SAFETY INSTRUCTIONS

For professional use only. Osbserve

allwarnings. Read and unserstand all

instructions before operating equip-

ment. Extreme caution should beused

when operating this equipment asper-

sonol injury and/or property damage

can result from equipment misuse.

Adequate protection isrecommended

toprevent splashing ofmaterial onto

the skin orinto the eyes.

WARNING

WARNING

NEVER point dispensing

valve atany part ofthe body or

atanother person.

PRESSURE RELIEF

PROCEDURE

Toreduce the risk ofserious

bodily injury, including splash-

ing into the eyes or onto the

skin, always follows this proce-

dure When ever you shut off the

pump, when checking or serv-

icing any part of the system,

and when installing, cleaning

or changing any part of the

system.

1. Disconnect air to the pump.

2. Point the dispensing valve

away from yourself and

others.

3. Open the dispensing valve

into an appropriate container

until pressure is relieved.

If you suspect that the dis-

pensing valve or hose is com-

pletely clogged orthat pressure

has not been fully relieved after

following the above procedure,

VERY SLOWLY loosen the hose

end coupling to relieve pressure

gradually, then loosen comple-

tely. Now clear the valve or

hose.

WARNING

WARNING

NEVER trytostop ordeflect

material from dispensing valve

orleakig connection orcom-

ponent with your hand orbody.

WARNING

ALWAYS check equipment

forproper operation before each

use, making sure safety devices

are inplace and operating porp-

erly. DONOT after ormodify

any part ofequipment as

this may cause amalfunction

and result inserious bodily

injury.

INSPECTION

INSTRUCTIONS

WARNING

ALWAYS follow the pressure

relief procedure after shutting

offthe pump, when checking

orservicing any part ofthe sys-

tem; and when installing, clean-

ing orchanging any part ofthe

system.

If overpressurizing of the equipment

is believed to hav occurred, contact the

factory authorized warranty and service

center nearest you for inspection of the

pump.

Specialized equipment and knowl-

edge is required for repair of this pump.

Contact the factory authorized warranty

and service center nearest you for repair

or adjustments other than maintenance

specified in this manual.

Annual inspection by the factory

authorized warranty and service center

nearest you is recommended.

Alist of factory authorized warranty

and service centers is available upon

request.

DAMAGED PUMPS

Any pump that appears to be damaged

in any way, is badly worn or operates

abnormally shall be removed from use

until repairs are made. Contact the

factory authorized warranty and service

center nearest you for repairs.

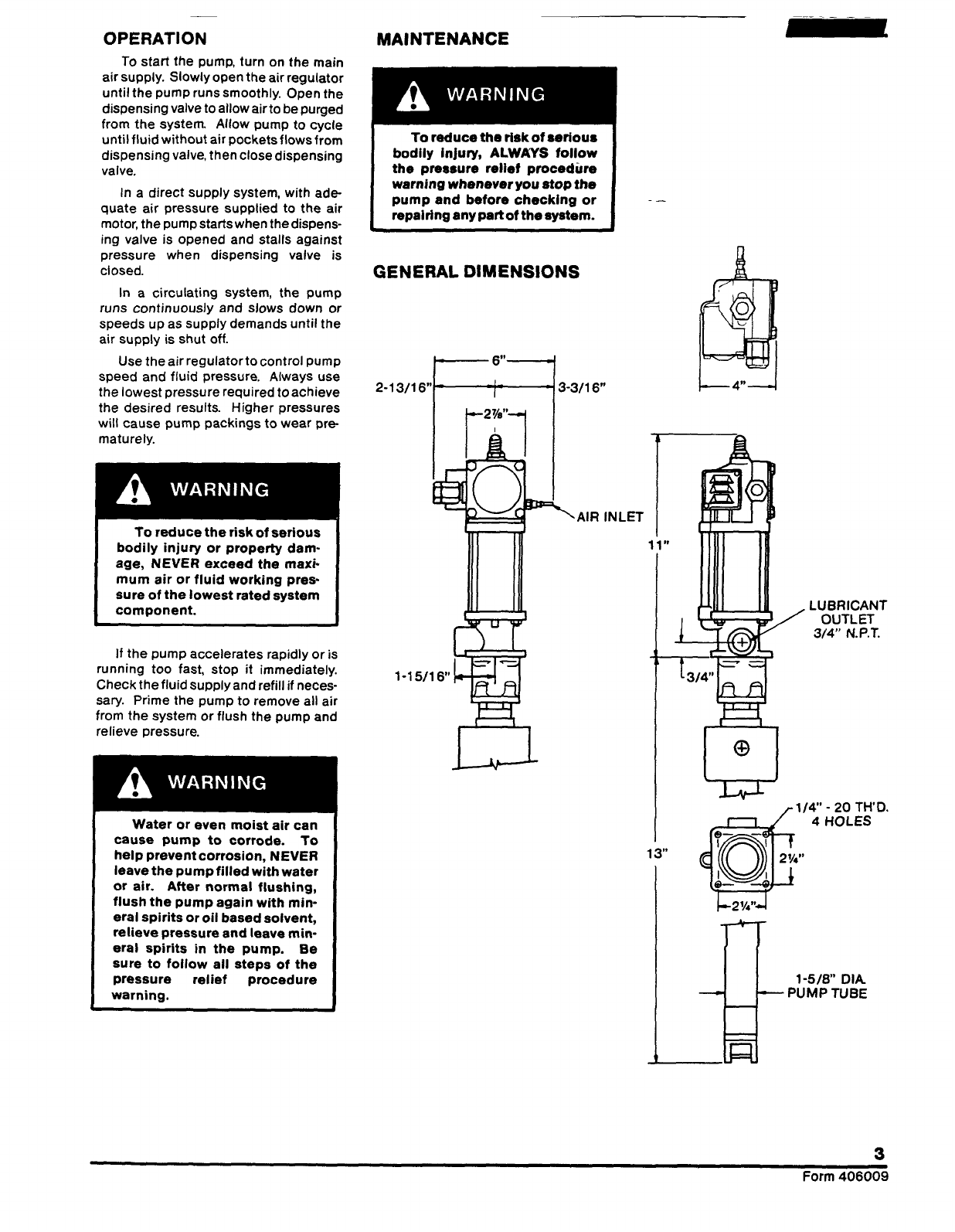

INSTALLATION

The typical installation shown is only

aguide for selecting and installing sys-

tem components. Contact your Lincoln

Representative for assistance in design-

ing asystem to suit your specific needs.

An air line filter/regulator/lubricator

isrecommended for use with your Lincoln

pump to remove harmful dirt and mois-

ture from the Compressed air supply,

and to provide automatic lubrication to

the air motor.

This pump can develop 600

PSl working pressure at 200

PSl maximum incoming air

pressure. Be sure that all sys-

tem equipment and accessories

are rated to withstand the maxi-

mum working pressure of this

pump. DO NOT exceed the

maximum working pressure of

the lowest rated component in

the system.

Flush the supply lines and hoses

with mineral spirits or oil based solvent

and blow dry with air before connecting

them to the system. This is to purge any

contaminants such as dirt, moisture, or

metal shavings that could damage the

pump or system components.

The pump was tested in lightweight

oil which was left in it to protect the

pump from corrosion. Flushing of the

pump before connecting it to the sys-

tem might be desired to prevent Pos-

sible contamination of the fluid you are

pumping.

WARNING

To reduce the risk of injury

from splashing orstatic sparking

when flushing the pump with

mineral spirits or oil based sol-

vent, always hold ametal part

of the dispensing valve firmly

to the side of agrounded metal

pail and operate pump at lowest

possible fluid pressure.

WARNING

ALWAYS read and follow the

fluid and solvent manufacture's

recommedndations regarding the

use ofprotective clothing and

equipment.