Electrolab DLS 2100 Series User manual

EL 29126_RevC

Last Updated: 02/2020 © 2020, Electrolab, Inc. All Rights Reserved.

USER MANUAL

DLS 2100 PRODUCT LINE

RU FLEX SENSOR W/ HLS

EL 29126_RevC

Last Updated: 02/2020 © 2020, Electrolab, Inc. All Rights Reserved.

© 2020 Electrolab, Inc.

ALL RIGHTS RESERVED.

This document may not be reproduced, copied (except for a single archive copy), used, disclosed,

transferred (including sold, leased, or rented) adapted or modified except in accordance with the terms and

conditions of the License Agreement between the user and Electrolab, Inc.

Electrolab, Inc. makes no representations of warranties with respect to the contents hereof and specifically

disclaims any implied warranties of merchantability of fitness for any particular purpose. Electrolab, Inc.

reserves the right to revise this publication and to make changes from time to time in its content without

the obligation to notify any person or organization of such revision or changes.

© 2020, Electrolab, Inc. March 2020

Contents

Sensor Assembly................................................................................................................................2

Installation.........................................................................................................................................2

Electrical Connection.........................................................................................................................3

Command syntax ...............................................................................................................................8

Data Request Commands ..................................................................................................................8

Report Level and Temperature ............................................................................................8

Report Level and Temperature Continuously (Factory Diagnostics)..................................10

Report 4-20mA Output Level (Version 3.09 and Higher) ...................................................10

Report Temperature Only ..................................................................................................10

Configuration Commands ................................................................................................................10

Assign Unit Number ............................................................................................................10

Assign Unit Number to Sensor with the Corresponding SN# (v3.15 or higher) .................11

Set Baud Rate .....................................................................................................................11

Set Number of Floats..........................................................................................................11

Set Level Offset...................................................................................................................11

Set Level Offsets for Individual Floats ................................................................................11

Set Temperature Offset......................................................................................................12

Set Multiple Temperature Sensor Offsets..........................................................................12

Set Receive to Transmit Delay............................................................................................12

Set 4-20mA Poll Period.......................................................................................................12

Set 4-20mA Maximum (20mA) Range.................................................................................12

Set the Modbus 16 Bit Unsigned Integer, 32 Bit or 2 X 16 Bit Floating Point Mode..........13

Force Sensor to Enter Boot Load Mode (Version 3.15 and Higher, (Future Use) ..............13

Enter High Level Electronic Shut Down (ESD Mode) (Version 3.15 and Higher)................13

UuuESDONn........................................................................................................................13

Exit High Level Electronic Shut Down (ESD Mode) (Version 3.15 and Higher)...................13

UuuESDOFF.........................................................................................................................13

Configuration Request Commands..................................................................................................14

Report Number of Floats....................................................................................................14

Report Level Offsets ...........................................................................................................14

Report Temperature Offset................................................................................................14

Report Multiple Temperature Offsets................................................................................14

Report Switch Distance ......................................................................................................14

Report Total Switches.........................................................................................................14

Report Receive to Transmit delay ......................................................................................15

Report 4-20mA Configuration ............................................................................................15

Report Serial Number.........................................................................................................15

Report Unit Number Corresponding to Serial Number (Version 3.15 and Higher)............15

Report Sensor Health Status (version 3.15 and higher) .....................................................16

Report the Level Error Setting (Version 3.09 and Higher)..................................................16

Report the Modbus 16 bit Unsigned Integer, 32 bit or 2 x 16 bit Floating Point Mode ....16

Report Battery Voltage.......................................................................................................16

Table 1. Read/Write Registers.........................................................................................................17

Table 2. Holding Registers................................................................................................................20

Table 3. Holding Registers (2 x 16 bit) .............................................................................................22

Table 4. Warning Codes ...................................................................................................................24

Table 5. Error Codes.........................................................................................................................24

© 2020, Electrolab, Inc. March 2020

© 2020, Electrolab, Inc. March 2020

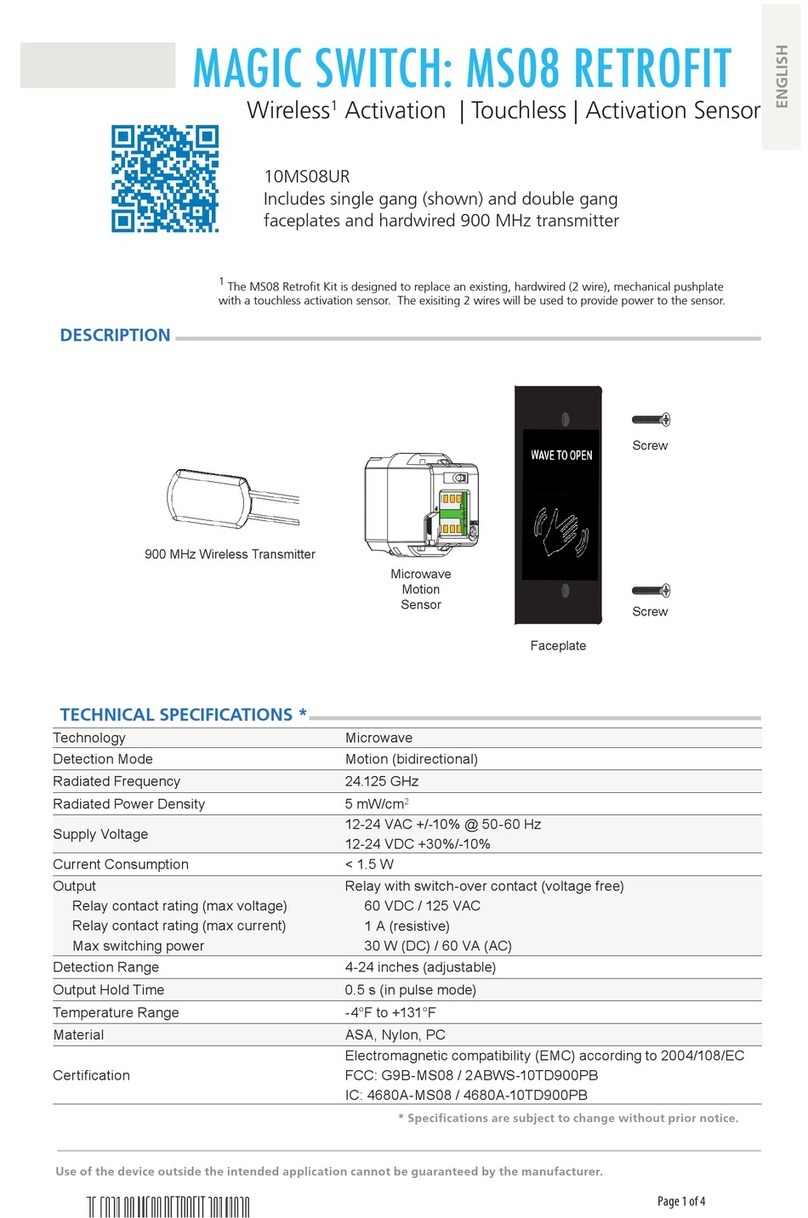

Description

The RU Flex 2100 Digital Level Sensor is a solid-state device that measures and reports fluid levels and

temperatures in storage tanks. It is called a digital sensor because it reports the

information in a serial

bit stream. The sensor uses a float embedded with magnets to sense

the top of a fluid level(s). There is a

temperature sensor mounted inside the tube fourteen inches from the bottom. When the sensor is

polled for data, a series of microprocessors read and determine the position of the float(s) along the

sensor tube. The main microprocessor then calculates the level and temperature and returns the data in

a serial stream or Modbus RTU format, dependent on the format of the request.

Communications

The serial communication protocol is RS485 2-wire or 4-wire, field selectable via jumpers on the fuse

board. The default baud rate is set to 9600, N, 8, 1. In 4-wire mode, one pair of wires is strictly for

transmitting and another pair is for receiving. For 2-wire mode, only one pair of wires is needed for

both transmit and receive. Two wires are needed for the power supply, therefore 4-wire

communications require a 3-pair cable while 2-wire communications require a 2-pair cable.

Wiring Connections

The sensor requires a power supply of 5.6 to 13 volts DC. To connect the sensor communication lines

to the telemetry equipment, connect the sensor data receive to the

RTU data transmit and the

sensors data transmit to the RTU data receive for 4-wire RS485 communications. For 2-wire RS485

communications, connect TX/RX+ from the sensor to TX/RX+ on the receiving equipment and TX/RX-

from the sensor to TX/RX- on the receiving equipment. The voltage supply can be connected to a

switched output so power is applied only during sensor polling.

© 2020, Electrolab, Inc. March 2020

Standard Installation

To install the sensor, follow the simple steps below while referring to the assembly diagram in Figure 2

at the end of this manual.

Sensor Assembly

1. Install the 2-inch hub sensor-grip and either the 4” x 2” or 3” x 2” reducer based on the port size

of the tank.

2. Remove the ground screw from the stainless steel sleeve on the sensor. With proper orientation,

slide this assembly onto the top stainless steel sleeve of the sensor and hand-tighten the cord

grip nut so that the assembly does not slide down.

3. Slide the 2-piece shaft collar clamp over the stainless sleeve.

4. Open the GR housing. Remove the sensor pigtail and attach the round connector to the sensor

flange connector, feeding the white connector through the 1” port. Attach the GR housing to the

sensor. Do not twist the pigtail wires during assembly.

5. Plug the white connector into the fuse board.

6. If not already installed, attach float(s) to the sensor tube using the float hardware provided.

The float carrier is designed to match the proper orientation of the switches.

7. Verify the float(s) move freely along the length of the flexible tube.

8. It is recommended that you use the HHC-1000 or a laptop running terminal software to

verify the sensor configuration and that the sensor is providing a level reading.

Installation

1. Carry the flexible sensor and the bottom weight separately up to the top of the tank.

2. Attach the weight to the bottom of the sensor tube while supporting the sensor so as to not allow

excess stress on the sensor.

3. Once the weight is secured, lower the sensor through the tank port, being careful to control the

sensor while uncoiling it into the tank.

4. When the sensor weight reaches bottom, loosen the cord grip nut and lower the cord grip

assembly to the tank port while holding the sensor from slipping further into the tank.

5. Screw the reducer bushing into the port. Raise the sensor up to make sure there is no slack in the

sensor while the weight still touches the bottom of the tank. Raise and lower the sensor a couple

of times to feel the position of the weight.

6. Tighten the cord grip to secure the sensor from sliding down.

7. Rest the 2-piece shaft collar clamp at the top of the cord grip and tighten the bolts using a ¼” hex

wrench to prevent the sensor from slipping over time.

CAUTION: CONFIRM THAT POWER IS OFF before proceeding.

© 2020, Electrolab, Inc. March 2020

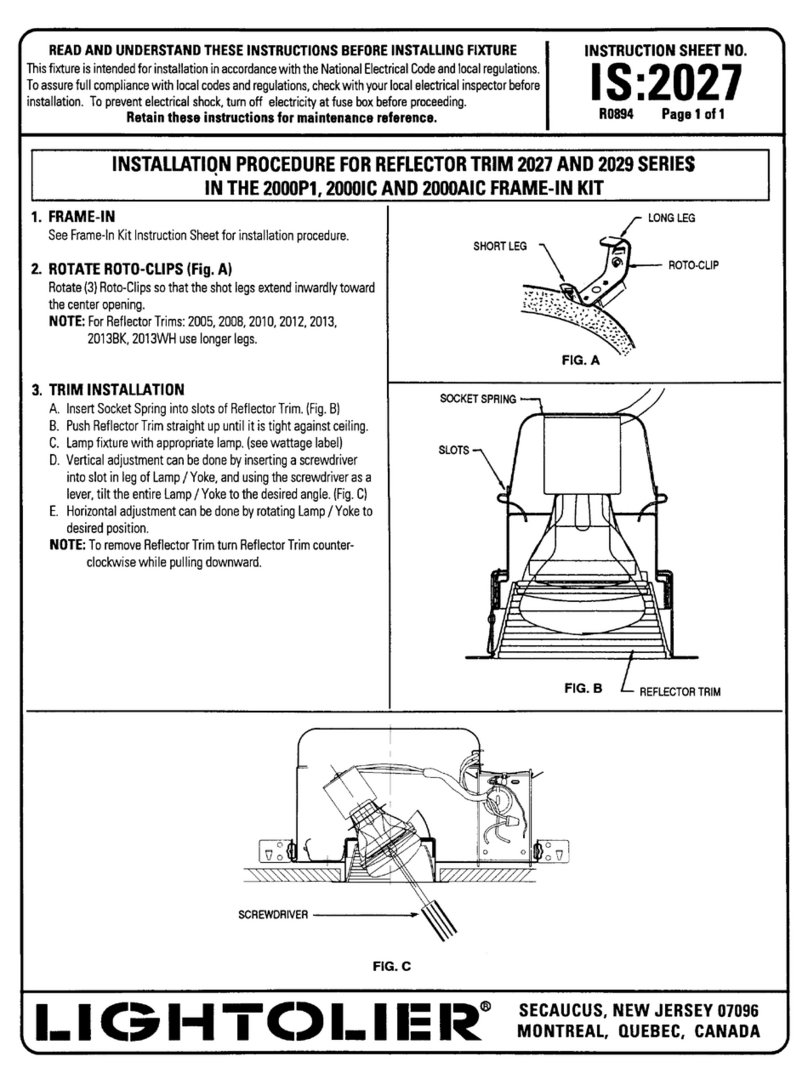

Electrical Connection

1. Feed the external cable/wires through the open port on the side of the housing. Unplug the gray,

6-position connector from the internal fuse board.

2. Using the white depressor tool, install the six wires (4-wire communication) or four wires (2- wire

communication) as directed in the connection (hook-up) diagram in Figure 3.

3. Plug in the connector. Route wires away from the housing threads and screw in the housing

cover.

© 2020, Electrolab, Inc. March 2020

HLS Option Installation

To install the sensor, follow the simple steps below while referring to the assembly diagram in Figure 2

at the end of this manual.

1.

Apply thread sealant to CG165200-FT 4x3.

2.

Screw CG into Reducer Bushing with proper orientation.

3.

Disassemble CG for ease of installation.

4.

Remove Ground Screw from sensor.

5.

Locate the label on the top of the sensor tube to find the break in the label.

6.

Slide separated parts onto the SS tube beginning with the nut and gasket with mounted

3/16” tube against the side of the tube with the break in the label (nut must sit against

gasket).

7.

Assemble CG and slide the assembly down the sensor tube within one foot from the top.

Hand-tighten the nut to keep the CG assembly from sliding down.

8.

Place stainless steel hose clamp on the sensor tube just above the CG assembly and

replace ground screw.

9.

Unroll sensor and pull HLS float and float stop down until fully extended.

10.

Lock in place by tightening the two set screws at the base of the SS tube.

11.

Attach Stainless Steel Clip from float carrier to Stainless Steel wire loop.

12.

Install the weight on the bottom of sensor on top of the catwalk prior to installation.

13.

Carefully lower the sensor into the tank port (avoid damaging the floats and test

apparatus).

14.

Make sure the HLS Stainless Steel wire is loose, but not excessively so.

15.

Unscrew the cord grip nut completely to loosen the rubber gasket so the sensor can rest

on the tank floor and not rotate.

16.

Screw the cord grip and reducer bushing into the tank port.

17.

Unscrew the chained screw cap from the test fixture to expose the pull-tab.

18.

Push the gasket down to seat in the cord grip body.

19.

The pull-tab should be loose, not taut.

20.

If the pull-tab is taut, push the 3/16” tube into the gasket until it is loose.

21.

Tighten the cord grip nut.

22.

HLS INSTALLATION COMPLETE.

© 2020, Electrolab, Inc. March 2020

DLS Calibration & Setting the Initial Offset

The Model 2100 Digital Level Sensor is designed to provide an accurate and dependable level

measurement for oil and water levels in production tanks. The only calibration required is to set the level

offset value in the DLS. This can be done in the DLS or at the EFM, RTU,

or PLC by determining the

difference of the level between the electronic reading and the

actual fluid level in the tank, measured

with an approved gauge line. Once the level offset is entered in either the DLS or SCADA system, the

level offset will be added to the raw value of the DLS to provide an accurate fluid level.

The level offset is determined by reading the DLS with the HHC-1000 Hand-Held Communicator while

simultaneously gauging the level in the tank. For best results, the

tank should not be in active

production so that the fluid is not agitated at the time of reading. If it is not possible to isolate the tank,

then it is recommended to take several readings of both the DLS and gauge line to make sure the

readings are consistent.

NOTE: If there is no fluid in the tank, the level offset cannot be determined.

NOTE: Due to the height of the weight, the typical offset will be 2 to 4 inches above the height of the

weight. This is due to the mechanical connection between the tube and the weight, as well as how the

float(s) move in the tank.

NOTE: The level offset is always added to the raw value. If a mistake is made when entering

the level

offset, reset the offset value to zero before proceeding to avoid large swings in readings. If there is an

offset programmed in the DLS and the actual level is not correctly displayed, simply changing the offset

value will not include the previous offset value.

EXAMPLE: If a 9.50” offset is in the DLS and the DLS is still reading ¼” below actual level,

the true offset

should be 9.75”. If you add a ¼” offset, the level reading will be 9.50” below actual level. Resetting the

level offset to zero will make it easier to determine the correct

offset value.

After installing the RU Flex 2100 DLS and before setting the initial offset, allow the sensor to rest in the

tank for 10-15 minutes. This will allow the sensor to relax and straighten out. Colder weather

environments and longer sensors should rest the full 15 minutes. Loosen the 2-piece shaft collar clamp

and cord grip. Lift the sensor up and down a few times before resetting the sensor in the tank and

retightening the cord grip and 2-piece shaft collar clamp. You are now ready to set the initial offset.

© 2020, Electrolab, Inc. March 2020

PROCEDURE

1. Using the Hand-Held Communicator (HHC-1000), connect to the DLS and take initial readings of

level and temperature. Refer to the HHC -1000 User Manual for instructions.

2. If readings are providing both water and oil levels, then verify that the two readings are more

than 3” apart. If the difference is less than 3”, the two floats will be

touching and a valid offset

cannot be determined.

3. Verify that the water level is above the point where the bottom weight connects to the sensor

tube. If the water is below the connection, then the water float is at the bottom of the sensor

and the level offset cannot be determined.

4. Using a gauge line, measure the actual level in the tank and note the level. Subtract the

electronic reading from the gauged level to determine the level offset value.

5. To program the level offset in the DLS using the HHC-1000, go to the “Set Points” menu and then

to the “Level” menu. Press F2 in the “Level” menu to bring up the level offset

screen.

6. To set the total fluid level offset, enter a value of 1for the top float and then enter the

offset

value. If the value is less than one, enter the decimal value, then press “Enter.”

7. To set the water-interface level offset, enter a value of 2for the bottom float, then enter the

offset value and press “Enter.”

8. To verify that the offset is correct, return to the main screen and read the level and temperature

values to verify the DLS is reading correctly.

9. Once the level offsets are entered, there is no further calibration required unless the

DLS is

removed and reinstalled in another tank.

EXAMPLE: If the actual level is 156.25” and the DLS reading is 146.50”, then the

offset value will be 9.75”

(156.25-146.50=9.75).

© 2020, Electrolab, Inc. March 2020

Testing and Troubleshooting

Refer to the list below to help diagnose problems with the Model 2100 DLS RU Flex w/ HLS.

Sensor is new and recently installed:

The sensor wiring is incorrect: Check the sensor connection (hook-up) diagram.

Wrong baud rate: (Factory default is 9600)

Wrong protocol: (Factory default is N81)

There is insufficient voltage: The sensor needs at least 5.6 VDC.

Sensor has been in service for some time but is not working:

There are corroded connections or damaged cables.

Blown fuse or shorted suppressor on the barrier board (if equipped). Check the fuses

with a continuity tester.

There is possible damage to sensor electronics.

Sensor sends inaccurate level or temperature:

An incorrect level or temperature offset is programmed into sensor, RTU, or host.

An incorrect number of floats are programmed. Check the sensor protocol list

to reprogram the sensor with the correct information.

Sensor is HLS Option (v3.16) with float on. Not programmed for High Level.

Sensor sends temperature but not level:

If the sensor reports error code 1, the float is not on the sensor in the correct

orientation. The white mark on the float must be on top of the strip on the side of

the

sensor (rigid sensors only).

An incorrect number of floats are programmed. Check the sensor protocol

command list to reprogram the sensor with the correct information.

Sensor has an HLS float installed and is not programmed for High Level.

© 2020, Electrolab, Inc. March 2020

Digital Level Sensor Protocol

Command syntax

Uppercase characters denote literals in the command and response streams.

Lowercase characters represent data fields in the command and response

streams. Further explanation of data field structure is provided as necessary

with each command.

All commands are terminated with carriage return <cr>.

All responses are terminated with Ccccc (cccc=16 bit CRC field in hexadecimal)

followed by a carriage return linefeed pair <cr><lf>. All alpha hexadecimal

characters are lowercase.

The prefix to all commands and responses is Uuu where uu is the unit number (00-

31). The unit number is the identity of the level sensor to which a command is

addressed or which generates the response. ‘*’may be used as a wild card character

for either digit in the unit number field ‘uu’. The responding level sensor will always

convert wildcard characters to the actual unit number.

Commands, which modify a level sensor configuration, always return the

command string and ‘OK’ if successful. ‘EEerr’ replaces ‘OK’ if there is a

problem storing the configuration data in the level sensor EEPROM.

Data Request Commands

Report Level and Temperature

Uuu?

uu is a two-digit unit number from 00 to 31( “*” may be used as a wildcard for either

digit)

Note: Do Not use the wildcard “**” if connected to more than one level sensor, as all sensors

will respond simultaneously.

Response: UuuDlll.llFtttEeeeeWwwww

uu = unit number

lll.ll = level in inches (repeated for sensors with 2 floats)

ttt = temperature in degrees F

eeee = error number

0 = No errors

1= No float detected

2 = One float is out of range on a two-float sensor

3 = Too many groups

4 = (reserved)

5 = Transmit to slave processor for level failed

6 = Transmit to slave processor for temperature failed

7 = Receive from slave processor of level failed

8 = Receive from slave processor of temperature failed

9 = No slave processors responding

© 2020, Electrolab, Inc. March 2020

Note: If errors 5 through 9 occur and persist after power cycling, the sensor should

be

returned for repair.

wwww = warning number

0= No warnings

1= Possible level degradation

2= Possible level degradation due to level offset

3= Missing HLS Float (when programmed for HLS)

4= Missing float when programmed for dual float (Replaces Error 2 on v3.18 RU

Flex only). The data response will have actual Product level and zero for the

Interface level.

Under normal circumstances the warning field is 0. It will display 1 if the sensor is

configured for two floats and only one group of switches is detected (i.e., only one float is

present or both floats are abutted).

Note: The number of decimal places in a data field implies nothing about the accuracy of

the

data (i.e., levels are not accurate to 0.01 inches).

© 2020, Electrolab, Inc. March 2020

Report Level and Temperature Continuously (Factory Diagnostics)

Uuu??

Response: Same as above, except continuously, with internal module configuration and

reported individual switch activation and groups of activated switches.

Note: The unit must be powered down before it will respond to other commands.

Report 4-20mA Output Level (Version 3.09 and Higher)

Uuu?M

Response: UuuMhhhhEeeeeWwwww

uu = unit number

hhhh = hex value 0x0000-0xFFFF eeee = error number

0 = No errors

1= No float detected

2 = One float is out of range on a two-float sensor

3 = Too many groups

4 = (reserved)

5 = Transmit to slave processor for level failed

6 = Transmit to slave processor for temperature failed

7 = Receive from slave processor of level failed

8 = Receive from slave processor of temperature failed

9 = No slave processors responding

Note: If errors 5 through 9 occur and persist after power cycling, the sensor should be

returned for repair.

wwww = warning number

0 = No warnings

1 = Possible level degradation

2 = Possible level degradation due to level offset

Report Temperature Only

Uuu?T

Response: UuuFxxEeeeeWwwww

xx= temperature

Configuration Commands

Assign Unit Number

UuuNnn

uu = unit number (from 00 to 31)

nn = new unit number

Note: Unit number 00 is not valid in Modbus RTU mode

Response: UuuNOK

uu = newly assigned unit number

© 2020, Electrolab, Inc. March 2020

Assign Unit Number to Sensor with the Corresponding SN# (v3.15 or higher)

UsssssssNnn

sssssss= seven-digit serial number

nn= two-digit unit number

Response:

UuuNOK

uu = new unit number

UuuEEerr Write to EEPROM failed

Set Baud Rate

UuuBbbbb[b][pds]

bbbb[b] = 1200, 9600, 14400, 19200, or 38400, (9600 is default); 57600 (v3.15 and higher)

pds = parity, data length, stop bit (pds options)

N81 (default) E71

O71

For example, to program Unit 00 to 9600 E 7 1 would be U00B9600E71

Note:

It is not necessary to power down the Model 2100 before this command takes

effect. The Model 1000 must have power cycled for this command to take effect.

Response: UnnBOK

Set Number of Floats

UuuFn

uu = unit number

n = float number (1 or 2 –Standard; 11 or 12 –1/8”Resolution; 11 –Single Float; 12 –Dual

Float)

Response: UuuFOK

Set Level Offset

UuuLOslll

Sets the offset for the level sensor

uu = unit number

sIIlI = sign and offset with two implied decimal places

Note: If two floats, assign the same offset to both

Response: UuuOLOK

Set Level Offsets for Individual Floats

UuuL[1|T]Oslll.ll

Sets the top float offset.

Example of setting top level offset for Unit 00 to 2.25 inches - U00L1O2.25

UuuL[2|B]Oslll.ll

Sets the bottom float offset. (Dual Float Sensor only)

Example of setting bottom level offset for water interface to 1.75 inches - U00L2O1.75

uu = unit number

slll.ll = sign and offset with two implied decimal places. The Plus (+) sign is assumed.

The Minus (-) must precede the offset value if required.

If no decimal places are required, then you do not need to add to value

.

Note: "O" in the command is the letter Oand not the number zero

Response: UuuLOOK

© 2020, Electrolab, Inc. March 2020

Set Temperature Offset

UuuOFsoo

uu = unit number

soo = -99 to 99 (optional sign)

Response: UuuOFOK

Set Multiple Temperature Sensor Offsets

UuuTnOso.o

uu = unit number

n = temperature sensor identifier (1-8, 1 is at top) so.o = -9.9 to 9.9 degrees (optional sign)

Response: UuuTnOOK

Set Receive to Transmit Delay

UuuRmmm

uu = unit number

mmm = milliseconds (50 to 250). The default is 127ms.

Response: UuuROK

Set 4-20mA Poll Period

UuuMPpppp

uu = unit number

pppp = seconds (Default is 30 seconds)

Response: UuuMPOK

Note: Poll Periods less than 20 seconds may shorten the life expectancy of the 4/20mA

converter board. The relay (which power cycles the sensor to reduce power consumption)

is rated for 10,000,000 cycles.

Set 4-20mA Minimum (4mA) Range

UuuMINmm.mm

uu = unit number

mm.mm = level for 4mA output (Default is 00.00)

Response: UuuMINOK

Set 4-20mA Maximum (20mA) Range

UuuMAXmmm.mm

uu = unit number

mmm.mm = level for 20mA output in inches (Default is 240.00”) Example: For 20-foot long

sensors = 240.00

Response: UuuMAXOK

Set the Level Error Setting (Version 3.09 and Higher)

UuuSETERRx

uu = unit number

x = 0 will set the level error report to be 999.99. This is the default setting.

x = 1 will set the level error report to be 000.00.

Response: UuuSETERROK

© 2020, Electrolab, Inc. March 2020

Set the Modbus 16 Bit Unsigned Integer, 32 Bit or 2 X 16 Bit Floating Point Mode

UuuIFxxxx

uu = unit number

xxxx = 1007 will set the 16 bit Unsigned integer mode. This is the default setting.

xxxx = 1008 will set the 32 bit floating point mode.

xxxx = 1009 will set the 2x16 bit floating point mode (v3.14 and higher).

Response: UuuIFOK

Force Sensor to Enter Boot Load Mode (Version 3.15 and Higher, (Future Use)

UUUFB

uu = two-digit unit number

Response: none

Enter High Level Electronic Shut Down (ESD Mode) (Version 3.15 and Higher)

UuuESDONn

uu = unit number

n = one-digit number from 1 to 3 which represents the number of level request

commands that will respond with the maximum level without cycling power. After this

number, the

sensor reverts to normal operation

Note: If power is cycled, then the count reverts back to the programmed number of

polls.

Response: UuuESDONOK ESD mode was successfully activated

Exit High Level Electronic Shut Down (ESD Mode) (Version 3.15 and Higher)

UuuESDOFF

Response: UuuESDOFFOK ESD mode exit successfully

Note: UuuESDON0 also turns off ESD mode

© 2020, Electrolab, Inc. March 2020

Configuration Request Commands

Report Number of Floats

UuuF?

Response: UuuFn

uu = unit number

n = number of floats (1 or 2 –Standard; 11 or 12 –1/8” Resolution; 11 – Single Float; 12 –

Dual Float).

Report Level Offsets

UuuLO?

Response: UuuL1Osnn.nnL2Osnn.nn

uu = unit number

snn.nn = sign and offset with two implied decimal places

Report Temperature Offset

UuuOF?

Response: UuuOFsff

uu = unit number

s = sign

ff = temperature offset (degrees F)

Report Multiple Temperature Offsets

UuuTO?

Response: UuuTnOs0.0

TnOsn.n repeated for additional temperature sensors

uu = unit number

n = temperature sensor (1-8, 1 is top sensor)

s = sign

0.0= temperature offset

Report Switch Distance

UuuD?

Response: UuuDd

uu = unit number

d = distance between switches as integral tenths of an inch (e.g., 5 = 0.5 inches, 10 = 1

inches)

UuuR?

Response: UuuRmmm

uu = unit number

mmm = delay

Report Total Switches

UuuS?

Response: UuuSssss

uu = unit number

ssss = total number of switches in the sensor

© 2020, Electrolab, Inc. March 2020

Report Receive to Transmit delay

UuuR?

Response: UuuRmmm

uu = unit number

mmm = delay in milliseconds

Report 4-20mA Configuration

UuuMC?

Response: UuuPppppL1_4MAll.ll_20MAhhh.hh

uu = unit number

Ppppp = Polling period in seconds

L1 = Data source is top float

_4MAll.ll = Level to output 4 mA

_20MAhhh.hh = Level to output 20 mA

Report Serial Number

UuuSN?

Response: UuuSNxxxxxxx

uu = unit number

xxxxxxxx = serial number.

Report Unit Number Corresponding to Serial Number (Version 3.15 and Higher)

UsssssssN?

sssssss = seven-digit serial number

Response: UsssssssNuu

uu = unit number

© 2020, Electrolab, Inc. March 2020

Report Sensor Health Status (version 3.15 and higher)

UuuH?

uu = two-digit unit number

Response:

grp0=ttt-bbb--grp1=ttt-bbb

grp3=ttt-bbb--grp4=ttt-bbb

UuuDlll.ll[Dlll.ll]Fttt[Fttt……]EeeeeWwwww

BATTERY-VOLTAGE:vv.vV

If sensor works in normal operation parameters the message will be

UuuSENSOR-OK

Error, one or more of the following error messages

NO-SWITCH-CLOSED

ONLY-ONE-GROUP-FOUND-ON-A-TWO-FLOAT-SYSTEM

TOO-MANY-GROUPS-TO-RESOLVE-THE-LEVEL

NO-FLOAT-CONFIGURED

TRANSMIT-TO-PIC-PROCESSOR-FOR-LEVEL-FAILED

RECEIVE-FROM-PIC-PROCESSOR-FOR-LEVEL-FAILED

TRANSMIT-TO-PIC-PROCESSOR-FOR-TEMP-FAILED

RECEIVE-FROM-PIC-PROCESSOR-FOR-TEMP-FAILED

Warning, one or all of the following warning messages:

WARNING!-POSSIBLE-LEVEL-DEGRADATION

WARNING!-POSSIBLE-LEVEL-DEGRADATION-DUE-TO-OFFSET

Report the Level Error Setting (Version 3.09 and Higher)

UuuSETERR?

Response: UuuSETERR=x

uu = unit number

x = 0 is set for level error report to be 999.99 (default)

x = 1 is set for level error report to be 000.00

Report the Modbus 16 bit Unsigned Integer, 32 bit or 2 x 16 bit Floating Point Mode

UuuIF?

Response: UuuIF=x

uu = unit number

x = 0 is set for 16 bit Unsigned integer mode. This is the default setting.

x = 1 is set for 32 bit floating point mode.

x = 2 is set for 2x16 bit floating point mode (v3.14 and higher)

Report Battery Voltage

UuuBV?

Response: UuuBVvv.vV

uu = unit number

vv.v = battery voltage in volts

Table of contents

Other Electrolab Accessories manuals