THERMODYNE 1200 G User manual

SERVICE

MANUAL

(05-23)

Thermodyne Foodservice Products, Inc.

4418 New Haven Avenue 1-800-526-9182

Fort Wayne, IN 46803 www.tdyne.com

ADDFLU ID

Out 1

Out 2

ADDFLU ID

Out 1

Out 2

ADDFLU ID

Out 1

Out 2

MODELS

1200 G

1300 G

1900 G

1200 DW

1900 DW

2100 DW

3000 P

6000 P

For additional information on Thermodyne Foodservice Products, Inc.,

or to locate an authorized parts and service provider in your area,

visit our website at www.tdyne.com.

Please visit our website to Register your Thermodyne unit. Registration ensures that you

get up-to-date warranty and product information, along with fast and convenient service.

http://www.tdyne.com/register.aspx

— 2 —

ELECTRICAL WARNINGS

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL ELECTRICAL

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD STARTUP AND ADJUSTMENTS OF

THE EQUIPMENT COVERED BY THIS MANUAL.

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING OR PERFORMING

MAINTENANCE ON THE EQUIPMENT.

WARNING: Failure to follow all the instructions in this manual can cause property

damage, injury or death.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death.

WARNING: Electrical connections should be performed only by a certied professional.

WARNING: Electrical and grounding connections must comply with the applicable

portions of the National Electric Code and/or all local electric codes. Failure to comply with this

procedure can cause property damage, injury or death.

WARNING: Before connecting the unit to the electrical supply, verify that the electrical and

grounding connections comply with the applicable portions of the National Electric Code and/or

other local electrical codes. Failure to comply with this procedure can cause property damage,

injury or death.

WARNING: Before connecting the unit to the electrical supply, verify that the electrical

connection agrees with the specications on the data plate. Failure to comply with this

procedure can cause property damage, injury or death.

WARNING: UL73 grounding instructions: This appliance must be connected to a

grounded, metal, permanent wiring system. Or an equipment-grounding conductor must be run

with the circuit conductors and connected to the equipment-grounding terminal or lead on the

appliance. Failure to comply with this procedure can cause property damage, injury or death.

WARNING: Appliances equipped with a exible electric supply cord, are provided with

a three-prong grounding plug. It is imperative that this plug be connected into a properly

grounded three-prong receptacle. Failure to comply with this procedure can cause property

damage, injury or death.

WARNING: If the receptacle is not the proper grounding type, contact an electrician. Do

not remove the grounding prong from the plug. Failure to comply with this procedure can cause

property damage, injury or death.

— 3 —

WARNING: Before performing any service that involves electrical connection or

disconnection and/or exposure to electrical components, always perform the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all circuits. Failure to comply with this procedure can

cause property damage, injury or death.

WARNING: Before removing any sheet metal panels, always perform the Electrical

LOCKOUT/TAGOUT Procedure. Be sure all circuits are disconnected. Failure to comply with this

procedure can cause property damage, injury or death.

WARNING: Do not operate this equipment without properly placing and securing all

covers and access panels. Failure to comply with this procedure can cause property damage,

injury or death.

WARNING: Do not use or store gasoline or other ammable vapors or liquids in the

vicinity of this or any other appliance. Failure to comply can cause property damage, injury or

death.

WARNING: In the event of a power failure, do not attempt to operate this appliance. Failure

to comply can cause property damage, injury or death.

— 4 —

TABLE OF CONTENTS

ELECTRICAL LOCKOUT/TAGOUT PROCEDURE .......................................................................................... 5

COVERS AND PANELS ................................................................................................................................... 6

Top Fill Cover ............................................................................................................................................. 6

Power Head Lid.......................................................................................................................................... 6

Side Panels ................................................................................................................................................ 7

Doors.......................................................................................................................................................... 7

COMPONENT LOCATOR................................................................................................................................. 8

Power Head Components .......................................................................................................................... 8

Delivery Manifold Components .................................................................................................................. 9

Return Manifold Components .................................................................................................................. 10

COMPONENT REMOVAL AND REPLACEMENT...........................................................................................11

ELECTRICAL COMPONENTS .................................................................................................................11

Power Toggle Switch...........................................................................................................................11

Add Fluid Light....................................................................................................................................11

Temperature Controller ...................................................................................................................... 12

Cooling Fan ....................................................................................................................................... 13

Power Cord ........................................................................................................................................ 14

POWER BOARD COMPONENTS ........................................................................................................... 14

Solid State Relay ............................................................................................................................... 14

Float Board ........................................................................................................................................ 15

PLUMBING COMPONENTS ................................................................................................................... 16

B&G Pump......................................................................................................................................... 16

Teon Hoses...................................................................................................................................... 17

Fluid Level Probes ............................................................................................................................. 18

Snap Disc .......................................................................................................................................... 19

THERMOCOUPLE................................................................................................................................... 20

HEAT ELEMENTS.................................................................................................................................... 21

MAINTENANCE PROCEDURES ................................................................................................................... 24

Temperature Controller Set Up Procedures.............................................................................................. 24

Keypad Operation .................................................................................................................................... 24

Set Up ...................................................................................................................................................... 24

Changing the Heat Transfer Fluid............................................................................................................. 24

Door Adjustment....................................................................................................................................... 26

Stainless Steel Care................................................................................................................................. 27

TROUBLESHOOTING.................................................................................................................................... 28

WIRING SCHEMATICS .................................................................................................................................. 29

WARRANTY ................................................................................................................................................... 31

HEAT TRANSFER FLUID MSDS ................................................................................................................... 31

— 5 —

ELECTRICAL LOCKOUT/TAGOUT PROCEDURE

WARNING

Before performing any service that involves

electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/

TAGOUT Procedure. Disconnect all circuits.

Failure to comply can cause property

damage, injury or death.

The Electrical LOCKOUT/TAGOUT Procedure is

used to protect personnel working on an electrical

appliance. Before performing any maintenance

or service that requires exposure to electrical

components, follow these steps:

1. In electrical box, place appliance circuit breaker

into OFF position.

2. Place a lock or other device on electrical box

cover to prevent someone from placing circuit

breaker ON.

3. Place a tag on electrical box cover to indicate

that appliance has been disconnected for

service and power should not be restored until

tag is removed by maintenance personnel.

4. Disconnect appliance power cord from

electrical outlet.

5. Place a tag on the cord to indicate that unit

has been disconnected for service and power

should not be restored until tag is removed by

maintenance personnel.

MODEL

GALLONS LITERS

PER

SHELF

(OZ)

125 OC 1. 5 3.78 14

200 NDNL 1.75 6.62 6

200 CT 1.75 6.62 6

250 OC 1.65 6.62 20

250 PNDT 2.1 7.95 6

BW3 1.65 6.25 6

BW4 1. 7 6.44 6

300 NDNL 1.91 7.23 6

300 CT 1.91 7.23 6

700 NDNL 2.25 8.52 14

700 CT 2.25 8.52 14

950 NDNL 2.16 8.18 20

300 OC 2.24 8.48 14

FLUID CAPACITIES (STANDARD SHELF CONFIGURATION)

MODEL

GALLONS LITERS

PER

SHELF

(OZ)

1200 G 2.22 8.40 13

1200 DW 2.3 8.71 14

1300 G 2.32 8.78 13

1600 NDNL 2.1 7.95 6

1900 G 3.02 11.43 13

1900 DW 3.06 11.58 14

2100 DW 3.59 13.59 20

6000 P 4.95 18.74 23.8

700 DP 2.25 8.52 14

1500 DP 3.01 11.39 14

742 HW 2.45 9.27 14

744 HW 3 11.36 28

1600 HZ 2.5 9.46 Top-14;

Bottom-6

— 6 —

COVERS AND PANELS

TOP FILL COVER

TheTop Fill Cover provides access to the Reservoir

Tank Cap without the requirement to remove the

entire Power Head Lid.Remove the cover to access

the Reservoir Tank Cap when the Add Fluid Light

is illuminated.

1. Place the Power Toggle Switch to the OFF

position.

2. Remove the Philips screws securing the Top

Fill Cover.

3. Remove the Top Fill Cover.

4. Reverse the procedure to reinstall the Top Fill

Cover.

Top Fill Cover

ADD FLUID

Out1

Out2

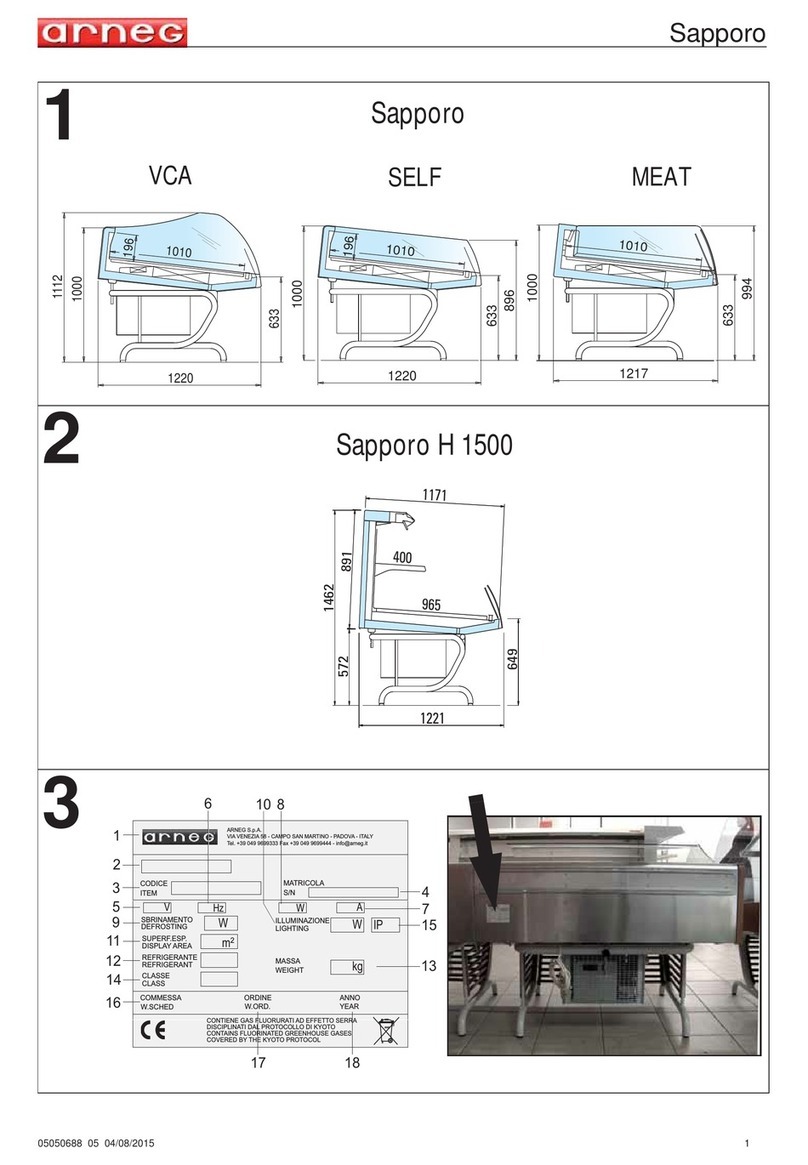

Figure 1: Top Fill Cover

POWER HEAD LID

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this procedure can cause

property damage, injury or death.

Removing the Power Head Lid provides access to

all of the components of the Power HeadAssembly.

1. Perform the ELECTRICAL LOCKOUT/

TAGOUT procedure.

2. Remove the Philips screws securing the Power

Head Lid.

3. Remove the Power Head Lid.

4. Reverse the procedure to reinstall the Power

Head Lid.

Power Head Lid

Figure 2: Power Head Lid

— 7 —

SIDE PANELS

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this procedure can cause

property damage, injury or death.

The Side Panels provide access to the Fluid

Delivery and Fluid Return systems.

1. Perform the ELECTRICAL LOCKOUT/

TAGOUT procedure.

2. Using a regular screwdriver turn the Quarter

Turn Post counterclockwise until it unlatches.

3. Repeat until all Quarter Turn Posts are loose.

4. Lift the Side Panel up and away from the unit.

5. Reverse the procedure to reinstall the Side

Panel.

Side

Panel

ADD FLUID

Out1

Out2

Figure 3: Side Panel Removal

DOORS

All DW, G & P models are supplied with doors

that lift off hinges. To remove the doors, open the

door slightly and lift it straight up and off the hinge.

— 8 —

COMPONENT LOCATOR

POWER HEAD COMPONENTS

23456789

10 11 12

1

3

4

15

5

11

10

9

6

7

17 1412 13 15 16 1 2

ADD FLUID

8

Figure 4: Power Head Components

1. Cooling Fan

2. B&G Pump

3. Reservoir Fill Cap

4. Reservoir Assembly

5. Contactor

6. Lighted Power Toggle Switch

7. Add Fluid Light

8. Temperature Controller

9. Solid State Relay

10. 120VAC Float Board

11. Neutral Lug

12. Heater Elements

13. Snap Disc

14. 16 PSI Pressure Cap

15. Fluid Level Probes

16. Thermocouple

17. Heater Tank Assembly

— 9 —

DELIVERY MANIFOLD COMPONENTS

73

4

2

1

6 5

Figure 5: Delivery Manifold Components

1. Delivery Line

2. Teon Washer

3. Shelf Plug

4. Power Cord

5. Delivery Manifold Assembly

6. Short Teon Hose

7. Shelf Elbow

— 10 —

RETURN MANIFOLD COMPONENTS

8

2

3

4

1

7 6 5

Figure 6: Return Manifold Components

1. Overow Tube

2. Shelf Plug

3. Teon Washer

4. Drain Tube

5. Drain Tube ON/OFF Valve

6. Return Manifold

7. Long Teon Hose

8. Shelf Elbow

— 11 —

COMPONENT REMOVAL AND REPLACEMENT

ELECTRICAL COMPONENTS

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this procedure can cause

property damage, injury or death.

WARNING

Certain components may be hot if the

unit was in operation prior to performing

a procedure. Allow the unit to cool before

beginning work.

POWER TOGGLE SWITCH

1. Perform the ELECTRICAL LOCKOUT/

TAGOUT procedure.

2. Perform the POWER HEAD LID removal

procedure.

3. Tag and disconnect the wires connected to

the Power Toggle Switch.

4. Squeeze the spring tabs that hold the switch

in place and push the switch through the front

of the unit.

Note: If the switch being removed is damaged,

it may be easier to break the spring tabs

off of the switch rather than attempting to

squeeze the spring tabs. If this method

is used, remember to remove the broken

tabs from the inside of the Power Head.

Spring

Tab

Power

Toggle

Switch

Figure 7: Power Toggle Switch Removal

CAUTION: Always use pliers when removing

electrical wire connectors. Do NOT pull on

the wires to remove the connectors.

5. Insert the new switch through the front of the

unit ensuring that the tabs lock into place.

6. Refer to thetagsorwiring schematictoreconnect

the wires to the new Power Toggle Switch.

7. Restore power to the unit and check the Power

Toggle Switch for proper operation.

8. Remove power from the unit.

9. Reverse the POWER HEAD LID removal

procedure to reinstall the Power Head Lid.

10. Restore power to the unit and verify proper

operation.

ADD FLUID LIGHT

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this procedure can cause

property damage, injury or death.

— 12 —

WARNING

Certain components may be hot if the

unit was in operation prior to performing

a procedure. Allow the unit to cool before

beginning work.

1. Perform the ELECTRICAL LOCKOUT/

TAGOUT procedure.

2. Perform the POWER HEAD LID removal

procedure.

3. Pull the light socket out from the Add Fluid

Light cover.

4. Tag and disconnect the two wire connectors.

Power

Toggle

Switch

Spring

Tabs

Add Fluid

Light

Light

Socket

Figure 8: Add Fluid Light Removal

5. Reverse the procedure to reinstall the Add

Fluid Light.

6. Restore power to the unit and check the Add

Fluid Light for proper operation.

Note: The Add Fluid Light will not illuminate if

the Heat Transfer Fluid level is sufficient.

Drain uid as necessary in order to test

for proper light operation. Refer to the

CHANGING HEAT TRANSFER FLUID

procedure for draining and adding Heat

Transfer Fluid.

7. Remove power from the unit.

8. Reverse the POWER HEAD LID removal

procedure to reinstall the Power Head Lid.

9.

Restore power to the unit and verify proper

operation.

TEMPERATURE CONTROLLER

The Temperature Controller consists of two

parts: the Controller Main Board (wire harness

terminals) and the Display/Pushbutton Board.

These two boards are connected by a multi-

conductor ribbon cable.

Display/ Pushbutton

MainBoard

Figure 9: Temperature Controller

1. Follow the LOCKOUT/TAGOUT procedure

using the procedures provided in the Lockout/

Tagout Procedures section of this manual.

2. Remove the Power Head Lid following the

instructions provided in the Panels and Covers

section of this manual.

3. The TBC-41 Controller is very easy to remove.

There are four screws and spacers apiece

holding the display and power boards. They

are different lengths: the spacers used with

the power board are 1/2" (12.7mm) long; the

spacers used with the display board are 5/16"

(8mm) long.

— 13 —

Springs (4)

1/2"(12.7mm)

Spacers(4)

Figure 10: Temperature Controller Removal

4. Restore the power and check the controller

for proper operation.

5. Remove the unit from its power source and

reattach the Power Head Lid.

6. Restore power to the unit and ensure it is

operating correctly.

NOTICE: The new Temperature Controller

may require set up procedures. Refer to the

Temperature Controller Set Up Procedures

section of this manual for set up procedures.

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this procedure can cause

property damage, injury or death.

WARNING

Certain components may be hot if the

unit was in operation prior to performing

a procedure. Allow the unit to cool before

beginning work.

COOLING FAN

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this procedure can cause

property damage, injury or death.

WARNING

Certain components may be hot if the

unit was in operation prior to performing

a procedure. Allow the unit to cool before

beginning work.

1. Perform the ELECTRICAL LOCKOUT/

TAGOUT procedure.

2. Perform the POWER HEAD LID removal

procedure.

3. Unplug the leads from the fan.

4. Remove the four screws securing the fan to

the Power Head.

Figure 11: Cooling Fan Removal

5. Reverse this procedure to install the new

Cooling Fan.

6. Restore power to the unit and ensure it is

operating correctly.

— 14 —

POWER CORD

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this procedure can cause

property damage, injury or death.

WARNING

Certain components may be hot if the

unit was in operation prior to performing

a procedure. Allow the unit to cool before

beginning work.

1. Perform the ELECTRICAL LOCKOUT/

TAGOUT procedure.

2. Perform the POWER HEAD LID removal

procedure.

3. Disconnect the Power Cord from the Contactor

and remove the ground screw securing the

green ground wire to the unit frame.

4. Refer to the wiring schematic to connect the

new power cord.

5. Restore power to the unit.

6. Verify the unit is working properly.

7. Remove power from the unit.

8. Reverse the POWER HEAD LID removal

procedure to reinstall the Power Head Lid.

9. Restore power to the unit and ensure it is

operating correctly.

POWER BOARD COMPONENTS

The Power Board Components include the Solid

State Relay, Contactor, Float Board and the Neutral

Lug.Under normal circumstances it should not be

necessary to replace either the Contactor or the

Neutral Lug.

Note: The Power Board is mounted on plastic

risers that allow for air to ow on the

underside of the board.It is not necessary

to remove the Power Board when replacing

one of its components; however it may

be necessary to loosen the screws that

secure the Power Board to the unit.Loosen

but do not remove the screws as they hold

the plastic risers in place.

Neutral

Lug

Power

Board

Contactor

120VAC

Float

Board

Solid State

Relay

Figure 12: Power Board Components

Solid State Relay

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this procedure can cause

property damage, injury or death.

WARNING

Certain components may be hot if the

unit was in operation prior to performing

a procedure. Allow the unit to cool before

beginning work.

1. Perform the ELECTRICAL LOCKOUT/

TAGOUT procedure.

2. Perform the POWER HEAD LID removal

procedure.

3. Tag and disconnect the wires to the Solid State

Relay.

4. Remove the Solid State Relay by removing the

two screws securing it to the Power Board.

It may be necessary to loosen the screws

securing the Power Board to gain access to

the screws at the front of the Solid state Relay.

— 15 —

Relay

Mounting

Screws

Plastic

Riser

Power Board

Mounting Screws

Figure 13: Solid State Relay Removal

5. Install the new Solid State Relay.

6. Reattach the screws securing the Power Board

to the unit.

7. Refer to the tags or the wiring schematic to

reconnect the wires to the new Solid State

Relay.

8. Restore power to the unit and verify operation.

9. Reverse the POWER HEAD LID removal

procedure to reinstall the Power Head Lid.

10.

Restore power to the unit and ensure it is

operating correctly.

Float Board

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this procedure can cause

property damage, injury or death.

WARNING

Certain components may be hot if the

unit was in operation prior to performing

a procedure. Allow the unit to cool before

beginning work.

1. Perform the ELECTRICAL LOCKOUT/

TAGOUT procedure.

2. Perform the POWER HEAD LID removal

procedure.

3. Tag and disconnect the wires attached to the

Float Board.

Note: It is NOT necessary to loosen the Power

Board screws to gain access to the Float

Board.

4. Remove the screws and plastic risers securing

the Float Board to the Power Board and lift the

Float Board out of the unit.

Float Board

Mounting

Screws

Plastic

Riser

Figure 14: Float Board Removal

5. Install the new Float Board making sure a

plastic riser is attached to each screw.

6. Refer to the tags or the wiring schematic to

reconnect the wires to the new Float Board.

7. Restore power to the unit and check it for

proper operation.

8. Remove power from the unit.

9. Reverse the POWER HEAD LID removal

procedure to reinstall the Power Head Lid.

10.

Restore power to the unit and ensure it is

operating correctly.

— 16 —

PLUMBING COMPONENTS

B&G Pump

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this procedure can cause

property damage, injury or death.

WARNING

Certain components may be hot if the

unit was in operation prior to performing

a procedure. Allow the unit to cool before

beginning work.

WARNING

Before servicing the plumbing system the heat

transfer uid must be drained from the system.

Additional tools required for this procedure:

• 1-1/16 Wrench

• 1-3/8 Wrench

• 7/16 Wrench

1. Perform the ELECTRICAL LOCKOUT/

TAGOUT procedure.

2. Perform the POWER HEAD LID removal

procedure.

3. Perform the SIDE PANEL removal procedure

to remove the left side panel.

4. Locate the Drain Tube and place it into an

empty pan.

Drain Valve

Drain

Tube

Figure 15: Drain Tube and Drain Valve

Location

5. Remove both the Heater Tank Pressure and

the Reservoir Caps.

Heater Tank

Cap

Reservoir

Cap

B&G Pump

Gaskets

Pump

Bracket

Delivery

Hose

Fitting

Pump

Unions

Figure 16: B&G Pump Removal

6. Open the Drain Valve to drain the Heat

Transfer Fluid.

7. Discard the drained uid. Refer to the HEAT

TRANSFER FLUID MATERIAL SAFETY DATA

SHEET provided at the end of this manual for

proper disposal of the uid.

8. Tag and disconnect the B&G pump wires.

9. Using the 1-1/16 wrench, remove the Delivery

Line.

10.

Using the 1-3/8 wrench, unscrew the unions

on both sides of the pump.

11.

Using the 7/16 wrench, remove the u-clamp

securing the pump to the Pump Bracket and

remove the pump.

12.

Place the new pump into position.

13.

Loosely connect the u-clamp.

14.

Ensure NEW gaskets are in place at both unions

and tighten the unions using the 1-3/8 wrench.

15.

Tighten the 7/16 nuts on the u-clamp.

16.

Reconnect the Delivery Line.

1 7.

Refer to the tags or wiring schematic to

reconnect the pump wires.

— 17 —

18.

Close the Drain Valve.

19.

Restore power to the unit.

20.

Fill the Heater Tank with FRESH Heat Transfer

Fluid and replace Heater Tank Pressure Cap.

2 1.

Fill the Reservoir Tank until the Add Fluid Light

goes out and replace Reservoir Tank Cap.

22.

Ensure there are no leaks at the pump unions

or Delivery Line ttings.

23.

Remove power from the unit.

24.

Reverse the POWER HEAD LID removal

procedure to reinstall the Power Head Lid.

25.

Reverse the SIDE PANEL removal procedure

to reinstall the panel.

26.

Restore the power to the unit and check it for

proper operation. It may be necessary to add

additional uid after the unit has operated for

several minutes.

Teon Hoses

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this procedure can cause

property damage, injury or death.

WARNING

Certain components may be hot if the

unit was in operation prior to performing

a procedure. Allow the unit to cool before

beginning work.

WARNING

Before servicing the plumbing system the

heat transfer uid must be drained from

the system.

Under normal operating circumstances it

should not be necessary to replace a hose.

Should a hose become damaged or begin

leaking it must be replaced. There are two

sets of Teflon Hoses installed on each unit.

The short Teflon Hoses are located on the

delivery side (left side) of the unit. The long

Teflon Hoses are located on the return side

(right side) of the unit. Both sets of hoses are

replaced in the following manner:

1. Perform the ELECTRICAL LOCKOUT/

TAGOUT procedure.

2. Perform the POWER HEAD LID removal

procedure.

3. Perform the SIDE PANEL removal

procedure to remove the applicable side

panel.

4. Locate the Drain Tube and place it into an

empty pan.

5. Remove Heater Tank Cap and Reservoir

Cap.

6. Open the Drain Valve to drain the Heat

Transfer Fluid.

7. Discard the drained fluid. Refer to the

Heat Transfer Fluid Material Safety Data

Sheet provided at the end of this manual

for proper disposal of the fluid.

8. Using an open end 3/4 wrench remove the

hose from the Shelf Elbow side first.

9. Using an open end 7/16 wrench remove

the hose from the manifold.

Shelf

Elbow

Manifold

Teflon Tube Drain Tube

Figure 17: Return Side of Unit

— 18 —

Shelf

Elbow

Manifold

Teflon Tube

Figure 18: Delivery Side of Unit

10. Attach the replacement Teon Hose to the

manifold rst, then attach the other end to the

Shelf Elbow using the appropriate wrenches.

11. Close the Drain Valve.

12. Restore power to the unit.

13. Fill the HeaterTank with FRESH HeatTransfer

Fluid and replace Heater Tank Pressure Cap.

14. Fill the ReservoirTank until theAdd Fluid Light

goes out and replace the ReservoirTank Cap.

15. Ensure there are no leaks around the ttings

of the new hose.

16. Remove power from the unit.

17. Reverse the POWER HEAD LID removal

procedure to reinstall the Power Head Lid.

18. Reverse the SIDE PANEL removal procedure

to reinstall the applicable side panel.

19. Restore power to the unit and check it for

proper operation. It may be necessary to add

additional uid after the unit has operated for

several minutes.

20. After the unit has operated for several minutes

remove the Side Panel where the hose was

replaced and ensure that it is not leaking.

Tighten as necessary.

21. Reattach the removed Side Panel.

Fluid Level Probes

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this

procedure can cause

property damage, injury or death.

WARNING

Certain components may be hot if the

unit was in operation prior to performing

a procedure. Allow the unit to cool before

beginning work.

WARNING

Before servicing the plumbing system the

heat transfer uid must be drained from

the system.

There are two Fluid Level Probes.One is installed

in the Heater Tank and the other is installed in

the Reservoir Tank. Before changing either of the

probes, check the uid levels in the Heater and

the Reservoir Tanks. Also, check the electrical

connection to the probes. The probes should test

as open with a continuity test when the tanks are

lled with uid.With an empty tank the probe should

test as closed during a continuity test.

1. Perform the ELECTRICAL LOCKOUT/

TAGOUT procedure.

2. Perform the POWER HEAD LID removal

procedure.

3. Perform the SIDE PANEL removal procedure

to remove the left side panel.

4. Locate the Drain Tube and place it into an

empty pan.

5. Remove the HeaterTank Cap and the Reservoir

Cap.

6. Open the DrainValve to drain the HeatTransfer

Fluid.

7. Discard the drained uid. Refer to the Heat

Transfer Fluid Material Safety Data Sheet

— 19 —

provided at the end of this manual for proper

disposal of the uid.

Fluid

Sensor

Probes

Figure 19: Fluid Level Probe Removal

8. Disconnect the Fluid Level Probe lead.

9. Remove the defective probe.

10. Install the new probe.

11. Reconnect the probe lead.

12. Restore power to the unit.

13. Close the uid Drain Valve.

14. Fill the Heater Tank and Reservoir Tank with

uid until the Low Fluid Light goes out.

15. Ensure that are no leaks around the newly

installed probe, tighten as needed.

16. Remove power from the unit.

17. Reverse the POWER HEAD LID removal

procedure to reinstall the Power Head Lid.

18. Reverse the SIDE PANEL removal procedure

to reinstall the panel.

19. Restore power to the unit and verify the unit

is operating correctly. It may be necessary to

add additional uid after the unit has operated

for several minutes.

SNAP DISC

WARNING

Before removing any sheet metal panels or

servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure.

Be sure all circuits are disconnected. Failure

to comply with this

procedure can cause

property damage, injury or death.

WARNING

Certain components may be hot if the

unit was in operation prior to performing

a procedure. Allow the unit to cool before

beginning work.

WARNING

Before servicing the plumbing system the

heat transfer uid must be drained from

the system.

The Snap Disc is located on the Heater Tank and

provides over-temperature protection for the unit.

1. Perform the ELECTRICAL LOCKOUT/

TAGOUT procedure.

2. Perform the POWER HEAD LID removal

procedure.

3. Perform the SIDE PANEL removal procedure

to remove the left side panel.

4. Locate the Drain Tube and place it into an

empty pan.

5. Remove Heater Tank Cap and Reservoir Cap.

6. Open the Drain Valve to drain the Heat

Transfer Fluid.

7. Discard the drained uid. Refer to the Heat

Transfer Fluid Material Safety Data Sheet

provided at the end of this manual for proper

disposal of the uid.

8. Tag and disconnect the Snap Disc wires.

— 20 —

Heater Tank

Cap Reservoir

Cap

Snap Disk

Figure 20: Snap Disc Location and Removal

9. Remove the defective Snap Disc.

10. Install the new Snap Disc.

11. Refer to the tags or the wiring schematic to

reconnect the wires to the new Snap Disc.

12. Restore power to the unit.

13. Close the uid Drain Valve.

14. Fill the Heater Tank and Reservoir Tank with

uid until the Low Fluid Light goes out.

15. Ensure that are no leaks around the newly

installed probe, tighten as needed.

16. Remove power from the unit.

17. Reverse the POWER HEAD LID removal

procedure to reinstall the Power Head Lid.

18. Reverse the SIDE PANEL removal procedure

to reinstall the panel.

19. Restore power to the unit and verify the unit

is operating correctly. It may be necessary to

add additional uid after the unit has operated

for several minutes.

THERMOCOUPLE

The Thermocouple is located on the Heater Tank.

NOTICE: In BW5SNDNL models the B&G Pump

and Heater Tank are located at the back of the

unit. Removal of the Back Panel is required

when servicing the B&G Pump or Heater Tank

Components.

1. Follow the LOCKOUT/TAGOUT procedure

using the procedures provided in the Lockout/

Tagout Procedures section of this manual.

2. Remove the Power Head Lid following the

instructions provided in the Panels and Covers

section of this manual.

3. Remove theleft side panelusingthe procedures

provided in the Panels and Covers section of

this manual.

4. Locate the Drain Tube and place it into an

empty pan.

5. Remove the Heater Tank Cap and the

Reservoir Cap.

6. Open the Drain Valve to drain the Heat

Transfer Fluid.

7. Discard the drained uid; refer to the Material

Safety Data Sheet provided in this manual for

proper disposal of uid.

8. The TBC-41 Controller is very easy to remove.

There are four springs and spacers apiece

holding the display and power boards. They

are different lengths: the spacers used with

the power board are 1/2" (12.7mm) long; the

springs used with the display board are 5/16"

(8mm) long.

Springs (4)

1/2"(12.7mm)

Spacers(4)

Figure 21: Controller

9. Note the location of and colors of the

Thermocouple wires on the Controller.

10. Remove the wires for the Controller terminals.

11. Remove the Thermocouple from the Heater

Tank.

This manual suits for next models

7

Table of contents