Electrolab 2110EX-12 User manual

EL 29132 Version: V.002

Last Updated: 01/2022

© 2022, Electrolab, Inc. All Rights Reserved.

USER MANUAL

Explosion Proof Housing - Digital

Model 2110EX-12 and Model 2110EX-24

Standard and HLS Versions

EL 29132 Version: V.002

Last Updated: 01/2022

© 2022, Electrolab, Inc. All Rights Reserved.

© 2022 Electrolab, Inc. ALL RIGHTS RESERVED.

This document may not be reproduced, copied (except for a single archive copy), used, disclosed,

transferred (including sold, leased, or rented) adapted or modified except in accordance with the

terms andconditions of the License Agreement between the user and Electrolab, Inc.

Electrolab, Inc. makes no representations of warranties with respect to the contents hereof and

specificallydisclaims any implied warranties of merchantability of fitness for any particular purpose.

Electrolab, Inc. reserves the right to revise this publication and to make changes from time to time in

its content without the obligation to notify any person or organization of such revision or changes.

USER MANUAL

Page 3of 16

Document # EL29132

Version: V.002

Model 2110EX Explosion Proof Housing

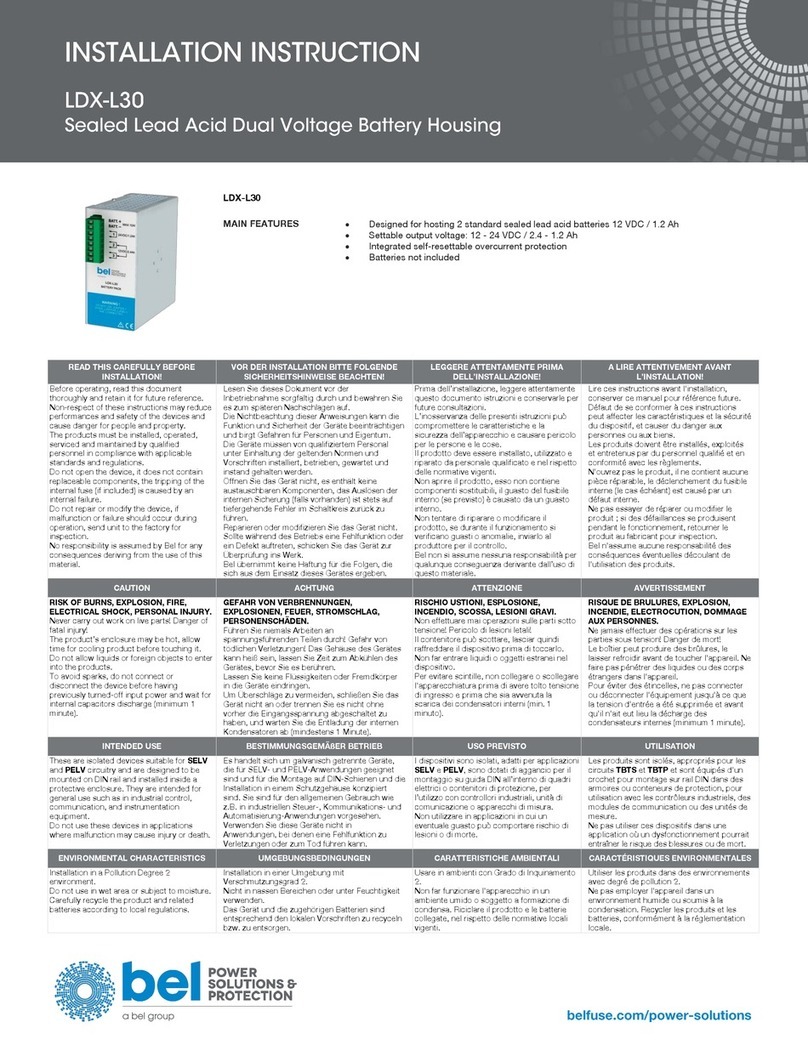

CHARACTERISTICS

General Desription:

The Model 2110EX is NRTL certified explosion proof for use in hazardous

locations/environments (Class I, Division 1, Group D) in accordance with UL1203,

UL61010-1, CSA C22.2 No. 30, and CSA C22.2 No. 61010-1. The device is also certified

to provide Intrinsically Safe output for use in hazardous locations (Class I, Division 1,

Group D) in accordance with ANSI/UL 913, CSA C22.2 No. 60079-0 and CSA C22.2 No.

60079-11.The Barrier Unit actively limits the current and voltage to protect intrinsically safe

equipment from power spikes and to maintain the intrinsic safety. The barrier provides

intrinsically safe power and intrinsically safe communication or I/O lines for devices located

in Hazardous Areas.

Functions:

The 2110EX is capable of delivering safe levels of supply power, 2-wire RS485 digital

signals or any other digital I/O lines, and also two emulated dry contact circuits.

SPECIAL WARNINGS

Use only NRTL – listed limited power supply. Voltage should not exceed 12VDC for

model 2110EX-12 and 24VDC for model 2110EX-24

Use only with certified Explosion Proof conduit or certified Explosion Proof cable and

connector (eg. CLX and TMCX products).

Always attach the cables to the connector strain relief plate with cable ties. This will

ensure that cables do not migrate in the enclosure if they are disconnected from

connector by accident.

Always lock the cover by fastening its hex screw with a hex socket; use a hex spanner

of 1.5mm.

AVERTISSEMENTS SPÉCIAUX

N'utilisez que des blocs d'alimentation limités NEC class 2 répertoriés d‘une

Laboratoire d'essai reconnu à l'échelle nationale. La tension ne doit pas dépasser

12VDC pour le modèle 2110EX-12 et 24VDC pour le modèle 2110EX-24

Utilisez uniquement des conduits certifiés antidéflagrants ou des câbles et connecteurs

certifiés antidéflagrants (par exemple, les produits CLX et TMCX).

Fixez toujours les câbles à la plaque de décharge de traction du connecteur avec des

colliers de serrage. Cela garantira que les câbles ne migreront pas dans le boîtier s'ils

sont déconnectés du connecteur par accident.

Verrouillez toujours le couvercle à l'aide d'une vis à six pans creux à l'aide d'une clé

hexagonale de 1,5 mm de diamètre.

TECHNICAL DATA

Supply (X1-1):

Voltage: 10 to 12 VDC max for Model 2110EX-12

22 to 24 VDC max for Model 2110EX-24

Maximum input current: 50 mA

Current consumption: 40 mA

Communication (I/O) lines input (X1-3 and X1-4):

USER MANUAL

Page 4of 16

Document # EL29132

Version: V.002

Voltage: 5 VDC nom / 6 VDC max

Maximum input current 50 mA

Dry contact circuits input (X2-1 to X2-2 and X2-3 to X2-4):

Voltage: 10 to 12 VDC max for Model 2110EX-12

22 to 24 VDC max for Model 2110EX-24

Maximum input current 50 mA

Internal minimum ON resistance: 65.5 Ω

Um:

12 VDC Model 2110EX-12 (Should be supplied only from NRTL-listed limited power

supply)

24 VDC Model 2110EX-24 (Should be supplied only from NRTL-listed limited power

supply)

Environmental Conditions:

Temperature:

Operating -40 to 70 °C

Storage -40 to 85 °C

Atmospheric conditions:

Pressure 1 atm.

Oxygen concentration not greater than 21%

Approvals:

UL1203 Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in

Hazardous (Classified) Locations

UL61010-1 Standard for Safety Electrical Equipment For Measurement, Control, and

Laboratory Use

CSA C22.2 No. 30 Explosion-proof enclosures for use in Class I hazardous locations

CSA C22.2 No. 61010-1 Safety requirements for electrical equipment for measurement,

control, and laboratory use

UL 913, Standard for Intrinsically Safe Apparatus and Associated

Apparatus for Hazard (Classified) Locations

UL 60079-11 (Intrinsic Safety "i" Zones 0 and 1)

CSA C22.2 No. 60079-0 Explosive atmospheres - Part 0: Equipment - General requirements

CSA C22.2 No. 60079-11 Explosive atmospheres - Part 11: Equipment protection by

intrinsic safety "i"

Mounting:

Weight: approx. – 1.8Kg (4 Lbs.)

Connection: WAGO polarized plug-in disconnect/connect cage clamp

connection terminal blocks to accomodate terminations up to 1.5mm2

Location: Class I Div 1 Group D Temperature code T4

Dimensions:

PCB: 3.17“ x 3.17“

Enclosure: 4.2“x5.7“x 5“ (HxLxW)

USER MANUAL

Page 5of 16

Document # EL29132

Version: V.002

TERMINAL CONNECTIONS

Table 1.

EXPLOSION PROOF CONNECTION

INTRINSICALLY SAFE CONNECTION

X1-L1 →VDC

X1-L2 →DC_GND

X1-L3 →Tx/Rx-

X1-L4 →Tx/Rx+

X2-L1 →HI

X2-L2 → SW

X2-L3 →HI-HI

X2-L4 →SW

J1-1 →Tx/Rx+

J1-2 →DC_GND

J1-3 →Tx/Rx-

J1-4 →VDC

J2-1 →DC_GND

J2-2 →DC_GND

J2-3 →HI-HI

J2-4 →HI

USER MANUAL

Page 6of 16

Document # EL29132

Version: V.002

ENTITY PARAMETERS TABLE

Table 2.

Terminals

2110EX Parameter

Must

be

Hazardous Area Device

Parameters

J1-4

Uo/Voc = 10.71 V

≤

Ui/ Vmax

J1-1 thru J1-4;

Io/Isc = 239.7 mA

≤

Ii / Imax

J1-1 thru J1-4;

Po= 0.5037 W

≤

Pi / Pmax

J1-1 thru J1-4;

Co/Ca= 66 µF

≥

Ci/Cidevice + C cable

J1-1 thru J1-4;

Lo/La= 4 mH

≥

Li/Lidevice + L cable

J2-4

Uo/Voc = 10.71 V

≤

Ui/ Vmax

J3-3

Uo/Voc = 10.71 V

≤

Ui/ Vmax

J2-1 thru J2-4;

Io/Isc = 18.03 mA

≤

Ii / Imax

J2-1 thru J2-4;

Po= 0.048 W

≤

Pi / Pmax

J2-1 thru J2-4;

Co/Ca= 66 µF

≥

Ci/Cidevice + C cable

J2-1 thru J2-4;

Lo/La= 4 mH

≥

Li/Lidevice + L cable

For installation in which both Ciand Liof the Intrinsically Safe Apparatus exceed 1% of the Coand

Lo parameters of the Associated Apparatus (excluding cable), then 50% of Coand Loparameters are

applicable and shall not be exceeded.

If cable parameters are unknown, the following values may be used: Capacitance 60pF per foot

(180pF per meter), inductance 0.20uH per foot (0.60µH per meter).

USER MANUAL

Page 7of 16

Document # EL29132

Version: V.002

WARNINGS

Not to be connected to control equipment that uses or generates more than 12VDC for

Model 2110EX-12 or 24VDC for Model 2110EX-24 with respect to earth ground.

The 2110EX must be installed, operated, and maintained only by qualified personnel, in

accordance to relevant national/international installation standards (National Electric Code

(NFPA, Article 504) and ANSI/ISA – RP12.6).

Particular care shall be given to segregation and clear identification of IS conductors from

non-IS conductors.

De-energized power source (turn off power supply voltage) before installing or removing

the connections when installed in Hazardous Area/Hazardous Locations or unless area is

known to be non-hazardous.

Warning: substitution of components may impair Intrinsic Safety.

Explosion Hazard: to prevent ignition of flammable or combustible atmospheres,

disconnect power before servicing or unless area is known to be non-hazardous.

The unit cannot be repaired by the end user and must be returned to the manufacturer or

authorized representative. Any unauthorized modification must be avoided and will void any

warranty.

Note: X1-L3 and X1-L4 inputs are not reverse polarity protected. If reverse polarity occurs the unit

will fail-safe by blowing the fuses. To avoid this situation, special care is required at installation.

AVERTISSEMENTS

Ne doit pas être connecté à un équipement de contrôle qui utilise ou génère plus de 12 VCC

pour le modèle 2110EX-12 ou 24 VCC pour le modèle 2110EX-24 par rapport à la terre.

Le 2110EX doit être installé, utilisé et entretenu uniquement par du personnel qualifié,

conformément aux normes d'installation nationales / internationales (National Electric Code

(NFPA, Article 504) et ANSI / ISA - RP12.6).

Une attention particulière doit être accordée à la séparation et à l'identification claire des

conducteurs IS des conducteurs non IS

Source d'alimentation hors tension (couper la tension d'alimentation) avant d'installer ou de

retirer les connexions lorsqu'elles sont installées dans des zones dangereuses / endroits

dangereux ou à moins que la zone ne soit reconnue comme non dangereuse.

Avertissement: la substitution de composants peut compromettre la sécurité

intrinsèque.

Risque d'explosion: pour éviter l'inflammation des atmosphères inflammables ou

combustibles, déconnectez l'alimentation avant l'entretien ou à moins que la zone ne

soit reconnue comme non dangereuse.

L'appareil ne peut pas être réparé par l'utilisateur final et doit être renvoyé au fabricant ou à

un représentant autorisé. Toute modification non autorisée doit être évitée.

Remarque: Les entrées X1-L3 et X1-L4 ne sont pas protégées contre l'inversion de polarité. Si

l'inversion de polarité se produit, l'unité sera en sécurité en soufflant les fusibles. Pour éviter cette

situation, une attention particulière est requise lors de l'installation.

USER MANUAL

Page 8of 16

Document # EL29132

Version: V.002

MARKING

Labels:

The Model 2110EX will be clearly marked on the label attached to the enclosure,

label drawing number is 2110EX-12V-00/2110EX-24V-00.

Serial Number:

For each PCB board a unique serial number will be generated after factory testing. The serial

number consists of five digits followed by letter Aor B(e.g. SN: 00101A) and will be clearly

printed with black permanent marker on a white rectangle located on the front side of the PCB.

Letter Ais used to specify the 12VDC model and letter Bto specify the 24VDC model.

For each unit a unique serial number will be generated after factory testing. The serial

number consists of 12 alphanumeric characters as below:

UMxMMYYnnnnn

where:

UM –12 for 12V model and 24 for 24V model;

x– S for standard version and H for HLS option;

MM – manufacturing month;

YY – manufacturing year;

nnnnn – 5 digit incremental number;

12S021800101 represents a 12VDC model device with standard sensor option manufactured in

February 2018 and having the assigned order number 00101.

The serial number will be clearly printed on the enclosure label.

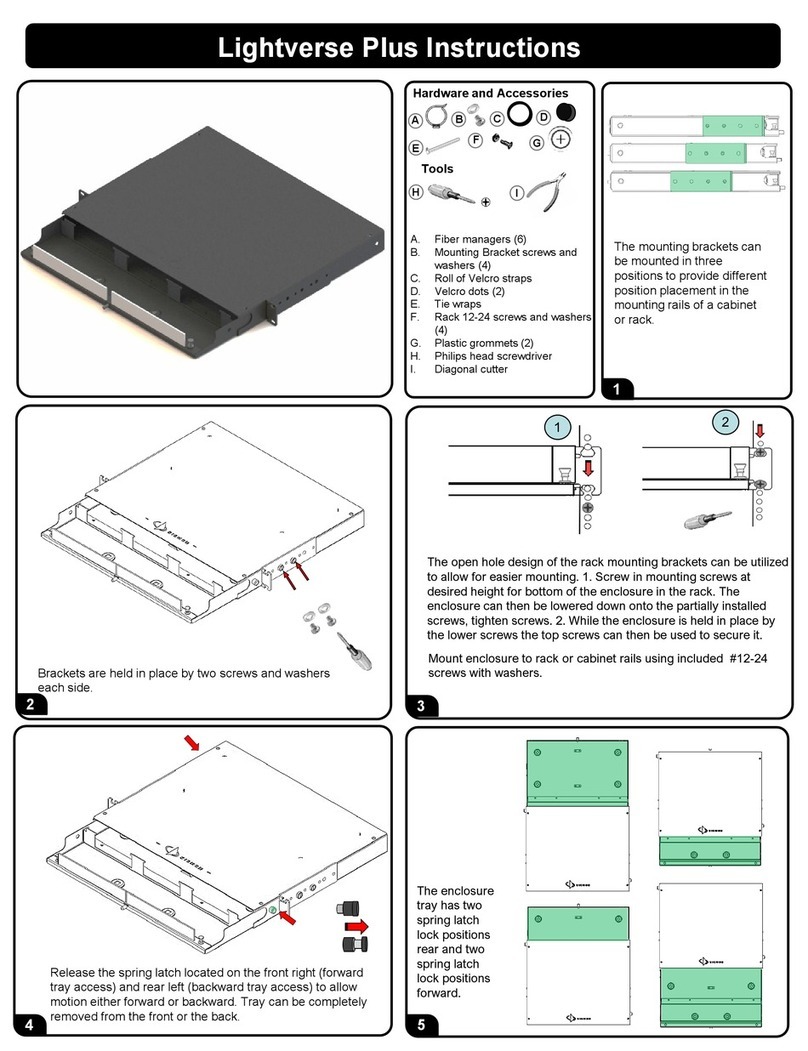

INSTALLATION

1. The unit can be mounted with any orientation over the entire ambient temperature range.

2. Use only explosion proof conduit or explosion proof cable to connect to the enclosure in

accordance with relevant national/international standards (National Electric Code (NFPA,

Article 504)).

3. Conduit seal is required within 18 inches of enclosure.

4. Electrical connection of conductors up to 1.5 mm2are accomodated by polarized plug-in

removable WAGO disconnect/connect cage clamp.

5. Connection to earth ground should use at least one wire with a minimum of 4 mm2copper or

at least two wires each with a minimum 1.5 mm2copper. The resistance path from device to

the point of connection should be less than 1 Ω.

6. Identify the function and location of each connection terminal using the wiring

diagram/control drawing (Drawing No. 2110EX-002).

7. Intrinsically safe conductors must be identified and segregated from non intrinsically safe

conductor and wired in accordance with relevant national/international standards (National

Electric Code (NFPA, Article 504) and ANSI/ISA – RP12.6).

8. Always attach the cables to the connector strain relief plate with cable ties. This will ensure

that cables do not migrate in the enclosure if they are disconnected from the connector by

accident. See pictures below.

9. The enclosure provides an IP54 minimum degree of mechanical protection for indoor and

outdoor installation.

USER MANUAL

Page 9of 16

Document # EL29132

Version: V.002

10. Lock the cover by fastening its hex screw with a hex socket; useahex spanner of 1.5mm.

11. Any unauthorized modification must be avoided.

12. Fuses are not field replaceable and the entire Explosion Proof Housing must be returned to

the manufacturer for repair.

13. Never change jumpers setting while device power is on.

STEP BY STEP INSTALLATION INSTRUCTIONS

1. Check device for proper model and voltage

a. Review the model number on the attached label and compare to the site power

requirements.

Example of a 24v Label

b. Open the enclosure and observe the voltage marked on the label placed on the inside

wall of the enclosure base.. Make sure the voltage matches the model number and

the location voltage requirements.

Example of a 24v Label

2. Loosen the nut on the top part of the 1-inch union, until it is almost removed.

3. Ensure the number of sensor connector pins match the number of 2110EX connector pins.

USER MANUAL

Page 10 of 16

Document # EL29132

Version: V.002

2110EX-xxH connector with 13 pins HLS sensor connector with 13 pins

2110EX-xx Connector with 6 pins Standard sensor connector with 6 pins

4. Apply thread sealant to the 1-inch NPT connector on the sensor.

5. Hold the 2110EX above the sensor flange connector with one hand; insert and tighten up the

connector to the sensor with the other hand. Sensor with HLS connections shown at left;

standard sensor connections shown at right.

Tighten connector

6. Unscrew the bottom part of the union from the 2110EX. Then screw the bottom part of the

union‘s 1-inch FNPT onto the sensor‘s 1-inch MNPT flange until hand tight. Make sure the

connector cable is not caught in the threads or joint. Tighten the union using a 1.5“ wrench

but do not overtighten.

Ensure cable is not caught in threads or joint

7. Screw together the union parts until hand tight. Make sure the thread are straight to avoid

thread damage. Use a 1.5“ wrench to hold the threaded adapter (bottom part of the union)

and a 2-1/16 “ torque wrench to tighten the union nut to 125 ft.*lbs.

Tighten connector

USER MANUAL

Page 11 of 16

Document # EL29132

Version: V.002

8. Connect the external RS485 communication and power wires to the orange connector X1

according to the control drawing 2110EX-002_RevA, following the pinout that is marked on

the circuit board. The wire size should be in the range 14 to 28 AWG. Secure the wires on

the pull tab using a cable tie.

9. Repeat step 8 for the gray HLS switch connector X2, if the 2110EX has the HLS option.

10. Seal the incoming conduit with a certified EX fitting within 18 inches from the 2110EX

enclosure.

USER MANUAL

Page 12 of 16

Document # EL29132

Version: V.002

Control Drawing

USER MANUAL

Page 13 of 16

Document # EL29132

Version: V.002

USER MANUAL

Page 14 of 16

Document # EL29132

Version: V.002

USER MANUAL

Page 15 of 16

Document # EL29132

Version: V.002

USER MANUAL

Page 16 of 16

Document # EL29132

Version: V.002

For more information contact Electrolab:

Electrolab, Inc.

159 Enterprise Parkway

Boerne, Texas

888-301-2400

www.electrolabcontrols.com

This manual suits for next models

1

Table of contents

Popular Enclosure manuals by other brands

Alfa Network

Alfa Network AWAP02O Specifications

extronics

extronics iBATT5XX Installation & operating manual

HYDROCOWL

HYDROCOWL Safe-T-Cover 800 Series Assembly instructions

Vantec

Vantec NexStar 3 specification

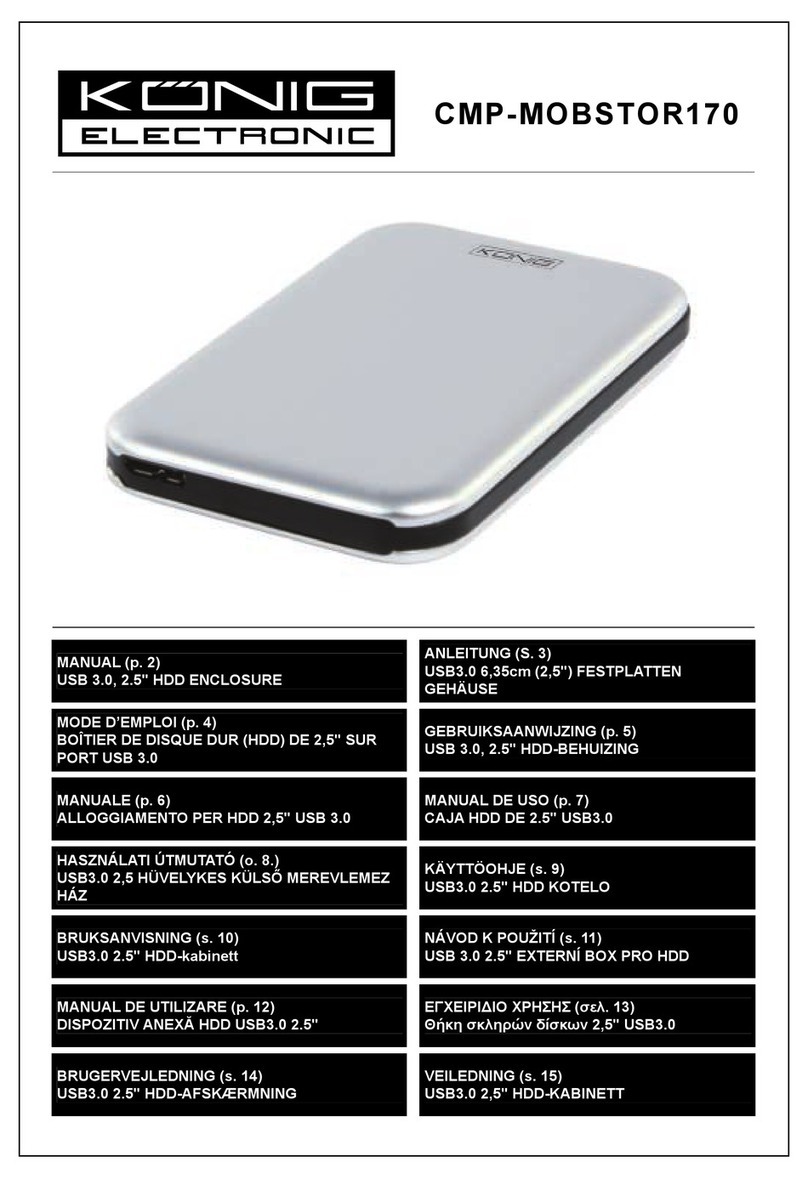

König Electronic

König Electronic CMP-MOBSTOR170 manual

Sumvision

Sumvision Cyclone MKV 2 user manual