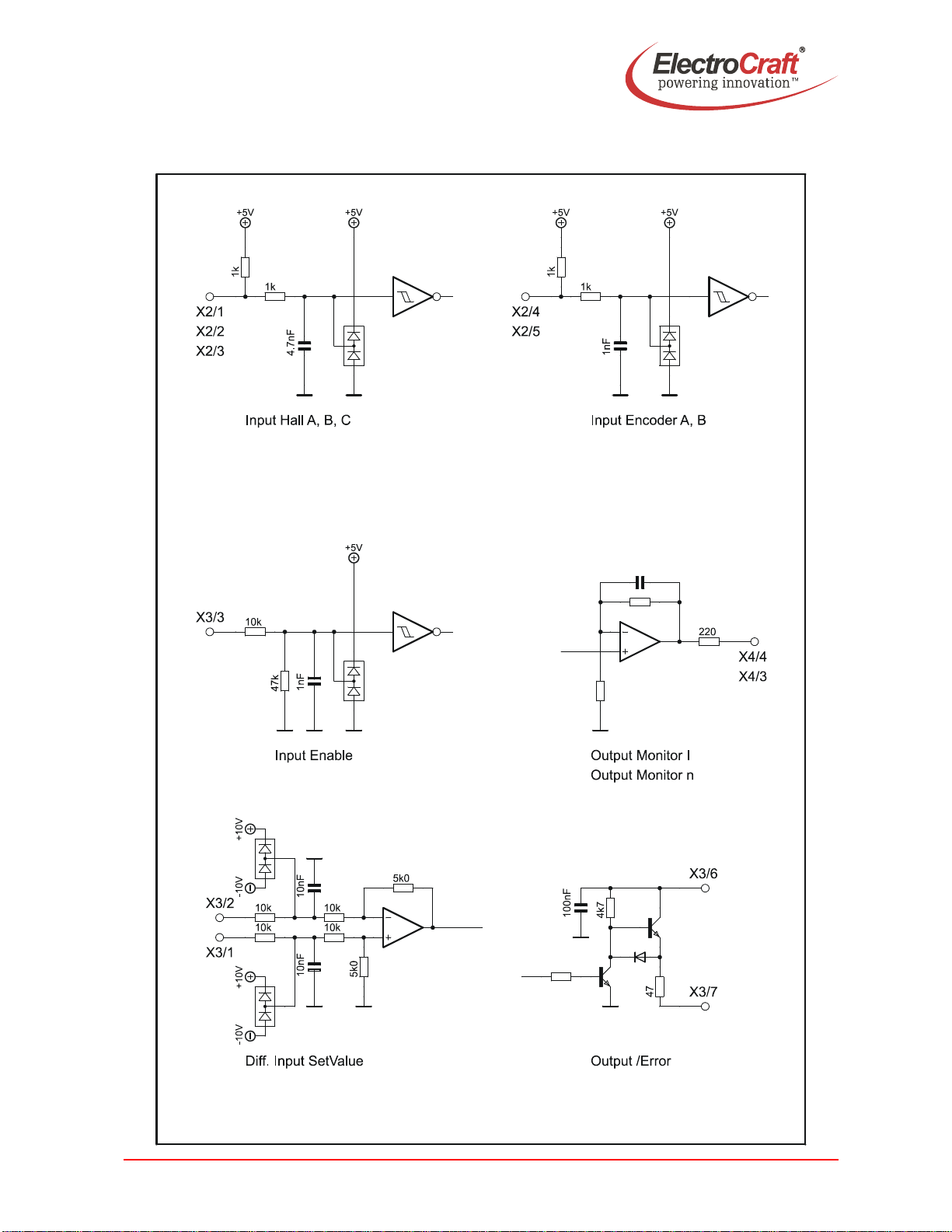

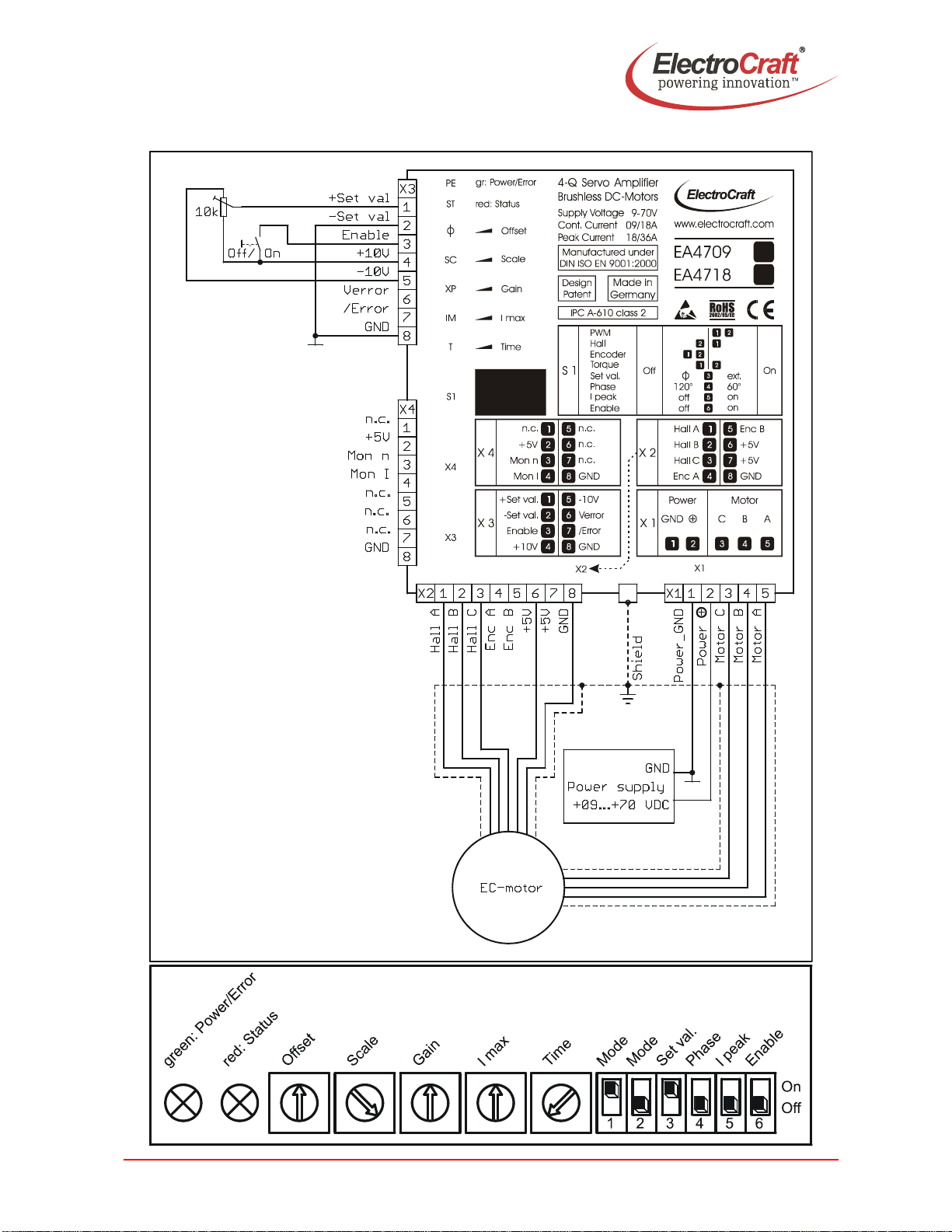

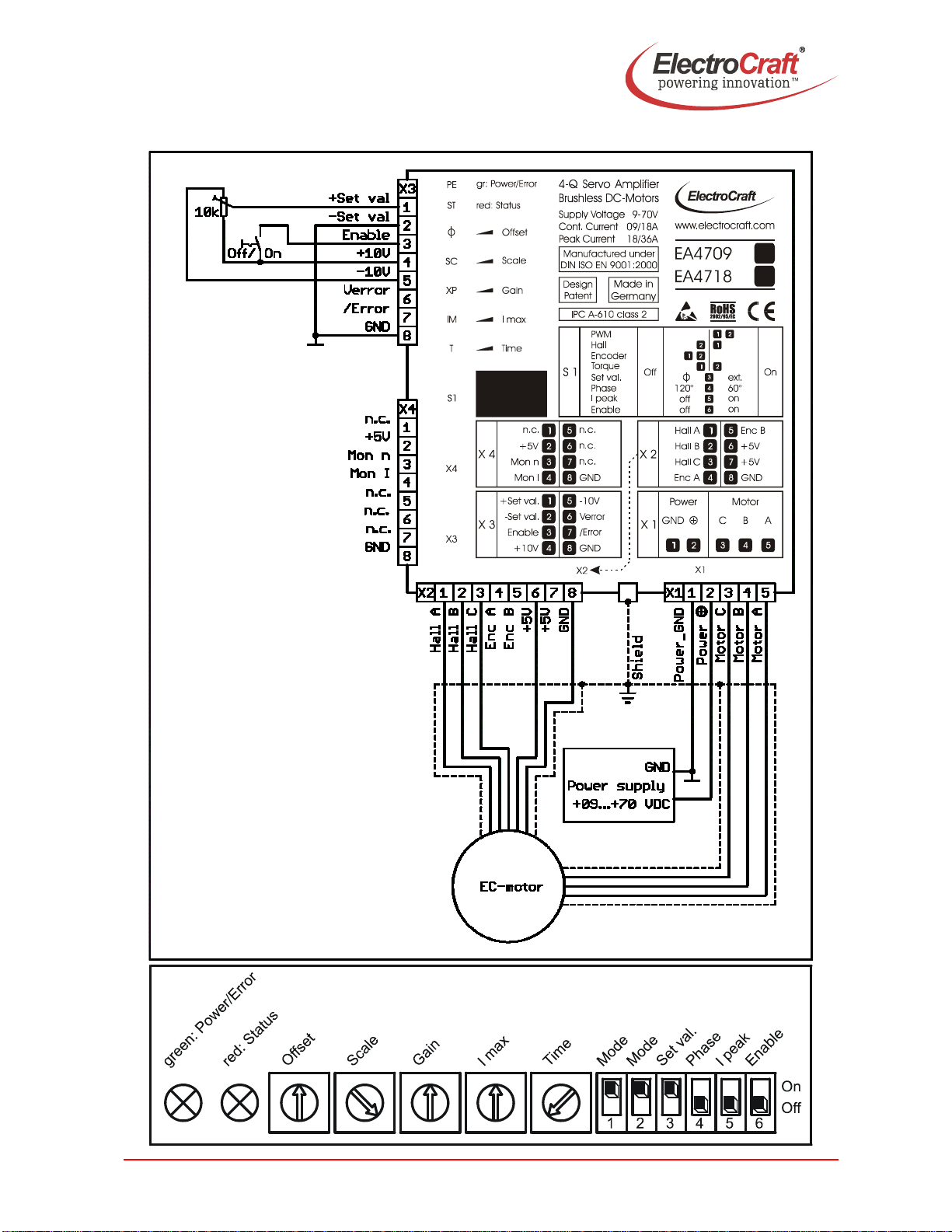

Electro-Craft EA4709 User manual

This manual suits for next models

1

Table of contents

Other Electro-Craft DC Drive manuals

Popular DC Drive manuals by other brands

GFA

GFA ELEKTROMAT SI 100.30 FU-55,00 10003917 10011 installation instructions

ABB

ABB ACS880-07 user manual

Selve

Selve Commeo SE Pro-RC quick start guide

GFA

GFA ELEKTROMAT SI 45.15-40,00 GA45/15GD installation instructions

Trane

Trane LonWorks TR1 Series VFD Installation instruction

YASKAWA

YASKAWA LA500 Installation and operation instruction

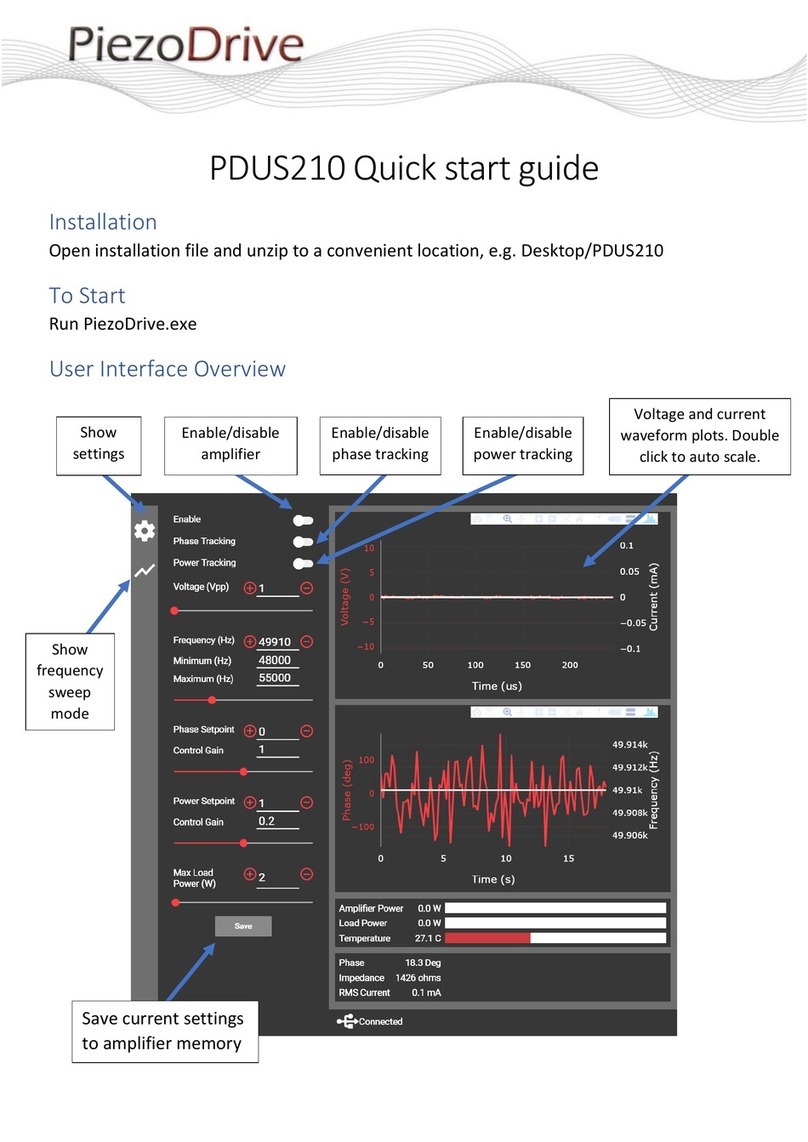

PiezoDrive

PiezoDrive PDUS210 quick start guide

GFA

GFA ELEKTROMAT FS 50.20-40,00 installation instructions

Bosch

Bosch Active Line Original operating instructions

MacDon

MacDon 279708 installation instructions

EUCHIPS

EUCHIPS EUP200AD-1H12V-0 quick start guide

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 755TS Series Hardware service