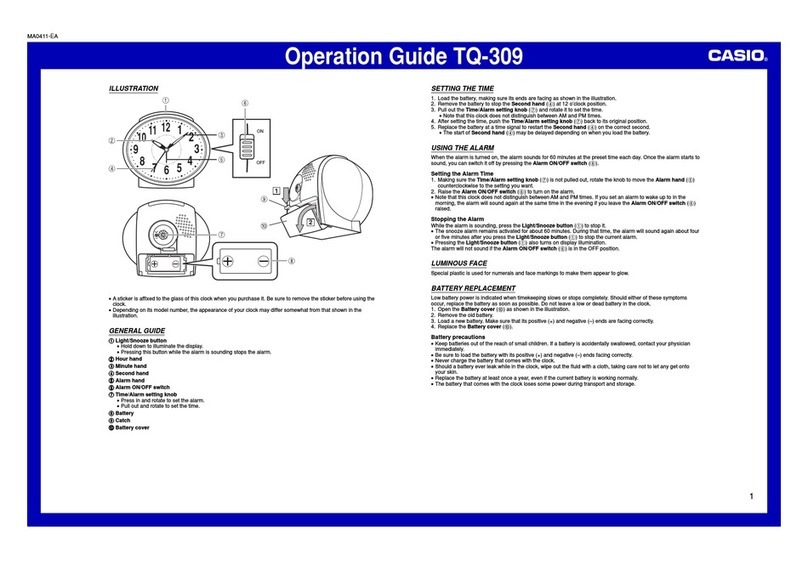

Electro-mech LX7406 User manual

Model LX7406

Owner's Manual

Indoor Locker Room Clock

The purpose of this manual is to explain how to install and maintain the Electro-Mech

Model LX7406 Indoor Locker Room Clock. Operation of the clock is covered in the

manual that ships with the control console for the main scoreboard display.

Original Filename: LX7406_Owner

Document Version: 1.6

Document Date: February 21, 2019

LX7406 Owner's Manual Revised February 21, 2019

Page 2 800.445.7846 · www.electro-mech.com

TABLE OF CONTENTS

Best Practices for Personal Safety and Product Care..................................................... 3

Product Specifications..................................................................................................... 4

Planning Your Scoreboard Installation ............................................................................ 6

Electrical Installation........................................................................................................ 8

Mechanical Installation.................................................................................................. 12

Testing, Operation, and Ongoing Care.......................................................................... 14

Maintenance.................................................................................................................. 15

Limited Warranty Statement.......................................................................................... 21

Revised February 21, 2019 LX7406 Owner's Manual

www.electro-mech.com · 800.445.7846 Page 3

BEST PRACTICES FOR PERSONAL SAFETY AND PRODUCT CARE

Thank you for choosing Electro-Mech products for your athletic facility. We hope you

will be pleased with the performance and appearance of your locker room clock. The

information in this document will help you maintain the equipment in its best condition.

Receiving Your Locker Room Clock

A locker room clock cabinet typically ships in a cardboard box. It is important to inspect

the packaging for damage when the cabinet arrives ─before signing any paperwork

telling the trucking company that you have received the clock in good condition. If

damage has occurred to the packaging, then damage may have occurred to the clock.

Where you find dents, scrapes, or holes in the packaging, peel back the cardboard to

expose the cabinet. Make notes on the paperwork provided by the trucking company

before accepting delivery. If the damage appears to be severe, refuse the shipment.

Contact Electro-Mech as soon as possible if you suspect shipping damage.

We recommend keeping the locker room clock cabinet in its packaging until the day of

installation. It is important to keep the box dry while the clock is inside. Wet cardboard

can adhere to the surface and damage the finish.

Conditions of Installation and Use for an Indoor Locker Room Clock

This locker room clock display is designed for installation and use in a dry environment.

Do not attempt to install or operate a locker room clock outdoors or in a wet location.

An indoor locker room clock display is typically attached to a locker room wall.

Accordingly, the cabinet includes keyhole slots for hanging the display on lag bolts.

(This document uses the term "lag bolt" to generically represent whatever fastener is

best suited for the type of structure on which the clock display will hang – bolts, hooks,

nails, etc.) Whatever method you choose for hanging the display, it is important to

make sure the wall and other materials can support the weight. Vibration may also be a

factor in selecting mounting techniques for locker room clocks.

In its standard configuration, the locker room clock display receives power through its

detachable power cord, which should plug into a 120 VAC electrical outlet. When the

display is not in use, you should disconnect it from power. For this reason, we

recommend installing a dedicated disconnect switch within sight of the locker room

clock display. In the "off" position, the switch should isolate all load-carrying conductors

(not the ground). This will help protect the locker room clock electronics from nearby

lightning strikes and other power fluctuations that might otherwise travel along the

power cables.

LX7406 Owner's Manual Revised February 21, 2019

Page 4 800.445.7846 · www.electro-mech.com

PRODUCT SPECIFICATIONS

General Description:

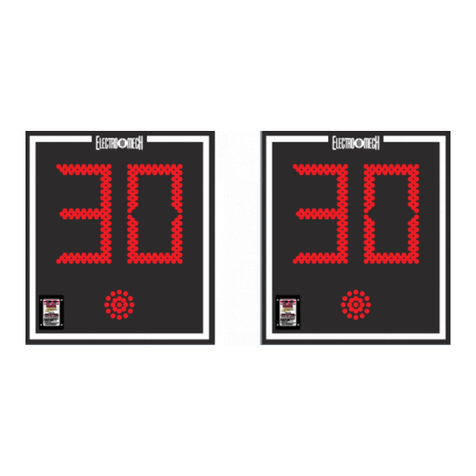

•Model LX7406 is an electronic scoreboard designed for permanent installation

indoors. The purpose of Model LX7406 is to display timing information in the

locker room during games or practice.

Standard Package Includes:

•One scoreboard cabinet

•One detachable power cable for standard configurations

* Note: For configurations with concealed wiring, attach power and data

cables to terminal blocks inside the cabinet.

•One stereo plug tip

Cabinet Dimensions and Weight:

•23 in (W) x 10 in (H) x 4 in (D), 12 lb

Cabinet Construction and Finish:

•The cabinet is formed from sheet aluminum and finished with black enamel paint.

Optional vinyl accent striping is available in eighteen standard colors.

Overview of LED Display Circuit Boards:

•Red LEDs (light emitting diodes) mounted on PCBs (printed circuit boards) form

all lighted digits. The illuminated PCBs are mounted behind the face of the

scoreboard cabinet. The face allows the epoxy shells of the LEDs to protrude,

maximizing viewing angle while providing impact-absorbing protection from

contact with stray balls and other flying objects. The LEDs may be dimmed to

reduce glare during night games. They are rated for 100,000 hours of use.

Display Features:

•4-Digit Period Clock, 6 inches tall, shows Time in MM:SS up to 99:59, counts up

or down, can show Tenths of Seconds during the final minute of a down-counting

Period, can show HH:MM in Time of Day Mode

Additional Standard Scoreboard Features:

•All serviceable components accessible from the front of the cabinet

•Integrated keyhole slots for hanging the display

Revised February 21, 2019 LX7406 Owner's Manual

www.electro-mech.com · 800.445.7846 Page 5

Optional Equipment and Features:

•Data cable for hard-wired installations

•ScoreLink RF communications system for wireless data transmission

* Receiver must be positioned with line of sight to transmitter

•MP-series control console

•Hard carrying case for control console and accessories

Power Requirements:

•The LX7406 locker room clock requires one circuit providing 0.3 amps, 120 VAC,

60 Hz.

•The detachable power cord shipped with standard configurations must be

plugged into a standard (NEMA 5-15R) power receptacle.

•Electro-Mech recommends installing a dedicated breaker to control power to the

locker room clock.

Mounting Requirements:

•Locker room clocks are designed to be mounted on a wall. The cabinet includes

two keyhole slots in the back to accept lag bolts with a maximum shaft diameter

of 3/8 inches.

•Lag bolts should be spaced 18 inches apart from center to center.

Safety Listing, Support, and Warranty Information:

•All LX-series scoreboard displays are ETL Listed to UL Standard 48 for Electric

Signs.

•Electro-Mech offers technical support at no charge over the phone or via the

Internet for the life of the product.

•The standard limited warranty covers factory labor on parts returned to Electro-

Mech within five years of the scoreboard's date of invoice.

•Additional support plans are available.

•The complete standard warranty statement is included near the end of this

document available.

LX7406 Owner's Manual Revised February 21, 2019

Page 6 800.445.7846 · www.electro-mech.com

PLANNING YOUR SCOREBOARD INSTALLATION

A good plan is important to the success of any project, and installing a locker room

clock is no exception. An important first step in planning for your locker room clock is

determining the optimal location. Key factors here are visibility and accessibility.

By "accessibility" we mean the ease with which you can get people, equipment, cabling,

etc. to the locker room clock display during installation, as well as ease-of-access for

future service. If you position a clock so that using a lift or ladder to reach it is

impractical, you will almost certainly add cost to the installation and to service calls.

By "visibility" we mean the ease with which players, coaches, and/or the scoreboard

operator can see the display. Most locker room clock displays are mounted on locker

room walls or other structures. Because every sports facility is unique, there is no one-

size-fits-all way to describe the perfect locker room clock location. We can tell you that

the vertical placement of a clock should be high enough to give players and coaches a

clear line of sight over the heads of others but low enough to prevent them from

straining their necks. For safety, you will want to keep the bottom of the cabinet at least

eight feet above the floor (to prevent people from smacking their heads against it).

For some indoor facilities, it is important to make sure people cannot – accidentally or

intentionally – interfere with the locker room clock display or cables connected to it. It is

advisable to keep the display away from direct exposure to showers or other sources of

moisture.

If you are planning for the construction or renovation of a new facility, then you will likely

have more options for locating your locker room clock. In addition, you may be able to

choose helpful positions for electrical outlets, plan for conduits, and control other details

that will make installation, operation, and service easier. Your scoreboard sales rep

should be able to answer questions and offer advice that will help you with these plans.

If you are adding this locker room clock to an existing facility, your options may be more

limited. In some cases, we can modify the clock cabinet to meet special needs. An

obvious example would be accommodating power entry through the back of the cabinet

rather than via the standard power cable on the side. These sorts of details must be

worked out prior to the release of a scoreboard order. Your sales rep can guide you

through the process.

The sections that follow in this document primarily discuss the details of the mechanical

and electrical installation of a single room clock. If your project includes multiple clocks,

scoreboards, or other electronic displays, please check with your scoreboard sales rep

to make sure you have any project-level documentation you may need.

Revised February 21, 2019 LX7406 Owner's Manual

www.electro-mech.com · 800.445.7846 Page 7

Before You Spend Your Time and Money...

Please keep in mind that the dimensions and other details referenced throughout this

document are specific to the standard configuration of this particular locker room clock

model. Before purchasing materials, running cabling, etc. you should verify with the

factory that you have the right documentation for your unique project.

It is possible that a government agency, such as your local city council, will require a

building permit or other documentation and approval forms related to the installation and

operation of your shot clock displays. In some cases the installation plan may require a

stamp from a locally licensed Professional Engineer (P.E.).

LX7406 Owner's Manual Revised February 21, 2019

Page 8 800.445.7846 · www.electro-mech.com

ELECTRICAL INSTALLATION

This section of the manual provides information that is important for locating power

receptacles, running cable, planning for conduit, and other steps needed in preparation

for bringing power and data to a locker room clock display. The final hookups for power

and data will happen after the mechanical installation, but it is wise to plan for key

pieces of the electrical installation prior to physically mounting the cabinet.

If your total scoreboard package includes other special accessories such as a sound

system, electronic message center, or video display, there may be additional cabling

and conduit needed to support this equipment. Please consult the documentation

provided with these items.

The standard configuration of this locker room clock includes a power cable that can be

plugged into a socket on the side of the cabinet. Input and output ports for data are

located here as well. For concealed wiring configurations, power and data cables enter

the cabinet via cutouts in the back. At the factory, it is possible to relocate these

connection points to accommodate special needs. Let your scoreboard sales rep know

about any custom requirements BEFORE we begin building your cabinets.

Revised February 21, 2019 LX7406 Owner's Manual

www.electro-mech.com · 800.445.7846 Page 9

Power Considerations

In standard configuration, each locker room clock display requires a standard (NEMA 5-

15R) AC power receptacle providing 120 VAC at 60 Hz. We recommend providing a

disconnect switch to kill power to this receptacle when the clock is not in use. Here we

will assume that the receptacle is available, or that power is being supplied directly via a

concealed wiring configuration. A Model LX7406 locker room clock draws a maximum of

0.3 amps.

Junction Boxes and Data Cable

In the unusual situation that your locker room clock includes a ScoreLink wireless

communication system, your work is done here. Skip to the next section.

A standard locker room clock usually acquires data as it is daisy-chained from the main

scoreboard display. However, some situations may require one or more junction boxes,

which you should permanently mount to

provide a stable point of termination for the

data cables. The idea is to connect the clock

to a junction box via a patch cable. So the

junction box will need to be mounted near the

clock (usually no more than 10 feet apart). In

many gyms, junction boxes are concealed

inside a larger floor box. They can be flush

mounted on a wall, externally mounted on

bleachers, or positioned anywhere else that

is convenient. Choose a location that is

protected so that the junction boxes and

cables are not likely to be stepped on, tripped

over, or have liquid (or anything else) spilled on them.

It is also important to label your junction boxes. The connectors used for scoreboard

data look very much like the type used in some audio systems. Plugging audio devices

into a scoreboard data line can damage the scoreboard system.

Each junction box ships with a length of cable

soldered to the stereo socket and tucked

inside the box. There should be no need to

solder cable to this socket during the

installation. Instead, splice the wires from the

data cable to the pigtail inside the junction

box, matching colors. The wires in the pigtail

are 22 AWG, and the cable should use the

same size conductors. The installer must

LX7406 Owner's Manual Revised February 21, 2019

Page 10 800.445.7846 · www.electro-mech.com

provide wire nuts, crimp splices, or other means to connect the wires.

The splice point should stay inside the junction box. That is, you want to feed the long

run of data cable into the box rather than pulling the pigtail out. Electro-Mech provides

a strain relief on one side of the junction box to secure the cable. You may choose to

connect conduit directly to the junction box, in which case the strain relief will not be

needed. The junction box is designed to accept 3/4-inch conduit fittings.

We recommend running data cable in conduit from the junction boxes to the shot clock

displays ─especially where the cable would otherwise be exposed. You should never

run data cable in the same conduit as power cable. Having more than one run of

scoreboard data cable in a single conduit is perfectly fine.

One more warning about data cable: Never split or branch the cable. The current loop

signal we use to transmit data to the scoreboard and shot clock displays will behave

unpredictably if it is divided between two destinations. There are other options for

getting synchronized data to two locations, including daisy chaining ─which will be

discussed below. If your facility calls for a more complicated cabling plan, it is best to

work out the details with your scoreboard sales rep prior to installation.

Stereo Plug

In standard configuration, data enters the locker room clock cabinet through a port

located along the side. There are two common methods for bringing the last few feet of

data cable to the clock. One method involves installing a junction box on the wall or

other structure near the display. From here you can run a patch cable to the shot

clock's data input port. The standard clock package does not include extra junction

boxes and patch cables for this type of cable

routing. However, the materials are readily

available from Electro-Mech.

The other method requires the right-angle

stereo plug assembly, which Electro-Mech

provides with all hard-wired indoor scoreboard

packages. In the case of locker room clocks,

there will be two plug assemblies to terminate

the two cable runs required. The assembly

consists of the main plug body, an insulating

sleeve, and a cover.

Revised February 21, 2019 LX7406 Owner's Manual

www.electro-mech.com · 800.445.7846 Page 11

Connecting data cable to the stereo plug requires soldering to two terminals. Slide the

cover and sleeve over the data cable before soldering. The terminal nearer the center

of the plug body connects to the tip of the socket. The black wire from the data cable

should be soldered to this terminal. The terminal that extends further from the center of

the plug body connects to the ring of the plug.

Solder the red wire here. The strain relief tabs

are connected to the shaft of the plug. When

you bend the tabs around the data cable, they

should be in contact with the shielding or the

bare drain wire.

Slide the insulator sleeve over the terminals and

screw the cover in place to complete the

assembly. Now you will be ready to plug the

data cable into the port at the top of the shot

clock cabinet when it is installed.

LX7406 Owner's Manual Revised February 21, 2019

Page 12 800.445.7846 · www.electro-mech.com

MECHANICAL INSTALLATION

This section of the manual describes options for installing locker room clock cabinets. If

your scoreboard project includes customizations or requires other special mounting

considerations, please contact Electro-Mech to request details specific to your project.

If you have unique requirements and would like to change the position or size of our

mounting hardware to accommodate them, we can probably help you out. But we need

to find out BEFORE we start building the cabinet. Let your scoreboard sales rep know

about any special needs as early in the process as possible.

Additional Materials and Tools

Most locker room clock displays are installed on locker room walls. Each locker room

clock cabinet includes a set of keyhole mounting points in the back to facilitate this type

of installation with the back of the display flat against a wall. Other techniques may

more appropriate for hanging the display on other structures. However, for the sake of

clarity and brevity, we will assume a wall. We will further assume that the wall is

capable of supporting the weight of the scoreboard cabinet and any accessories to be

mounted with it.

The wall could be made of cinder blocks, framed with wood and covered in drywall, or

constructed any number of other ways. Because different fasteners are appropriate for

different walls, we cannot specify a particular type of fastener. As previously indicated,

this document uses the term "lag bolt" to generically represent whatever fastener is best

suited for the type of structure on which the scoreboard display will hang. To use the

mounting tabs provided with the scoreboard, you will need two such lag bolts. The

keyhole slots stamped into the back of the display allow for a bolt diameter of 3/8 inches

or less.

In addition to the wall and the two lag bolts, this document also assumes the installer

has access to tools and skills for...

•Working at the height designated for positioning of the scoreboard display

•Anchoring the lag bolts

•Lifting the scoreboard cabinet into position

Revised February 21, 2019 LX7406 Owner's Manual

www.electro-mech.com · 800.445.7846 Page 13

Below are the standard dimensions of an LX7406 locker room clock. Lag bolts

for hanging the clock should be placed 18 inches apart from center to center.

LX7406 Owner's Manual Revised February 21, 2019

Page 14 800.445.7846 · www.electro-mech.com

TESTING, OPERATION, AND ONGOING CARE

After all power, data, and other connections are in place, it is time to test the locker

room clock. Apply power to the locker room clock display first. Although there is no

harm in powering the control console first, powering the clock first should result in the

numeric displays remaining blank. Seeing any LEDs illuminated on a locker room clock

display prior to the availability of data from the control console would indicate a problem

inside of the locker room clock cabinet.

Next, power up the control console. For wired setups, connect any stereo patch cables

to the data output ports on the back of the control console. The other ends of these

patch cables are typically plugged into junction boxes, but may be plugged directly into

the data input port on the side of the locker room clock.

The locker room clock display should begin showing data within a few seconds,

displaying the same information as the clock on the main scoreboard display. The

console buttons that control the main scoreboard clock also control the locker room

clock. For more details about how the control console works, consult the

documentation that ships with it.

Scheduled Testing and Maintenance

The locker room clock does not require scheduled maintenance procedures. However,

it is important to check for problems prior to a game. We recommend running through

the tests described above between two and four weeks prior to the start of a season (or

anytime you plan to use the locker room clock after a gap of more than a month).

During the season, test out the locker room clock the day before each game.

After the Game, and After the Season

Whenever you are not using your locker room clock, use the disconnect switch to cut

power to the display. You should unplug the control console from its power source and

from the data cables as well. It is not necessary to take steps beyond this, even if the

locker room clock will not be used for several months.

Revised February 21, 2019 LX7406 Owner's Manual

www.electro-mech.com · 800.445.7846 Page 15

MAINTENANCE

We hope your scoreboard system provides years of trouble free service. In the event of

a problem, the material that follows will provide some information about contacting

technical support as well as some details about the parts inside your scoreboard

display.

Contacting Technical Support

Our support staff is available via phone or e-mail Monday through Friday 8:00 through

5:00 Eastern. Our web address and phone number is printed at the bottom of this page.

When contacting Electro-Mech for support, it helps to have the scoreboard model

(LX7406) handy as well as the version of the software running on your control console.

If your control console includes an LCD display, you will see the software version flash

briefly (for about three seconds) on the screen when you first apply power. Whether

you have the LCD display or not, you should find on the bottom of the control console a

product label which gives the software version.

If you are reading this manual in search of help with a different scoreboard model, for

outdoor scoreboards, you can find the model number printed on a metal plate attached

to the back of the scoreboard cabinet near where the power enters. For indoor

scoreboards, the model number is usually printed on a label at the top center of the

cabinet near the attachment point for the power cable.

If you are troubleshooting a problem, the most important information to have is an exact

description of which parts of your scoreboard system are working and which parts are

not working. The best person to make contact with our support team is someone who

has seen the problem first hand. Better yet, give us a call when you are there at the

scoreboard display and can walk through a few simple tests with one of our technicians.

Scoreboard problems are rarely so complicated that diagnosing them requires skills

beyond using a screwdriver and a ladder. Similarly, replacing parts is straightforward

process that does not require complex tools or special knowledge.

LX7406 Owner's Manual Revised February 21, 2019

Page 16 800.445.7846 · www.electro-mech.com

Parts Exchange

If, after working with our support staff, you discover that a part needs to be serviced or

replaced, the next step is to send the part to Electro-Mech for repair. During the

warranty period, we repair parts and return them via UPS ground service at no charge.

We can ship parts via overnight service for an additional charge. For work that falls

outside of the warranty terms, we can, upon request, provide an estimate of repair costs

on returned parts before performing the work. The typical turnaround on repair work is

less than three business days

Electro-Mech maintains a supply of common parts for immediate shipment. Some

customers choose to purchase new parts for immediate use and will later send old parts

back to us to be repaired and returned as "backup" stock. In some cases our support

plans include the option for shipping replacement parts to the customer once our

service staff has identified a problem. The customer will then return the damaged part

after receiving the replacement. Electro-Mech requires a valid credit card number

before initiating a shipment of this type. We do not apply charges to the card unless the

customer does not return parts within ten days or if the returned parts require work

outside of our warranty terms.

Our shipping address:

Electro-Mech Scoreboard Co.

72 Industrial Blvd.

Wrightsville, GA 31096

Revised February 21, 2019 LX7406 Owner's Manual

www.electro-mech.com · 800.445.7846 Page 17

Location of Serviceable Parts

All serviceable components are accessible by removing the face of the locker room

clock cabinet. The next section of this document discusses removing and replacing the

illuminated PCB assembly.

* In the unusual situation that your locker room clock includes a ScoreLink wireless data

kit, the receiver unit will be accessible on the bottom right side.

LX7406 Owner's Manual Revised February 21, 2019

Page 18 800.445.7846 · www.electro-mech.com

Illuminated PCB Assemblies

LED assemblies and circuit boards (but not individual LEDs) are field replaceable parts.

Each LED is soldered to a PCB (printed circuit board) which is, in turn, attached to the

metal face of the clock with machine screws. You will need a 1/4-inch nut driver to

remove these screws.

Removing an LED Assembly, Step-By-Step:

•Disconnect power to the locker room

clock cabinet before performing any

service work.

•Remove the machine screws from the

face of the display, leaving for last one

of the screws along the top.

•Support the face piece with one hand

as you remove the final screw.

•Rotate the face so that you can see

the PCB behind it and the cable

connections along the back side.

•Unplug the ribbon cables, and, if present, the power cables from the PCBs.

•Set the LED assembly aside and save the screws for later.

If your purpose in removing the LED assembly was to provide access to the

components behind it, you may skip the next part about removing and replacing the

LED printed circuit board.

The LED circuit board is held to the face by

several nuts, which you can remove using a

3/8-inch nut driver. Be careful to keep the

whole assembly right side up when you

return it to the locker room clock cabinet.

Revised February 21, 2019 LX7406 Owner's Manual

www.electro-mech.com · 800.445.7846 Page 19

Power Supplies and Fuses

In standard configuration, the AC power socket on the side of the locker room clock

serves as the point of entry for power. In the concealed wiring configuration, AC power

enters through the cutouts on the back of the clock cabinet. In this case, the installer

brings the power cable to a terminal block, accessible by removing the digit assembly

from the front of the cabinet. From the power terminal block, or from the back of the AC

socket, the line side of AC passes through a 5-amp fuse on the way to the Mean Well

RSP-320-24 power supply module. This is an AG style fuse, which should only be

replaced with a fuse of the same style and rating.

Power connections are made along a row of screw terminals on one side of the power

supply module. The Mean Well RSP-320-24 module in the cabinet provides 18.9 VDC

to the illuminated digits and driver. If you replace a power supply module, check the

output voltage to make certain it is set to 18.9 VDC.

LX7406 Owner's Manual Revised February 21, 2019

Page 20 800.445.7846 · www.electro-mech.com

LX Driver

LX Driver circuit boards do the work of

interpreting data sent from the control

console to the scoreboard display. Using that

information, the drivers decide which of the

LEDs should be illuminated and which should

not. The single LX Driver in a locker room

clock decodes data representing each digit

used in the scoreboard. The driver sends

signals to the LED circuit boards via ribbon

cables. The table below lists the names and

purposes of the various connectors on the LX

Driver.

LX17 Driver Functions

Connector

Function

J2 (Data In)

N/A (or rarely from ScoreLink)

J3 (Data Out)

To Data Out Socket

J4 (Word 1 Low)

Minutes Ones

J5 (Word 1 High)

Minutes Tens

J6 (Word 2 Low)

Seconds Ones

J7 (DC Power In)

18.9 VDC

J8 (Word 3)

N/A

J9 (Word 2 High)

Seconds Tens

J10 (Word 4)

N/A

J15

N/A

H5/BLK (Data In)

From Data In Socket

H6/RED (Data In)

From Data In Socket

H7/SHLD (Data In)

From Data In Socket

Jumper Pins

X = Shunt Installed

H13 (J4/J5 Blanking)

H16 (J4/J5 Blanking)

X

H14 (J6/J9 Blanking)

H17 (J6/J9 Blanking)

H15 (Not Used)

H18 (Test Prog)

H3 (Horn2 No Dim)

X

H11 (Horn1 No Dim)

X

H19 (Not Used)

H1 (Memory Ret.)

H2 (Group +1)

X

H4 (Bank +2)

H12 (Bank +1)

X

Table of contents

Other Electro-mech Clock manuals

Popular Clock manuals by other brands

L’Epee

L’Epee LA TOUR User instructions

Perel

Perel WC219 user manual

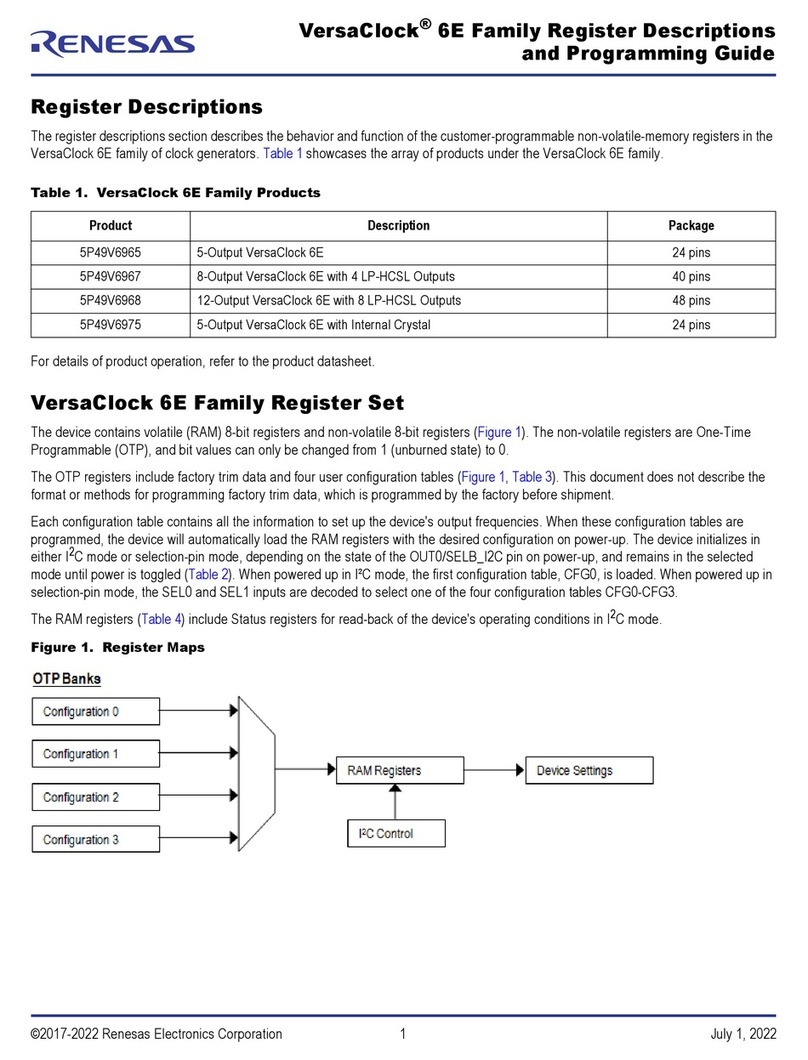

Renesas

Renesas VersaClock 6E Series Register Descriptions and Programming Guide

TMI Products

TMI Products VD54B Technical guide & parts catalogue

WESTERSTRAND

WESTERSTRAND Analogue NTP Clock manual

American Time

American Time Global Series Quick start installation guide