Electrolux Professional 601138 User manual

26

Foreword ...................................................................... 27

A.1 General information ............................................. 28

A.1.1 General safety instructions ....................................................28

A.1.2 Additional Indications...............................................................28

A.1.3 Introduction....................................................................................28

A.1.4 Intended use and restrictions..............................................28

A.1.5 Test and inspection ...................................................................28

A.1.6 Definitions........................................................................................28

A.1.7 Machine and manufacturer's identification data.....29

A.1.8 Appliance identification..........................................................29

A.1.9 Copyright..........................................................................................29

A.1.10 Responsibility ..............................................................................29

A.1.11 Personal protection equipment ......................................30

A.1.12 Keeping the manual................................................................30

A.1.13 Recipients of the manual.....................................................30

A.2 Technical data........................................................ 31

A.2.1 General description....................................................................31

A.2.2 Main data..........................................................................................31

A.2.3 Performance, electric energy consumption and wire

diagrams........................................................................................................31

A.2.3.1 Characteristics............................................................................31

A.2.3.2 Wiring diagrams........................................................................32

B.1 Transport, handling and storage ......................... 33

B.1.1 Introduction.....................................................................................33

B.1.2 Transport: instructions for the carrier...............................33

B.1.3 Handling ............................................................................................33

B.1.4 Procedures for handling operations.................................33

B.1.5 Shifting................................................................................................33

B.1.6 Placing the load.............................................................................33

B.1.7 Storage................................................................................................33

B.2 Installation and assembly..................................... 34

B.2.2 Machine space limits..................................................................34

B.2.3 Positioning........................................................................................34

B.2.3.1 Opening of the packaging .................................................34

B.2.3.2 Installation.....................................................................................34

B.2.4 Disposal of packing.....................................................................34

B.2.5 Electrical connection .................................................................34

C.1 Operation............................................................... 35

C.1.1.1Controls...........................................................................................35

C.1.1.2 Mechanical safety devices..................................................35

C.1.1.3 Testing.............................................................................................35

C.2 Settings .................................................................. 35

C.2.1 Setting the work set point......................................................35

C.2.2 Maintenance and care of the slicer ..................................35

C.2.3 Sharpening operations.............................................................35

C.2.4 Sharpening blade........................................................................35

C.8 General safety rules .............................................. 36

C.8.1 Introduction....................................................................................36

C.8.2 Protection devices installed on the machine.............36

C.8.2.1 Mechanical safety ....................................................................36

C.8.2.2 Electrical safety..........................................................................36

C.8.3 Safety signs to be placed on the machine or near its

area ...................................................................................................................36

C.8.4 End of use.........................................................................................36

C.8.5 Instructions for use and maintenance............................36

C.8.6 Reasonably foreseeable improper use ...........................37

C.8.7 Residual risks...................................................................................37

D.1 Machine cleaning and maintenance.................... 38

D.1.1 General instructions...................................................................38

D.1.2 Parts removal..................................................................................38

D.1.3 Cleaning ............................................................................................38

D.1.1 Routine maintenance ..............................................................39

D.1.1.1 Precautions for maintenance ..........................................39

D.1.1.2 Blade change..............................................................................39

D.1.1.3 Precautions in case of long idle periods....................39

D.1.2 Extraordinary maintenance...................................................40

D.1.2.1 Quick troubleshooting guide...........................................40

D.1.3 Maintenance intervals..............................................................40

D.1.3.1 Maintenance frequency ......................................................40

D.1.3.2 Training...........................................................................................41

D.1.4 Disassembly ....................................................................................41

D.1.5 Decommissioning.......................................................................41

D.2 Machine disposal .................................................. 41

D.2.1 Waste storage.................................................................................41

D.2.2 Procedure regarding appliance dismantling macro

operations.....................................................................................................42

D.3 Enclosed documents............................................. 42

27

Foreword

The installation, use and maintenance manual (hereinafter Manual) provides the user with information necessary for

correct and safe use of the machine (hereinafter “machine” or “appliance”).

The following must not be considered a long and exacting list of warnings, but rather a set of instructions suitable for improv-

ing machine performance in every respect and, above all, preventing injury to persons and animals and damage to property

due to improper operating procedures.

All persons involved in machine transport, installation, commissioning, use and maintenance, repair and disassembly must

consult and carefully read this manual before carrying out the various operations, in order to avoid wrong and improper actions

that could compromise the machine's integrity or endanger people. Make sure to periodically inform the user regarding the

safety regulations. It is also important to instruct and update personnel authorised to operate on the machine, regarding its

use and maintenance.

The manual must be available to operators and carefully kept in the place where the machine is used, so that it is always at

hand for consultation in case of doubts or whenever required.

If, after reading this manual, there are still doubts regarding machine use, do not hesitate to contact the Manufacturer or the

authorisedServiceCentretoreceivepromptandpreciseassistance forbetteroperationandmaximumefficiencyofthemachine.

During all stages of machine use, always respect the current regulations on safety, work hygiene and environmental protec-

tion. It is the user's responsibility to make sure the machine is started and operated only in optimum conditions of safety for

people, animals and property.

The manufacturer declines any liability for operations carried out on the appliance without respecting the in-

structions given in this manual.

No part of this manual may be reproduced.

28

A.1 General information

A.1.1 General safety instructions

To ensuresafeuse ofthe machine and a properunderstanding

of the manual it is necessary to be familiar with the terms and

typographical conventions used in the documentation.

The following symbols are used in the manual to indicate and

identify the various types of hazards:

WARNING

Danger for the health and

safety of operators.

WARNING

Danger of electrocution -

dangerous voltage.

Words further explaining the type of hazard are placed next

to the symbols in the text.Warnings serve to ensure the safety

of personnel.

A.1.2 Additional Indications

In this manual the risks arising from incorrect use will be

marked with:

ATTENTION

Risk of damage to the machine or the product.

The parts of the text preceded by the following symbol:

NOTE

Clarications and explanations

provide recommendations to keep in mind during the entire

life-cycle of the product.

The drawings and diagrams given in the manual are not in

scale. They supplement the written information with an out-

line, but are not intended to be a detailed representation of

the machine supplied.

The numerical values given on the machine installation dia-

grams refer to measurements in mm.

A.1.3 Introduction

Given below is some information regarding the machine's in-

tended use, its testing, and a description of the symbols used

(thatidentifythetypeofwarning),thedefinitionsoftermsused

in the manual and useful information for the appliance user.

A.1.4 Intended use and restrictions

Our appliances are designed and optimised in order to obtain

high performance and efficiency. These slicers have been

manufactured to slice cooked and raw charcuterie, warm and

cold meats, bread and cheese, stoneless fruit and vegetables.

They can slice thicknesses up to 15mm. They are not suitable

for cutting frozen goods, charcuterie and meat on the bone or

fruit with stones. Any attempt to slice said products or similar

foods may result in serious damage to the machine and shall

cause the warranty to become void.

Any other use is deemed improper. The appliance must not

be used by people (including children) with limited physi-

cal, sensory or mental abilities or without experience and

knowledge of it, unless supervised or instructed in its use by

those responsible for their safety.

ATTENTION

The machine is not suitable for installation out-

doors and/or in places exposed to atmospheric

agents (rain, direct sunlight, etc.).

A.1.5 Test and inspection

Our appliances are designed and optimised, with laboratory

testing, in order to obtain high performance and efficiency.

The product is shipped ready for use.

Passingofthetests(visualinspection-electricaltest-functional

test) is guaranteed and certified by the specific enclosures.

A.1.6 Denitions

Listed below are the definitions of the main terms used in

the manual. It is advisable to read them carefully before use.

Operator

machineinstallation, adjustment, use,maintenance,cleaning,

repair and transport personnel.

Manufacturer

Electrolux Professional SpA or any other service centre autho-

rised by Electrolux Professional SpA.

Operator for normal machine use

anoperatorwho has been informed and trained regardingthe

tasks and hazards involved in normal machine use.

After-sales service or specialised technician

an operator instructed/trained by the Manufacturer and who,

basedon hisprofessionalandspecifictraining,experience and

knowledge of the accident-prevention regulations, is able to

appraise the operations to be carried out on the machine and

recogniseandpreventanyrisks.Hisprofessionalismcoversthe

mechanical, electrotechnical and electronics fields.

Danger

source of possible injury or harm to health.

Hazardous situation

any situation where an operator is exposed to one or more

hazards.

Risk

a combination of probabilities and risks of injury or harm to

health in a hazardous situation.

Protection devices

safety measures consisting of the use of specific technical

means (guards and safety devices) for protecting operators

against risks.

Guard

an element of a machine used in a specific way to provide

protection by means of a physical barrier.

Safety device

a device (other than a guard) that eliminates or reduces the

risk; it can be used alone or i n combination with a guard.

29

Customer

theperson whopurchasedthemachine and/orwhomanages

and uses it (e.g. company, entrepreneur, firm).

Electrocution

an accidental discharge of electric current on a human body.

A.1.7 Machine and manufacturer's identication data

A reproduction of the marking or data plate on the machine

is given below:

(1) Slicer model

(2) Voltage

(3) Single- or three-phase

(4) Frequency

(5) Power

(6) Amperage

(7) Serial number

(8) Year of production

(9) Name and address of the manufacturer

When installing the appliance, make sure the electrical con-

nection is carried out in compliance with that specified on

the data plate.

ATTENTION

Do not remove, tamper

withormakethemachine's

marking illegible.

NOTE

Refertothedatagivenonthemachine'smarking

for relations with the Manufacturer (e.g. when

ordering spare parts, etc.).

NOTE

When scrapping the machine, the marking must

be destroyed.

A.1.8 Appliance identication

This manual applies to various appliance models. For further

details regarding your model, refer to par.“xxx Dimensions,

performance and consumption”.

A.1.9 Copyright

Thismanualisintendedsolelyforconsultation by the operator

and can only be given to third parties with the permission of

Electrolux Professional SpA.

A.1.10 Responsibility

The Manufacturer declines any liability for damage and mal-

functioning caused by:

`non-compliance with the instructions contained in this

manual;

`repairs not carried out in a workmanlike fashion, and

replacements with parts different from those specified

in the spare parts catalogue (the fitting and use of non-

original spare parts and accessories can negatively affect

machine operation and invalidates the warranty);

`operations by non-specialised technicians;

`unauthorised modifications or operations;

`inadequate maintenance;

`improper machine use;

`unforeseeable extraordinary events;

`use of the machine by uninformed and untrained per-

sonnel;

`non-application of the current provisions in the count-

ry of use, concerning safety, hygiene and health in the

workplace.

The Manufacturer declines any liability for damage caused

by arbitrary modifications and conversions carried out by the

user or the Customer.

The employer, workplace manager or service technician are

responsible for identifying and choosing adequate and suita-

ble personal protection equipment to be worn by operators,

in compliance with regulations in force in the country of use.

ElectroluxProfessionalSpAdeclinesanyliabilityforinaccuracies

containedin the manual,ifduetoprintingortranslationerrors.

Any supplements to the installation, use and maintenance

manual the Customer receives from the Manufacturer will

form an integral part of the manual and therefore must be

kept together with it.

30

A.1.11 Personal protection equipment

Given below is a summary table of the Personal Protection Equipment (PPE) to be used during the various phases of the machi-

ne's service life.

Phase

Protection

garments

Safety

footwear

Gloves Glasses Ear

protectors

Mask Safety

helmet

Transport

Handling

Unpacking

Installation

Normal use

Adjustments

Routine cleaning

Extraordinary cleaning

Maintenance

Dismantling

Scrapping

Legend: PPE required; PPE available or to be used if necessary; PPE not required.

(*) During Normal use, gloves protect hands from the cold tray when being removed from the appliance.

Note: The gloves to be worn during cleaning are the type suitable for contact with the cooling fins (metal plates).

Failure to use the personal protection equipment by operators, specialised technicians or users can involve exposure to chemical

risk and possible damage to health.

A.1.13 Recipients of the manual

This manual is intended for:

`the carrier and handling personnel;

`installation and commissioning personnel;

`theemployerofmachineusersandtheworkplacemanager;

`operators for normal machine use;

`specialised technicians - after-sales service (see service

manual).

A.1.12 Keeping the manual

The manual must be carefully kept for the entire life of the

machine, until scrapping.

The manual must stay with the machine in case of transfer,

sale, hire, granting of use or leasing.

31

A.2 Technical data

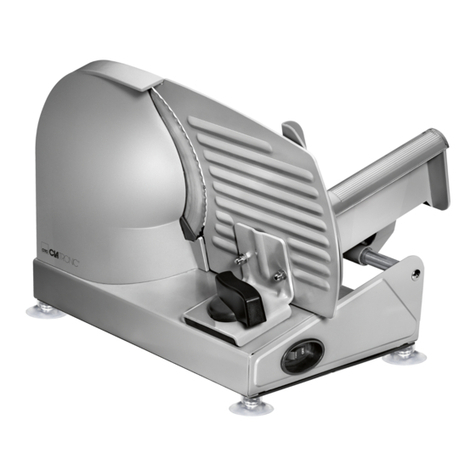

A.2.1 GENERAL DESCRIPTION

The models listed on page 1 are designed to:

`Continuously cut any type of cold cuts, ham without bones,

meat and cheese

`Be safe to use, clean and service

`Ensure the highest degree of hygiene for all contact food

parts thanks to its stainless material

`Ensure the maximum cutting precision

`Be used between +5°C and +40°C

A.2.2 MAIN DATA

`External polished and anodised parts made in magnesium

aluminum alloy suitable for food contact, as prescribed by

1935/2004/CE European regulation

`Small parts and details made in stainless steel to avoid

oxidation

`Blade run by a high quality Poly-V transmission motor

`Noise and vibration of the machine are not disturbing for

the user

`Built-in blade sharpener to make sharpening and cleaning

easier

`Mechanical protection in compliance with the current

legislation

`Protection of the electrical parts in compliance with the

current legislation

`The pressure of sound emission on work station is below

70 dB(A)

`The vibration the user’s arm is subject to is below 2,5m/s2

A.2.3PERFORMANCE,ELECTRICENERGYCONSUMPTION

AND WIRE DIAGRAMS

WARNING!! THE ELECTRICAL STANDARDS FOR WHICHTHE

MACHINEISDESIGNEDARESTATEDONTHEPLATEONTHELEFT

SIDE OF THE SLICER. PLEASE MAKE SURE THAT THE VOLTAGE

OF THE POWER GRID IS THE SAME AS THE ONE STATED ON

THE MACHINE PLATE. MAKE SURE THAT A PROTECTION FROM

ELECTRIC OVERLOAD IS IN PLACE BEFORE CONNECTING THE

EQUIPMENT TO THE POWER GRID

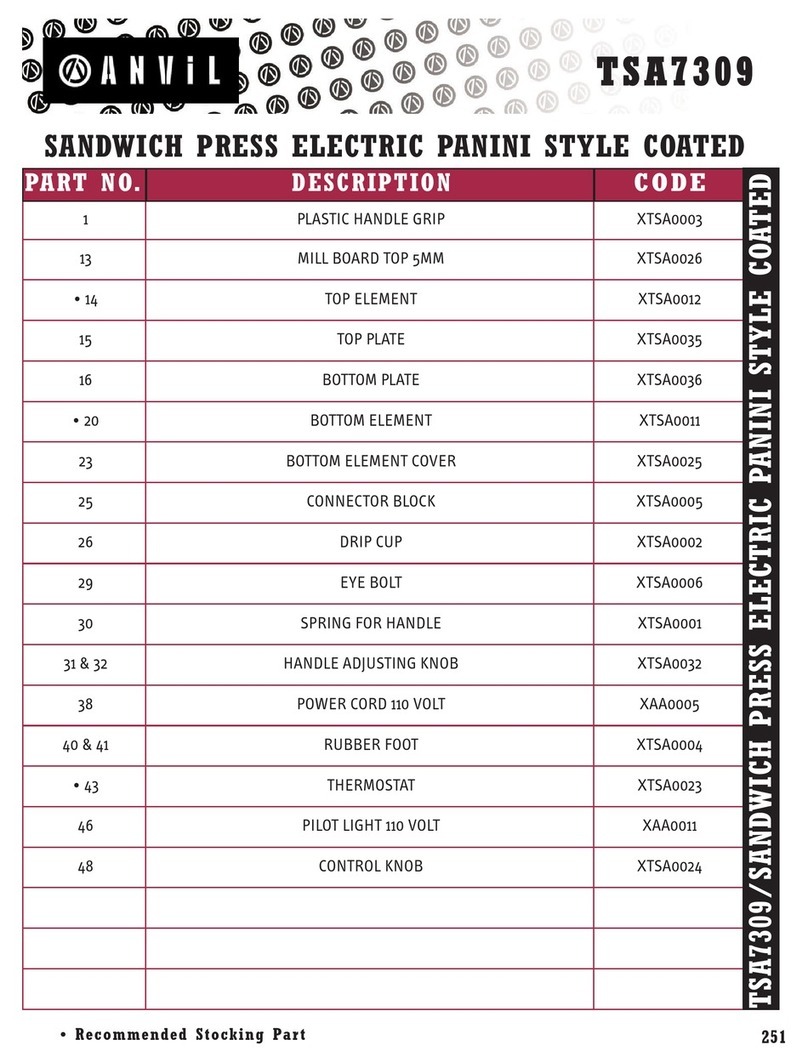

A.2.3.1 CHARACTERISTICS

SLICER MODEL

601138

601114

LUX 250

EASY 250

601139

601115

603330

LUX 300P

601142

EASY 300P

601140

603331

LUX 350

EASY 350

601141

603332

LUX 370

EASY 370

LUX 390

EASY 390

BLADE DIAMETER 250 250 300 300 350 370 390

ABILITY OF CUT (mm)

ROUND PRODUCT 180 180 220 220 265 270 280

SQUARE PRODUCT 180X180 180X180 220X220 220X220 265X265 270X270 280X280

RECTANGULAR PRODUCT 220X180 220X180 230X220 230X220 340X265 340X270 340X280

CUTTING THICKNESS 0-15 0-15 0-15 0-15 0-24 0-24 0-24

TECHNICAL CHARACTERISTICS

VOLTAGE SINGLE PHASE

230V

SINGLE PHASE

230V

SINGLE PHASE

230V

THREE PHASE

380V

SINGLE PHASE

230V

THREE PHASE

380V

SINGLE PHASE

230V

THREE PHASE

380V

SINGLE PHASE

230V

THREE PHASE

380V

SINGLE PHASE

230V

THREE PHASE

380V

MOTOR POWER 0,20KW 0,25KW 0,22KW 0,25KW 0,37KW 0,37KW 0,37KW

ABSORPTION 0,85 A 1,3 A 2,8 A

1,2 A

1,3 A

1 A

2,8 A

1,1 A

2,8 A

1,1 A

2,8 A

1,1 A

WEIGHT (KG) 28 28 32 32 49 53 56

STANDARD EQUIPMENT BRUSH, OILCAN BRUSH, OILCAN BRUSH, OILCAN BRUSH, OILCAN BRUSH, OILCAN BRUSH, OILCAN BRUSH, OILCAN

PACKING DIMENSIONS

(mm) 660X660 H650 660X660 H650 850X660 H660 850X660 H660 850X660 H660 850X660 H660 850X660 H660

32

A.2.3.2 WIRING DIAGRAMS

SLICING

MACHINES

R

SLICING

MACHINES

R

SLICING

MACHINES

R

SLICING

MACHINES

R

601138 - 601114 - 601139 - 601115 - 603330 -

LUX 250 - LUX 300P - LUX 350 - LUX - 370 -

LUX 390 - EASY 250 - EASY 300P - EASY 350 -

EASY 370 - EASY 390

601140 - 603331 - 601141 - 603332 -

LUX 250 - LUX 300P - LUX 350 - LUX 370 -

LUX 390 - EASY 250 - EASY 300P -

EASY 350 - EASY 370 - EASY 390

33

B.1 Transport, handling and storage

B.1.1 Introduction

Transportation, either from one facility to another or inside

the same one, must be done with means with suitable ma-

ximum load.

B.1.2 Transport: instructions for the carrier

ATTENTION

Do not stand under sus-

pended loads during load-

ing/unloading operations.

Unauthorised personnel

must not enter the work

area.

Theweightoftheappliance

alone is not sucient to

keep it steady.

NOTE

The transported load can shift:

`when braking;

`when accelerating;

`in corners;

`on rough roads.

B.1.3 Handling

Arrange a suitable area with flat floor for machine unloading

and storage operations.

B.1.4 Procedures for handling operations

For correct and safe lifting operations:

`use the type of equipment most suitable for characteri-

stics and capacity (e.g. electric pallet truck or lift truck);

`cover sharp edges;

Before lifting:

`send all operators to a safe position and prevent persons

from entering the handling area;

`make sure the load is stable;

`make sure no material can fall during lifting. Manoeuvre

vertically in order to avoid impacts;

`handle the machine, keeping it at minimum height from

the ground.

ATTENTION

For machine lifting and

anchoring,donotusemov-

able or weak parts such as:

plastic protections (Fig.1

Pos.K),meatcarriage(Fig.1

Pos.B) meat pusher and its

knob (Fig.1PosC, P),on-o

buttons protruding from

themachine(Fig.2,Pos.I,D).

B.1.5 Shifting

The operator must:

`have a general view of the path to be followed;

`stop the manoeuvre in case of hazardous situations.

ATTENTION

Do not push or pull the

appliance to move it, as it

may tip over.

B.1.6 Placing the load

Before placing the load, make sure the way is free and that

the floor is flat and can take the load. Remove the appliance

from the wooden pallet, move it to one side, then slide it

onto the floor.

B.1.7 Storage

The machine and/or its parts must be stored and protected

from damp, in a non-aggressive place, free of vibrations and

with room temperatures between -10°C and 50°C. The place

wherethemachineis storedmusthavea flatsupportsurfaceto

avoid deforming the machine or damage to the support feet.

ATTENTION

Appliance positioning, in-

stallation and disassembly

must be carried out by a

specialised technician.

ATTENTION

Do not make modications to the parts sup-

plied with the appliance. Any missing or faulty

parts must be replaced with original parts.

34

B.2.3.2. Installation

Place the slicer on a smooth, flat and stable surface. Any une-

venness of the surface on which the machine is rested can

be compensated using the adjustable feet. In the event the

motor ventilation area faces a wall, make sure that a space of

at least 200mm is left between it and the wall.

Leave enoughroomaroundtheslicersothatitcanbe properly

operated, cleaned and serviced.

It is advisable to leave a space of at least 300mm free around

the machine.The slicer works properly in places with a relative

humidity level of less than 80% and near sources of heat of

no more than 30°C.

B.2.4 Disposal of packing

The packing must be disposed of in compliance with the cur-

rent regulations in the country where the appliance is used.

Allthepackingmaterialsareenvironmentallyfriendly.Theycan

be safely kept, recycled or burned in an appropriate waste in-

cinerationplant.Recyclableplasticparts aremarkedasfollows:

PE

polyethylene: outer wrapping,

instructions bag

PP

polypropylene: straps

The parts in wood and cardboard can be disposed of, re-

specting the current regulations in the country where the

machine is used.

B.2.5 Electrical connection

ATTENTION

If the power cable is dam-

aged it must be replaced

by the After-Sales Service

or in any case by qualied

personnel,inorderprevent

any risk.

Plug the machine into the outlet, making sure that the system

featuresanelectricaloverloadcutout.Toimprovesafetyfurther,

in the wall power supply insert a 50% higher amperage fuse

than the consumption (Ampere) marked in the rating plate

(see paragraph A.1.7).

The blade should rotate anticlockwise seen from theblade

guard side. Should the direction of rotation of the three-phase

slicers be incorrect, invert two of the three wires in the plug.

The connection to the electrical grid must be done in com-

pliance with the local regulation.

ATTENTION

Work on the electrical sys-

tems must only be carried

out by a qualied electri-

cian.

B.2 Installation and assembly

To ensure correct operation of the appliance and maintain

safe conditions during use, carefully follow the instructions

given below in this section.

ATTENTION

Theaboveoperationsmust

be carried out by the spe-

cialised technician in con-

formity with the current

safety regulations, regard-

ingtheequipmentusedand

the operating procedures.

Before moving the appli-

ancemakesurethecapacity

of the lifting equipment

used is suitable for its

weight.

B.2.2 Machine space limits

A suitable space must be left around the machine (for ope-

rations, maintenance, etc.). This space must be increased in

case of use and/or transfer of other equipment and/or means

or if exit routes are necessary inside the workplace. Refer to

par. “B.2.3 Positioning” for information regarding distances

from any other machines present in the room (in fact, close

proximity can create problems of condensate forming on the

walls of the appliance).

B.2.3 Positioning

On receiving the box containing the slicer, make sure that it is

intact and has not been damaged during transit.

B.2.3.1 Opening of the packaging

1- Cut and remove the plastic straps;

2 - Remove the metal staples;

3 - Open the box on its upper side, locate the user guide,

maintenance manual and CE conformity declaration;

4 - Remove the slicer from the box by lifting it upwards;

WARNING!! USERS MUST FOLLOW THE INSTRUCTIONS OF

PARAGRAPH B.1.3 THOROUGHLY TO AVOID ANY DAMAGE TO

THE EQUIPMENT AND DANGER FOR PEOPLE DURING THE

WHOLE PROCEDURE.

5 - Remove the polyethylene bag;

6- Lift the machine: two people are required to handle the

machine, using the feet as handholds;

7 - Check the contents of the packaging, making sure they

correspond to the specifications on the documents;

WARNING:THEPACKAGINGCANBEDISPOSEDOFASMUNICIPAL

SOLIDWASTE:COMPLYWITHTHELAWDISPOSITIONSINFORCE

IN THE PLACE OF INSTALLATION. DO NOT LITTER: DISPOSE OF

THE PARTS MAKING UP THE PACKAGING APPROPRIATELY.

35

C.1 Operation

Use the slicer as it was designed to be used. Never push the

product towards the blade by hand. The product carriage is

tilted so as to enable the product to slide towards the blade

under its own weight. Keep hands well away from the blade

and use the relevant handle to move the product carriage

safely back and forth.

C.1.1.1 Controls

The slicers are switched on and off electrically by means of

two buttons, I (start) and O (stop). Both feature a white lamp

which indicates when the blade is rotating. The machine fe-

atures a safety switch in the blade guard connected with a

no voltage relay. Every time the supply voltage is cut off, the

button“I”(start)mustbepressedtostartthe machineupagain.

C.1.1.2 Mechanical safety devices

`With the exception of the actual cutting section, the

blade is totally protected by an irremovable guard which

cannot be removed.

`The product carriage can be removed only if the fence

covers the blade and the graduated knob position is

between 15 and 0.

`Thesliceassemblycanonly beopened(usingthe gradua-

ted knob) if the product carriage is secured in its normal

operating position.

`The blade can only be removed using the bladeremoval

tool supplied.

`None of the safety devices can be removed; dismant-

ling or tampering with them would make the machine

unsafe, and result in the manufacturer no longer being

responsible for any accidents.

C.1.1.3 Testing

`Make sure all the slicer components are assembled

properly.

`Check the handwheel securing the blade guard is locked

in place.

`Press the start button and check the machine can be

switched on and off.

`Check the sliding of the product carriage and product

press.

`Check the sharpening device works properly.

`Check the opening of the slice assembly

C.2 Settings

C.2.1. Setting the work set point

WARNING!! WITH SWITCHED OFF MOTOR, MAKE SURETHE

EDGE OF THE BLADE IS COVERED AND PROTECTED BY THE

FENCE BEFORE PUTTING THE PRODUCT ON THE MACHINE.

WARNING!! THE PRODUCT CUT MUST BE DONE BY USING

THE SPECIAL HANDLES AND KNOBS.

WARNING!! IT IS THEREFORE FORBIDDEN TO BLOCK THE

PRODUCT ON THE CARRIAGE WITH HANDS.

1) Put the graduated knob (A) in the position between 15

(fifteen) and 0 (zero) by turning the knob clockwise on full

lock. Make sure the blade edge is fully covered and protected

by the fence.

2) Move the product carriage “B” as far away from blade “K”

as possible.

3) Lift the product press“C”using the relevant handle. Set the

product down on the product carriage, lower the product

press onto or behind the product.

4) Select the desired thickness by means of knob“A”.

5) Press the button “I”(start).

WARNING!! ALWAYS CHECKTHATTHELIGHTINTHEON-OFF

BUTTON TURNS ON AS THE EQUIPMENT IS SWITCHED ON.

6) Push the product carriage to slice the product by means

of handle “D”.

7) Once you have finished using the machine, swith it off by

pressing the “O” (stop) button and set the graduated knob

in the space between 15 (fifteen) and “0” (zero) by turning it

clockwiseonfulllock.Makesuretheblade edgeisfullycovered

and protected by the fence.

C.2.2. Maintenance and care of the slicer

For the sake of hygiene, the slicer must be kept clean.The ma-

chine must be disassembled and cleaned at the end of each

working day, and whenever the type of product being sliced

is changed (e.g. change from raw meats to cooked meats)

following the sequence illustrated in fig. 2.

C.2.3. Sharpening operations

WARNING!! the sharpening operation must be performed

by skilled personnel.

Never attempt to clean the blade whilst it is moving. The

sharpening device can no longer sharpen the blade once its

diameter is worn down by 6 mm.

If the slicer is to work properly, the blade must be kept sharp.

It is better to sharpen it a little daily than a lot once a week.

WARNING!! THE BLADE MUST BE CLEANED AS DESCRIBED

IN PARAGRAPH D.1.3 BEFORE SHARPENING.

DO NOT SHARPEN THE BLADE ANY FURTHER WHEN THE

DISTANCE BETWEEN BLADE EDGE AND BLADE GUARD

INTERNAL BORDER REACHES 6MM. AT THIS POINT IT IS

COMPULSORY TO CHANGE THE BLADE BY THOROUGHLY

FOLLOWING THE INSTRUCTIONS OF PARAGRAPH D.1.1.2

Sharpening a dirty blade results in a poor sharpening and

the deterioration of the sharpener and its stones, leading to

muchworseperformance.Remove anystoneremainfrom the

blade and the machine with a cloth soaked with soapy water

or alcohol after sharpening.

36

C.8.2.2 Electrical safety

The slicer’s electrical system is EN 60204 -1 compliant.

A relay in the control circuit makes that the re-start of the

equipment after an accidental power failure has to be done

manually (voluntary reset).

C.8.3 Safety signs to be placed on the machine or near

its area

Danger Meaning

danger of electrocution

(shown on electrical parts with

indication of voltage)

ATTENTION

Do not remove, tamper

with or make illegible the

safety, danger and instruc-

tion signs and labels on

the machine.

C.8.4 End of use

When the appliance is no longer to be used, make it unusable

by removing the mains power supply wiring.

C.8.5 Instructions for use and maintenance

Risks mainly of a mechanical, thermal and electrical nature

exist in the machine.

Where possible the risks have been neutralised:

`directly, by means of adequate design solutions,

`indirectly by using guards, protection and safety devices.

Any anomalous situations are signalled on the control panel

display.

During maintenance several risks remain, as these could not

be eliminated, and must be neutralised by adopting specific

measures and precautions.

Donotcarryoutanychecking,cleaning,repairormaintenance

operations on moving parts.

Workers must be informed of this prohibition by means of

clearly visible signs.

To guarantee machine efficiency and correct operation, pe-

riodical maintenance must be carried out according to the

instructions given in this manual.

Inparticular,makesuretoperiodicallycheckcorrect operation

of all the safety devices and the insulation of electrical cables,

which must be replaced if damaged.

WARNING!! Before sharpening make sure the graduated

knob is in the position between 15 (fifteen) and 0 (zero), that

is on full clock clockwise with blade edge fully covered and

protected by the fence.

C.2.4. Sharpening blade (Fig. 4)

1) Remove the grease from the blade both inside and out

using a cloth dampened with alcohol.

2)Turn the knob half a turn fig. 4.1. Lift the sharpening device,

rotate it 180° and lower it again fig. 4.2, secure the sharpening

device in place by tightening the knob half a turn.

3) Start the machine up, press the button until the grinding

wheel presses slightly against the blade. This operation is

complete when a slight burr forms on the front edge of the

blade: this is checked by switching off the machine Fig. 4.3.

4) Start the machine up, press the appropriate knob Fig. 4.4

until the deburring wheel approaches the blade for a maxi-

mum of 2 seconds. Switch off the machine and make sure the

burr has been removed.

5) Return the sharpening device to its initial position by tur-

ning the knob Fig. 4.1. Clean the blade and all the parts cove-

red with the dust produced by the sharpening using a cloth

dampened with alcohol.

C.8 General safety rules

C.8.1 Introduction

The machines have electric and/or mechanical safety devices

for protecting workers and the machine itself. Therefore the

user must not remove or tamper with such devices.

The Manufacturer declines any liability for damage due to

tampering or their non-use.

C.8.2 Protection devices installed on the machine

C.8.2.1 Mechanical safety

As far as mechanical risk is concerned, the slicer is

EN1974:1998+A1 “Slicing machines - Safety and hygiene re-

quirements”Europeanregulationcompliant,andthereforealso

complies with 2006/42/CE Machinery Directive.

The most important protection devices are:

a) FIXED blade guard ring to protect the whole pat of the

machine not used while cutting.

b)Carriage removable for cleaning only with graduated knob

in full lock clockwise, and therefore with fully covered and

protectedbladeedge.Theseconditionsremainmechanically

unchanged as long as the carriage is removed.

c) Removable blade cover for cleaning.

d) Clear plastic fingers protection fixed to the carriage. Built-in

aluminum thumb protection on the carriage.

e) Meat pusher with hilt handle positioned at least 150mm

from the blade

f) Plastic blade remover tool for a safe blade removal.

WARNING!! The protectionare not removable.Anyattempt

to remove or disassemble them makes the slicer a dangerous

equipmentforwhichtheproducerisnottobeheldresposible.

37

ATTENTION

Extraordinary machine

maintenance operations

must only be carried out

by specialised technicians

provided with all the ap-

propriate personal pro-

tection equipment (safe-

ty shoes, gloves, glasses,

overalls, etc.), tools, uten-

sils and ancillary means.

Never operate the ma-

chine, removing, modify-

ing or tampering with the

guards, protection or safe-

ty devices.

Before carrying out any

operation on the machine,

always consult the manu-

al, which gives the correct

procedures and contains

important information on

safety.

C.8.6 Reasonably foreseeable improper use

Improper use is any use different from that specified in this

manual. During machine operation, other types of work or

activities deemed improper and that in general can involve

risks for the safety of operators and damage to the appliance

are not allowed.

Reasonably foreseeable improper use includes:

`lack of machine maintenance, cleaning and periodical

checks;

`structuralchangesormodificationstotheoperatinglogic;

`tampering with the guards or safety devices;

`failure to use personal protection equipment by opera-

tors,specialisedtechniciansand maintenancepersonnel;

`failure to use suitable accessories (e.g. use of unsuitable

equipment or ladders);

`keeping combustible or flammable materials, or in any

case materials not compatible with or pertinent to the

work, near the machine;

`wrong machine installation;

`placing in the machine any objects or things not com-

patible with refrigeration, freezing or preservation, or

that can damage the machine, cause injury or pollute

the environment;

`climbing on the machine;

`non-compliance with the requirements for correct ma-

chine use;

`other actions that give rise to risks not eliminable by the

Manufacturer.

ATTENTION

The previously described

actions are prohibited!

C.8.7 Residual risks

The machine has several risks that were not completely eli-

minated from a design standpoint or with the installation of

adequate protection devices.

Nevertheless,throughthismanualthe Manufacturerhastaken

steps to inform operators of such risks, carefully indicating the

personal protection equipment to be used by them.

Sufficient spaces are provided for during the machine instal-

lation stages in order to limit these risks.

To preserve these conditions, the areas around the machine

must always be:

`kept free of obstacles (e.g. ladders, tools, containers,

boxes, etc.);

`clean and dry;

`well lit.

For the Customer's complete information, the residual risks

remaining on the machine are indicated below: such actions

are deemed improper and therefore strictly forbidden.

Residual risk Description of hazardous situation

EXPOSED BLADE

PART NOT

PROTECTED

BY THE BLADE

GUARD RING

FOLLOW THE INSTRUCTIONS OF

PARAGRAPHC.2OFTHEMANUALWHILE

USING THE SLICER

BLADE GUARD

PLEASE NOTE THAT THE BLADE GUARD

RING DOES NOT COMPLETELY PREVENT

CUTTING RISK INTHE SHARPENER AREA,

EVEN THOUGH THE POSSIBILITY AND

SERIOUSNESS OF ANY ACCIDENT IS

HIGHLY DECREASED

MEAT PUSHER

WITH SPIKES

THE MEAT PUSHER SPIKES MAY HURT

USERS IF TOUCHED WITH HANDS

38

Do not use sodium hypochlorite based products or abrasive

detergent for cleaning to prevent the anodised parts of the

machine from damage.

D.1.2 Parts removal

REMOVALOFTHECARRIAGEWITHINTERLOCK(Fig. 2 eFig.2/A)

1) Isolate the machine from the power supply by unplugging

it, or switching off the automatic switch located near the

outlet. Never settle for simply pressing the slicer’s “O”button.

2) Put the graduated knob (A) in the position between 15 (fif-

teen) and 0 (zero) by turning the knob clockwise on full lock.

Make sure the blade edge is fully covered and protected by

the fence. (Fig. 2/A)

3) Unscrew handwheel“Q”completely in any position.

4) With a relatively firm jerk, pull the product carriage towards

the stop “R” so that the locking mechanism engages. Slide

the product carriage unit vertically from its guide. The slice

assembly remains locked in the“0” position.

5) Unscrew the fastening handwheel“F”completely, hold the

blade guard“L” and remove it from the machine completely

6) Always check that in these conditions the fence is blocked.

REMOVAL OF THE COVER BLADE (Fig.2)

1) Unscrew the cover blade knob completely (F)

2) Press the knob in order to slightly press the internal part of

the cover blade (L) too and move it from its position

3) Remove the cover blade by holding the knob or the upper

edge of the disk.

Make sure that the user has been properly trained to use the

machine as prescribed by this manual.

Use only water and neutral detergent / disinfectant (PH 7-8)

for degreasing and disinfection, rinse and dry only with clean

water and a soft, dry cloth.

Do not use the aforementioned products at temperatures

above 45°C.

REMOVAL OF THE SHARPENER (FIG.2)

WARNING!! beware of the exposed cutting blade edges

that could injure the user when the sharpener is not in place.

`Unscrew the knob with 3 turns (H)

`Hold the knob (V) and lift the sharpener upwards removing

it from the slicer.

D.1.3 Cleaning

BLADE CLEANING

WARNING!! The maximum attention must be paid during

the procedure due to cutting risk. Before cleaning the blade,

unplug the machine from the power grid.

`Close the fence: put the graduated knob (A) in the posi-

tion between 15 (fifteen) and 0 (zero) by turning the knob

clockwise on full lock. Make sure the blade edge is fully

covered and protected by the fence (Fig. 2/A).

`To do this make sure that the cover blade and the carriage

have already been removed.

`Press the front surface with a wet cloth and slowly move it

from the center to the edge of the blade while turning the

blade with a hand.

`Repeat for the back of the blade.

`Dry the blade following the same procedure with a soft,

dry cloth.

D.1 Machine cleaning and

maintenance

ATTENTION

Before carrying out any

cleaning or maintenance,

disconnect the appliance

from the power supply and

carefully unplug it.

During maintenance, the

cableandplugmustbekept

in a visible position by the

operator carrying out the

work.

Do not touch the appliance

with wet hands or feet or

when barefoot.

ATTENTION

Do not remove the safety

guards.

Use suitable personal pro-

tectionequipment(protec-

tive gloves).

WARNING!! BEFORE CLEANING OR SERVICING THE SLICER,

MAKE SURE THAT:

`THE PLUG IS NOT CONNECTED TO THE POWER GRID

`THE FENCE HAS BEEN CLOSED BY TURNING THE

GRADUATEDKNOB“A”CLOCKWISEONFULLLOCKTILLTHE

POSITION BETWEEN “15” (FIFTEEN) AND “0” (ZERO), AND

THEREFORE THE BLADE EDGE IS COMPLETELY COVERED

AND PRTECTED BY THE FENCE.

D.1.1 General instructions

In order to maintain the highest degree of hygiene, the slicer

hastobecleanedattheendof everyworking dayandanytime

a new product is cut (ex.: cooked meat is cut after fresh meat),

as showed in picture 2.

Make sure that the user has been properly trained to use the

machine as prescribed by this manual.

Use only water and neutral detergent / disinfectant (PH 7-8)

for degreasing and disinfection, rinse and dry only with clean

water and a soft, dry cloth.

Do not use the aforementioned products at temperatures

above 45 ° C.

39

BLADE GUARD RING CLEANING

WARNING!! The maximum attention must be paid during

the procedure due to cutting risk. Before cleaning the blade,

unplug the machine from the power grid.

`Close the fence: put the graduated knob (A) in the posi-

tion between 15 (fifteen) and 0 (zero) by turning the knob

clockwise on full lock. Make sure the blade edge is fully

covered and protected by the fence (Fig. 2/A).

`To do this make sure that the cover blade and the carriage

have already been removed.

`Slightly press the cloth against the ring and manually rotate

it on the whole ring.

REMOVED PARTS CLEANING

All parts removed as instructed in paragraph D.1.2, with the

exception of the sharpener, must be cleaned with neutral

detergents or disinfectants. Once cleaned, the parts must be

dried with a dry cloth and assembled again by following the

procedure of paragraph D.1.2 in reverse order.

`The cleaning of the sharpener must be done only with a dry

brush.Use onlybrushandsolventtocleanthestonesaswell.

SLICER CASTING CLEANING

`Remove with hands or a wet cloth the bigger remains of

the product.

`Thoroughly clean the casting with a wet cloth and/or a

brush/spray and neutral detergent.

`Sanitise it with a cloth or brush and the products approved

by the Ministerial Supervisory Organisations mentioned in

paragraph D1.1

`Rinse with clear water and a cloth or brush.

WARNING!! Do not use water jets to clean the upper parts

of the casting and the lower ones inside.

D.1.1 Routine maintenance

ATTENTION

Disconnect the power sup-

ply before cleaning the

appliance.

D.1.1.1 Precautions for maintenance

Routine maintenance operations can be carried out by non-

specialised personnel, carefully following the instructions

given below. The manufacturer declines any liability for

operationscarriedoutonthemachinewithoutfollowing

these instructions.

`Clean the slicer thoroughly as described in section D.1

depending on the use frequency, but at least once a day

`Sharpen the blade when necessary

`Lubricate the marked parts in Fig.3 every two months

or anytime the carriage does not move properly. Please

only use MARCOL 82 ESSO or WHITE OIL 105 BERGOIL.

Lubrication should be done frequently with moderate

amounts of product.

ATTENTION

Do not clean the machine

with jets of water.

ATTENTION

Do not use steel wool or similar material to

clean the stainless steel surfaces. Do not use

detergents containing chlorine, solvent-based

detergents (e.g. trichloro-ethylene) or abrasive

powders.

`The power cord can be changed only by a specialised tech-

nician or the technical assistance service.

`A specialised technician or the technical service will also

change the sharpening and honing stones when worn

out or too greased.

D.1.1.2 Blade change

ATTENZIONE!! WHEN THE DISTANCE BETWEEN BLADE

EDGE AND BLADE GUARD INTERNAL BORDER REACHES 6MM.

AT THIS POINT IT IS COMPULSORY TO IMMEDIATELY CHANGE

THE BLADE.

ATTENZIONE!! Themaximumattentionmustbepaidduring

the procedure due to cutting risk. Before cleaning the blade,

unplug the machine from the power grid.

ATTENZIONE!! This procedure can be carried out only by

a specialised technician or the technical assistance service as

described in paragraph D.1.1.3

`Close the fence: put the graduated knob (A) in the posi-

tion between 15 (fifteen) and 0 (zero) by turning the knob

clockwise on full lock. Make sure the blade edge is fully

covered and protected by the fence (Fig. 2/A).

`To do this make sure that the cover blade and the carriage

have already been removed.

`Position the blade remover“J”(Fig. 2) and fix it on the threa-

dedholes of thebladeusingthetwo“W”handwheels (Fig.2).

With a screwdriver unscrew the 4 or 3 blade screws, then

remove the blade, grabbing the two handwheel.

ATTENZIONE!! The maximum attention must be paid

during the procedure due to cutting risk: PLEASE NOTE THAT

THE PRESENCE OFTHE BLADE REMOVER ONTHE BLADE DOES

NOT COMPLETELY PREVENT CUTTING RISK, EVEN THOUGH

THE POSSIBILITY AND SERIOUSNESS OF ANY ACCIDENT IS

HIGHLY DECREASED.

`To mount the blade back again, follow the instructions of

paragraph D.1.1.2 in reverse order.

D.1.1.3 Precautions in case of long idle periods

If the appliance is not going to be used for some time, take

the following precautions:

`Make sure the power cord is intact

`Make sure the on-off buttons are intact

`Lubricate the marked parts on paragraph D.1.1.1 before use

`Sharpen the blade as described in paragraph C.2.3 – C.2.4

ATTENTION

Work on the electrical

equipment must only be

carried out by a special-

ised electrician or the Af-

ter-Sales Service.

40

B. During operation the blade slows down or stops:

`Unsuitable products are being sliced (frozen ones or

products with bones)

`Blunt blade

`Appliance designed for three-phase 380-400V power

supply, but connected to three-phase 220-240V supply

C. The machine is very noisy:

`Wear of drive system or motor

`Wear of blade support bearings

D. The carriage is difficult to remove:

`The graduated knob is not on full lock

`Users have to pull the carriage towards themselves

`Wear of cinematic system components

D.1.3 Maintenance intervals

The inspection and maintenance intervals depend on the

actual machine operating conditions and ambient condi-

tions (presence of dust, damp, etc.), therefore precise time

intervals cannot be given. In any case, careful and periodical

machine maintenance is advisable in order to minimise ser-

vice interruptions.

It is advisable to stipulate a preventive and scheduled

maintenance contract with the After-Sales Service.

D.1.3.1 Maintenance frequency

To ensure constant machine efficiency, it is advisable to carry

outthecheckswiththefrequency givenin the followingtable:

Maintenance, inspections, checks and cleaning Frequency

Routine cleaning

general cleaning of machine and surrounding area

daily

Mechanical protection devices

check their condition and for any deformation,

loosening or removed parts

monthly

Control

check the mechanical part, for cracks or

deformation, tightening of screws: check the

readability and condition of words, stickers and

symbols and restore if necessary

yearly

Machine structure

tightening of main bolts (screws, fixing systems,

etc.) of machine

yearly

Safety signs

check the readability and condition of safety signs

yearly

Blade

check that the distance between the blade and

the blade guard ring is below 6mm. Otherwise the

blade must be changed immediately (see section

D.1.1.2)

weekly

Sharpening stones

check their wear and abrasiveness. Replace them if

they are worn out

monthly

Lubrication

lubricate the marked parts in fig.3 with the

supplied oil

monthly

Electrical connection cable and plug

check the connection cable (replace if necessary)

and plug

yearly

General machine overhaul

check all components, electrical equipment,

corrosion, pipes…

every

10years*

ATTENTION

Machine maintenance,

checking and overhaul

operations must only be

carried out by a special-

ised technician or the Af-

ter-Sales Service, provided

withsuitablepersonal pro-

tection equipment (safety

shoesandgloves),toolsand

ancillary means.

Put the machine in safe

conditions before starting

any maintenance opera-

tion.

Respect the requirements

for the various routine and

extraordinarymaintenance

operations. Non-compli-

ance with the instructions

can create risks for person-

nel.

Aftercarryingout maintenance makesurethe machine isable

to work safely and, in particular, that the protection and safety

devices are efficient.

D.1.2 Extraordinary maintenance

ATTENTION

WEARPROTECTIVEGLOVES

AND A MASK WHEN CAR-

RYING OUT ANY EXTRAOR-

DINARY MAINTENANCE

OPERATIONS.

NOTE

Extraordinary maintenance must be carried out

by specialised personnel, who can ask the man-

ufacturer to supply a servicing manual.

D.1.2.1 Quick troubleshooting guide

In some cases, faults can be eliminated easily and quickly by

following a brief troubleshooting guide:

A. The machine cannot be switched on:

`No power supply in appliance

`No main power supply

`Faulty electrical circuit

41

(*) the machine is designed and built for a duration of about

10 years. After this period of time (from commissioning) the

machine must undergo a general inspection and overhaul.

Some examples of checks to be carried out are given below.

`check for any oxidised electrical components or parts; if

necessary, replace them and restore the initial conditions;

`check the structure and welded joints in particular;

`check and replace bolts and/or screws, also checking for

any loose components;

`check the electrical and electronic system;

`check the functionality of safety devices;

`checkthegeneralconditionofprotectiondevicesandguards.

ATTENTION

Machine maintenance,

checking and overhaul

operations must only be

carried out by a special-

ised technician or the Af-

ter-Sales Service, provided

withsuitablepersonal pro-

tection equipment (safety

shoesandgloves),toolsand

ancillary means.

ATTENTION

Work on the electrical

equipment must only be

carried out by a special-

ised electrician or the Af-

ter-Sales Service.

D.1.3.2 Training

During the machine’s installation, it is absolutely essential that

an operator of age be trained in the regular use-cleaning-

care-sharpeningoftheblade,especiallyregardingthehazards

which are likely to be encountered if the machine is used

incorrectly. The training will be given by the suitably autho-

rized installer who is familiar with the European community

machine standards.

D.1.4 Disassembly

Iftheappliancehastobedisassembledandthen reassembled,

make sure the various parts are assembled in the correct order

(if necessary mark them during disassembly).

Beforedisassemblingthemachine,makesuretocarefullycheck

its condition, and in particular any parts of the structure that

can give or break. Before starting disassembly:

`remove all the pieces (if present) in the machine;

`disconnect the power supply;

`enclose the work area;

`place a sign on the Main Electrical Panel indicating that

themachineisundergoingmaintenance and not to carry

out manoeuvres;

`carry out the disassembly operations.

ATTENTION

All scrapping operations

must occur with the ma-

chinestoppedandcoldand

theelectricalpowersupply

disconnected.

Work on the electrical

equipment must only be

carried out by a qualied

electrician, with the power

supply disconnected.

ATTENTION

To carry out these opera-

tions,appropriatePPEmust

be used.

During disassembly and

handling of the various

parts, the minimum height

from the floor must be

maintained.

D.1.5 Decommissioning

If the machine cannot be repaired, carry out the decommis-

sioning operations, signalling the failure with a suitable sign,

andrequestassistanceofthemanufacturer'safter-salesservice.

D.2 Machine disposal

ATTENTION

Dismantling operations

mustbecarriedoutbyquali-

ed personnel.

ATTENTION

Work on the electrical

equipment must only be

carried out by a qualied

electrician, with the power

supply disconnected.

D.2.1 Waste storage

Attheend of theproduct's life-cycle, makesureitis not disper-

sed in the environment. The doors must be removed before

scrapping the appliance.

special waste materials can be stored temporarily while awai-

ting treatment for disposal and/or permanent storage.

42

ATTENTION

Make the appliance unus-

ablebyremovingthepower

cableandanycompartment

closing devices, to prevent

the possibility of someone

becoming trapped inside.

NOTE

When scrapping the machine, the“CE”marking,

thismanualandotherdocumentsconcerningthe

appliance must be destroyed.

D.3 Enclosed documents

`Wiring diagram

`Installation diagram

`”CE”Declaration of Conformity

In any case, the current environmental protection laws in the

user's country must be observed.

D.2.2Procedureregardingappliancedismantlingmacro

operations

Before disposing of the machine, make sure to carefully check

its physical condition, and in particular any parts of the struc-

ture that can give or break during scrapping.

The machine's parts must be disposed of in a differentiated

way, according to their different characteristics (e.g. metals,

oils, greases, plastic, rubber, etc.).

Different regulations are in force in the various countries, the-

refore comply with the provisions of the laws and competent

bodies in the country where scrapping takes place.

In general, the appliance must be taken to a specialised col-

lection/scrapping centre.

Dismantletheappliance,groupingthecomponentsaccording

to their chemical characteristics, remembering that the com-

pressor contains lubricant oil and refrigerant fluid which can

be recycled, and that the refrigerator components are special

waste assimilable with urban waste.

The symbol on the product indicates that this product

should not be treated as domestic waste, but must be

correctly disposed of in order to prevent any negative

consequences for the environment and human health.

For further information on the recycling of this product,

contact the local dealer or agent, the after-sales service

or the local body responsible for waste disposal.

This manual suits for next models

19

Table of contents

Other Electrolux Professional Kitchen Appliance manuals