Wiring Diagam

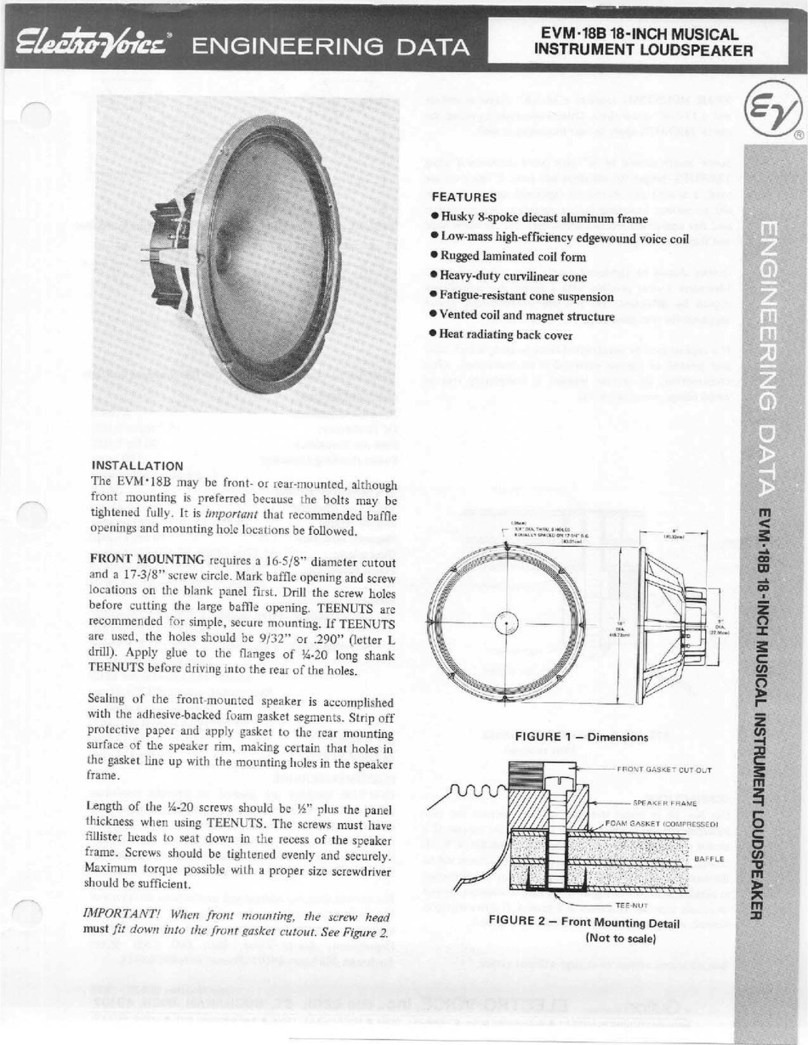

Dimensions

Mounting the System in a Ceiling

Using the T-bar Support Accessories

The Electro-Voice®EP Series ceiling speaker systems have been designed

to accommodate a wide range of ceiling tile and structural ceiling materials.

The spring assemblies can accommodate a range of material thicknesses

from 0.375-inch up to 1.25-inch thick.

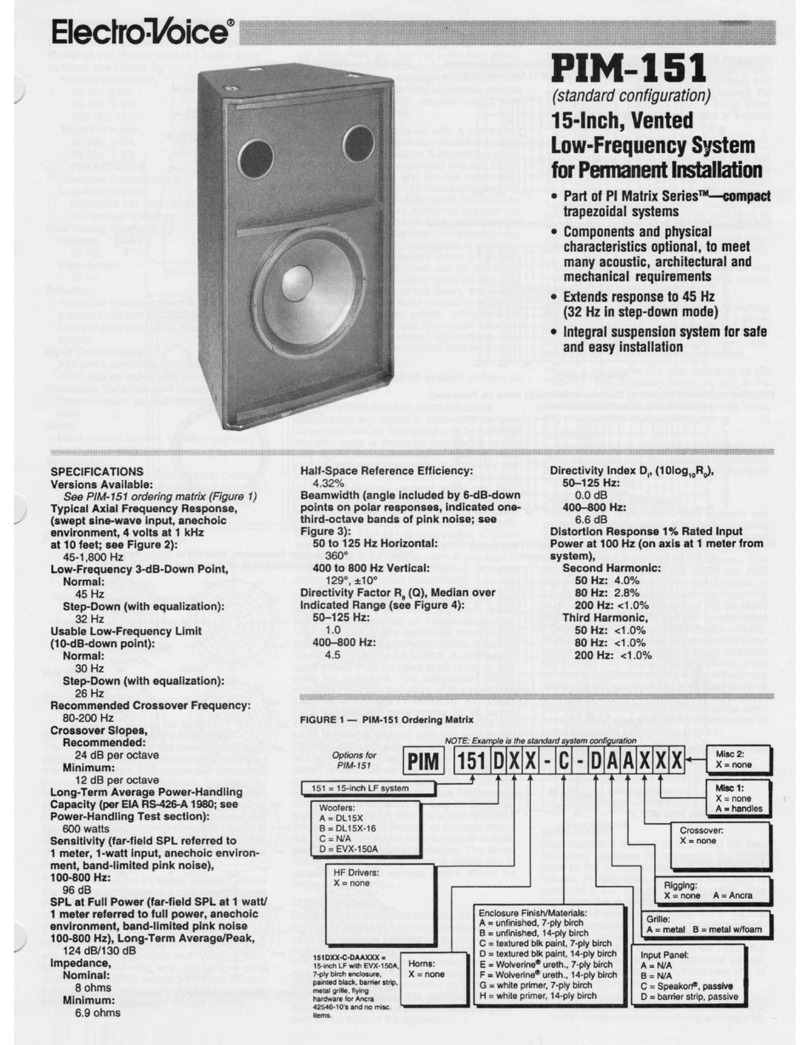

Before beginning the installation, determine the type of material employed

in the ceiling. For all “soft”ceiling tiles, it is imperative that the optional CTB

ceiling tile bridge be utilized. The support rails are 603 mm (23-3/4 in.) long

and will support a loudspeaker system in a 2 ft x 4 ft (or 2 ft x 2 ft) tile. In

addition, if angled at 10 to 15 degrees, the tile bridge can be used with 600-

mm tiles (see Figure A).

Figure A

Ceilings constructed from particle board, gypsum board or plaster do not

normally require the use of a tile bridge.

Preparing the Wires

The ceiling system is provided with an eight-way barrier strip that provides

access to each transformer tap. Up to #10 gauge wire can be used, and a

choice of both screw terminal or spring-loaded push terminals have been

provided (see Figure B). The recommended strip length is 6.4 mm to 8.0

mm (0.250 in. to 0.312 in.).

Using Conduit Fittings

The rear cover has provisions for use of a junction box, or gland-nut style

fitting (see Figure E). This allows both solid and flexible conduit to be

connected directly to the system. If local codes require the use of conduit,

ensure that it is well supported. Too much unsupported weight may prevent

the ceiling system from closing flush against the ceiling surface.

Selecting a Transformer Tap

The transformer tap of choice can be obtained by making connection

between the ground terminal (# 1) and any of the wattage taps indicated on

the input label (#5, 6, 7 or 8). Either 70-V or 100-V lines can be used —

refer to the input panel label to determine the appropriate wattage for the

line voltage used (see Figure B).

Figure B

Cutting Mounting Holes

•The hole for the 4-inch systems should be 171 mm (6.75 in.) (See

Figure C)

•The hole for the 6.5-inch systems should be 203 mm (8.00 in.)

•The hole for the 8-inch systems should be 241 mm (9.50 in.)

Note: The CTB-Series of tile support bridges provide a perfect hole template

and will center the hole on the width of the tile.

Figure C

Check for electrical conduit/wiring and other hazards before cutting the

hole. In addition, allow sufficient clearance for both the depth of the

loudspeaker/enclosure and any electrical fittings used.

Installation

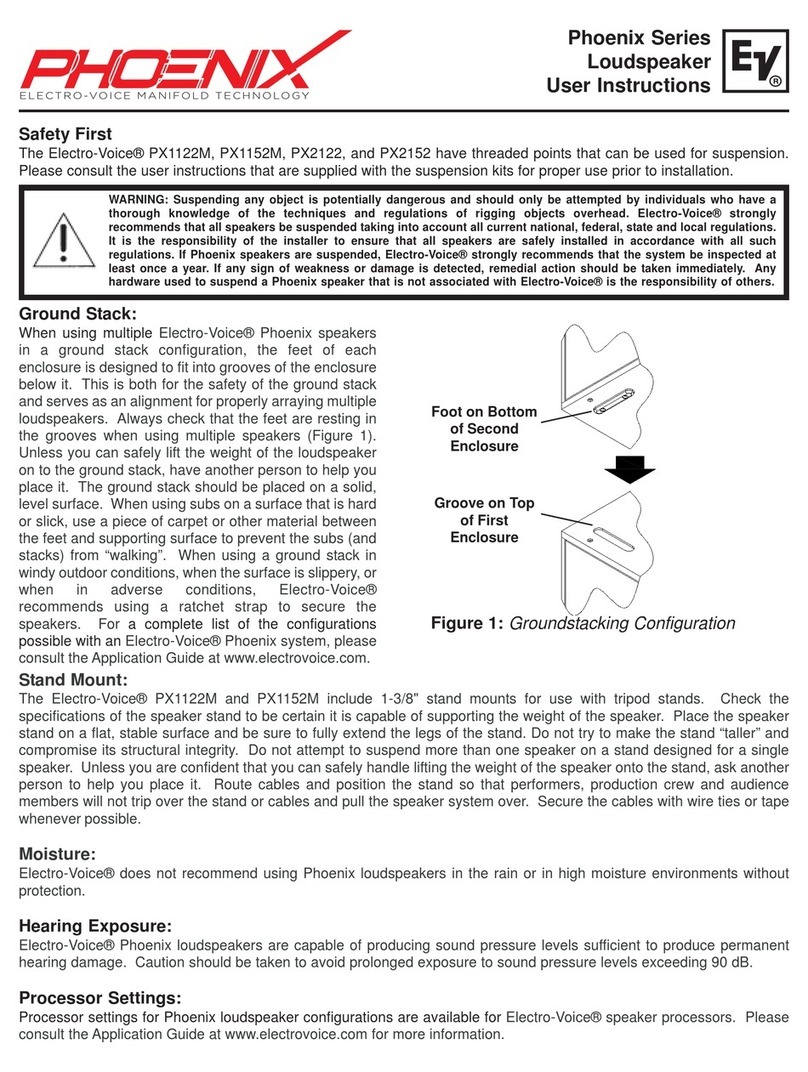

T-bar support

The T-bar system is comprised of two support bars and a support bridge.

The bars are inserted through tabs formed in the two sides of the bridge

and can be adjusted to allow the cut-out to be positioned at any point on the

width of a ceiling tile. Additionally, the tile bridge system can be moved

along the drop ceiling support rails and positioned at any point along the

length of a ceiling tile. The ceiling bridge should be positioned directly

above the hole cut in the ceiling tile with the bridge resting directly against

the rear of the tile.

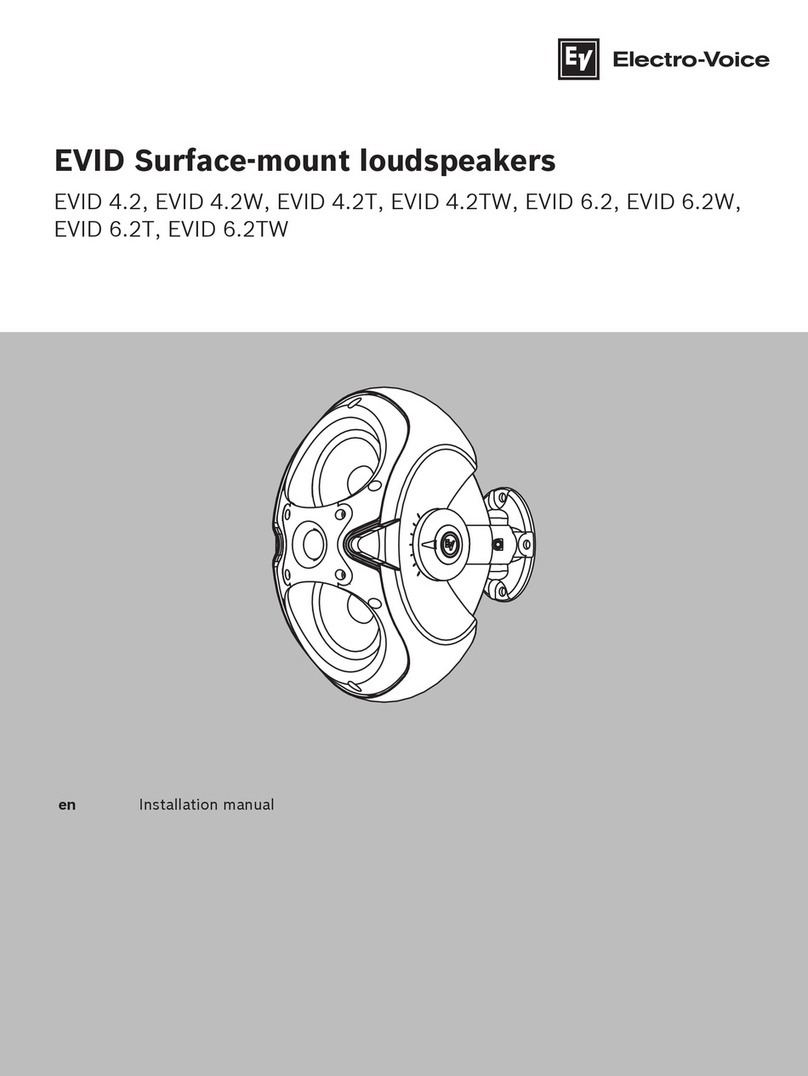

Bezel / Spring Assembly

The bezel/spring assembly is installed from the “room side”by pushing

the inner tubular section up through the hole cut in the ceiling tile. If a tile

bridge is used, the bezel inner tube will also pass through the hole in the tile

bridge. The top leg of the clamp springs ([3] for the 4-inch and 6.5-inch

systems and [4] for the 8-inch system) should be released, one at a time,

by reaching through the hole. Ensure that the metal arms are seated firmly,

and evenly, on the ceiling

Figure D

tile or ceiling tile/bridge combination (see Figure D). Then push the bottom

leg of the clamp spring up through the slot in the spring bracket pushing

slightly counter clockwise to lock in position. This keeps constant pressure

on the spring leg.

Figure E

Loudspeaker System Assembly

Before installing the ceiling loudspeaker system it is necessary to pull the

hook up wire downwards through the hole in the ceiling and make electrical

connection to the terminal block on the rear cover —as previously

discussed. If required by local regulations, a mounting point is provided on

the rear cover that can be used for the attachment of a safety chain, or

wire (see Figure B).

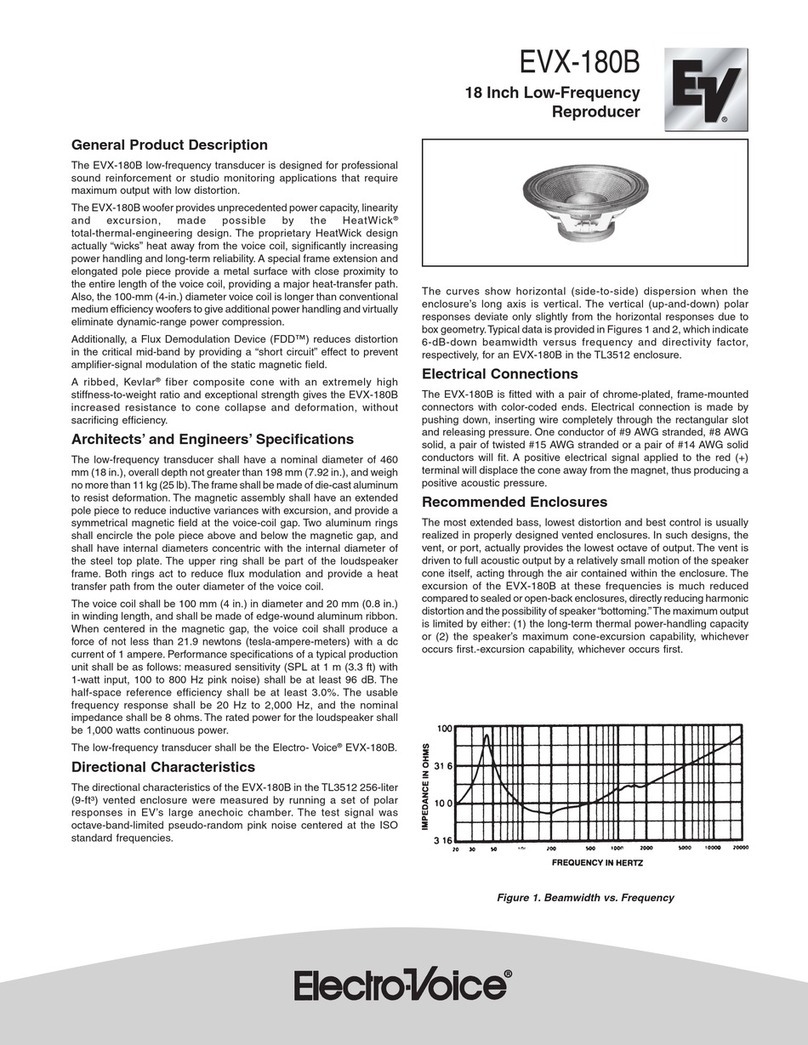

All Electro-Voice®EP Series loudspeaker systems can be installed by

pushing this assembly through the central opening of the bezel assembly

and then rotating the grille/loudspeaker until the “pins”on this item align

with the “bayonet”slots on the bezel assembly (see Figure F).

Figure F

Removing a Loudspeaker System Assembly

A loudspeaker system can be removed by pushing upwards on the grille

and rotating the grille/loudspeaker combination until the pins on the grille

escape the bayonet slots on the bezel assembly (see Figure F). Disconnect

the safety chain or cable (if employed) and disconnect the electrical

connection.

Painting Loudspeaker Assemblies

Bezels

The bezels may be painted before or after installation. Use conventional

spray or roller equipment to paint the loudspeaker bezel when the rest of

the ceiling is painted. Latex and oil based paints will adhere easily to the

loudspeaker bezel, but can scratch if handled carelessly.

Figure G

Grille/Loudspeaker Assemblies

Brushes or rollers may clog the grilles, interfering with the acoustic

performance of the ceiling system. Additionally, a high-pressure spray system

may penetrate through the cloth barrier, coming into contact with, and

damaging, the paper cone. Instead, spray paint the grilles with lacquer or

enamel paint in aerosol cans. (A professional, siphon feed spray gun may

also be used, provided the pressure is sufficiently low to prevent cone damage).

Place the grille/loudspeaker system on a flat surface, facing upwards. Clean

the grilles first to remove all possible contaminants. Apply the paint at a 45

degree angle to the grille surface, (see Figure G). Rotate the grille 180 degrees

and apply a second coat of paint. Alternatively, the grille can be removed

from the loudspeaker enclosure by the removal of three self tapping screws

in the vertical section of the grille (see Figure F).

Safety Regulations

All Electro-Voice®EP Series of ceiling loudspeaker systems comply with

the following standards:

·UL 1480 (general purpose category) [The UL category is ueay, the

control number is 8682 and the file number is E121872]

·UL 2043 (air handling spaces)

·NFPA 70 NEC 1993 Article 300-22 (C) and UL 2043: NFPA 90A-1993

Installation of air-conditioning and ventilation systems, section 2-3.10.1

(a) exception 2.

Packaging

Please note that Electro-Voice®EP Series ceiling loudspeaker systems are

packaged and sold in quantities of (6). In addition, the systems are delivered

in two containers pack 1 of 2 which contains (6) grille / loudspeaker assemblies

and pack 2 of 2 which contains (6) bezel assemblies.This arrangement allows

the sound contractor to deliver the bezel (pack 2 of 2) to the construction site

earlier for installation by a subcontractor (when appropriate). Pack I of 2 can

be retained (locked in a secure part of construction site or on the sound

contractors premises) until the completion date when the sound contractor

can complete the installation. The optional tile bridge CTB-4 (packaged in

quantities of six) must be ordered separately.

Architects’ and Engineers’ Specifications

EP405-8T/EP405-16T Duplex Ceiling Loudspeaker Systems

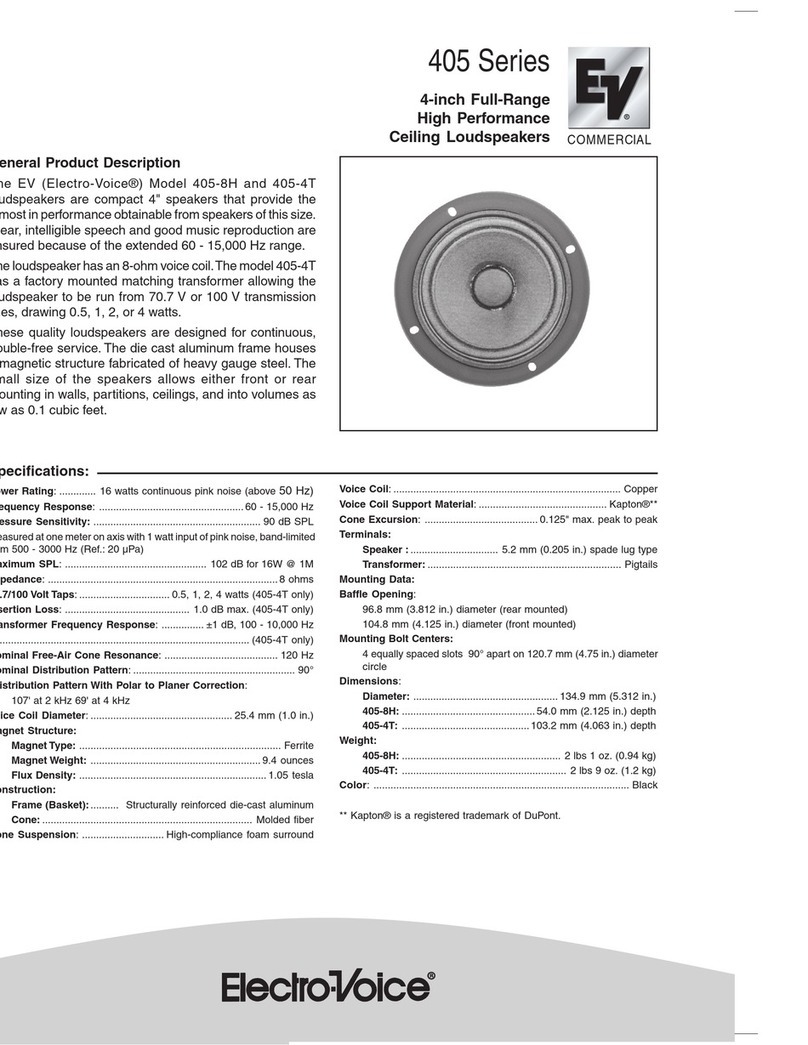

The loudspeaker systems shall comprise of a spring/bezel assembly,

front grille, rear enclosure, transformer and 4-inch full-range loudspeaker.

The loudspeaker system shall meet the requirements of UL 2043. The

loudspeaker will feature a 4-inch curvilinear cone and a high-temperature

voice-coil assembly. The loudspeaker shall meet the following criteria. AES

power rating shall be 16 watts of band-limited pink noise (105 Hz to 15

kHz, 6 dB crest factor). Frequency response, uniform from 105 Hz to 15

kHz. Pressure sensitivity, 90 dB SPL at 1 meter (88 dB at 4 feet) on axis

with one watt of band-limited pink noise from 500 Hz to 3 kHz (ref. 20 ìPa).

Minimum impedance, 7.0 ohms. The loudspeaker shall be 203 mm (8.00

in.) in diameter and 184 mm (7.25 in.) deep. Weight shall be 2.0 kg (4.5 lb)

[EP4058T] and 2.3 kg (5.0 lb) [EP405-16T]. The ceiling loudspeakers

packages shall be the Electro-Voice®models EP405-8T with an 8-watt

transformer; and EP405-16T with a 16-watt transformer.