air-o-chill

air-o-chill Blast Chiller/Shock

Freezer 61 - 66/55lbs (30/25kg)

ITEM #

MODEL #

NAME #

SIS #

AIA #

Short Form Speciication

Item No.

APPROVAL:

Electrolux Proessional, Inc.

www.electroluxusa.com/professional

10200 David Taylor Drive, Charlotte, NC 2262 • Telephone Number: 66-449-4200 • Fax Number: 704-547-7401

air-o-chill

air-o-chill Blast Chiller/Shock Freezer 61 - 66/55lbs (30/25kg)

air-o-chill

air-o-chill Blast Chiller/Shock Freezer

61 - 66/55lbs (30/25kg)

726303 (AOFS061CU)Blast Chiller/Shock Freezer

61 - 208V/3p/60Hz

726304 (AOFS061CTU)Blast Chiller/Shock Freezer

61 - 208V/3p/60Hz - tower

confiuration

Unit to be Electrolux air-o-chill® Blast Chiller/Shock Freezer

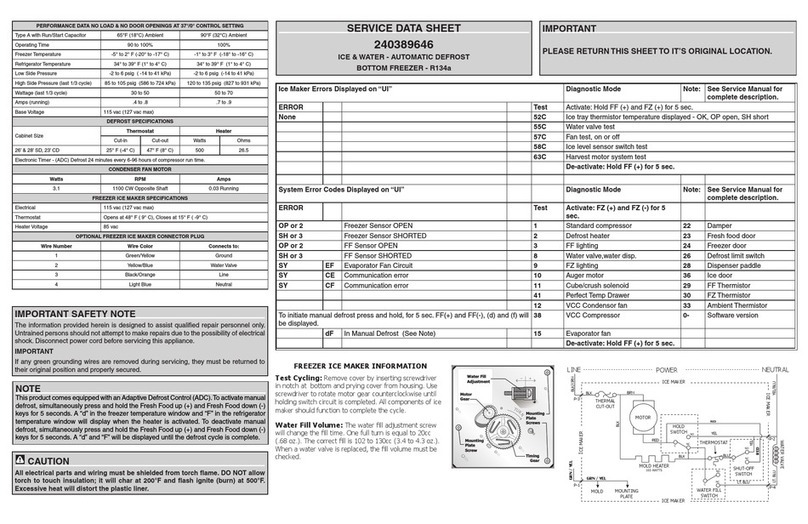

Soft-chilling, Hard-chilling and Blastfreezing ccles. At the end of each

Blast-chilling- or freezing ccle the unit shall automaticall activate a

holding ccle. Defrost ccle is automaticall and intelligentl activated:

ice build up on evaporator is automaticall detected and defrost

activated to maximize performance efficienc. Manual activation of

defrost ccle is possible. Unit does not have an heat limitation and can

accept food directl from oven at cooking temperature. The unit features

both time and core temperature controlled chilling ccles. One core

temperature probe is provided as standard, up to three are available.

Covered b Electrolux Platinum Star® Service Program two-ear parts

and one-ear labor warrant, installation start-up and performance checkup

after one ear from installation.

Main Features

•Onl Blast Chiller/Shock Freezer designed to accept hot product

directl from the oven.

•No need to reduce food temperature to 160 °F (70 °C) before

starting the chill ccle

•Ergonomical placement of control panel, reduces operator

fatigue and need to kneel down to reach controls.

•Load capacit: 66 lbs (30 kg) in chilling; 55 lbs. (25 kg) in

freezing.

•Will chill product from 160 °F (70 °C) to 38 °F (3 °C) or below in

less than 90 minutes.

•Will freeze product from 160° F (70 °C) to 0° F (-17 °C) or below

in less than 240 minutes.

•Eas-to-use, electronic control panel. Full programmable.

•3-sensor core probe as standard and automatic detection

of the core probe insertion.

•Hot gas defrosting sstem.

•Cruise: the chiller automaticall sets the parameters for the

quickes and best chilling (it works b probe).

•Soft Chilling 28° F (–2°C).

•Hard Chilling -4° F (–20°C).

•Holding at 37° F (3°C) (automaticall activated at the end of each

ccle).

•Turbo cooling: non-stop mode, working temperature: from 39 to

-32° F (4°C to -35°C).

•Shock freezing: low air temperature adjustable up to -41°F (-41º

C.)

•Ice Cream Mode: brings down ice-cream temperature to 7°F

(-14°C)(measured at the core when probe is inserted).

•Standard equipped with one 3-sensor temperature probe.

•Automatic Intelligent and manual defrost modes.

•Displa: large LED for temperature and time/core temperature

read out.

•Audible alarms and visual indicators for food safet (HACCP)

issues and

separate audible and visual for unit malfunctions.

•During ccle, temperature and time is monitored

•On-board HACCP monitoring capable

•UV lamps built-in (upon request)

Construction

•Developed and produced in ISO 9001 and ISO 14001 certified

factor.

•Evaporator with antirust protection.

•Motors and fan waterproof protected IP23.

•No water connections required.

•Stand alone printer as accessor.

•Inner cell with full rounded corners.

•High densit polurethane insulation, 2.5" (60 mm) tickness,

HCFC free.

•Removable magnetic gasket door with hgienic design.

•Ventilator swinging hinged panel for access to the evaporator for

cleaning.