retaining pin and bolt. The retaining

bolt and pin are shipped installed in the main boom

assembly. Attach the dipper arm to the main boom in

the following manner:

(1) Remove the 1” x 6 ½” plated bolt (Item 8 in the

main boom assembly) from the main boom. Using an

overhead hoist, raise the main boom until the dipper

arm (Item 1) can be inserted between the side plates on

the top end of the main boom as shown in Fig. 2. Re-

insert the 1” x 6 ½” plated bolt from the left side

through the boom and the dipper arm. Secure the bolt

with a 1” self-locking hex nut (Item 9 in the main boom

assembly).

Fig. 2

(2) Raise rod end of dipper (crowd) cylinder and slide

the cylinder clevis astraddle the top anchor lug on the

dipper arm as shown in Fig. . Secure the cylinder to

the dipper arm with a 1” x ” cylinder pin (Item 6 in the

main boom assembly) and two each bobby pin clips

(Item 7 in the main boom assembly).

Fig.

( ) Install one each of the SAE 6 O-Ring to JIC 6 Flare

straight adapter fittings (Item 1 in box parts) into each

of the ports of the bucket cylinder (Item 5).

1

8 9

7

7

6

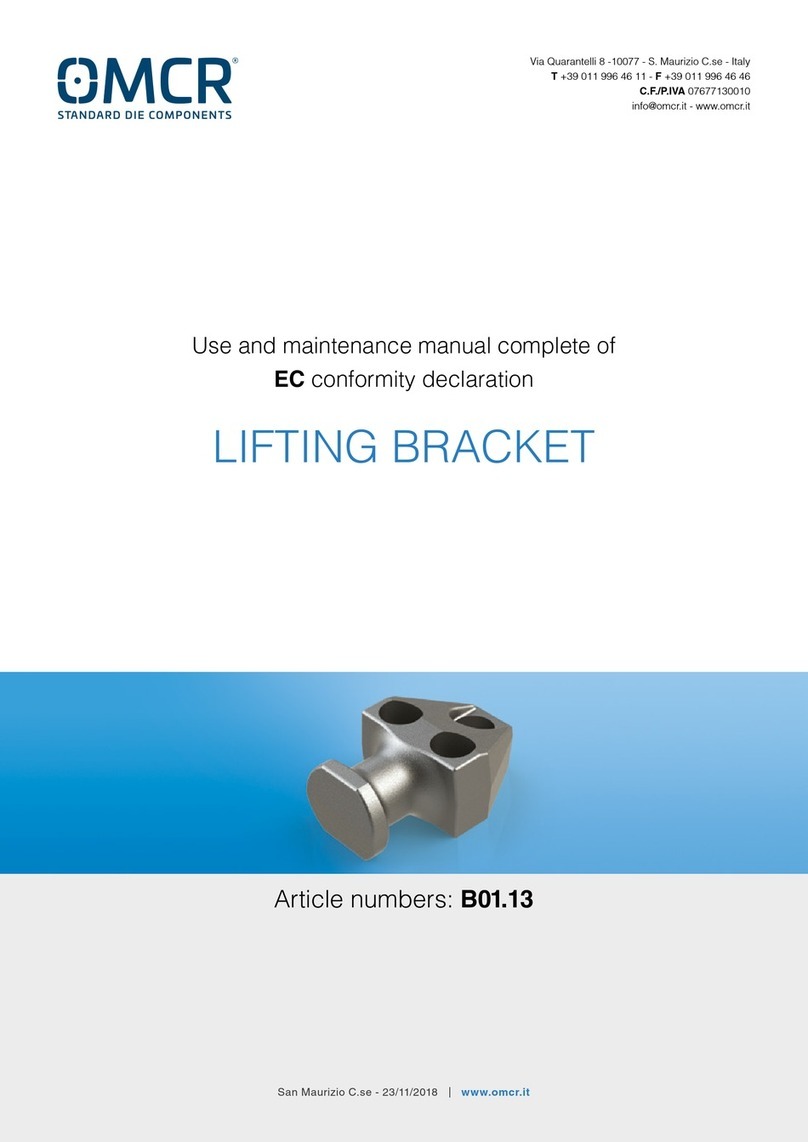

MD8 MAIN FRAME ASSEMBLY

13

Fig. 1

ITEM DESCRIPTION QUANTITY

1 Main Frame 1

2 *Step, Right 1

* Step, Left 1

4 *Grab Bar 1

5 Arm, Stabilizer 2

6 Pin, Stabilizer Arm ¾” x 9 ½” 2

7 *Guard, Stabilizer 2

8 Pin, Stabilizer Guard ½” x 5” 2

9 *Cylinder, Stabilizer 2

10 *Pin, Cylinder 1” x ” 4

11 *Cotter Pin /16” x 1 ½” 14

12 Cotter Pin 1/8” x 1” 4

1 *Adaptor Fitting SAE 6 O-Ring to JIC 6 Flare Straight 4

14 *Ties, Plastic Hose 4

15 Bolt, Machine G5P 1” x 10 ½” 1

16 Nut, Hex Self-Locking 1

17 Spacer 1” I.D. x 1 5/16” O.D. x 5” 1

*ITEMS NOTED ARE SHIPPED IN BACKHOE PARTS BOX

1

8

8

5

5

15 6

6

17 16

MD8 MAIN FRAME INSTALLATION

14

The MD8 main frame assembly, Fig 1, is shipped with

some of the retaining pins and bolts installed. It will be

necessary to remove the pins as the different parts are

assembled on the main frame. The main frame should

be installed on the mounting frame plate as follows:

(1) Position the Backhoe Mainframe (item 1) over the

mounting plate on the mounting Frame. Maneuver the

main frame until the eight holes in the main frame

align with the eight (8) holes in the mounting plate.

Secure the mainframe with eight (8) each 5/8” x 2”

machine bolts, lockwashers and hex nuts supplied in

the mounting frame kit. Torque the bolts and nuts per

Table 1, Page 9.

Fig. 2

(2) Install the left step (Item ) in the step mounting

receptacle located on the left side of the Backhoe main

frame with orientation of the step as shown in Fig. .

( ) Repeat step two to install the right step (Item 2).

Fig.

(4) Install the grab bar (Item 4) in the grab bar

mounting receptacle located on the inside of the side

plates and just above the top plate. Secure the grab bar

with two (2) /16” x 1 ½” cotter pins (Item 11) as

shown in Fig. 4.

Fig. 4

(5) Attach the left stabilizer arm (Item 5) between

the stabilizer mounting lugs, located on the left side of

the mainframe near lower edge, securing the arm to the

mainframe with one (1) each stabilizer pin (Item 6) and

two (2) each /16” x 1 ½” cotter pins as shown in Fig.

5.

Fig. 5

(6) Repeat step 5 for the right side stabilizer arm.

1

Bolts, Machine 5/8” x 2”

1

2

11

10 9

5

10

6

4

11

MD8 MAIN FRAME INSTALLATION

15

(7) Attach base end of one (1) each stabilizer cylinder

(Item 9) to left side of main frame cylinder anchor lug,

located in the center and just above the base end of the

stabilizer arm, using one each cylinder pin (Item 10)

and two each /16” x 1 ½” cotter pins (Item 11) as

shown in Fig. 5.

(8) Attach the rod end of the stabilizer cylinder to the

anchor lug, located in the center of the stabilizer arm

near the stabilizer foot, using one each cylinder pin

(Item 10) and two each /16” x 1 ½” cotter pins (Item

11) as shown in Fig. 5.

(9) Attach the right side stabilizer cylinder by

repeating steps 7 and 8.

(10) Attach the right stabilizer guard (Item 7) over the

mounting receptacle, located on the upper portion of

the main frame side plate, aligning the two holes in the

stabilizer guard with the mounting receptacle and

inserting the guard pin (Item 8) through the guard and

receptacle. Secure the pin with two each 1/8” x 1”

cotter pins (Item 12) as shown in Fig. 6.

Fig. 6

(11) Attach the left stabilizer guard by repeating

step 11.

(12) Install one each of the SAE 6 O-Ring to JIC 6

Flare Straight adaptor fittings (Item 1 in box parts list,

page 5) in both ports of the right and left stabilizer

cylinders (four (4) required) as shown in Fig. 6.

NOTE: I is very impor an o check he orque on he eigh 5/8” x 2” machine bol s re aining he mainframe o he

moun ing frame op pla e af er eigh (8) hours of opera ion and every 40 hours of opera ion hereaf er. I is

accep able, once opera ion of backhoe and moun ing frame adap a ion o rac or has proved sa isfac ory, o weld he

mainframe o he moun ing ki .

1

7

8

9

12

MD8 MAIN BOOM ASSEMBLY

16

6

FIG. 1

ITEM DESCRIPTION QUANTITY

1 Main Boom 1

2 Cylinder, Main Boom 1

Pin, Cylinder ¾” x 2 ¾” 1

4 Cotter Pin 1/8” x 1” 2

5 Cylinder, Crowd 1

6 Bolt, Machine 1” x 6 ½” 1

7 Nut, Self-Locking 1” 1

8 Clamp, Hose 4” 2

9 Bolt, Machine ¼” x 1 ¼” 2

2

9

8

7

1

MD8 MAIN BOOM INSTALLATION

17

The MD8 main boom assembly, Fig. 1, is shipped with

the retaining pins and bolts installed. It will be

necessary to remove the pins and bolts as the main

boom is being assembled to the main frame. The main

boom should be attached to the swing shaft as follows:

(1) Remove the 1” x 10 ½” plated bolt (Item 15 in the

main frame assembly) and the 1” I.D. x 1 5/16” O.D. x

5” spacer (Item 17 in the main frame assembly) from

the yoke of the swing shaft. Position the base end of the

main boom (Item 1) between the mounting ears (use two

men or overhead hoist) and insert the spacer

between the boom swivel lugs. Re-insert the 1” x

10 ½” plated bolt through the yoke ears, spacer and the

boom swivel lugs as shown in Fig. 2. The head of the

bolt should be seated (or locked) against the shoulder

on the outside surface of the mounting ears to prevent

the bolt from turning during operation. Fasten the bolt in

place with the 1” self-locking hex nut and tighten for

tight fit but not sufficiently to warp the yoke mounting

ears.

Fig. 2

(2) Mount the base end of the main boom cylinder (Item

2) with flat top end of the swing shaft between the ears

on the cylinder clevis. Secure the cylinder with the ¾”

x 2 ¾” cylinder pin (Item ) and two cotter pins (Item 4)

as show in Fig. .

Fig.

( ) Install one each of the SAE 6 O-Ring to JIC 6 Flare

Straight adapter fittings (Item 1 in box parts list, page

5) in both ports of the crowd cylinder.

1

17 15

4

2

MD8 DIPPER ARM ASSEMBLY

18

FIG. 1

ITEM DESCRIPTION QUANTITY

1 Dipper (Crowd) Arm 1

2 Pin, Locking Arm 1” x 7 7/8” 1

Plate, Locking Pin 1

4 Bolt, Machine G5P ½” x 1 ½” 1

5 Washer, Lock ½”

6 Spacer, Locking Pin 1” I.D. x 1 ¾” O.D. x 1/8” 2

7 Spacer, Locking Pin ½” I.D. x 1” O.D. x 1 ¼” 2

8 Bolt, Machine G5P ½” x 2 ¼” 2

9 Bolt, Machine G5P 1” x 4 ½” 1

10 Nut, Self-Locking Hex 1” 1

11 Cylinder, Bucket 1

12 Pin, Bucket Link 1” x 6 ¼” 1

1 Spacers, Bucket Link 1” I.D. x 1 ¼” O.D. x 2” 2

14 Cotter Pin /16” x 1 ½” 2

1

12

4

9, 10 8

11

1

14

This manual suits for next models

1

Table of contents