ELEC-MECH SAFE-AID TS350 User manual

SAFE-AID TS350

DUMP TRUCK LEVEL INDICATOR

Operators Manual - Version I

! WARNING !

THE PURPOSE OF THIS MANUAL IS TO PROVIDE THE USER WITH THE OPERATING

PROCEDURES ESSENTIAL FOR THE PROMOTION OF PROPER MACHINE OPERATION FOR ITS

INTENDED USE. THE IMPORTANCE OF PROPER USAGE CANNOT BE OVERSTRESSED. ALL

INFORMATION IN THIS MANUAL SHOULD BE READ AND UNDERSTOOD BEFORE ANY

ATTEMPT IS MADE TO OPERATE THE MACHINE.

SINCE THE MANUFACTURER HAS NO DIRECT CONTROL OVER MACHINE APPLICATION AND

OPERATION, CONFORMANCE WITH GOOD SAFETY PRACTICE IN THIS AREA IS THE

RESPONSIBILITY OF THE USER AND HIS OPERATING PERSONNEL.

ALL PROCEDURES ARE BASED ON THE USE OF THE SYSTEM UNDER PROPER OPERATING

CONDITIONS, WITH NO DEVIATIONS FROM THE ORIGINAL DESIGN. ALTERATION AND OR

MODIFICATION OF THE EQUIPMENT IS STRICTLY FORBIDDEN WITHOUT PRIOR WRITTEN

APPROVAL FROM ELEC-MECH (PTY) LTD.

BEFORE OPERATING A MACHINE EQUIPPED WITH A SAFE-AID TS350 THE OPERATOR MUST

READ THE INFORMATION IN THIS MANUAL CAREFULLY. CORRECT FUNCTIONING OF THE

SYSTEM DEPENDS UPON ROUTINE DAILY INSPECTION AND ANY SUSPECTED FAULTS OR

APPARENT DAMAGE SHOULD BE IMMEDIATELY REPORTED TO THE RESPONSIBLE PERSON

BEFORE USING THE MACHINE.

SAFE AID TS350 DUMP TRUCK LEVEL INDICATOR OPERATORS’ MANUAL VERSION 1 Page 2

Contents

SYSTEM USE ....................................................................................................................................... 3

SYSTEM STARTUP ............................................................................................................................. 3

OPERATING SCREEN......................................................................................................................... 4

ERRORS & ALARMS .......................................................................................................................... 5

SET DATE & TIME .............................................................................................................................. 7

PRE-OPERATION CHECKS ............................................................................................................... 7

TOUCH SCREEN CALIBRATION ..................................................................................................... 8

INSTALLATION DETAILS ............................................................................................................... 10

SAFE AID TS350 DUMP TRUCK LEVEL INDICATOR OPERATORS’ MANUAL VERSION 1

Page 3

SYSTEMUSE

The Safe-Aid TS350 unit is designed with ease

of operation in mind. The system goes directly

into its monitoring screen requiring no input from

the operator. All inputs to the system are done

by the operator via the touch screen. The touch

screen is sensitive to touch therefore it is not

necessary to push hard on the screen (if touch

screen does not work or selects incorrectly see

Touch Screen Calibration).

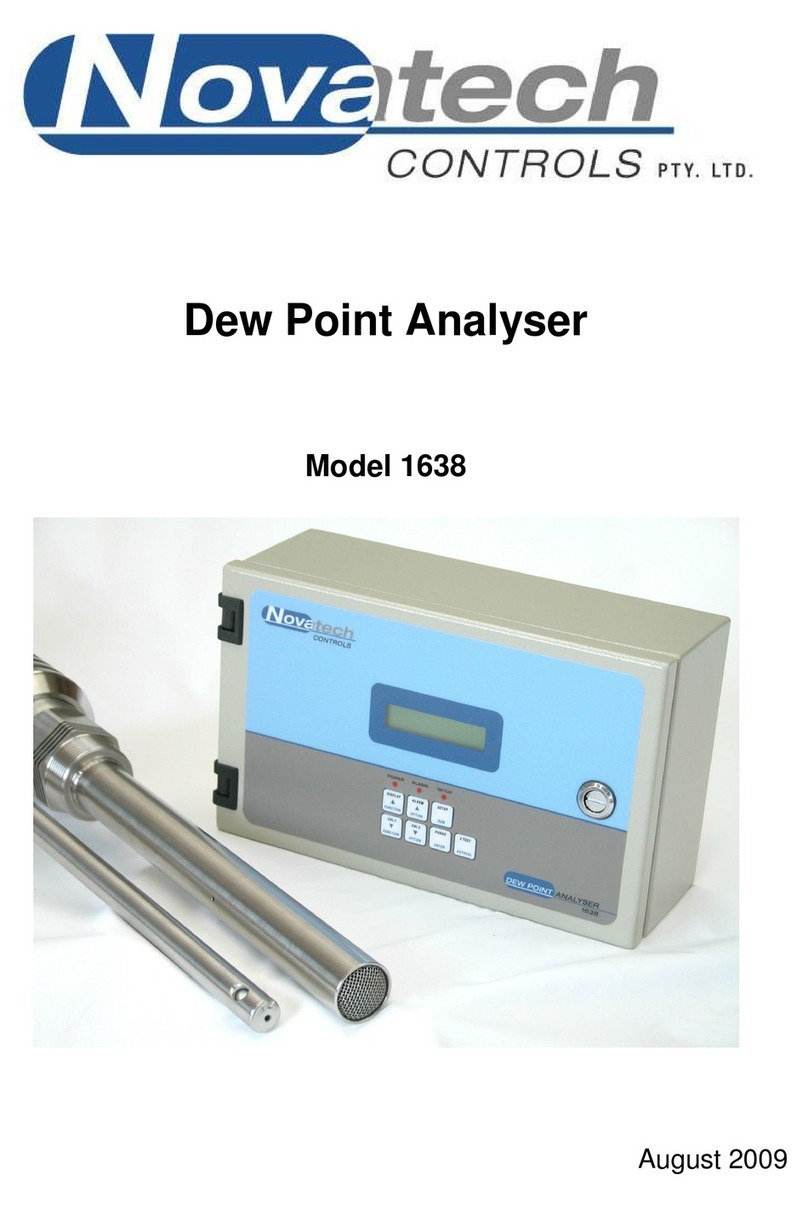

SYSTEMSTARTUP

The TS350 display unit will automatically power

up when the machine is switched on and the

buzzer will sound once.

The system will run a CRC (cyclic redundancy

check) to make sure that all raw data is correct.

Once the system has completed the CRC the

buzzer will sound again, and a set of internal

diagnostics (watchdogs) will be utilised to verify

that all inputs and outputs are working correctly.

At this point screen calibration can be done if

required (see Screen Calibration for process).

This screen displays the display serial number

as well as the firmware version:

S/N CLSS – serial number

Version – Firmware Version

SAFE AID TS350 DUMP TRUCK LEVEL INDICATOR OPERATORS’ MANUAL VERSION 1

Page 4

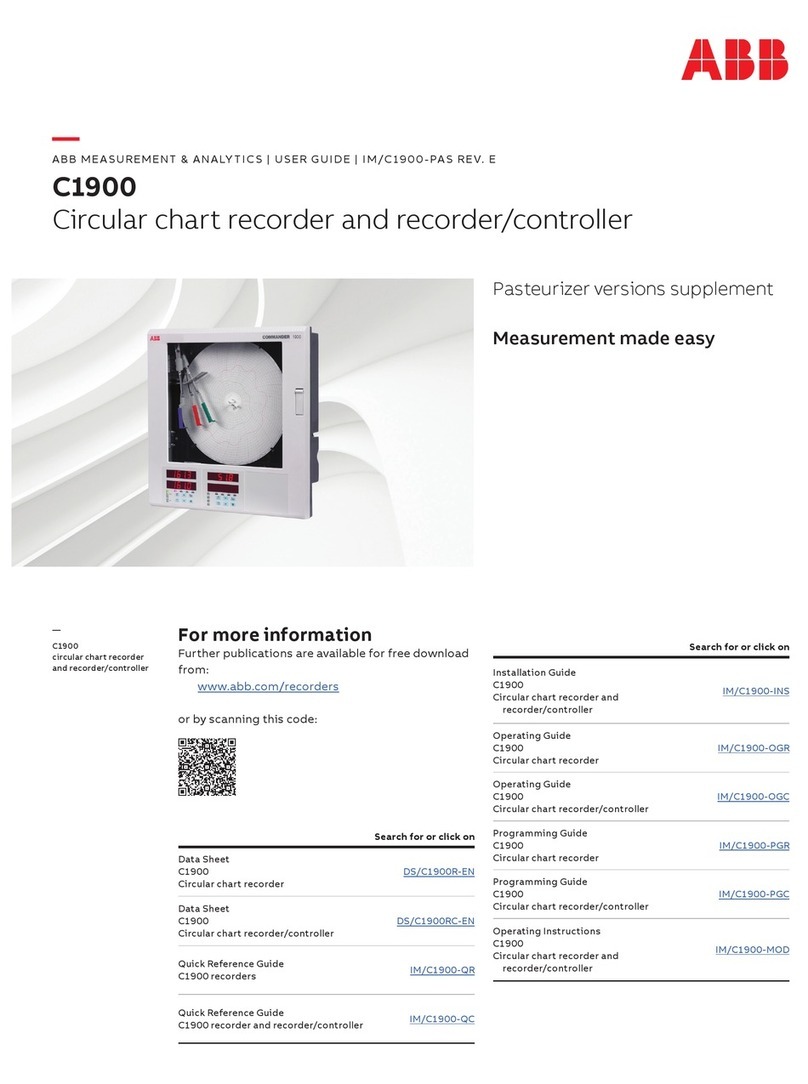

OPERATINGSCREEN

The current machine information can be viewed

from here.

In operating mode, you can see all the current parameters.

X & Y axis of machine where is X is left to right of machine and Y is front to back. The

positive angle will be shown which will be shown on the position where the machine is

highest. The position of the cursor moves towards the high angle.

Load Bin Down – automatically monitored by a proximity switch therefore should be

confirmed as working before starting work. Switch is activated when load bin is down.

Load Bin Up - automatically monitored by a proximity switch therefore should be confirmed

as working before starting work. When the switch contact is broken or in case of failure this

is the default setting.

SAFE AID TS350 DUMP TRUCK LEVEL INDICATOR OPERATORS’ MANUAL VERSION 1

Page 5

Park Brake On – automatically monitored by a pressure switch therefore should be confirmed

as working before starting work. Fail safe operation so will show as off in case of switch

failure.

Date & Time – The TS350 system has an internal real time clock which displays date a time

on the main running screen in the top left-hand corner This must be checked monthly and set

as and when required as the data logger uses this for setting the logged information – Set

Date & Time

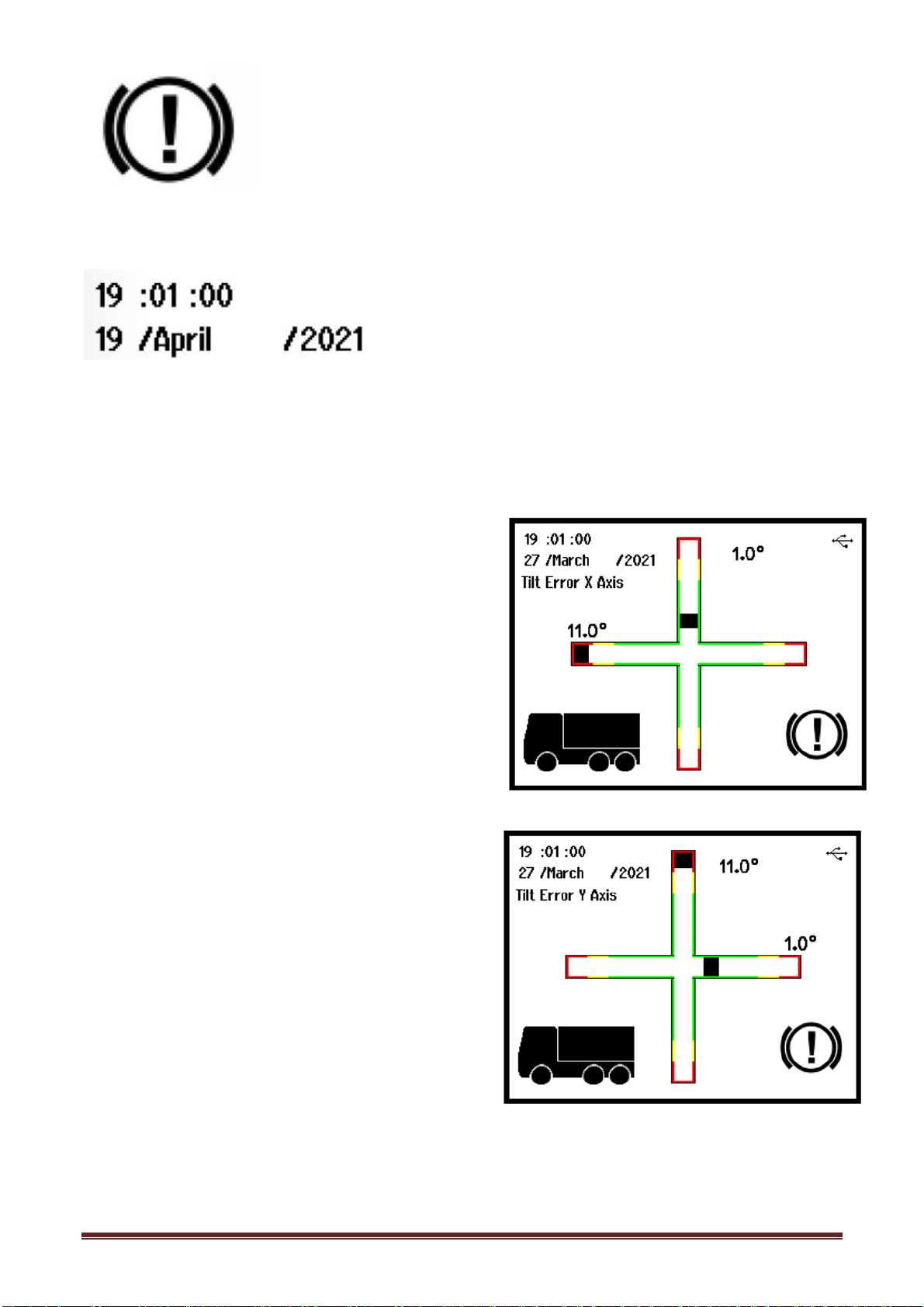

ERRORS&ALARMS

The system monitors the following functions:

X Axis – alarm at pre-set angle

Y Axis – alarm at pre-set angle

SAFE AID TS350 DUMP TRUCK LEVEL INDICATOR OPERATORS’ MANUAL VERSION 1

Page 6

Load Bin Down - must be down when park brake

is off after a pre-set time delay. Loadbed Up Error

displayed when park brake is disengaged, and the

load bed is not down.

Park Brake – monitored when engaged.

SAFE AID TS350 DUMP TRUCK LEVEL INDICATOR OPERATORS’ MANUAL VERSION 1 Page 7

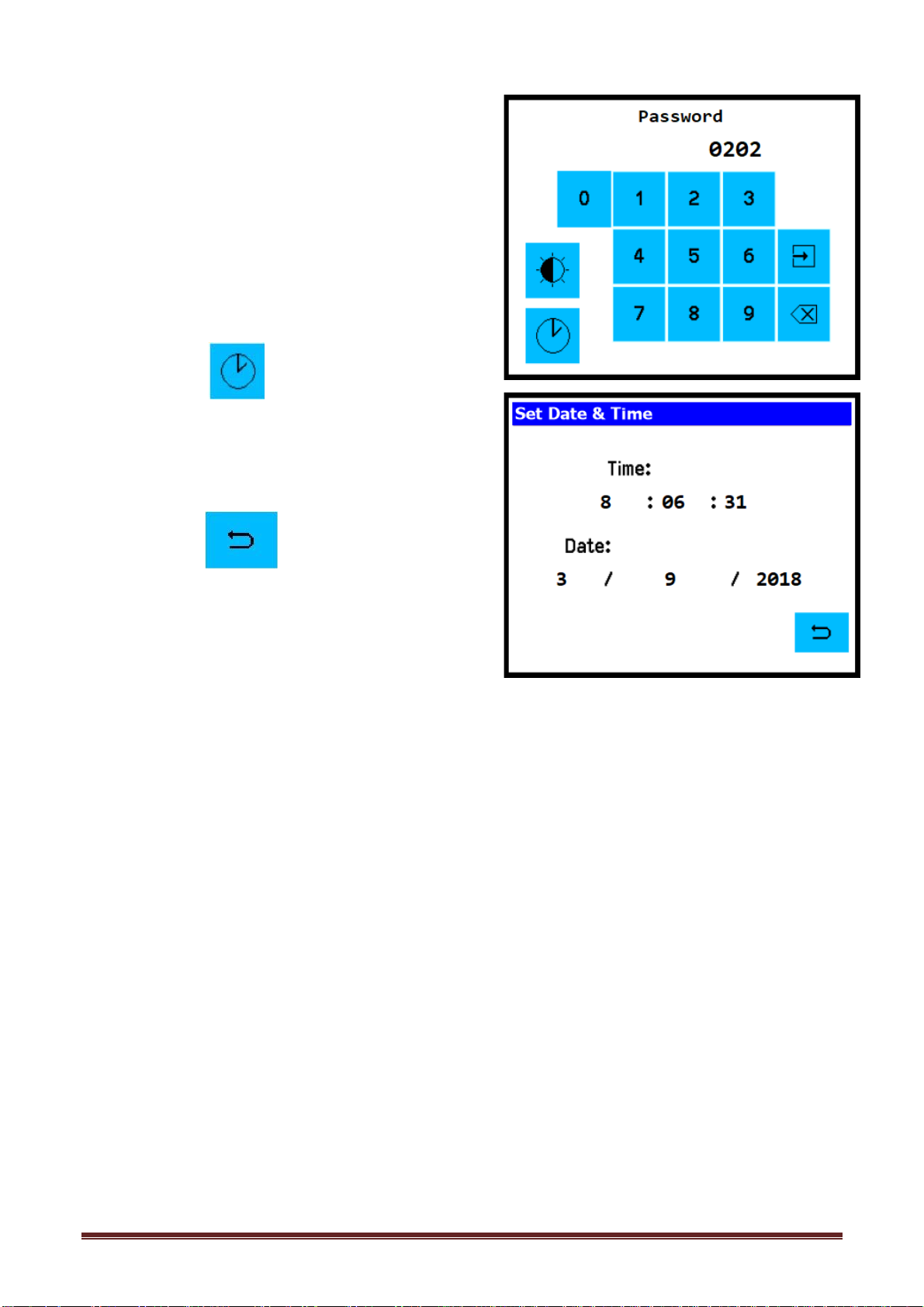

SETDATE&TIME

The date and time can be adjusted as required, if

the date and time does not save the battery for the

real time clock is no longer working (see Real

Time Clock battery replacement).

Use the following steps to adjust the date & time:

1. Press the top left-hand corner and the

Password screen will be displayed.

2. Press the and the Set Date & Time

screen will be displayed. Select the data to be

adjusted and set the correct time and date.

3. Time format is 24 Hour Clock hh : mm : ss

4. Date format is dd / mm / yyyy

5. Once the time & date have been adjusted

press the button to return to the

operating screen.

PRE‐OPERATIONCHECKS

1. Date and time – ensure correct date and time – if incorrect see Set Date & Time

2. Machine level indicator – Check level is showing correct by looking at slope of machine

and seeing that the indication is correct. If incorrect service call needs to be logged.

3. Load bed down indicator – Check load bed shows down if not service call needs to be

logged.

4. Park Brake Engaged – Check park brake shows on if not service call needs to be

logged.

SAFE AID TS350 DUMP TRUCK LEVEL INDICATOR OPERATORS’ MANUAL VERSION 1

Page 8

TOUCHSCREENCALIBRATION

If the screen is not responding correctly to

touch, the touch screen may need to be

calibrated. Make sure that the Front Facia

(Sticker) is in good condition (no dents or

damage) as this can affect the touch screen.

Replace Front Facia if damaged.

Switch the TS350 display power off, power up

the TS350 while pressing in the middle of the

screen.

While the splash screen is on, keep pressing in

the centre of the screen for a full five seconds

until the touch calibration is activated and

loaded. Immediately lift your finger and follow the

on-screen instructions.

If the calibration screen has been entered by

accident and touch calibration is not necessary,

press the Exit button without pushing anywhere

else on the screen to continue with normal start

up procedures.

If the touch screen calibration is required follow

the below procedure:

Press and hold finger where the two lines meet

inside the small box at the top left-hand corner.

Calibration works fine when using a finger but for

better results use a pen taking care not to press

too hard or the screen will be damaged.

Hold finger/pen in this area until prompted to lift.

Prompts will then be given for three more touch

zones resulting in co-ordinates for all four

corners of the screen.

Once calibration is complete the software

automatically goes to the working screen.

TS350 Front Facia’s are available from the manufacturer at a nominal charge and

should be changed as part of a maintenance schedule

SAFE AID TS350 DUMP TRUCK LEVEL INDICATOR OPERATORS’ MANUAL VERSION 1

Page 9

SAFE AID TS350 DUMP TRUCK LEVEL INDICATOR OPERATORS’ MANUAL VERSION 1

Page 10

INSTALLATIONDETAILS

Reg No. 1983/011830/07

Tel No: +27 (0) 11 792-1084

P.O. Box 2704

Randburg

2125

South Africa

Email: [email protected]

www.elecmech.co.za

Notes:

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Installation Done By:

Table of contents

Popular Measuring Instrument manuals by other brands

Compass

Compass 238 210 instruction manual

David White

David White Realist TR-300 4.5 quick start guide

PRECISION DIGITAL

PRECISION DIGITAL Loop Leader PD689 instruction manual

ICP DAS USA

ICP DAS USA PMD series user manual

Lutron Electronics

Lutron Electronics PCD-431 Operation manual

WEBTEC

WEBTEC FI750 Series user manual