Electro Industries SM1-16 User manual

SubstationMultiplexor

SM1-16

with

ETHERNET OPTION

Electro Industries/GaugeTech

Installation & Operation Manual

Revision 1.01

August 14, 2002

Doc # E113-7-07-101

1800 Shames Drive

Westbury, New York 11590

Tel: 516-334-0870 Fax: 516-338-4741

“The Leader in Web Accessed Power Monitoring ”

Substation Multiplexor SM1-16

with Ethernet Option

User Manual

Revision 1.01

Published by:

Electro Industries/GaugeTech

1800 Shames Drive

Westbury, NY 11590

All rights reserved. No part of this

publication may be reproduced or

transmitted in any form or by any

means, electronic or mechanical,

including photocopying, recording,

or information storage or retrieval

systems or any future forms of

duplication, for any purpose other

than the purchaser’s use, without the

expressed written permission of

Electro Industries/GaugeTech.

© 2002

Electro Industries/GaugeTech

Printed in the United States of

America.

eElectro Industries/GaugeTech Doc # E113-7-07-101 I

eElectro Industries/GaugeTech Doc # E113-7-07-101 II

Customer Service and SupportCustomer Service and Support

Customer support is available 9:00 am to 4:30 pm, eastern standard time, Monday through Friday.

Please have the model, serial number and a detailed problem description available. If the problem

concerns a particular reading, please have all meter readings available. When returning any merchandise

to EIG, a return authorization number is required. For customer or technical assistance, repair or

calibration, phone 516-334-0870 or fax 516-338-4741.

Product WarrantyProduct Warranty

Electro Industries/GaugeTech warrants all products to be free from defects in material and workmanship

for a period of four years from the date of shipment. During the warranty period, we will, at our option,

either repair or replace any product that proves to be defective.

To exercise this warranty, fax or call our customer-service department. You will receive prompt

assistance and return instructions. Send the instrument, transportation prepaid, to EIG at 1800 Shames

Drive, Westbury, NY 11590. Repairs will be made and the instrument will be returned.

Limitation of WarrantyLimitation of Warranty

This warranty does not apply to defects resulting from unauthorized modification, misuse, or use for any

reason other than electrical power monitoring.

OUR PRODUCTS ARE NOT TO BE USED FOR PRIMARY OVER-CURRENT

PROTECTION. ANY PROTECTION FEATURE IN OUR PRODUCTS IS TO BE USED FOR

ALARM OR SECONDARY PROTECTION ONLY.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. ELECTRO INDUSTRIES/GAUGETECH

SHALL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL OR CONSEQUENTIAL

DAMAGES ARISING FROM ANY AUTHORIZED OR UNAUTHORIZED USE OF ANY

ELECTRO INDUSTRIES/GAUGETECH PRODUCT. LIABILITY SHALL BE LIMITED TO

THE ORIGINAL COST OF THE PRODUCT SOLD.

Statement of CalibrationStatement of Calibration

Our instruments are inspected and tested in accordance with specifications published by Electro

Industries/GaugeTech. The accuracy and a calibration of our instruments are traceable to the National

Institute of Standards and Technology through equipment that is calibrated at planned intervals by

comparison to certified standards.

DisclaimerDisclaimer

The information presented in this publication has been carefully checked for reliability; however, no

responsibility is assumed for inaccuracies. The information contained in this document is subject to

change without notice.

eElectro Industries/GaugeTech Doc # E113-7-07-101 III

About Electro Industries/GaugeTechAbout Electro Industries/GaugeTech

Electro Industries/GaugeTech was founded in 1973 by Dr. Samuel Kagan. Dr. Kagan’s first innovation,

an affordable, easy-to-use AC power meter, revolutionized the power-monitoring field. In the 1980s Dr.

Kagan and his team at EIG developed a digital multifunction monitor capable of measuring every aspect

of power. EIG further transformed AC power metering and power distribution with the Futura+ device,

which supplies all the functionality of a fault recorder, an event recorder and a data logger in one single

meter. Today, with the Nexus 1250 and a wide variety of dependable solutions, EIG is a leader in the

development and production of power-monitoring products. All EIG products are designed,

manufactured, tested and calibrated at our facility in Westbury, New York.

EIG Product Applications

nMultifunction power monitoring

nSingle and multifunction power monitoring

nPower-quality monitoring

nOnboard data logging for trending power usage and quality

nDisturbance analysis

Nexus 1250

n0.04% Watt-hour Accuracy

nExpandable I/O and Trending

nDemand Integration Intervals

nHarmonics to the 127th Order

Futura+ Series

nPower-quality monitoring

nHigh-accuracy AC metering

nOnboard data logging

nOnboard fault and voltage recording

DM Series

nThree-phase multifunction monitoring

nWattage, VAR and amperage

nModbus, Modbus Plus, DNP 3.0 and Ethernet protocols

nAnalog retransmit signals (0–1 and 4–20mA)

Single-Function Meters

nAC voltage and amperage

nDC voltage and amperage

nAC wattage

nSingle-phase monitoring with maximum and minimum demands

nTransducer readouts

Portable Analyzers

nPower-quality analysis

nEnergy analysis

Table

of

Contents

Chapter 1: Ethernet Option Installation

1.1: Mounting Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2: Communication Connections . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3: RS232 Wiring Details . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4: RS485 Wiring Details . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.5: Communication Overview . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.6: Connecting the Substation Multiplexor Directly to a Computer . . . . . . . . . 1-11

1.7: Connecting to the Substation Multiplexor Using the Internal Modem . . . . . . 1-11

1.8: Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Chapter 2: Ethernet Option Configuration

2.1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2: Ethernet Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3: Ethernet Option Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.4: Default IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.5: AutoIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.6: Setting the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.7: Networking Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.8: Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3: Ethernet Option Operation

3.1: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2: Alternate Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3: Using Windows®HyperTerminal with the Substation Multiplexor . . . . . . . . 3-3

3.4: Using EIG’s Futura Communicator with the Substation Multiplexor . . . . . . . 3-6

3.5: Command Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.6: Port Program Commands . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.7: Port Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.8: Unit Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.9: Site ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.10: Go to Throughput Mode . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.11: Go to Boot Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.12: Go to Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.13: Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.14: Contact Information for EIG . . . . . . . . . . . . . . . . . . . . . . . 3-14

Electro Industries/GaugeTech

Doc # E113-7-07-101 IV

Electro Industries/GaugeTech

Doc # E113-7-07-101 1-1

Chapter

1

Ethernet

Option

Installation

1.1:

Mounting

Information

QThe Substation Multiplexor with Ethernet Option is designed to mount in a standard, 19-inch panel

rack. Mounting for all Substation Multiplexors is the same, regardless of option selection. Use a #10

screw in each of the four slots on the flange to ensure that the unit is installed securely.

TToopp

VViieeww

Electro Industries/GaugeTech

Doc # E113-7-07-101 1-2

FFrroonntt

VViieeww

Electro Industries/GaugeTech

Doc # E113-7-07-101 1-3

SSiiddee

VViieeww

Electro Industries/GaugeTech

Doc # E113-7-07-101 1-4

Master Port for Ethernet

Standard RJ45. Set the

232(DCE) Network Switch

to Network when using

Ethernet.

Slave Ports 1 & 2

2-wire RS485

232(DCE) Network Switch for Master Port

When using Ethernet, set to Network.

When connecting directly to a computer from the RS232

Master Port, set to 232 (DCE).

Slave Ports 3–16

9-pin female RS232 ports.

Use a standard RS232 cable.

Power Supply

Relay (Detail)

Master Port RS232

For direct connection to a

computer.

BBaacckk

PPaanneell

1.2:

Communication

Connections

•All Slave Ports are factory-set to operate at 9600 baud and

the Master Ports are factory-set to operate at 57600 baud.

•The maximum baud rate for all Slave Ports is 57600.

••The baud rate for a Master Port is 57600.

Com

N.O.

N.C.

Electro Industries/GaugeTech

Doc # E113-7-07-101 1-5

Slave Port LEDs

Shows which Slave Port the Multiplexor is programmed to use.

FFrroonntt

PPaanneell

Network Link LED

RxD/TxD/RTS LEDs

RxD/TxD LEDs illuminate when the

unit is Receiving or Transmitting Data.

Power Indicator

Electro Industries/GaugeTech

Doc # E113-7-07-101 1-6

1.3:

RS232

Wiring

Details

QRS232 communication is capable for a distance up to 50 feet (15.2 m). The Master Port and Slave

Ports 3–16 are 9-pin female RS232 ports. Use standard RS232 extension cables for all RS232

connections.

QThe RS232 Master Port enables the Substation Multiplexor to communicate directly with a computer

or connect to an external modem. The Master Port is DCE or DTE selectable. Set the switch beneath

the port to:

•DTE when using a modem (internal or external).

•DCE when connecting the Substation Multiplexor directly to a computer.

RS232

Female

Port

QSlave Ports 3–16 are DTE configured. When connecting an RS232 Slave Port to another DTE

device, use a Null Modem to reverse the Rx and Tx pins, as shown below:

RS232 Slave Port Pin

Assignments

PIN DTE

1 N/A

2Rx

3Tx

4 DTR

5 Gnd

6 DSR

7RTS

8 CTS

9 N/A

RS232 Master Port

Pin Assignments

PIN DTE DCE

1 DCD DCD

2Rx Tx

3Tx Rx

4 DTR DSR

5 Gnd Gnd

6 DSR DTR

7 RTS CTS

8 CTS RTS

9 Ring Ring

Shorted Internally

Electro Industries/GaugeTech

Doc # E113-7-07-101 1-7

1.4:

RS485

Wiring

Details

QRS485 communication allows multiple devices to communicate on a bus. The Substation

Multiplexor’s Slave Ports 1 and 2 are 2-wire RS485 terminals, capable for a distance of up to 4000

feet (1219 meters).

•Use a shielded, twisted pair cable, AWG 22 (0.33 square mm) or larger.

•Establish point-to-point configurations for each device on a RS485 bus: Connect (+) terminals to

(+) terminals; connect (-) terminals to (-) terminals.

•Protect cables from sources of electrical noise.

•Avoid both “star” and “tee” connections (see diagrams on the following pages). No more than

two cables should be connected at any one point on an RS485 network, whether the connections

are for devices, converters or terminal strips.

•Include all segments when calculating the total cable length of a network. If you are not using an

RS485 repeater, the maximum length for cable connecting all devices is 4000 feet (1219 meters).

•Connect devices using the diagrams on the following pages. A correct connection requires 1/4

watt resistors connected to the (+) and (-) terminals of each device at the end of a straight-line

bus. The line impedance of the cable and the resistor should match. Generally, a 100- or

120-Ohm resistor will work.

Electro Industries/GaugeTech

Doc # E113-7-07-101 1-8

Correct Connection

Electro Industries/GaugeTech

Doc # E113-7-07-101 1-9

Incorrect Connection: “T”

Incorrect Connection: “Star”

“Star” Connection Incorrect!

The three wires connected in a

“Star” shape on both the (+) and

(-) terminals will cause interfer-

ence problems.

RS485 Ports

RS485 Port

“Tee” Connection Incorrect!

The three wires connected in a

“T” shape on both the (+) and (-)

terminals will cause interference

problems.

Electro Industries/GaugeTech

Doc # E113-7-07-101 1-10

1.5:

Communication

Overview

Electro Industries/GaugeTech

Doc # E113-7-07-101 1-11

1.6:

Connecting

the

Substation

Multiplexor

Directly

to

a

Computer

1. Use an RS232 cable to connect the Substation Multiplexor’s Master Port to an available RS232 port

on the computer.

2. Set the 232(DCE)Network switch beneath the Master Port to 232(DCE).

3. The Master Port is factory-set to operate at 57600 baud. To configure and communicate with the

Substation Multiplexor, run a standard terminal program on the computer, such as Windows

HyperTerminal. See Chapter 4 for details.

1.7:

Connecting

to

the

Substation

Multiplexor

Using

the

Ethernet.

1. Connect an RJ-45 cable to the Substation Multiplexor’s RJ-45 jack.

2. Set the 232(DCE) Network switch beneath the Master Port to Network.

3. Use a standard terminal program on the computer, such as Windows®HyperTerminal, to connect to

the Substation Multiplexor and configure it. See Chapter 4 for details.

4. The Ethernet Port is factory-set to operate at 57600 baud. You should keep the port set to 57600 after

you have connected.

Electro Industries/GaugeTech

Doc # E113-7-07-101 1-12

1.8:

Technical

Specifications

Interface

RS232 & RS485 Asynchronous 8 data bits, no parity, 1 stop bit

Network RJ-45 (10BASE-T)

Connectors

Slave Ports 1 & 2 Half-duplex RS485

Slave Ports 3–16 DB-9F DTE type RS232

Master Port RS232/DCE type

Ethernet Port RJ-45 type

Size 3.5” (8.8 cm)H x 19.0” (48.26 cm)W x 8.08” (20.52 cm)D

Weight 12 lbs (5.4kg)

LEDs Power, Network Link, Data Activity of Slave Ports (RxD, TxD, RTS)

Data Rate 600–57.6k BPS; All standard rates, port specific

Signals Supported

Master Port/Ethernet TxD, RxD

Slave Ports (1–16) TxD, Rxd, CTS, RTS

Flow Control

Master Port None

Slave Ports (1–16) RTS/CTS or none (port specific)

Reset Time No Reset, 5 minutes, 10 minutes

Buffer Size Two 16k buffers

Isolation 1500 Vdc

Control Power Options

Suffix -115A 115 Vac +/-20%

Suffix -D2 125 Vac/dc +/-20%

Suffix -D 24–48 Vdc +/-20%

Suffix -230A 230 Vac +/-20%

Control Power Burden 10VA Maximum

Operating Temperature -20 to +70°C

Humidity Up to 95% non-condensing

Electro Industries/GaugeTech

Doc #: E113-7-07-101 2-1

Chapter

2

Ethernet

Option

Configuration

2.1:

Introduction

QThe Ethernet Option gives the user the capability of integrated network connectivity to multiple

devices over Ethernet. This chapter will give the user an overview of how the Ethernet Option

works. Detailed here are the main components of an Ethernet interface and how they are configured.

2.2:

Ethernet

Module

QThe Ethernet connection is made with a small module which is embedded in the meter. This small

but powerful module has an RJ-45 Port and the Network Link LED on the front panel tells you when

the unit is connected to the network and is sending and receiving data. When the unit is active, you

actually hear distinct clicking sounds as the Ethernet module does its job.

2.3:

Ethernet

Option

Setup

QThis chapter covers the required steps to get the Ethernet Interface on-line and working. There is

only one method used to log into the Ethernet Server and set up the IP address:

•Network Port Login: make a Telnet connection to the network port (9999).

QIt is important to consider the following points before logging into and configuring the Ethernet

Interface:

•The Ethernet Interface's IP address must be configured before a network connection is available.

•Only one person at a time may be logged into the network port. This eliminates the possibility

of several people trying to configure the Ethernet Interface simultaneously.

2.4:

Default

IP

Address

QThe Ethernet Interface ships with a default IP address set to 0.0.0.0, which automatically enables

DHCP within the Ethernet Interface.

Provided a DHCP server exists on the network, it will supply the Ethernet Interface with an IP

address, gateway address and subnet mask when the Ethernet Interface boots up. If no DHCP

server exists, the Ethernet Interface will respond with a diagnostic error: the Network Link LED

blinks five times.

Electro Industries/GaugeTech

Doc #: E113-7-07-101 2-2

2.5:

AutoIP

QAutoIP allows an Ethernet Interface to obtain an address in a network that does not have a DHCP

server. Windows 98 and 2000 also support AutoIP.

AutoIP assigns a random valid address to the Ethernet Interface in the range of 169.254.x.1 to

169.254.x.1 (x can be between 0 and 255). This range of IP addresses is not to be used over the

Internet. If the Ethernet Interface has not been configured manually and cannot find a DHCP server,

it automatically chooses an address from the reserved range. The Ethernet Interface then uses the

Address Resolution Protocol (ARP) to send out a request asking if any node is using that address.

If another node is using the same address, the Ethernet Interface assigns another IP address, reboots

and repeats the sequence.

NOTE: AutoIP-enabled Ethernet Interfaces are constantly looking for DHCP servers. If a DHCP

server becomes available on the network, the AutoIP-enabled Ethernet Interface switches to the

DHCP server-provided address and the unit reboots. If the DHCP server exists but denies the

Ethernet Interface an IP address, the Ethernet Interface does not attach to the network, but waits and

retries.

•AutoIP allows a small network of AutoIP-enabled devices to be set up without any need for a

DHCP server or static IP addresses.

•AutoIP can be disabled be setting the IP address to 0.0.1.0. The 1 in the third octet is the

disabling factor.

2.6:

Setting

the

IP Address

QThe Ethernet Interface's IP address must be configured before a network connection is available. If

the IP address was not set automatically via DHCP, set it now using a network and the setup

(configuration) menu.

QNETWORK PORT LOGIN

The ARP method is available under UNIX and Windows-based systems. The Ethernet Interface will

set its address from the first directed TCP/IP packet it receives.

QARP ON UNIX

On a Unix host, create an entry in the host's ARP table using the intended IP address and the

hardware address of the Ethernet Interface, which is found on the product label.

arp -s 135.15.173.121.00:20:4a:xx:xx:xx

Electro Industries/GaugeTech

Doc #: E113-7-07-101 2-3

QARP ON WINDOWS

In order for the ARP command to work on Windows, the RP table on the PC must have at least one

IP address defined other than its own. If the ARP table is empty, the command will return an error

message. Type ARP -A at the DOS command prompt to verify that there is at least one entry in the

ARP table.

If the local machine is the only entry, ping another IP address on your network to build a new entry

in the ARP table; the IP address must be a host other than the machine on which you are working.

Once there is at least one additional entry in the ARP table, use the following command to ARP the

IP address to the Ethernet Interface:

QTELNET TO PORT 1

Now open a Telnet connection to Port 1. The connection will fail quickly (3 seconds). But the

Ethernet Interface will temporarily change its IP address to the one designated in this step.

QTELNET TO PORT 9999

Finally, open a Telnet connection to port 9999 and set all required parameters.

NOTE: This IP address is temporary and will revert to the default value when the Ethernet

Interface's power is reset, unless you log into the Ethernet Interface and store the changes

permanently.

2.7:

Networking

Configuration

QCertain parameters must be configured before the Ethernet Interface can function on a network. The

Ethernet Interface can be locally or remotely configured using the following procedures:

Use a Telnet connection to configure the unit over the network. The Ethernet Interface's

configuration is stored in nonvolatile memory (NVRam) and is retained without power. The

configuration can be changed at any time. The Ethernet Interface performs a reset after the

configuration has been changed and stored.

As mentioned above, to configure the Ethernet Interface over the network, establish a Telnet

connection to port 9999. From the Windows Start menu, click Run and type the following

command, where x.x.x.x is the IP address and 9999 is the Ethernet Interface's fixed network

arp -s 135.15.173.121 00-20-4a-xx-xx-xx

telnet 135.15.173.121 1

telnet 135.15.173.121 9999

Table of contents

Popular Multiplexer manuals by other brands

Sanyo

Sanyo MPX-MS92P instruction manual

Pickering

Pickering 20-610 user manual

Patton electronics

Patton electronics Multiport Asynchronous Statistical Multiplexer... Getting started guide

C&H

C&H 24 Channel 1x4 Multiplexer Module VX415C Specifications

Keithley

Keithley 7014 manual

Pantron

Pantron IMX-A832I manual

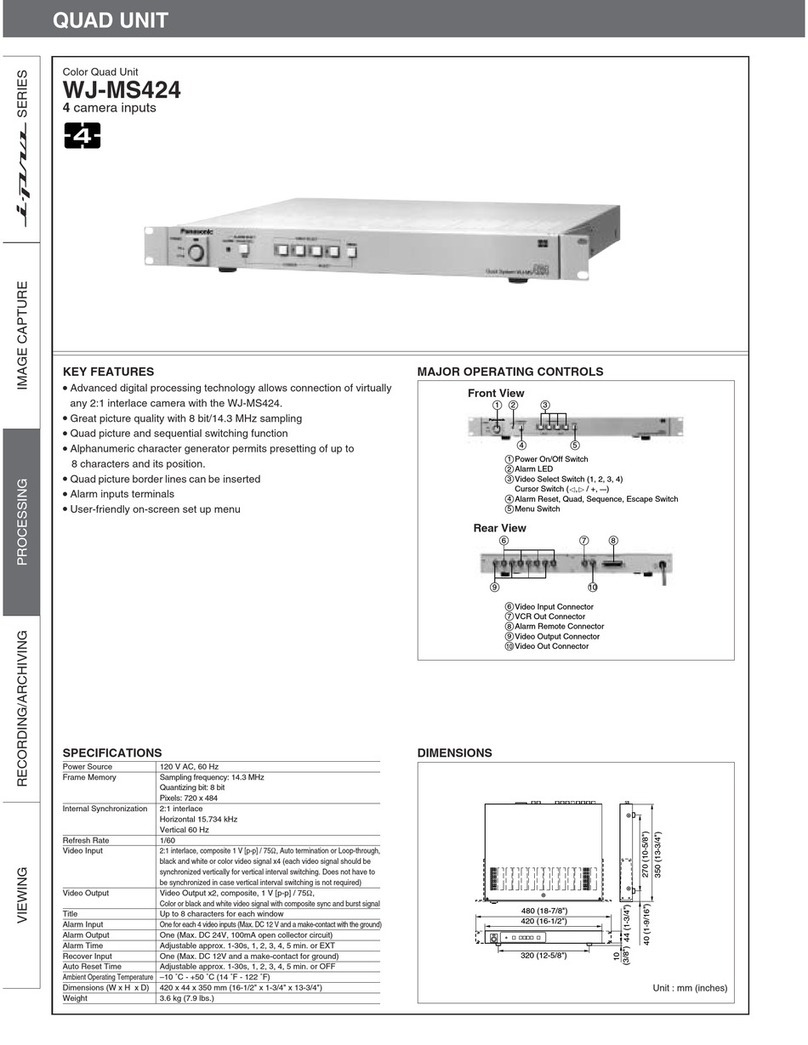

Panasonic

Panasonic WJMS424 - QUAD UNIT Specifications

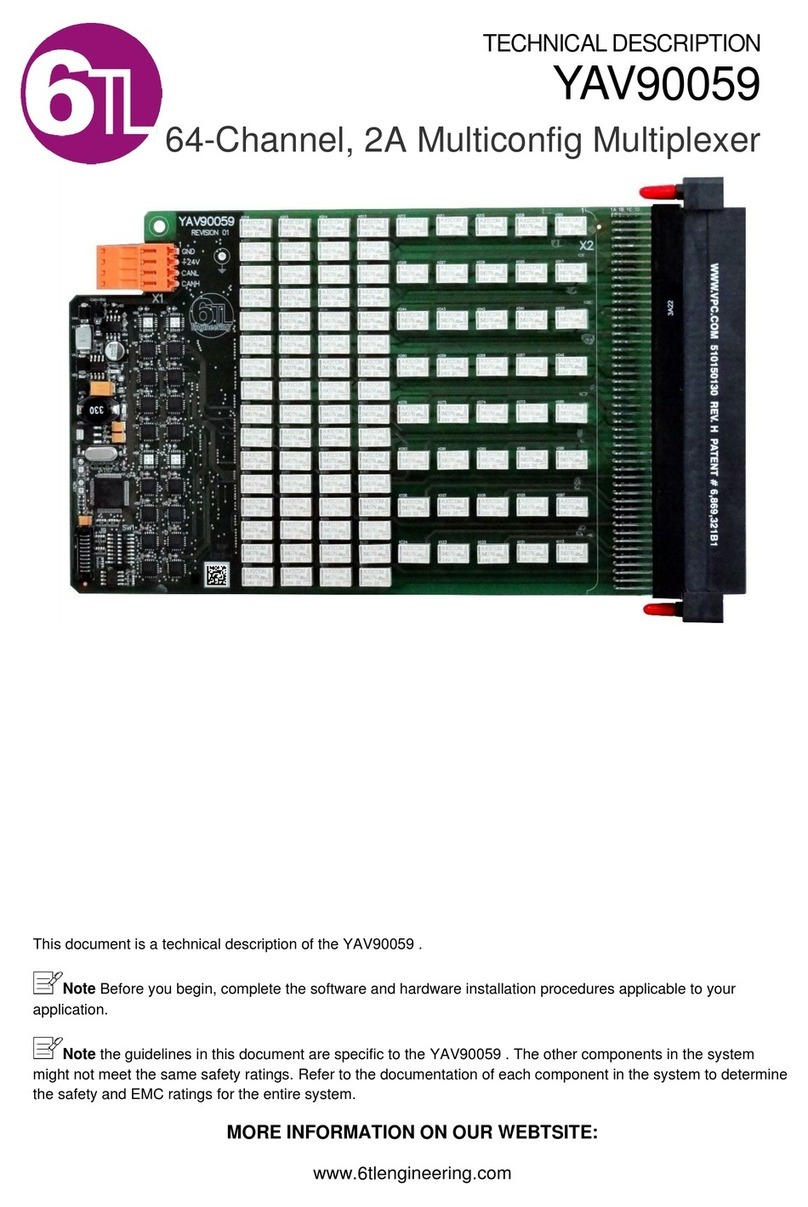

6TL

6TL YAV90059 Technical description

Philips

Philips LTC 2600 Series Quick reference guide

ADTRAN

ADTRAN TSU 610 user manual

Net to Net Technologies

Net to Net Technologies 12-Port VoSHDSL Access Multiplexer... user guide

Alcatel-Lucent

Alcatel-Lucent 7330 Product information guide