36Examining the installation site ..................................................................

36Required tools .....................................................................................

36Unpacking the delivery ...........................................................................

37Installing the drive ................................................................................

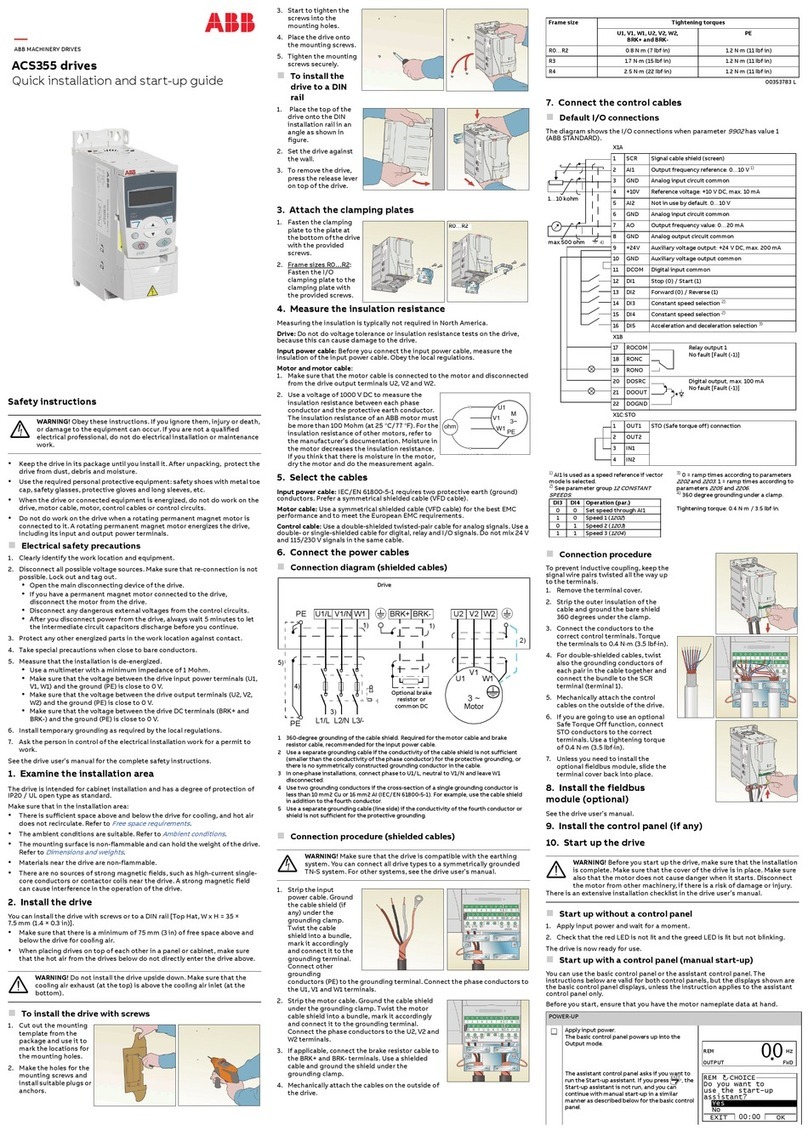

37To install the drive with screws ..............................................................

37To install the drive to a DIN installation rail ................................................

5 Guidelines for planning the electrical installation

39Contents of this chapter ..........................................................................

39Limitation of liability ...............................................................................

39Selecting the main supply disconnecting device .............................................

39European Union ...............................................................................

40North America ..................................................................................

40Other regions ..................................................................................

40Selecting the main contactor ....................................................................

40Checking the compatibility of the motor and drive ...........................................

40Selecting the power cables ......................................................................

40General guidelines ............................................................................

41Typical power cable sizes ....................................................................

41Power cable types .............................................................................

41Preferred power cable types .............................................................

42Alternate power cable types ..............................................................

42Not allowed power cable types ..........................................................

43Additional guidelines, North America .......................................................

43Metal conduit ...............................................................................

43Power cable shield ............................................................................

44Selecting the control cables .....................................................................

44Shielding ........................................................................................

44Signals in separate cables ...................................................................

44Signals that can be run in the same cable .................................................

44Relay cable type ...............................................................................

45Control panel to drive cable ..................................................................

45Routing the cables ................................................................................

45General guidelines – IEC .....................................................................

45General guidelines – North America ........................................................

46

Continuous motor cable shield/conduit or enclosure for equipment on the motor

cable .............................................................................................

47Separate control cable ducts ................................................................

47Implementing short-circuit and thermal overload protection ................................

47Protecting the drive and input power cable in short-circuits .............................

47Protecting the motor and motor cable in short-circuits ...................................

47

Protecting the drive, and the input power and motor cables against thermal over-

load ..............................................................................................

47Protecting the motor against thermal overload ...........................................

48

Protecting the motor against overload without thermal model or temperature

sensors .........................................................................................

48Implementing a motor temperature sensor connection .....................................

49Protecting the drive against ground faults .....................................................

49Residual current device compatibility ......................................................

49Implementing the Emergency stop function ..................................................

49Implementing the Safe torque off function ....................................................

49Using a safety switch between the drive and the motor .....................................

6 Table of contents