ELECTRO FREEZE SLX400 Manual

Operator's Manual

with Replacement Parts List

H.C. Duke & Son, LLC P/N 184584 June 14, 2013 Printed in USA

SOFT SERVE

TWIST MODEL

SLX400, SLX400E,

SLX500

184584 6/14/13

Operator'sManual

for the

ElectroFreezeModel

SLX400, SLX400E and

SLX500

Soft Serve Freezers

All contents © Copyright 2013 H.C. Duke & Son, LLC, 2116 Eighth Avenue, East Moline Illinois 61244

ii

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

WARNING

CAUTION

DANGER

2. Understand Signal Words ....

SAFETY FIRST!

Follow these four steps to safety ....

1. Recognize Safety Information ....Look for this

safety alert symbol throughout this manual.

Thesignal words— DANGER, WARNING and

CAUTION — areused withthe safetyalert symbol

(DANGERdecals onthe freezermay ormay not

havethe safetyalert symbol,but themessage is

thesame). Decals withthe wordsDANGER,

WARNING or CAUTION appearonthe freezer.

DANGER identifiesthe mostserioushazard.

Decalswith thewords DANGER orWARNING are

typicallynear specifichazards on thefreezer.

Generalprecautions arelisted on CAUTION safety

decals.

In this manual,CAUTION messageswith thesafety

alertsymbol call attentionto safetymessages.

When you see this symbol on your freezer or in this

manual,be alertto thepotential forpersonal injury.

Followrecommended precautions andsafe

operatingpractices.

iii

ELECTRO FREEZE Soft Serve Model SLX400, SLX400E, SLX500

SAFETY FIRST!

3. Follow Safety Instructions ....

4. Operate Safely ....

Read and understand all safety messages in this

manual. Read and understand the decal safety

messages on your freezer. Take notice of the

location of all decals on the freezer and keep the

safety decals in good condition. Check them

periodically and replace missing, damaged or

illegible safety decals. The safety decals must

remain in place and legible for the life of the

freezer. If you need new decals, use the

information and illustrations on pages iv and v of

this manual to identify the decal and contact your

local distributor — or H.C. Duke & Son, LLC.

DO NOT attempt to operate the freezer until you

read and understand all safety messages and the

operating instructions in this manual.

DO NOT allowuntrained personnelto maintainor

servicethis machine.Failure tofollow this

instructionmay resultin severepersonalinjury. DO

NOT operatethe freezerunless allservice panels

andaccess doorsare securedwith screws.DO

NOT attemptto maintainor repairthe freezeruntil

the main power supply has been disconnected.

Some freezers have more than one disconnect

switch. Contact your local Electro Freeze

Distributor for authorized service.

iv

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

Safety Decal Locations

Youmaycontactyourlocal authorized

ElectroFreezeDistributor,asfollows:

NAME:_______________________

ADDRESS:____________________

______________________________

PHONE:_______________________

or — forfactoryserviceassistance —

contactH.C.Duke&Son, LLC,Electro

FreezeServiceDepartmentbyphoneor

FAX:

Phone: (309)755-4553

(800)755-4545

FAX: (309)755-9858

E-mail: [email protected]

(Thedecalsonthenextpagearenum-

bered1and2.Thosenumberscorrespond

tothenumbersinthetablebelow.The

tableprovidesthepartnumber,descrip-

tion,andquantityfor eachdecal.)

Donotattempttooperatethefreezeruntil

allsafetyprecautionsandoperating

instructionsinthismanualarereadand

understood.

Takenoticeofallwarning,caution,instruc-

tionandinformationdecals(orlabels)on

thefreezerasshown inthefiguretothe

right.Thelabelshavebeenputthereto

helpmaintainasafeworkingenvironment.

Thelabelshavebeendesignedtowith-

standwashingandcleaning.Alllabels

mustremainlegiblefor thelifeofthe

freezer.Checklabelsperiodicallytobe

suretheycanberecognizedaswarning

labels.

Ifitisnecessarytoreplaceany label,

pleasecontactyourlocalauthorized

ElectroFreezeDistributororH.C.Duke&

Son,LLCWhenreadytoorderyouwill

needtodeterminethe(1)partnumber,(2)

typeoflabel,(3)locationoflabel,and(4)

quantityrequired,andincludeareturn

shippingaddress.

No. Part No. Description (Qty)

1HC165025-03 Decal — Beater Warning Black(1)

2HC165025-04 Decal — Beater Warning Twist (1)

3HC165126 Decal— Panel Removal Warning (3)

v

ELECTRO FREEZE Soft Serve Model SLX400, SLX400E, SLX500

HC165025-04

1HC165025-03

Hazardousrotatingbeatershaft.Donot

operateunitwithdispenseheadremoved

.

Beforeremoving dispense head:

1.Turnall control switches to "OFF", and

2.Disconnect all powersupplies. Unit mayhave

morethan onepowersupply.

Located behind

the head

2

Safety Decal Locations (continued)

WARNING

!

Hazardous moving parts.

Machine starts automatically.

Do not operate with panel

removed.

P/N 165126

2

vi

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

Table of Contents

Safety First!

...............................................................................................ii

Safety Decal Locations

................................................................... iv

PART I

1 Introduction

............................................................................................... 1

2 Note to Installer

...................................................................................... 1

2.1 UncratingandInspection............................................................................... 2

2.2 Installation ..................................................................................................... 3

2.3 ElectricalRequirements-ModelsSLX500andSLX400................................. 3

2.4 ElectricalRequirements-ModelSLX400E .................................................... 4

2.5 ElectricalConnections ................................................................................... 4

3 Specifications

.......................................................................................... 5

3.1 Particulars....................................................................................................... 5

3.2 DataPlate ....................................................................................................... 6

3.3 ReferenceInformation .................................................................................... 6

3.4 InstallationDate .............................................................................................. 7

3.5 Dimensions. .................................................................................................... 7

4 Virtual Quality Management System (VQM)

Terminology

.............................................................................................. 8

5 Part Names and Functions

........................................................ 10

6 Operator Controls & Indicators

.............................................. 13

6.1 FreezerSymbol .......................................................................................... 14

6.2 LeftSideControls ....................................................................................... 14

6.3 IndicatesModeofOperation ...................................................................... 14

6.4 OFFIndicator .............................................................................................. 14

6.5 Functionsbuttons(Four) ............................................................................. 14

6.6 InformationWindow ................................................................................... 14

6.7 Washor Clean Mode .................................................................................. 14

6.8 NightModeButton ...................................................................................... 15

6.9 FreezeModeButton ................................................................................... 15

6.10 OFFButton .................................................................................................. 15

6.11 LeftSideBeater"ON"Button...................................................................... 15

vii

ELECTRO FREEZE Soft Serve Model SLX400, SLX400E, SLX500

6 Operator Controls & Indicators (continued)

6.12 LeftSideBeater"OFF"Button.................................................................... 15

6.13 ArrowButtons.............................................................................................. 15

6.14 PowerSwitch .............................................................................................. 16

6.12 MixFeedTube&Regulator........................................................................ 16

7 Operator Display Hidden Menu..................................

17

8 Disassembly and Cleaning

........................................................ 20

8.1 CleaningAccessories................................................................................... 20

8.2 DisassemblyInstructions.............................................................................. 21

8.3 CleaningInstructions ................................................................................... 23

9 Assembly

................................................................................................... 25

10 Start-up Instructions

........................................................................ 28

10.1 Sanitizing .................................................................................................... 28

10.2 Priming........................................................................................................ 30

10.2.1 StandardPrimingInsturctions ................................................................. 30

10.2.2 PrimingInstructions ................................................................................. 31

11 Closing Procedures

.........................................................................

32

11.1 NightSwitchOperation .............................................................................. 32

11.2 DrainingProduct ........................................................................................ 33

12 Soft Serve Information

................................................................... 34

12.1 Overrun ....................................................................................................... 34

12.2 Rerun........................................................................................................... 34

13 Routine Maintenance

...................................................................... 35

14 Troubleshooting Tables

................................................................ 39

PART II

REPLACEMENT PARTS with ILLUSTRATIONS

*

*

RefertoPartIITableofContentsforhelpwithlocatingpartnumbersandillustrations.

Table of Contents (continued)

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

184584

1

2 Note to Installer

1 Introduction

Gravityfedsoftservefreezermodels

SLX400,SLX400E,andSLX500arede-

signedtoproducesoftserveicecream,ice

milk,yogurt,andsimilarfrozendairy

products,withaproductservingtempera-

turerangeof15to25°F(-9to-4°C).Ifsuch

productsarepreparedfrompowdered

concentrate,theyshouldbeprecooledto

40°F(4°C)priortointroductiontothe

freezer.Use ofotherproducts inthis

machineisconsideredmisuse(seeWar-

ranty).

Thismanualhasbeenpreparedtoassist

youintheproperoperationandgeneral

maintenanceoftheElectroFreezemodel

SLX400,SLX400E,andSLX500freezers.

Makesureallpersonnelresponsiblefor

equipmentoperationcompletelyreadand

understandthismanualbeforeoperatingthe

freezer.Whenproperlyoperatedand

maintained,thefreezerwillproducea

consistentqualityproduct.

Ifyourequiretechnicalassistance,please

contactyourlocalauthorized Electro

FreezeDistributor,asfollows:

Name:

Address:

Phone:

Forfactoryserviceassistance — contact

H.C.Duke &Son, LLC,ElectroFreeze

ServiceDepartmentasfollows.

Phone: (309)755-4553

(800)755-4545

FAX: (309)755-9858

E-mail: [email protected]

This freezer must be installed and serviced by an Electro Freeze Distributor or

authorized service technician in accordance with the installation instructions.

After installation the warranty registration card must be completed and re-

turned to validate the warranty.

2

184584

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

2.1 Uncrating and Inspection

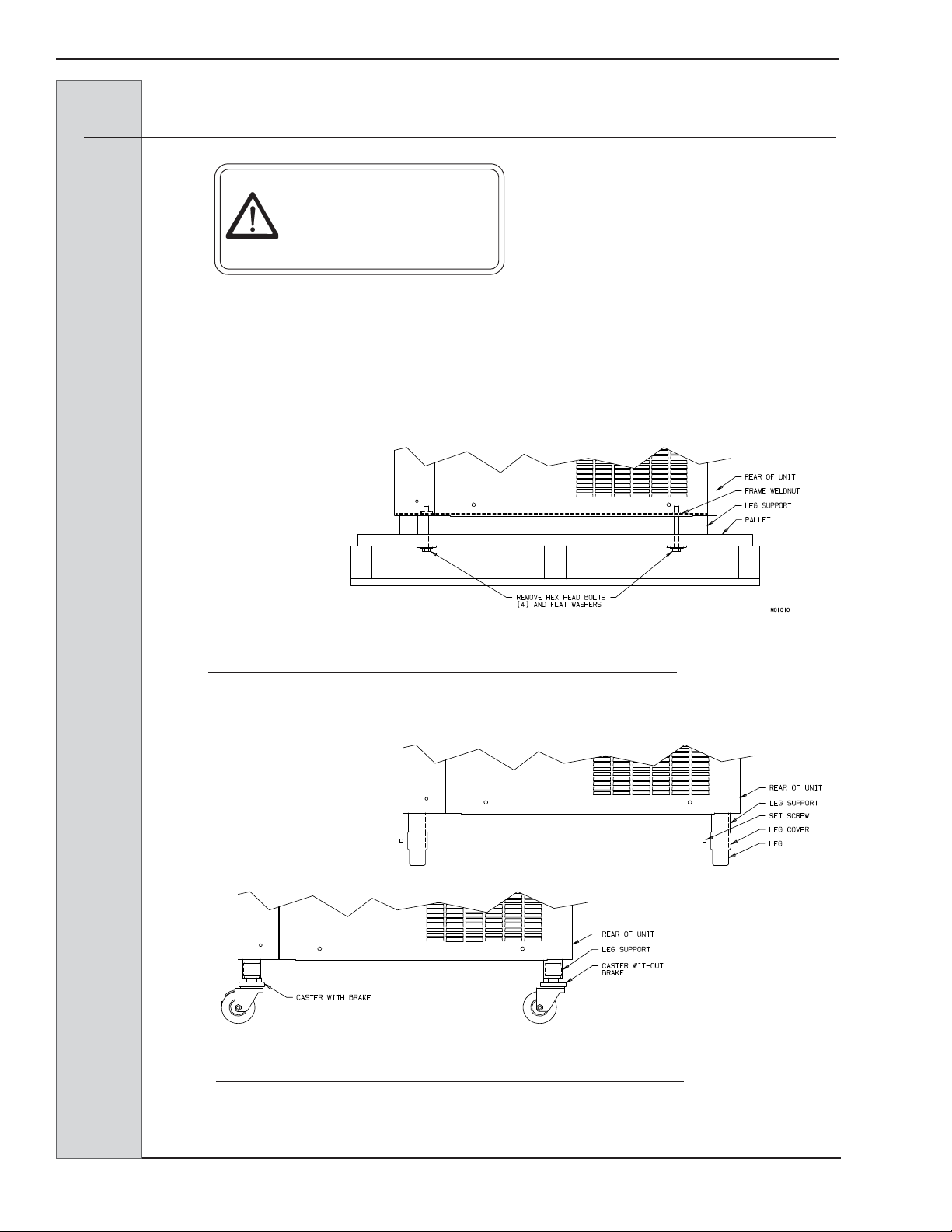

Figure 2-1 Machine bolted to Shipping Base

CAUTION

Be sure to properly

support the machine when

removing bolts and

installing legs or casters.

When the unit is received and while the

carrier is still present, inspect the ship-

ping carton for any damage that may

have occurred in transit. If the

SHOCKWATCH

®

label indicates red

and/or the carton is broken, torn, or

punctured, note the damage on the

carrier’s freight bill and notify the

carrier’s local agent immediately.

1. Remove the carton from the

pallet, and move the machine as close

as possible to the permanent location.

2. Remove the shipping bolts on

the bottom of the freezer (figure 2-1)

and install either the legs or casters

(figure 2-2).

Figure 2-2 Installing Mounting Legs or Casters

NOTE: Screw casters

or legs all the way in

coupling, then adjust

to level side to side

with a 1/4” slope to

the front.

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

184584

3

2.2 Installation

CAUTION

All materials and

connections must conform

to local requirements and

be in compliance with the

National Electrical Code

(NEC).

1. Thefreezerisdesignedforindoor

useandmustbeprotectedfromoutdoor

weatherconditions.

2. Wherecodespermit,Electro

Freezerecommendsthatthefloormodel

freezersbeinstalledoncastersandhave

flexiblewaterandelectricalconnections

foreasierserviceandcleaning.

3. Allmodelsarerequiredtobeopen

atthetop,haveaminimum6-inch(15.2

cm)rearclearanceand0inchesonthe

sidepanelsforadequateventilation.

Anythingblockingventilationofthefreezer

(includingconedispensers)willreducethe

efficiencyofthefreezer.

4. Aircooled model SLX500will

needanairdeflectoriftheunitistobe

placedagainstarearwall.The6”widex

21-7/8”longdeflectoristobemountedto

thelowerrearscrewson thebackpanelof

thefreezer.Failure to install the deflec-

tor will void warranty.

5. Water-cooledmodelsrequirea

3/8-inchMPTwaterinletandwaterwaste

connection. Theconnectionsarefoundon

thebottom,underthecompressormounting

area.Theyaretagged“WaterInlet”and

“WaterWaste.”Amanualshut-offvalve

shouldbeinstalled inthe waterinletlineat

thetimeofinstallation.Thewaterpressure

mustbebetween35-140psig(241-965

kPa)forproperoperation.

6. Placethefreezer inits final

location and adjust the legs or casters

so that it is level side-to-side and the

frontisapproximately1/4-inch lowerthan

thereartoallowproperdrainageofthe

freezingcylinder.

2.3 Electrical Requirements-Models SLX500 and SLX400

CAUTION

To prevent accidental

electrical shock, a positive

earth ground is required.

1. Always verify electrical specifi-

cations on the data plate (figure 3-1) of

each freezer. Data plate specifications

will always supersede the information in

this manual.

2. Supply voltage must be within +

10% of voltage indicated on the name-

plate. Also, on three-phase systems,

voltage between phases must be bal-

anced within 2%. (More than a 6 volt

difference between any two voltage

measurements at 208-230 volts indi-

cates a possible imbalance.) Request

your local power company to correct any

voltage problem.

3. An easily accessible main power

disconnect must be provided for all

poles of the wiring to the freezer.

4

184584

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

CAUTION

Toprevent accidental

electricalshock, a positive

earthground isrequired.

1. Freezerrequiresonepowersupply.

Alwayscheckthedataplate forproperfuse

size,wireampacity,and electricalspecifi-

cations.

2. Refertothewiringdiagramprovided

forproperpowerconnections.

3. Electricalconnectionsfor

modelsSLX500and SLX400 aremadein

ajunctionbox. Facingthefrontofthe

freezer itislocatedbehindtheright side

paneltowardsthebackandbottomofthe

frame.

4. TheModel SLX400E issupplied

withacordan aNEMA6-20P plugthat

plugsintoa6-20Rreceptacle.SeeFigure

2-3.

2.5 Electrical Connections

4. Useaflexibleconnectionwhen

permissible.Copperwiresarerequiredfor

connectiontofreezer.Allmaterialsand

connectionsmustconformtolocalcodes

and/ortheNationalElectricalCode.

5. Forall3phasefreezers,beater

shaftrotationmustbeclockwiseasviewed

fromthefrontofthefreezer.

3. Supplyvoltagemustbewithin

±10%ofvoltageindicatedonthenameplate.

4. Aneasilyaccessiblemain power

disconnectmustbeprovidedforallpolesof

thewiringtothefreezer.

2.4 Electrical Requirements - Model SLX400E ONLY

CAUTION

Toprevent accidental

electricalshock, a

receptaclewith a positive

earthground isrequired.

1. Alwaysverifyelectricalspecifica-

tionsonthedataplate(figure4-1)ofeach

individualfreezer.Dataplatespecifications

willalwayssupersedetheinformationin

thismanual.

2. Thisfreezerrequiresaprotected20

amp220voltcircuit.Connectthefreezerto

acircuitseparatefrom anyotherelectrical

equipment.ThefreezerplugwillfitaNEMA

6-20Rreceptacle. Seefigure2-3.

Figure2-3 Plug

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

184584

5

3.1 Particulars

3 Specifications

Width(in/cm) ...........................22-1/8/ 56.2

Height(in/cm).................... 60-11/16/154.15

Depth (in/cm) ........................ 30-1/8/76.52

SLX500 SLX400 SLX400E

Weight(lb/kg)................................. 539/244 ....................... 500/226 ...................... 475/215

CylinderCompressor.... 2HP/10500(BTU/hr) ... 1.3HP/6900(BTU/hr) .. 1.3HP/6900(BTU/hr)

1.9kw(Motor) ................1.3kw(Motor) ...............1.3kw(Motor)

3.2kw(Cooling) ............. 2.1kw(Cooling) ............ 2.1kw(Cooling)

HopperCompressor .... 1/10HP/500(BTU/hr) ... 1/10HP/500(BTU/hr) ... 1/10HP/500(BTU/hr)

BeaterMotor ........................ (2) 2HP/1.5 kw ............ (2)1HP/0.75kw .......... (2)1HP/0.75kw

Refrigerant-Cylinder...........................R-404a .......................... R-404a ..........................R-404a

Refrigerant-Hopper ............................R-134a ...........................R-134a ..........................R-134a

Charge Cylinder(lbs/kg)(A/C)) .......... 4.4 / 2.0 .......................... 4/1.81 ......................... 4/1.81

Charge-Cylinder(lbs/kg)(W/C) ........ 3.75 /1.7 ....................... 3.4 /1.54 ...................... 3.4 /1.54

Charge-Hopper (oz/kg) ........................7 / .2 ............................. 7 / .2 .............................7 / .2

Cooling....................................... AirorWater ................... AirorWater .................. AirorWater

Hopper(qt/ltr) ............................. (2) 16/ 15.1 ................... (2)12/ 11.4 .................. (2)12 /11.4

Cylinder(qt/ltr).............................(2)3.7/ 3.5 ....................(2)2.7 / 2.6 ...................(2) 2.7 / 2.6

A/C = AirCooled

W/C = WaterCooled

6

184584

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

Write in

Reference Informa-

tion HERE!

3.3 Reference Information

Fillinthefollowinginformationassoonas

youreceiveyourElectroFreezeSLX400

series or SLX500freezer.(Theitem

numbers—encircled,below —correspond

tothecalloutnumbersinfigure3-1.)

1 ModelNumber:_________________

2 SerialNumber:__________________

3 Electrical Spec: Voltage ________

Phase _______ Hertz _________

4 Max.FuseSize:__________________

5 Min.CircuitAmpacity___________

3.2 Data Plate

The data plate provides important

information that the operator should

record and have available for parts

ordering, warranty inquiries and service

requests.

Figure 3-1

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

184584

7

Figure3-2 ElectroFreezeSLXSeries

ThedimensionsoftheSLXSeriesfreezers

areprovidedinfigure3-2below.

3.5 Dimensions

3.4 Installation Date

Fillinthedateofinstallation,andthename, address,andphonenumberoftheinstallerin

thespaceprovidedbelow.Thisinformationwillbeneededwhenorderingpartsorservicefor

thefreezer.

Date of installation: ____________________________________

Installed by: ____________________________________

Address: ____________________________________

____________________________________

Phone: ____________________________________

8

184584

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

4 Virtual Quality Management System (VQM)

Terminology

AmpControlBoard:........... Board is located in the main contactor box responsible for

monitoringthe beater motor amperage and communicating

that value to the main P.C. Board.

BeaterRun:....................... This D.O.B. timer used to delay the beater motor after the

refrigerationshuts down. Beater Run Range: 0 to 10 seconds

DemandRun Comp: .......... The D.O.B. timer used to delay the compressor when product

is being drawn. Demand Run Comp. Range: 0 to 12 seconds

Dual Hyst: ......................... The differential usedwhen productis being drawnout ofthe

centerspigot or when both side spigots have been drawn

simultaneously. Dual Hysteresis range: 7 to 20°F

Hysteresis (Hyst): ............. Symbolizes the differential setting. Hysteresis range: 7 to

20°F i.e. if your cut in is at 18°F and your Hysteresis is at

10°F your unit will cut out at 8°F

IdleRun Comp: ................. Delay on break (D.O.B.) timer used for the compressor when

the unit is in idle mode/no product being drawn. Idle Run

Comp. Range: 0 to 12 seconds

Idle: ................................... When the unit is cycling on temperature and no product is

beingdispensed

Lock outs: ......................... Allows the function of a specific feature/button to be

temporarily disabled to deter unnecessary usage of that

feature.

Main P.C. Board: ............... Main Control board for the unit, housed behind the trim strip

panel. This board has many connectors on it and is

responsiblefor the main operations of the unit.

MembraneSwitch: ............ The black Electro Freeze decal visible on the front of the unit,

whichhouses the hidden operator, technician, soft, and hard

keys used to navigate the menus

Single Hyst: ...................... The differential used when product is being drawn out of one

barrel. Single Hysteresis range: 7 to 20°F

Slope/DemandSlope:........ Utilizes a function within the system to watch the

temperature change as the unit freezes a barrel. If utilizing

the slope feature and the unit sees a lack of temperature

change during freeze down, the unit will cycle off. This will

preventa freeze up condition due to a long run time. Demand

Slope range: 0 to -0.2

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

184584

9

Temp. Comp.:.................... Temperaturecomparison,utilized when the slope feature is

turned on. It prevents the system from seeing the slope

temperaturecurve until a determined temperature is reached.

Once that temperature has been reached then the system

will examine the curve and shut down if necessary.

Temp. Comp. Range: -10 to 15°F

TemperatureOffset: ........... A function that allows temperature adjustment to the

operator.Adjustablefrom1-9 and 5 being neutral/no change,

Lowerthan5=colderandgreaterthan5=warmer

U.I./User Interface: ........... The board that lies directly behind the membrane switch on

the front panel. This board houses the LED screen that

displays the menus and operations. The membrane switch is

connected to this board via a ribbon cable. This board also

has its own software.

4 Virtual Quality Management System (VQM)

Terminology (continued)

10

184584

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

5 Part Names and Functions

6 ROD - PLUNGER

Starts the freezer when dispensing.

Must be in place for proper

operation.

7 PIN - HANDLE

Secures handle to the head.

8 KNOB - HAND

Secures the head to the freezing

cylinder.

9 HANDLE - DISPENSE - SIDE

Opens and closes the plunger to

start and stop the flow of product

from the freezer.

10 HANDLE - DISPENSING - CENTER

Opens and closes the plunger to

start and stop the flow of swirl

product from the freezer.

11 NOZZLE - SERRATED

Forms the frozen product as it is

dispensed.

1 HEAD - DISPENSE

Encloses the freezing cylinder and

provides an opening for product to be

dispensed.

2 O-RINGS - HEAD

Seals the head to the freezing

cylinder. Must be lubricated.

3 PLUNGERS - DISPENSE - SIDE

Seals the product opening in the head

when closed. Allows product to flow

when open.

4 O-RINGS - PLUNGER

Seals the plunger in the head. Must be

lubricated to seal and slide freely.

5 PLUNGER - DISPENSE - CENTER

Seals the product opening in the head

when closed. Combines ice cream

from both cylinders to form swirl

cones.

Thefollowingdescriptionsrefertofigure5-1.Thenumberprecedingthepartnamecorre-

spondstothenumberinthefigure.

Figure5-1 HeadAssembly

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

184584

11

5 Part Names and Functions (continued)

Figure5-2 BeaterShaftAssemblies

Thefollowingdescriptionsrefertofigure5-2.Thenumberprecedingthepartnamecorre-

spondstothenumberinthefigure.

SEAL-BEATERSHAFT

Sealstheopeningbetweenthe

freezingcylinderandthebeatershaft.

Consistsofthefollowing:

4 SEAL-BEATERSHAFT

5 WASHER-DOUBLESHAFT

SEAL

1 BAR-BREAKER

Keepsproductblendedinthecenter

ofthebeatershaft.

2 SHAFT-ASSY.BEATER

Rotatesinthefreezingcylinder,

blendingairandmix.Ejectsproduct

whendispensingplungerisopened.

3 BLADE-SCRAPER

Scrapesthefrozenproductfromthe

freezingcylinder.

12

184584

ELECTRO FREEZE Soft Serve Models SLX400, SLX400E, SLX500

5 Part Names and Functions (continued)

Figure5-3 MixFeedTubeAssembly

1 TUBE - MIX FEED.

Metersthecorrectamountofmixand

airintothefreezingcylinderfromthe

hopper.

2 REGULATOR.

Providesadjustmentonmixfeedrate

andapositiveshut-offofmixflowto

thefreezingcylinder.

3 O-RING-TUBE.

Sealstheopeningbetweenthehopper

andmixfeedtube.(O-ringsdonot

needlubrication.)

Thefollowingdescriptionsrefertofigure5-3.Thenumberprecedingthepartnamecorre-

spondstothenumberinthefigure.

REGULATOR

ORING

MIXFEED TUBE

This manual suits for next models

2

Table of contents

Popular Commercial Food Equipment manuals by other brands

Vollrath

Vollrath STOELTING Flavor Burst STL-80BLD Operator's manual

True

True TDB-24-48-1-G-1-HC installation manual

Mono

Mono Ecotouch Operation and maintenance manual

Ruhle

Ruhle IR 56 Quick installation guide

Diamond

Diamond G77/PL4T-N installation instructions

Victor

Victor STADIA HC31SSLGH5 operating manual