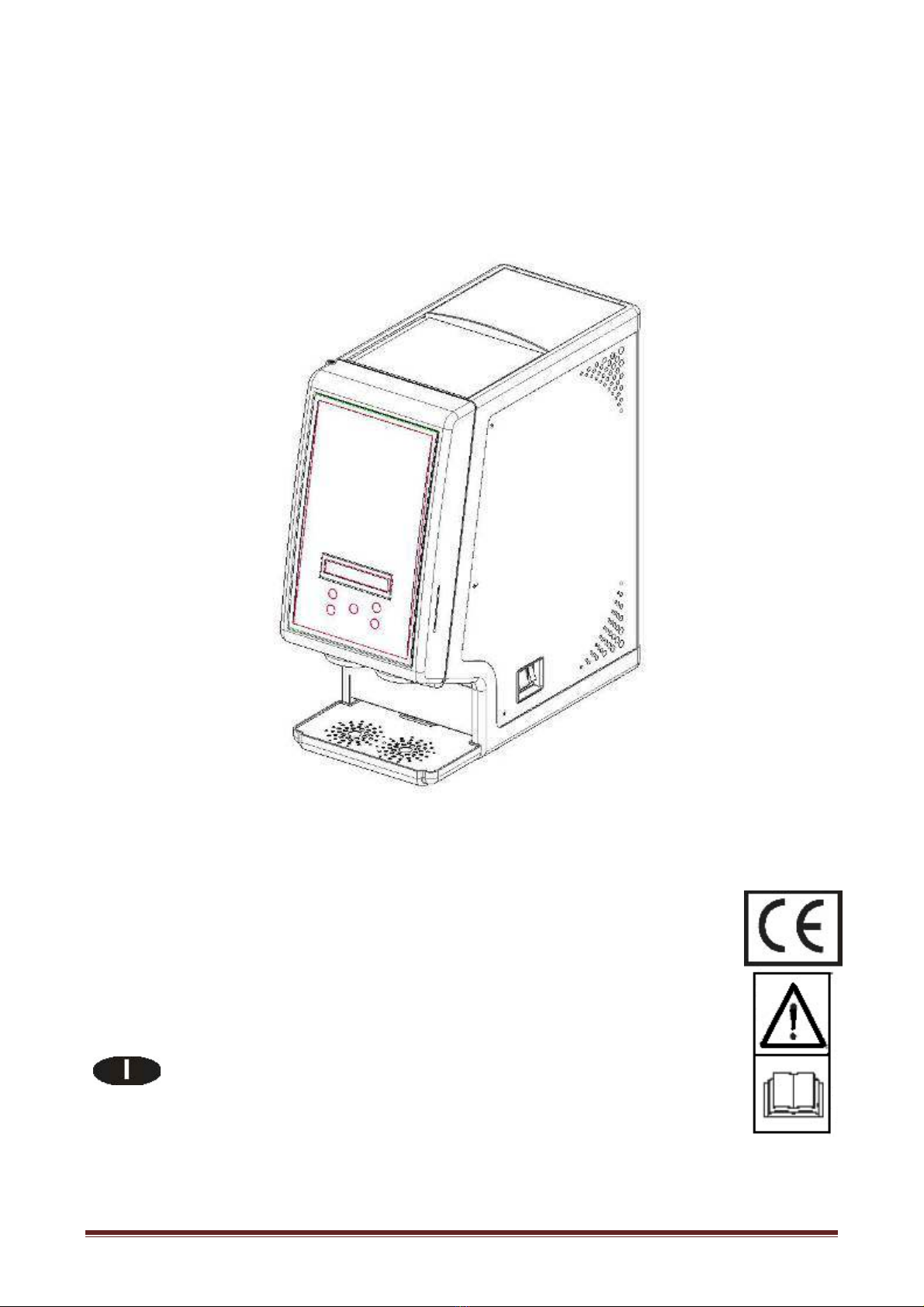

Electrolux Professional GH2 NEW User manual

Pag. 1

USE AND MAINTENANCE

MANUAL

GH2 NEW

Dimensions:

D x L x H --- 410 x 200 x 480 mm

Official language of the manufacturer

Model: GH2 NEW

Issue: 02

/2019

Revisio level:

05

Pag. 2

Pag. 3

All rights of reproduction of this manual are reserved to Electrolux Professio al SPA. Reproduction, even partial, is

prohibited.

he descriptions and illustrations refer to the specific machine/equipment. Electrolux Professio al SPA reserves the

right to make at any time any modification they may deem appropriate for serial production.

his manual:

is an integral part of the supply and must be carefully read for proper use in accordance with the essential

safety requirements;

it is drafted according to the provisions of the Machinery Directive 2006/42/EC and contains the technical

information necessary to properly carry out all safety procedures;

must be carefully stored (protected in a transparent waterproof casing to prevent its wear) and must

accompany the machine throughout its life, including any ownership transfer. In the event of loss or wear,

you may receive a copy, requesting it to Electrolux Professio al SPA reporting the data on the

identification plate

Electrolux Professio al SPA disclaims any liability for improper use of the machine/equipment and/or for damage

caused by operations not covered by this manual.

Pag. 4

Co te ts of this ma ual

0. SAFETY INSTRUCTIONS

1. GENERAL INFORMATION

1.1 SYMBOLS AND TERMS USED IN THE MANUAL

1.2 STAFF TASKS

2. SAFETY PRECAUTIONS FOR THE OPERATOR

2.1 ELECTRICAL EQUIPMENT

3. PRESENTATION OF THE MACHINE

3.1 INTENDED USE

3.2 FORBIDDEN USES

3.3 MACHINE IDENTIFICATION DATA

4. TECHNICAL DATA

4.1 ENVIRONMENTAL CONDITIONS

4.2 VIBRATIONS

4.3 ELECTROMAGNETIC ENVIRONMENT

4.4 NOISE

5. MACHINE SAFETY DEVICES AND GUARDS

5.1 DEFINITION OF MACHINE ZONES

5.2 SAFETY SYSTEMS AND GUARDS

5.2.1 POSITION OF GUARDS AND SAFETY DEVICES

6 RESIDUAL RISKS AND LOCATION OF PICTOGRAMS

7. UNPACKING, TRANSPORTATION & STORAGE

7.1 UNPACKING AND CHECKING THE CONTENTS

7.2 LIFTING

7.3 STORAGE

8. COMMISSIONING AND OPERATION

8.1 RESPONSIBILITIES OF THE USER

8.2 MACHINE LEVELLING

8.3 ELECTRICAL CONNECTION

8.4 DESCRIPTION OF THE MACHINE

8.5 FIRST INSTALLATION AND DAILY STARTUP OPERATIONS

8.6 OPERATION

8.7 CLEANING OPERATIONS

8.8 FAILURE ANALYSIS

9. MAINTENANCE

9.1 MAINTENANCE OPERATIONS

10. UNINSTALL - DISPOSAL

11. WIRINIG DIAGRAM

Pag. 5

0. SAFETY INSTRUCTIONS

T

his i stallatio a d operatio ma ual is a i tegral part of the equipme t a d must

be kept for future co sultatio .

U

less otherwise stated, this ma ual is addressed to operators (staff members who

uses the equipme t o a daily basis) a d to serviceme (staff members qualified to

carry out the i stallatio a d/or mai te a ce).

T

he parts of the ma ual addressed

o ly to serviceme are poi ted out accordi gly. Please read carefully the war i gs

listed here below before i stallatio a d start-up of the equipme t.

T

his equipme t

has bee desig ed to produce coffee, hot chocolate a d similar products i powder

a d soluble i water, do ot use for melt froze product a d i case the product is

froze , do ot operate the applia ce

U

po receipt of the equipme t, make sure that its part umber matches the o e

specified i the order, which ca be fou d o all the delivery docume ts.

T

his equipme t is exclusively desti ed to the purpose for which it was desig ed.

T

he ma ufacturer ca ot be held respo sible for a y damage due to improper use.

T

his applia ce ca be used by childre aged from 8 years a d above a d perso s

with reduced physical, se sory or me tal capabilities or lack of experie ce a d

k owledge if they have bee give

supervisio or i structio co cer i g use of the applia ce i a safe way a d

u dersta d the hazards i volved.

C

hildre shall ot play with the applia ce.

C

lea i g a d user mai te a ce shall ot be made

by childre without supervisio .

T

his equipme t is ot suitable for outdoor use. This machi e is ot suitable for

i stallatio i locatio s where water jets are used a d it must ot be clea ed by a

water jet.

T

he applia ce is o ly to be i stalled i locatio s where its use a d mai te a ce is

restricted to trai ed perso el.

D

o ot store explosive substa ces such as aerosol ca s with a flammable propella t

i this applia ce.

T

his applia ce is i te ded to be used i household a d similar applicatio s such as

–

s

taff kitche areas i shops, offices a d other worki g e viro me ts;

–

F

arm houses a d by clie ts i hotels, motels a d other reside tial type

e viro me ts;

–

b

ed a d breakfast type e viro me ts;

–

c

ateri g a d similar o -retail applicatio s.

T

he i stallatio a d subseque t servici g operatio s must be carried out by skilled

members who have bee trai ed to use the device a d i complia ce with the

regulatio s i force.

Pag. 6

he machine has to be placed on a sturdy, horizontal surface making sure it is well ventilated

by leaving a gap of 20 cm around it and do not install it near heat sources (fig.1); we

recomme d you to mai tai a room temperature betwee 24 a d 32°C.

F

or a safe and correct installation, it is essential to provide a suitable socket controlled by a

thermal cut-out switch whose contacts are at least 3 mm apart, in accordance with the current

national safety regulations.

I

f the power cable is damaged, it must be replaced by the manufacturer, its after sale service

or by qualified personnel, to prevent any possible risk.

he continuous, equivalent, weighted level of acoustic pressure is below 70 dB.

S

afety conditions during maintenance

o ensure sufficient industrial safety, the operator must observe the following points:

•

W

ith the machine on, avoid touching exposed components or electrical connections as

the machine is under dangerous voltages.

•

I

f you remove a guard or replace an electrical component, always make sure that you

have previously switched off the tension from the entire line.

•

A

ny maintenance operation must be carried out by qualified, authorized personnel.

•

A

ny kind of maintenance operation must be carried out with the machine off, checking

that the electric power has been previously turned off, that the water system (if present)

is closed and that the pneumatic system (if present) has been depressurized.

•

D

o not carry out any electrical maintenance in the presence of water or in areas with

high humidity.

•

M

ake sure the area where you carry out maintenance operations, is clean and dry.

•

I

f the line is live, cover the exposed terminals and work safely, always adopting

appropriate protections.

•

N

ever put your body, limbs or fingers in the chambers or openings of the machine when

it is operating.

•

D

o not wear watches, rings, jewelry; avoid wearing loose or dangling apparel such as

ties, torn garments, scarves, unbuttoned jackets, which could accidentally become

entangled in the moving parts of the machine.

A

lso not collected hair can be sucked in

from the motor fans, resulting in scalp laceration.

•

O

nly wear approved safety garments.

•

W

hen there is a possibility of getting hit by projections or from falling solid parts or

similar, use safety glasses with side blinkers, helmets or gloves, if necessary.

•

W

hen working with presence of heat on areas, surfaces or materials, it may be required

to wear gloves and other personal protective equipment, to avoid burns in case of

manual intervention.

Pag. 7

W

hen replacing parts, use only original spare parts.

o contact the technical service center, see page 2 of this manual.

A

ll repairs must be supervised by a person in charge

F

or the entire duration of maintenance

and repair work on the machine, the mai switch must remain off (in zero position).

A

ll the mai te a ce operatio s must be carried out with the machi e

stopped a d electric power tur ed off. It is always ecessary to refer to the

occupatio al officer for all regulatio s applicable i the give case.

R

outine and scheduled maintenance

R

outine maintenance involves a few simple operations which can be carried out by the

operator of the equipment.

o obtain maximum service life and the best economy of

operation we recommend that you follow carefully the instructions in this chapter.

R

outine maintenance concerns mechanical tasks (adjustments, lubrication, cleaning)

and electric tasks to be carried out periodically on the machine by checking the tables

in the following pages.

I

n order to successfully perform maintenance operations, it is

necessary to pay particular attention to the following general rules.

G

e eral rules for the mai te a ce of the mecha ical compo e ts

•

D

uring the removal of the components, avoid dust entering in work areas and in

the components.

•

D

o not use petrol or inflammable solvents as detergent, always use authorized

commercial solvents provided they are not flammable or toxic.

•

D

o not use compressed air to clean mechanical parts.

he dust should be removed only by

vacuum cleaner or cloths.

G

e eral rules for the mai te a ce of the electric compo e ts

•

P

ay attention to the following general rules for electrical components.

•

D

o not drill holes on electric cables which contain wires.

•

D

o not use water, pieces of sponge, damp and/or abrasive cloths to clean the

machine and the electrical components.

•

D

o not use compressed air to clean the electric components.

he dust should

be removed only by vacuum cleaner or with a cloth dampened with mild

detergent.

I

t is important to avoid the penetration of detergents in electric

parts.

I

Pag. 8

C

leaning procedures

I

n order to maintain the unit in like-new operating condition and to respect current

regulations, it’s absolutely necessary to frequently and carefully perform the cleaning

operations as described below.

I

n case of prolonged shutdown (winter storage), the machine must be disassembled, washed

and sanitized according to the instructions in this manual before start-up to ensure the best

possible cleanliness.

!Cautio !

E

lectric shock hazard. Do ot splash water o switches or allow water to flow o to

electrical compo e ts i side the machi e.

!Cautio !

T

o preve t bacteria growth, use o ly sa itizers approved for plastic a d rubber

objects, failure to do so could create a health hazard.

N

OTE: it is responsibility of the operator to be aware of and conform to the requirements of

current local, state and federal laws concerning the frequency of cleaning and conservation of

products used.

he cleaning instructions explained in this section are essential procedures to remove bacteria

and maintain a sanitarily clean machine.

W

e recommend to perform the cleaning and sanitizing procedures every day and

anyway according to the local laws.

he machine and the mix manufacturers decline all responsibility to damage that directly or

indirectly derives from people, animals, as consequence of failure to comply with all cleaning

and sanitation instructions indicated in this manual.

Pag. 9

Y

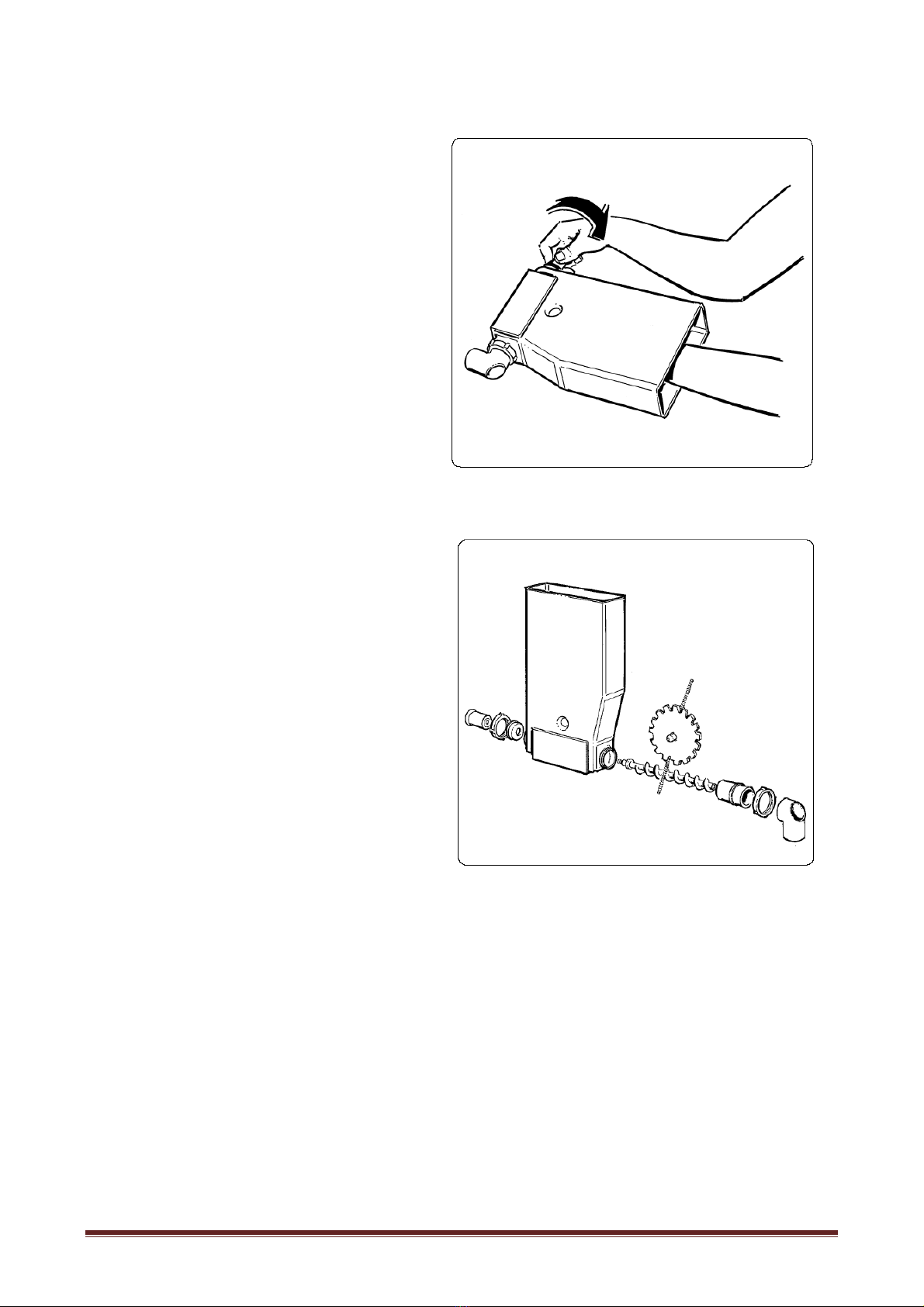

P1

R

I

n order to always have a correct operation of the equipment, it is essential to perform

frequent and thorough cleansing and to comply with applicable health regulations.

!Cautio !

D

o not use water jets under pressure while cleaning

!Cautio !

A

ll cleaning operations must be carried out after switching off the machine and unplugging

the power cord.

N

ever clean the machine when it is on.

E

very day (daily clea i g)

o avoid the formation of lumps inside the brewing pipes, it is necessary to perform a daily

wash, by pressing and holding the "n" button at the end of the working day before performing

the component cleaning operations described below:

•

R

elease the product container Y from the mixing unit;

•

R

otate upwards the outlet fitting R of the powder container

and pull out to remove it.

•

R

emove the splash cover P1;

•

P

ull up on the top of the mixer S to separate it from the

funnel Q.

•

L

ift the funnel Q and pull it outwards.

S Q

Pag. 10

X

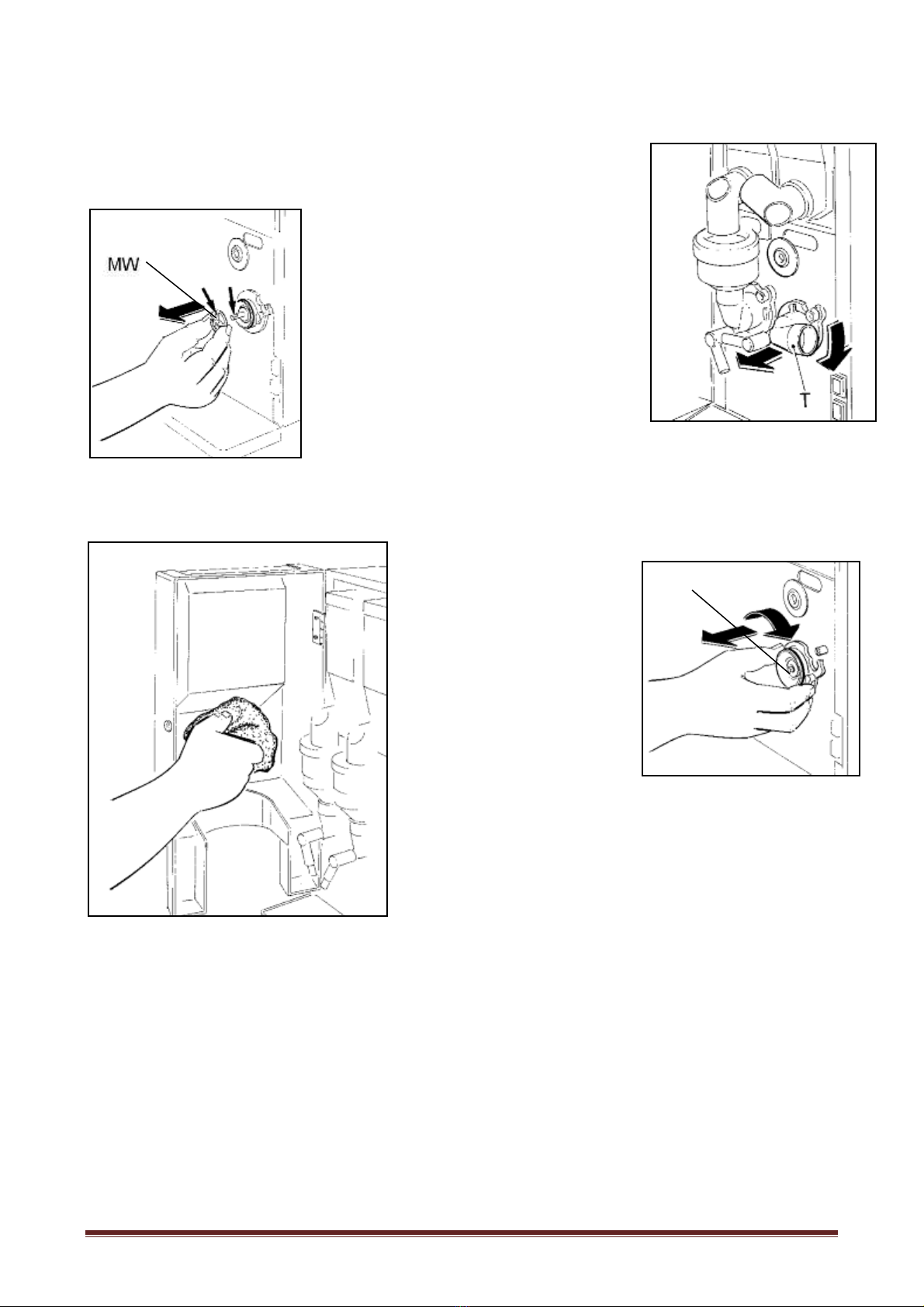

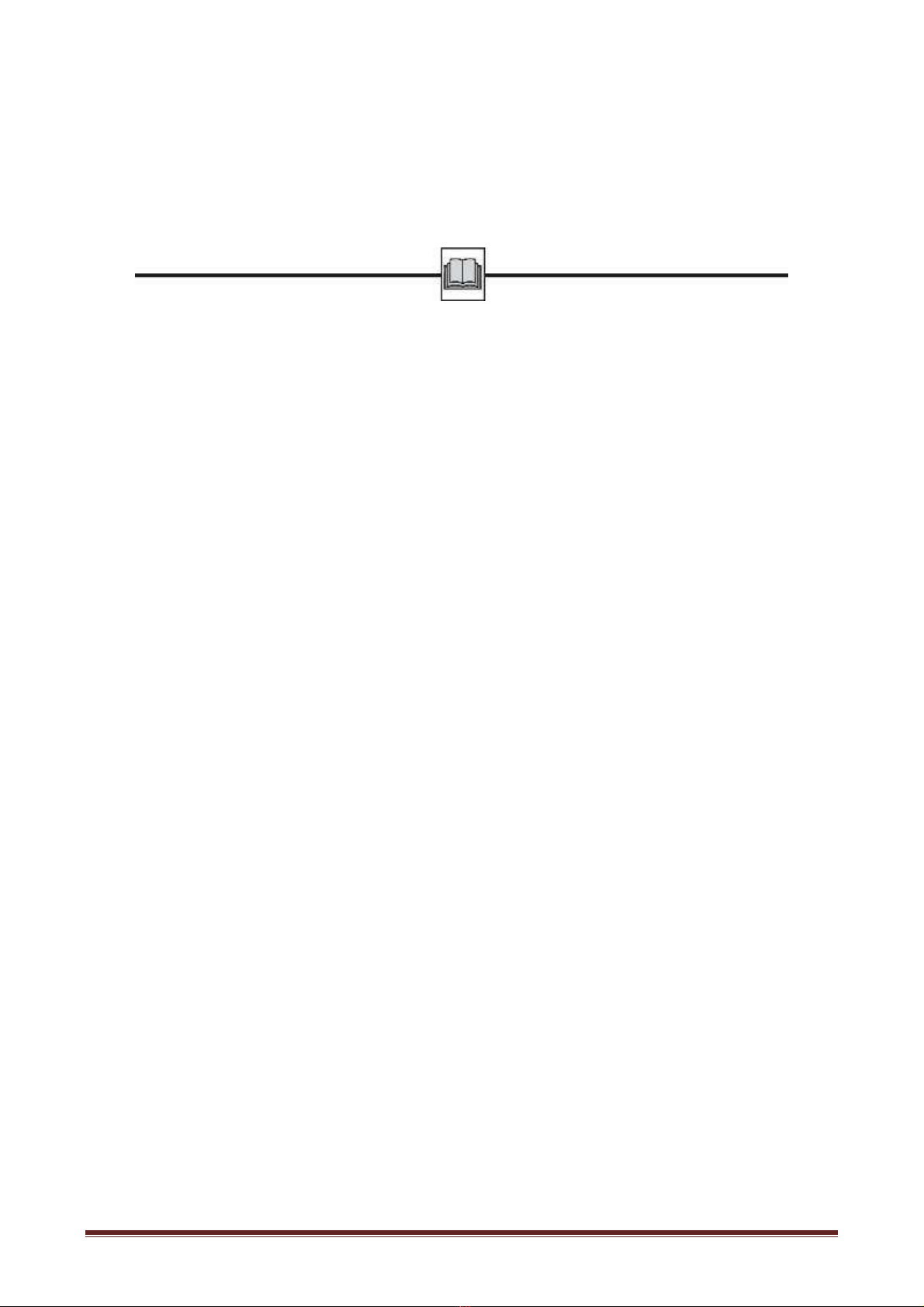

•

R

otate clockwise the mixer and pull it outwards to remove it;

•

R

emove the product mixing wheel

MW using a screwdriver;

C

autio : duri g refitti g

operatio s, the poi t i dicated by

the arrow o the wheel a d the

groove o the shaft must

correspo d.

•

R

otate the support X, and pull to remove it.

•

C

arefully clean all of these components with warm water, dry them completely and refit

them.

•

C

arefully clean the

inside of the door to

remove any drops of

product.

W

eekly

C

lean the tank W.

P

eriodically check the cleanliness of the filter installed on the pipe J1.

Pag. 11

M

o thly

C

lean the containers of the soluble

products.

•

C

arefully empty the containers of the

soluble products from any product build

up inside them.

•

H

olding with one hand the central gear,

rotate counterclockwise the motor shaft

coupling.

•

I

n doing so, all the components that are

part of the container will disassemble, as

shown in the Figure to the side.

•

C

arefully clean all the parts removed

with warm water and wash liquid. hen,

rinse them carefully, dry them perfectly

and reassemble.

o avoid condensations of product inside

the container due to the presence of

moisture that may compromise the correct

operation of the equipment, it is essential

that the containers are perfectly dried

before being installed.

Pag. 12

1. GENERAL INFORMATION

his user manual refers to the chocolate machine and reflects the state of the machine at the

time of delivery. It contains the main information for installation, use, monitoring and

maintenance of the machine. Includes a list of spare parts.

his manual is an integral part of the machine and should always be carefully stored up to the

final dismantling of the machine.

In the event of damage that makes the copy of the manual in your possession unusable, you

may request a copy to the customer service or contact the reseller:

Electrolux Professio al SPA

Viale Treviso 15

33170 Porde o e

www.electrolux.com/professio al

specifying the type of machine and the serial number on the plate of the machine.

he customer support service is always available to provide, upon request, information about

updates that Electrolux Professio al SPA has applied to the machines.

Electrolux Professio al SPA shall be relieved of any liability for damage caused by:

• unauthorised use of the machine

• use by non qualified and/or non trained personnel (the user should be qualified and/or

trained by a echnical Service Centre or equivalent person)

• Incorrect installation (if performed by non trained customer)

• power supply faults

• inadequate maintenance or cleaning of the machine

• unauthorised modifications and operations

• wrong manoeuvres

• use of non-original spare parts

• use of accessories not foreseen or not authorized in writing

• total or partial failure to observe the instructions

• exceptional events

Without the written consent of Electrolux Professio al SPA, the partial reproduction of this

manual is prohibited, and its contents cannot be used for purposes other than those provided

for in the user relationship.

his original manual is in Italian, the only official language the manufacturer is responsible for

in case of non-conformance with the translations. In the case of translations, the user should

contact the dealer or the manufacturer if he does not fully understand the text.

Pag. 13

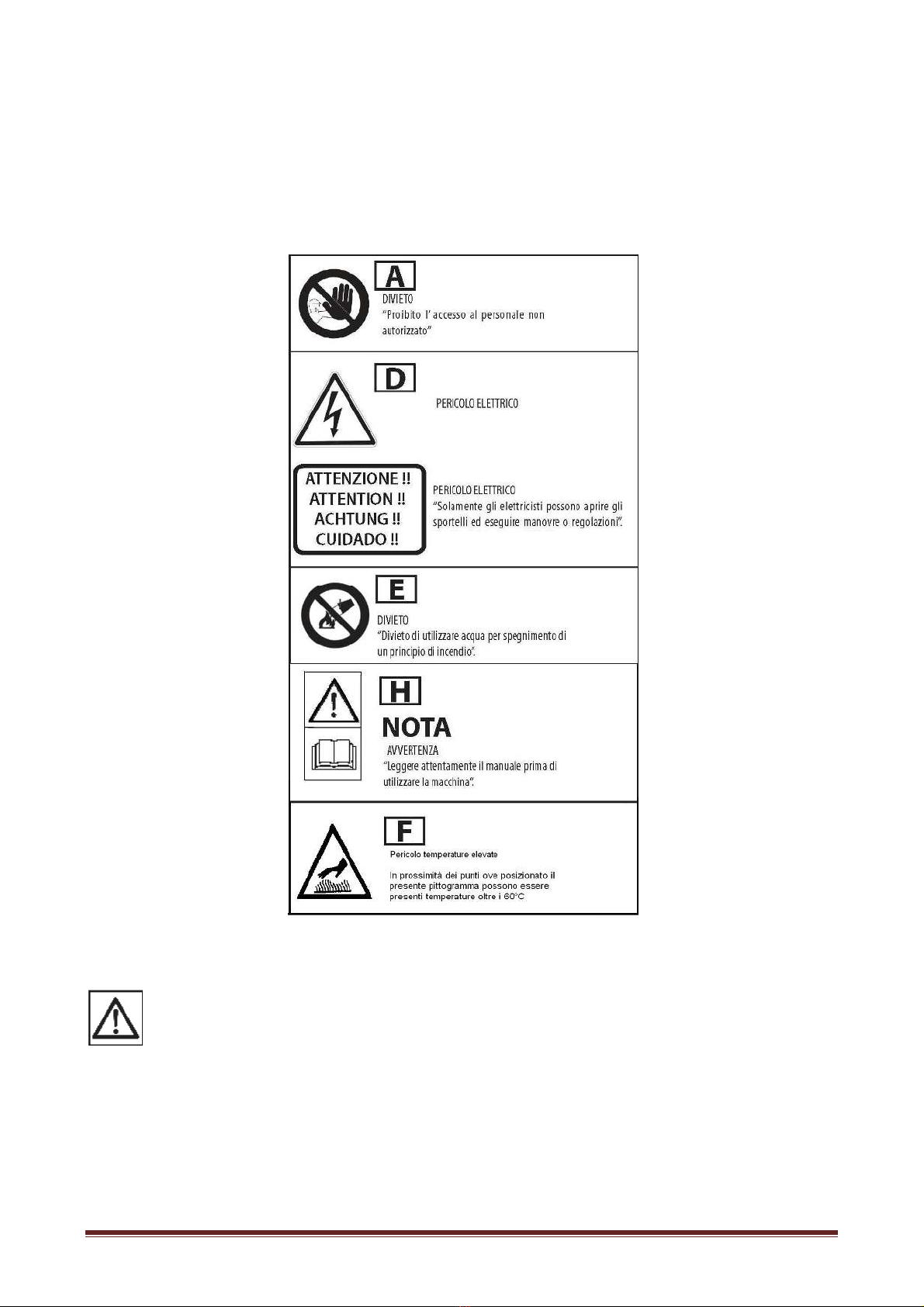

1.1 SYMBOLS AND TERMS USED IN THE MANUAL

Cautio

Indicates instructions that only if properly followed avoid risk situatio s for

people, informs o da gers a d how to avoid them, suggests behavioural

procedures.

War i g

Indicates situations that may cause a risk to the machine and/or to the product

being processed and/or for the environment.

N.B.

Indicates useful information for the consultation of the manual and the good

operation of the machine.

Operator/s

Staff responsible for the various activities related to the entire life cycle of the

machine, handling, installation, use, ordinary and extraordinary maintenance of the

machine.

Mecha ical mai te a ce tech icia

Indicates routine and scheduled maintenance procedures to be performed safely.

hese are the responsibility of the person authorised and trained for such

purposes.

Electrical mai te a ce tech icia

Indicates routine and scheduled maintenance procedures to be performed safely.

hese are the responsibility of the person authorised and trained for such purposes.

Qualified tech icia (Tech ical Service Ce tre)

Indicates the procedures of installation, commissioning and/or corrective

maintenance (electrical/mechanical) that rest with the service technician who is an

employee or is authorized by the manufacturer.

Meaning of terms and definitions:

Exposed perso : any person who is wholly or partially in a dangerous area.

Da gerous area: any area inside and/or close to the machine which constitutes a

risk for the safety and health of the person.

PPE: personal protective equipment

Operators: trained operators authorized to operate the machine (on specific

workstations, general control panel and button panels) and to

perform a visual check of correct operation.

Mai tai ers: specialized operators, authorized for routine maintenance of the

machine, each one with its skills (mechanical and electrical).

Qualified tech icia s: operators employed by the Manufacturer or by the echnical

Service Centre, trained for corrective maintenance.

Pag. 14

1.2 STAFF TASKS

he tasks of the staff are shown below. he corrective action of a Customer Service Centre is

foreseen only in case of specific anomalies or processing issues that are not solved.

Care of the operator (user):

- operations on push button controls, that are related only to normal use;

- visual check of proper functioning of the machine;

- cleaning.

Care of the mai te a ce tech icia :

- mechanical adjustments;

- use of manual controls for work groups operating checks;

- routine maintenance operations;

- corrective maintenance operations, replacements of defective parts (if authorised by the

manufacturer).

Care of the electric tech icia :

- electrical adjustments;

- periodic check of the efficiency of the safety systems;

- use of manual controls for work groups operating checks;

- corrective maintenance operations, replacements of defective parts (if authorised by the

manufacturer).

Care of Tech ical Service Ce tre:

- supplying to the operators and maintainers the support for the time necessary to

understand the proper use and adjustment of the machine and the contents of the manual;

- ensuring the consistency of activities and tasks, following training, recorded with

appropriate individual certificate (later, this task and related checks are the responsibility

of the user).

Pag. 15

2. SAFETY PRECAUTIONS FOR THE OPERATOR

he user of the machine must know the machine and the safety devices indicated in this

manual prior to installation, commissioning, use and maintenance or other operations on the

machine. He designates the personnel in charge of the operation of the machine and is

responsible for their training with particular reference to the existing safety standards.

he user shall supervise and respect the following items:

• Do not allow unauthorised personnel to work on the machine.

• Do not use the machine if faulty.

• Before using the machine, ensure that any unsafe condition has been properly

eliminated;

• Make sure that guards and other protections are in place and that all safety devices are

present and efficient.

• Make sure that the area of the operator is safe and there are no foreign objects;

• Any maintenance operation must be carried out with the machine isolated from energy

distribution networks (electricity or other);

• When prescribed, personal protective equipment must be used;

• Operations of connection, commissioning, maintenance, measurements and

adjustments of the electrical equipment or its components can only be carried out by

qualified personnel.

During normal operation, fixed or movable guards must remain in their seats, properly

fastened and in conditions of total integrity.

Should these protections be removed, for control and maintenance operations, it is mandatory

to restore their efficiency before restarting the machine.

Also apply as reported in Chapter 4.1 ENVIRONMEN AL CONDI IONS.

2.1 ELECTRICAL EQUIPMENT

Operatio s of co ectio , commissioning, maintenance, measurements and adjustments of

the electrical equipment or its components can only be carried out by qualified personnel. It

should be remembered that the frequency converters create dangerous voltages for the health

of persons. Before working on these devices, if they are installed, it is necessary to read the

relevant documentation provided by the manufacturer of the device.

For work to be carried out with live parts, it is necessary to respect the laws in force.

Avoid cable bending and stretching that could break the wires.

Pag. 16

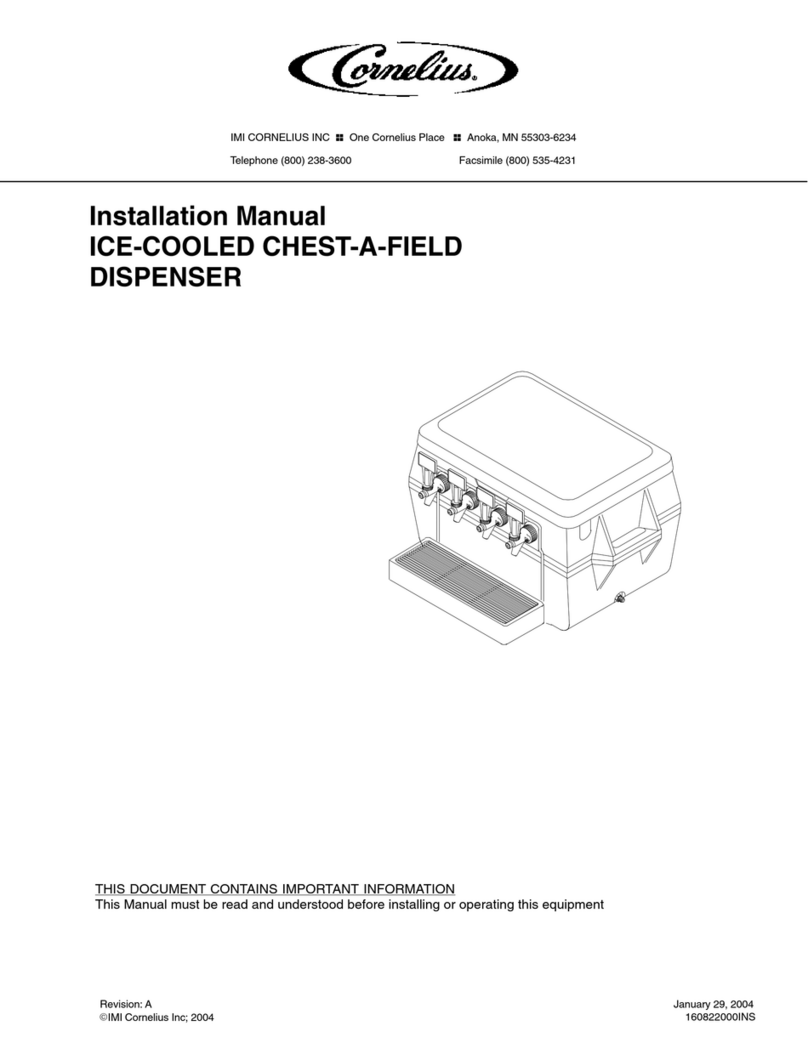

3. PRESENTATION OF THE MACHINE

his machine is a dispenser of freshly brewed hot drinks prepared by mixing hot water with

soluble products.

3.1 INTENDED USE

he machine is designed for professional use in a civilian environment with normal ambient

conditions. he environment where the machine is used must be closed and covered, protected

from the inclemency of the weather, and with the following characteristics:

- emperature: +24/+32 °C;

- Max. relative humidity 45% (non-condensing); temperature/humidity values which exceed

those mentioned above can seriously damage the components.

Accurate information about "serial umber and Model" will allow the service to provide fast,

accurate answers.

3.2 FORBIDDEN USES

A y other use of the machi e or of the product bei g processed is co sidered

misuse, ot i te ded use, because the co seque t risks ca ot be evaluated.

herefore Electrolux Professio al SPA is exempt from all responsibility deriving from failure

to comply with these requirements.

he machine must be used only for the purposes expressly reported in the paragraphs

above and as detailed below. In particular it is forbidden to use it in the following

ways:

- With different energy and performance values.

- Without one or more guards intact and functioning.

- If not properly installed according to the instructions given in this manual.

- Use of machine surfaces such as walking surfaces or support surfaces for other bodies.

- Environments in explosive atmosphere.

- Use outdoors.

he equipment is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience or knowledge, unless they have been able

to benefit, via a person responsible for their safety, of supervision or instruction concerning the

use of the equipment. Children should be supervised to ensure that they do not play with the

equipment.

3.3 MACHINE IDENTIFICATION DATA

Machine identification data is reported on the specific plate.

Pag. 17

4. TECHNICAL DATA

Each machine is equipped with an identification plate with the items shown in the following figure.

he data on the plate are printed indelibly or etched.

• For no reason the data shown on the plate can be altered.

• he mass is shown on the individual machines that make up the plant.

Note that all values a d work data of the

machi e i dicated i this user ma ual

are mea t as maximum values a d ca

be achieved by the machi e (i

complia ce with the specificatio s

i dicated i respect of each parameter)

exclusively for short sessio s of work.

The machi e ca ot achieve these

maximum work parameters

co ti uously whe it is operati g. As

ormal for all machi es, the machi e of

Electrolux Professio al SPA should be

selected a d used referri g to its

average work parameters, it is ot

correct to select a d use the Machi e

referri g to its maximum performa ce

parameters.

DETAILED TECHNICAL DATA

Do ot deviate from the values or worki g limits described i the Tech ical

Data i this ma ual a d i the e closed o es. A y other o desig ated use,

as it does ot co form to the desig a d tech ical specificatio s, is

co sidered to be "NOT ALLOWED".

BASIC SPECIFICA IONS:

Power supply voltage : 230 V and schuko civil socket

aux : 18 V

Frequency : 50 Hz

Max installed power : 1300 W max.

Consumption (1h in standby) : 0.020kWh

Consumption (12 40cc cups per hour): 0.098kWh

Weight of the structure : 13 Kg

Height of the worktop/ ground : on table

Pag. 18

4.1 ENVIRONMENTAL CONDITIONS

he machine must operate only where there is no danger of explosion or fire as it is not

realized in explosion-proof execution.

It is therefore forbidde to i stall a d operate it i areas where there is a

risk of explosio .

he workplace of the machine must have sufficient natural light and be equipped with

adequate artificial lighting and aeration to safeguard the operator's safety and health. It is up

to the user to evaluate the need for an adequate suction system to eliminate vapour and dust

generated during the work process. he lighting of the premises must comply with the laws in

force in the country where the machine is installed, ensure good visibility of the product and of

every area of the equipment, avoid creating hazardous reflections and allow clear reading of

the control panels as well as the detection of emergency buttons; therefore, an illumination

value of at least 400 Lux/mt is expected.

War i g

he area defined as "Operator Zone" must be dry, clean and free of clutter.

4.2 VIBRATIONS

In operating conditions that are in accordance with the instructions for proper use, no

vibrations are present.

4.3 ELECTROMAGNETIC ENVIRONMENT

he Machine is designed to operate properly in a civil electromagnetic environment, it is within

the emission limits and is protected against induced disturbances.

4.4 NOISE

he sound emission levels of the Machine vary depending on the various phases of use; the

tests carried out have shown that they never exceed 70dB.

Pag. 19

5 MACHINE SAFETY DEVICES AND GUARDS

he safety devices and guards must not be tampered with. Before commissioning the machine,

make sure that they work properly and are correctly positioned, verifying their efficiency.

5.1 DEFINITION OF MACHINE ZONES

WORK ZONE

hese are zones within the frame, where the user and other operators have free access during

normal operation. In these zones you can check the normal operation of the machine and/or

quickly operate the push-buttons. In this case, the work areas correspond to the perimeter of

the machine and the "command" positions, with the minimum spaces required for access by

people and/or means.

Control station (about 20 cm around the machine) in front of the button panel and in the areas

reserved to the operator.

Area reserved for qualified maintainers or echnical Service Centre he internal zones of the electrical

cabinet and the machine are considered reserved areas; in these areas it is forbidden to operate

(introducing limbs or other tools)

he following areas are considered hazardous areas with residual risk:

• the area inside the machine near the boiler. he danger is related to the

boiler temperature ranging from 80°C to 100°C

• the product delivery area. he danger is related to the product temperature

which is around 80°C

• For the maintainer there are minor cutting risks due to the presence of

burrs (removable with the use of gloves, with no risk of trapping/crushing

of upper limb fingers)

5.2 SAFETY SYSTEMS AND GUARDS

The machi e is equipped with fixed a d movable guards a d protectio s desig ed to preve t

co tact with movable or da gerous i ter al parts (orga s a d materials).

5.2.1 POSITION OF GUARDS AND SAFETY DEVICES

GUARD

• fixed guards made of sheet that protect the inside of the machine are removable with tools only by

a maintainer.

Pag. 20

6 RESIDUAL RISKS AND LOCATION OF PICTOGRAMS

Points or areas of the machine that have residual hazards, feature safety adhesive pictograms (symbols)

to draw the attention of the operators. his paragraph lists the remaining risk points even without the

presence of pictogram.

War i g plates a d pictograms that perform safety fu ctio s must ot be removed,

covered or damaged. If they are wor out or are removed, it is ecessary to restore

their positio by applyi g a ew o e.

Table of contents

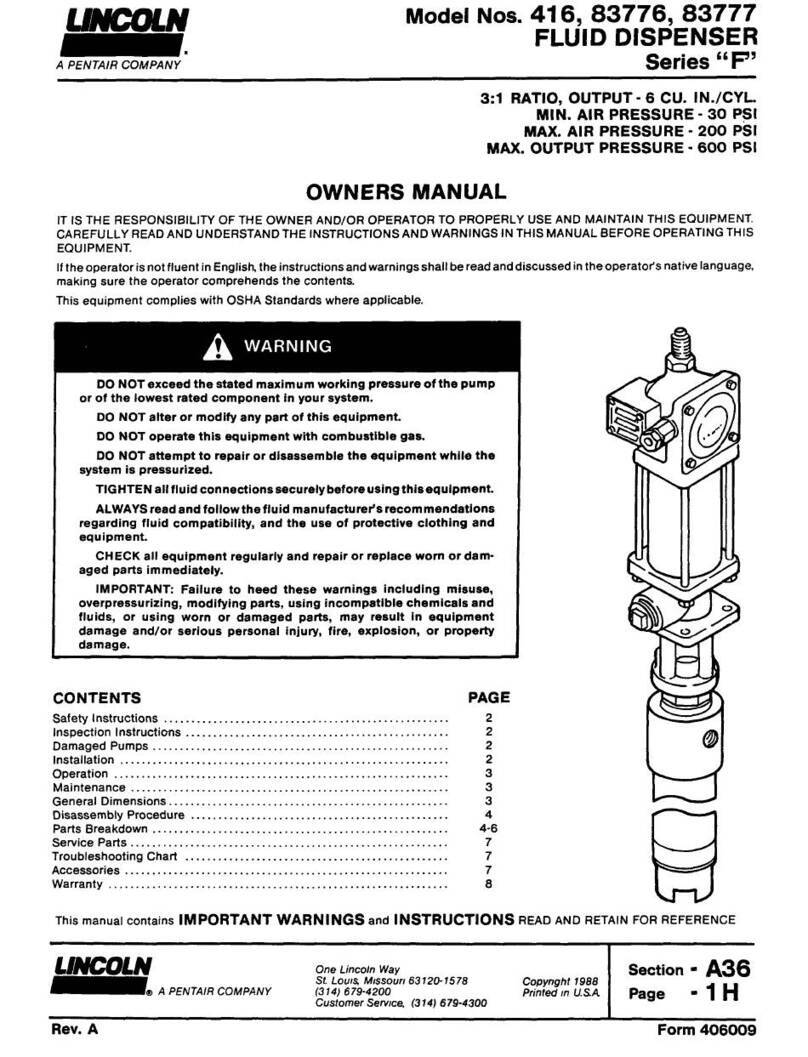

Popular Dispenser manuals by other brands

Cornelius

Cornelius ICE-COOLED CHEST-A-FIELD DISPENSER installation manual

Franke

Franke RODAN RODX600ME Installation and operating instructions

Bunn

Bunn Ultra NX Service & repair manual

Pentair

Pentair LINCOLN 416 owner's manual

socorex

socorex CALIBREX universal 520 operating instructions

CareCo

CareCo DL14036 quick start guide