GASER S1500-P User manual

MEATBALL MAKING MACHINE

Mod. S1500-P

-2-

INDEX

1. INDUSTRIAS GASER ............................................................................................................... 3

2. EC DECLARATION OF CONFORMITY ...................................................................................... 4

3. HYGIENE CERTIFICATE........................................................................................................... 5

4. INTRODUCTION....................................................................................................................... 6

4.1 Safety.................................................................................................................................6

4.2 Hygiene ..............................................................................................................................6

5. TECHNICAL SPECIFICATIONS................................................................................................. 7

6. RECEIPT AND START-UP......................................................................................................... 8

6.1 Receipt ...............................................................................................................................8

6.2 Start-up...............................................................................................................................8

7. CLEANING..............................................................................................................................11

8. MAINTENANCE.......................................................................................................................13

9. TROUBLESHOOTING..............................................................................................................14

10. GENERAL DIAGRAM.............................................................................................................15

10.1 Overview.........................................................................................................................15

10.2 Complete meatball former unit..........................................................................................18

10.3 Ram limit switch unit ........................................................................................................19

10.4 Flexible meat entry tube unit.............................................................................................20

10.5 Meatball former unit .........................................................................................................21

10.6. Filter regulator with pressure gauge unit...........................................................................23

11. PNEUMATIC DIAGRAM..........................................................................................................24

12. WIRING DIAGRAM ................................................................................................................25

-3-

1. INDUSTRIAS GASER

Since its foundation in 1969, INDUSTRIAS GASER has specialised in manufacturing a range of

stainless-steel machinery for the meat industry.

Since 1985 we have constantly developed technology for GASER-brand hamburger-forming

machines, developing a distinctive system based on a SIMPLER, MORE EFFECTIVE AND MORE

ECONOMICAL TECHNIQUE.

In the 1990s, INDUSTRIAS GASER expanded into markets in various countries around the world, and

not just in the hamburger sector.

We are aware that our work would be of no value without the trust of our existing clients and partners

or the interest shown by those who wish to join them.

We thank them all.

INDUSTRIAS GASER GASER EUROPA

Salt, Girona, SPAIN L’viv, UKRAINE

INDUSTRIAS GASER Ctra, Bescanó, 15, Pol. Torre Mirona 17190 Salt (Girona) - Spain

Tel. 34 972 23 65 72 | Fax 34 972 23 63 66 | Whatsapp: (34) 679 49 65 06

email: gaser@gaser.com

GASER EUROPA вул.Б.Лепкого,1 81160 смт.Щирець Пустомитівский р-н Львівська область

Украіна - Ukraine

Tel. 38 (03230) 67251/84

Fax 38 (03230) 67191

email: gasereuropa@gaser.com

For more information about the company and its products: www.gaser.com

-4-

2. EC DECLARATION OF CONFORMITY

We declare under our responsibility that the following machine:

Brand: GASER

Model: S1500-P

Serial no.

Year of construction:

is in conformity with the following regulations

UNE-EN ISO 12100:2012

UNE-EN ISO 14120:2016

UNE-EN ISO 14121-1:2008

UNE-EN ISO 13849-1:2008/AC:2009

UNE-EN ISO 4414:2011

and is in conformity with the following directives

Machinery directive: 2006/42/CE

It is forbidden to make any change or modification to the machine without the prior written permission

of our technical department. Use of the machine in these conditions could cause accidents, in which

case INDUSTRIAS GASER S.L. accepts no liability for the improper use of the machine.

Salt,

CARLOS GARGANTA SERRAMITJA

TECHNICAL DIRECTOR INDUSTRIAS GASER S.L.

-5-

3. HYGIENE CERTIFICATE

We declare the machine:

Brand: GASER

Model: S1500-P

Serial no.

Year of construction:

is in conformity with the following regulations

Regulation (EC) 1935/2004, materials and articles in contact with food, repealing Directives

80/590/EEC and 89/109/EEC.

This means that all of the types of steel and plastic from which the machine is constructed and which

are in contact with the meat comply with the hygiene rules and regulations in force.

* Plastic material: polyethylene terephthalate (PETP), white, density 1.37 g/cm3,

Manufactured in accordance with DIN 50014.

* Stainless steel: AISI 304, manufactured in accordance with European regulations EN-10088,

Chemical composition: C≤0.07% Si≤0.75% Mn≤2% Cr=18-19% Ni=8-10%

Salt,

CARLOS GARGANTA SERRAMITJA

TECHNICAL DIRECTOR INDUSTRIAS GASER S.L.

-6-

4. INTRODUCTION

Before using or handling the machine, you must read this manual carefully.

The instructions in this document are, whenever possible, accompanied by illustrations to help with

understanding of how to start, use and clean the machine.

This manual is subject to amendment.

4.1 Safety

It is forbidden to make any change or modification to the machine without the prior written permission

of our technical department. Use of the machine in these conditions could cause accidents, in which

case INDUSTRIAS GASER S.L. accepts no liability for improper use of the machine.

The machine has been designed for use with food products and must be used in the way described in

this manual. Any use other than the specified one will involve risk for the user and for the machine.

INDUSTRIAS GASER S.L. accepts no liability either for damage to the machine or personal injury or

injury to third parties that this use might cause.

4.2 Hygiene

All of the materials used in the manufacture of the machine and which come into contact with food

comply with Regulation 1935/2004. Consequently, the machine has the CE mark.

It is not recommended to use detergents containing chlorine, any of its derivatives or any other product

that could damage the construction materials of the machine.

-7-

5. TECHNICAL SPECIFICATIONS

1. Fits any sausage filler

2. Made from stainless steel

3. Tabletop machine (table optional)

4. Compressed air operation between 4 and 6 bar (kg/cm2)

5. Air consumption: 150 litres/minute

6. Maximum production 15 000 meatballs/hour (depending on type of mixture and the speed of the

sausage filler.

7. Weights of 7, 12, 15, 20, 25, 30 and 35 grams

8. Measurements of the machine 450 × 200 × 600 mm

9. Machine weight 25 kg

-8-

6. RECEIPT AND START-UP

6.1 Receipt

When you receive the machine, you must first check that it is in perfect conditions, without any

damage, dents or knocks.

If there is any problem, we advise you notify the distributor or INDUSTRIAS GASER S.L. directly.

6.2 Start-up

1. It is important that when it starts producing meatballs, the machine is completely clean to ensure it

works properly.

2. It must be connected to a compressed air network. Its normal operating pressure is 4 to 6 kg/cm2,

depending on how quickly you want it to operate.

3. The most appropriate mixtures are those that after being prepared or mixed are kept in the

conservation chamber for several hours at temperatures between 0 and 4 ºC.

4. These machines can be connected to any hydraulic piston sausage filler or any continuous

sausage filler.

5. The machine is connected to the sausage filler with a 30 mm diameter funnel connected to the

meat entry tube (Pos. 4, Overview)

Image 1, S1500-P with sausage filler

-9-

6. If you want to change the weight of the meatballs, you must change the ball joint (Pos. 3. Meatball

former unit) and the ram (Pos. 2, Meatball former unit).

When making the change, displace the valve (Pos. 3. Overview) so that the protruding pivot and

the fixed part of the valve are in contact when the ram is in its most extended position. Fix the

valve at this point.

Image 2, Changing meatball weight

-10-

7. The machine can be acquired with a table (RECOMMENDED OPTIONALACCESSORY).

Image 3. S1500-P

8. In case you don’t acquire GASER table, the machine will be sent with two standard feet (Pos. 40,

Overview). In order to work safely you must fix the machine to the table. Working with the machine

when it is not fixed to the table could be a risk for the worker and the machine. The machine could

be suddenly pushed from the filler out of the table and sent down to the floor.

9. Load the filler with the mixture to be used, packing it down slightly, to ensure that there are no

large air pockets in the mixture.

10.The filler lever is fixed; there should never be anyone pulling on this lever. The mixture exit velocity

is controlled using the regulator included on all fillers.

11.When starting the machine up, make sure that the cap nuts that hold the former in place and the

connecting nut (Pos. 13, Overview) are tightened. Also make sure the door is properly closed.

12.The machine is ready to start production.

-11-

7. CLEANING

When you have finished using the machine, it must be cleaned. To do so, follow these steps:

1. Disconnect the meatball former from the sausage filler using the connecting nut (Pos. 13,

Overview) and open the lid using the knob (Pos. 49, Overview).

Image 4. Disconnecting the sausage filler

Image 5. Opening the lid

2. Loosen and remove the two cap nuts and the support guardrail from the former unit (Pos. 7

overview).

Image 6. Loosening cap nuts

-12-

3. Extract the support unit from the former (Pos. 6, Overview) along with the former support (Pos. 2,

overview).

Image 7. Extracting former unit

4. Separate the main components of the former unit and its support.

Image 8. Former unit and support unit components

Image 9. Former unit and support unit assembly

5. Once all the components have been separated they can be cleaned with high pressure water.

Clean the rest of the machine with a damp cloth. Never clean it with pressurised water.

Image 10. Machine ready for cleaning

-13-

8. MAINTENANCE

1. Every 150 hours of work take the lid off the mechanism box (Pos. 46, Overview) and lubricate the

rotating fork pin (Pos. 21, Overview) and the cylinder rods (Pos. 36 and 37, Overview).

2. Regularly check the condition of the moving components: bearings, shafts, cylinders, ball joint,

ram, etc.

3. Periodically check the machine’s seals.

4. Regularly check the condition of the machine’s valves, manifolds and compressed air connections.

5. Periodically check the general condition of the machine.

-14-

9. TROUBLESHOOTING

The table below lists the problems that might occur with the machine, their potential causes and how

to solve them.

Problem

Cause

Solution

The machine does not start

Machine is not connected to

the air network

Connect the machine to the network

Insufficient air pressure

See manual “6.2. Start-up”, point 2

The door is not properly closed

Close the door properly

Ram limit switch poorly

adjusted

See manual “6.2. Start-up”, point 6

There is air pressure but the

machine still will not start or

runs very slowly

Internal air leak

See manual “8. Maintenance”, points 3

and 4

Valve or manifold in poor

condition

See manual “8. Maintenance”, point 4

The machine makes a noise

Internal components not

lubricated

See manual “8. Maintenance”, point 1

The ball joint does not turn

Anti-rotation bearing broken or

in poor condition

See manual “8. Maintenance”, point 2

Mixture too thick

Thin the product

Meat leaking from the former

unit

Cap nuts not tightened

properly

See manual “6.2. Start-up”, point 10

Seals in poor condition

See manual “8. Maintenance”, point 3

Split bearings or ball joint worn

or in poor condition

See manual “8. Maintenance”, point 2

-15-

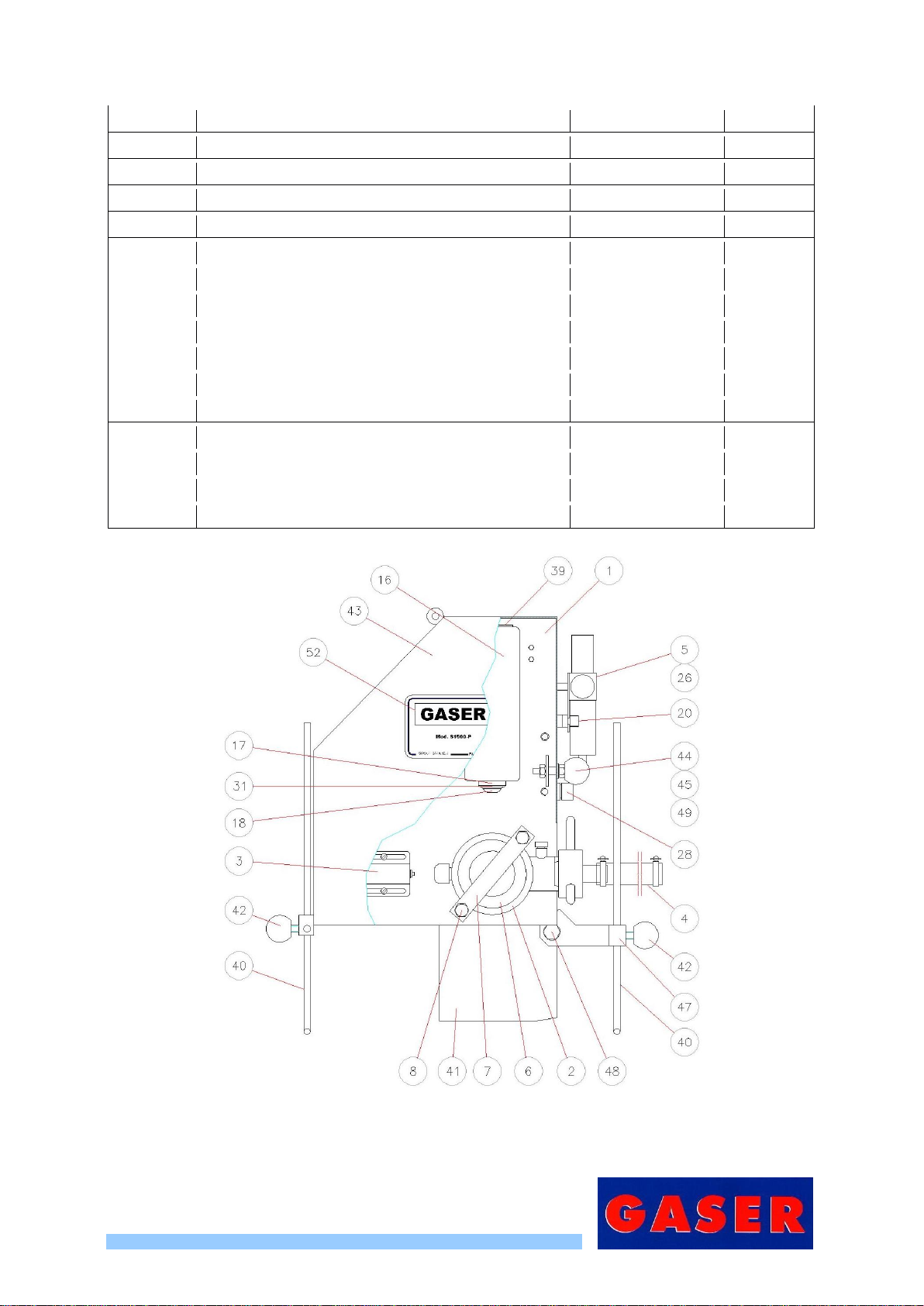

10. GENERAL DIAGRAM

10.1 Overview

Number

Description

Reference

Units

1

MEATBALL MACHINE CHASSIS

15010100

1

2

UNIT MEATBALL FORMER HOLDER

17850000-P

1

3

RAM LIMIT SWITCH UNIT

17870000

1

4

FLEXIBLE MEAT ENTRY TUBE UNIT

17810000

1

5

UNIT FILTER REGULATOR W. PRESSURE GAUGE

17550000

1

6

FORMER UNIT

156X0000

1

7

FORMER SUPPORT HANDRAIL

15020400-P

1

8

FORMER SUPPORT BAR

15071300

2

9

FORMER SHAFT SUPPORT HANDRAIL

15080100

1

10

FORMER SHAFT WITH KEYSEAT

15080200

1

11

FORMER SHAFT SUPPORT

15080700

1

12

INNER MACHINE CRANK

15081400

1

13

STAINLESS SAUSAGE FILLER CONNECTING NUT

15110000

1

14

STAINLESS M16 × 1.5 PNEUMATIC NUT

NE0108M161.5

1

15

REGULATOR HOLE COVER

SI0226GPN300F1

1

16

MEATBALL CYLINDER PROTECTION & SUPPORT

15071000-P

1

17

EJECTOR CYLINDER RETAINER SUPPORT

15071100

1

18

METABALL EJECTOR CYLINDER HEAD

15071200-P

1

19

O-RING EPDM 70 SHAØ14 × 2.5 mm

SI06090142.5

1

20

M8 FIXING KNOB

00040200

1

21

FORK AND PIN UNIT

00670000

1

24

MANIFOLD SUPPORT BRACKET

15081800

1

25

PRESSURE SWITCH SUPPORT

15082000

1

26

AIR FILTER SUPPORT BRACKET

15190100

1

27

VESTA PRESSURE SWITCH UNIT

15720000

2

28

CONTINUOUS SAUSAGE FILLER BASE UNIT

15760000

1

29

NOT VALVE

NE0215NOTC

1

30

NOT VALVE BASE

NE0315709K18

1

31

EJECTOR CYLINDER SCRAPER

NE0215WSW253347

1

32

MANIFOLD

NE0315DJ5214

2

33

E-28310 LIMIT SWITCH

NE0315E28310

1

34

DISTRIBUTOR 40 × 40 × 20 1/4”

NE0315R4040201

1

35

NICKEL VALVE 3/2 1/8”

17740000

1

36

MEATBALL EJECTOR CYLINDER 20 × 25

NE1315020/025

1

-16-

37

VESTA CYLINDER 32 × 75

NE1315032/075

1

38

E-32 DIN471 STAINLESS CIRCLIP

SI0109E320471

1

39

GLAND CAP

SI0226T4838111.5

1

40

DOUBLE FOOT WITHOUT FIXING THREAD

15130100

2

41

OUTLET RAMP

15130200

1

42

FOOT FIXING KNOB

15130300

4

43

FRONT DOOR

15160100

1

44

DOOR LATCH

15160200

1

45

LATCH SLEEVE

15160300

1

46

BACK COVER

15160800

1

47

“T” SUPPORT DOUBLE FRONT FOOT

17591100

1

48

M10 × 100 DIN933 HEX SCREW

FE0108M101000933

1

49

ROUND KNOB M10 Ø40 BLACK

SI0212ESF40M10

1

50

FORMER SHAFT BUSHING

00050400

1

51

INLET NUT INNER CONE

15110300

1

52

MACHINE BRAND STICKER S-1500

PA0230S1500

1

Figure 1. Standard overview 1

-17-

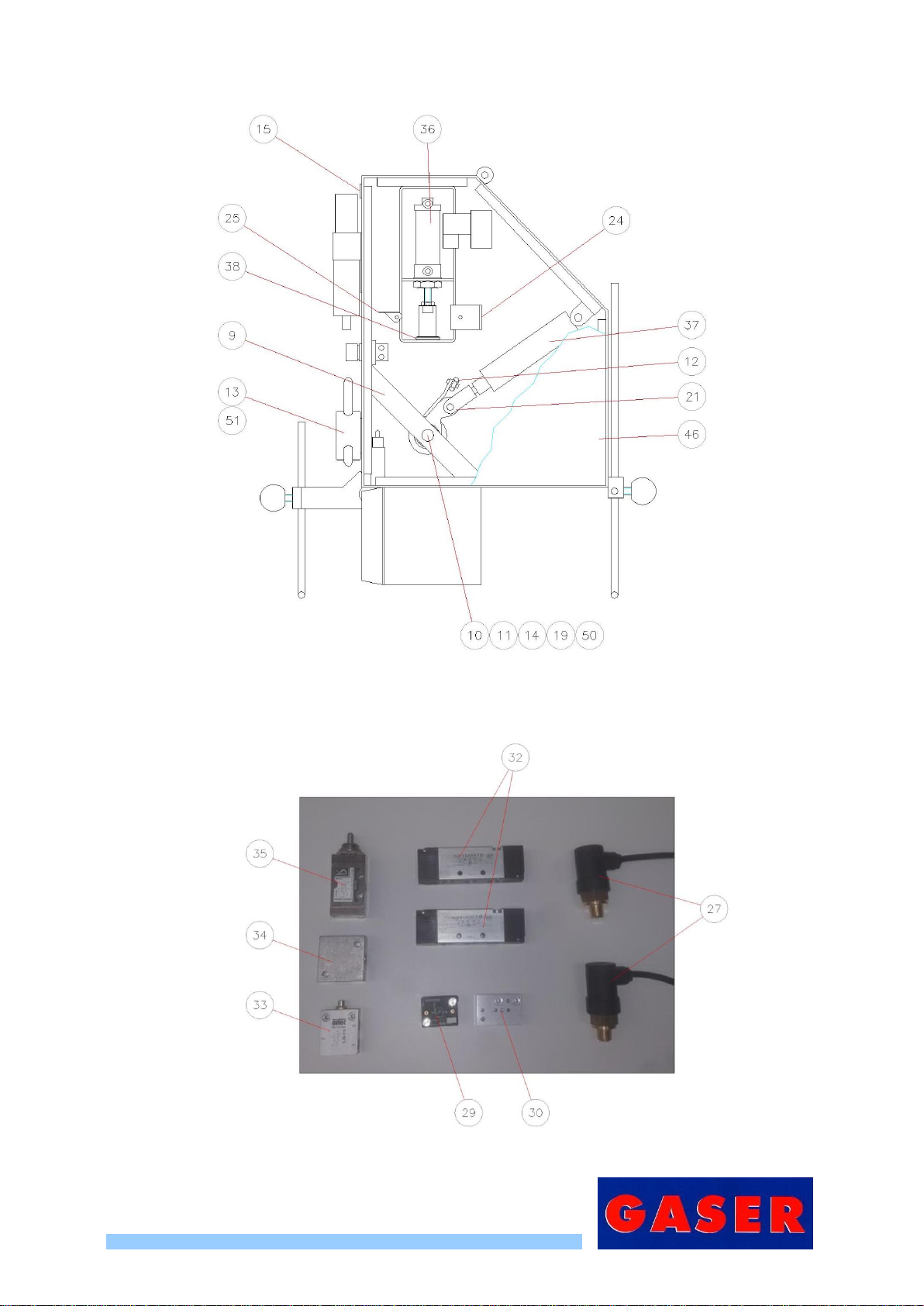

Figure 2. Standard overview 2

Figure 3. Standard overview 3

-18-

10.2 Complete meatball former unit

Ref. 17850000-P

Position

Description

Reference

Units

1

MEATBALL FORMER HOLDER

15020100-P

1

2

KNURLED SCREW VALVE

15020600

1

3

STAINLESS STEEL BALL Ø8mm AISI304

SI0109B08

1

Figure 3. Complete meatball former holder unit

-19-

10.3 Ram limit switch unit

Ref. 17870000

Number

Description

Reference

Units

1

RAM LIMIT SWITCH PROTECTION

15070400

1

2

RAM LIMIT SWITCH BUTTON

15070700

1

3

E25310 BOARD

15081700

1

4

E-25310 LIMIT SWITCH

NE0315E25310

1

5

DIN94 STAINLESS SPLIT PIN Ø2.5 × 20

SI0109PA2502094

1

6

RAM LIMIT SWITCH SPRING

SI0114159.80.75

1

Figure 4. Ram limit switch unit

-20-

10.4 Flexible meat entry tube unit

Ref. 17810000

Number

Description

Reference

Units

1

MEAT ENTRY TUBE

00110300

1

2

BARBED SAUSAGE FILLER CONNECTION TUBE

17810100

1

3

ENTRY TUBE CLAMP

00110200

2

Figure 5. Flexible meat entry tube unit

Table of contents

Other GASER Kitchen Appliance manuals