Electronics FIT 7223 User manual

ESD

ESD

!"

!!

!!

!Kindlyforwardthisproductmanualtotheenduser.

Theuser is requestedto read themanual thoroughly

beforeoperatingtheinstrument.

#$

Warranty CertificateWarranty Certificate

Warranty CertificateWarranty Certificate

Warranty Certificate

This instrument is warranted against any manu-

facturing defects for a period of twelve months

from the date of installation, or eighteen months

from the date of supply, which ever is early.

Kindly note that:

1. The warranty is limited to repairing the instru-

ment and no responsibility is taken for any

other damage resulted

2. The warranty will be void if the instrument is

opened or tampered in any way

3. The faulty instrument has to be returned to

our factory, carriage prepaid & duly insured.

ProductCategory : Programmable

Process Controller

Model No. : FIT 7223

Serialnumber : ________________

Dateofdespatch : ________________

Authorizedsignatory : ________________

Companyseal

WarrantyCertificate ...

PROGRAMMABLE PROCESS CONTROLLER

TheInsideStuff

AsYouUnpack ................. 2

Introduction ................. 3

PrincipleOfOperation ................. 4

Features ................. 4

Specifications ................. 5

Illustrations ................. 6

Operation ................. 7

Modesof Operation ................. 8

ProgrammingFlowChart ................. 9

InstallationProcedure ................. 13

Calibration Procedure ................. 14

ModbusProtocol ................. 16

ImportantTerms ................. 19

WarrantyCertificate ................. 20

20 1

ESD

ESD

As you unpack

We need your feedback :

Everyattemptismadetomakethismanualclearandeasyto

understand,so thattheuser caninstall,takecare ofandfeel

confident in using our product.We welcome your valued

suggestionsto help us improvethis product as wellas the

document and make it more user friendly.

""

""

"

Congratulations

on buying a

Programmable Process Controller!

Asyou unpackkindlyensure that

1.Thematerialreceivedisingoodcondition

2.Youhavereceivedthefollowingmaterial:

a) ProgrammableProcessController as per your

order

b) Mountingbracket pair

d) ThismanualalongwithWarrantycertificate

In case of any discrepancies contact our customer support

departmentimmediately.

We are sure you will get long and trouble free service

from our system.

219

Important Terms

1) ControlLogic (CL):The logic forrelayactuation,i.e.

a)CL= HighControlAction.The control action is

suchthattheprocesstemperaturemustnotgoabovethe

setpoint.Processvalue<SetpointRelayON

Thisisgenerallyusedinheatingapplications.

b)CL= Low ControlAction.The control action is

suchthatthe process temperature must not go below the

setpoint.Processvalue>SetpointRelayON

Thisisgenerallyusedincoolingapplications.

2) Hysteresis:The On / Off differentialgapforan On / Off

controller.Figuresbelowshow thehysteresisfor bothhigh

and low control logic.

Arrowsindicate Process temperature trajectory.

SP = Setpoint

HYS = Hysteresis

ESD

ESD

Introduction

Flowindicators

and totalizers

play an

mportantpartin

any process

industry.Quick

and accurate

measurement

and controlof

aprocessvalue

will improve

the final

product

quality,

reliability and

reduce

rejection.

Process indication and control is therefore one of the prime

considerationsinanyprocessindustry

TheFIT7223seriesisaMicrocontrollerbasedProcessIndicator

cumControllerwithuserfriendlyprogrammingfacility.TheFIT

7223has been designed forfastandaccurate measurement and

controlof process value. Linearisationofsignalsprovides high

accuracy even for most nonlinear sensors. The instrument is

designedusinghighly reliable electronic components. Process

valueisdisplayeddirectlyindigits,givingbetterresolution.

The FIT 7223 accepts 4 - 20 mA as input. Wide ranges of

measurementsare available depending on thesensor used.

Theinstrument is immune to mechanicalvibrations.Even the

mountingpositionwillnotaffectthemeasurementaccuracy.

ProgrammableProcessController FIT7223

18 3

ESD

ESD

Useofhighlyreliableelectroniccomponentswithlowtempearature

coefficientensures long andtroublefreeservice.The instrument is

testedforitsperformanceundervariousclimaticconditions.

Principle of Operation :

TheFIT7223seriesisbasedontheprinciple highinputimpedance

amplifierfeedingan analog to digital convertor. The input signal

generatedbythetransducerisfedtoasignalconditioningamplifier,

outputofwhichisdigitisedbytheADC.Thisdigitalsignalislinearised

by software, displayed and compared to the set value by the

microcontroller whichinitiates the programmedrelayaction. The

linearisation,displayandrelaysarecontrolledbythemicrocontroller

byvirtue ofthesystem software.

Features :

#Microcontrollerbasedlogic

#Linearisationof controlledvariableachievedthrough

softwaregivinghighaccuracy

#Highlycompact

#Dustand verminproofenclosure with epoxypowder

coating.

#Userselectable ControlLogic

#Programmingthroughtactilemembranekeys

#NVRAMenables data storageevenineventsofprolonged

powerfailure

#Fastresponse time

#RS 232 / RS 485 Modbus protocol supported

#Failsaferelaylogic

#MaximumMTBFandminimumMTTR

417

Function : Read Input Registers ( 04

)

Message Format :

(Response by the slave forthe request initiated by the master)

Message Format :

(Request initiated by the master)

Slave

Address Function

Code Start Address

( Hi ) ( Lo )

No. of points

( Hi ) ( Lo )

CRC

( Lo )

( Hi )

xx 03 or 04 0300 0000 xx xx

Slave

Address Function

Code Start Address Flow value

( Hi ) ( Lo )

CRC

( Lo )

( Hi )

xx 03 or 04 xxxx

( Hi )

xx xx xx

( Hi ) ( Lo )

xxxx

( Hi ) ( Lo )

xxxx

1st setpoint

value 2nd setpoint

value

Function : Read Input Registers ( 04 )

Message Format :

(Response by the slave forthe request initiated by the master)

Message Format :

(Request initiated by the master)

Slave

Address Function

Code Start Address

( Hi ) ( Lo )

No. of points

( Hi ) ( Lo )

CRC

( Lo )

( Hi )

xx 03 or 04 050a 0000 xx xx

Slave

Address Function

Code

Start

Address

( Hi )

Decimal value

for digit 1 & 2

( Hi ) ( Lo )

CRC

( Lo )

( Hi )

xx 03 or 04 xxxxxx xx xx

( Hi ) ( Lo )

xxxx ( Hi ) ( Lo )

xxxx ( Hi ) ( Lo )

xxxx

Decimal value

for digit 3& 4 Decimal value

for digit 5& 6 Decimal value

for digit 9 &10

Decimal value

for digit 7 &8

( Lo )

xx

( Hi ) xx

Function : Read Input Registers ( 16 )

Message Format :

(Request initiated by the master)

Slave

Address Function

Code Start Address

( Hi ) ( Lo )

No. of points

( Hi ) ( Lo )

CRC

( Lo )

( Hi )

x

x10 xxxx xxxx xx xx

Message Format :

(Response by the slave forthe request initiated by the master)

Slave

Address Function

Code

A

ddress

value

( Hi ) ( Lo )

CRC

( Lo )( Hi )

x

x10

x

x

x

x

x

x

x

x

( Hi ) ( Lo )

xxxx

Quantity

value ( Lo )( Hi )

xx xx

( Lo )( Hi )

xx xx

Number of

points

( Hi )

xx

1st setpoint

value 2nd setpoint

value

ESD

ESD

Model :FIT7223

Control action : On/ Off

Range :Programmablefrom 0to9999

Input : 4-20 mA

Indication accuracy : +/- 0.1 % of FS +/- 1 digit

Accuracy deviation due to

a) Temperature change : +/- 0.02 % / oC , ref at 25 oC

b) Supply Variation : +/- 0.01%/V

No. of Setpoints :Two

Setpoint Adjust and Read: Through Flat Membrane key pads and 4 digit

display respectively on front panel

Outputs :1set of potential free Relay change over contacts

rated 5Amp resistive at 230 VAC per setpoint

:24VDC, +/- 1V, @30 mAsupply

Relay logic : User selectable High or Low logic.

Relay ON indication : By Red LED per setpoint

On / Off hystersis : Programmable from 0.2to 9.9%

Display :16x2Alfa NumericLCD withback LED

Character size :2.95(W)x4.35(H)mm

Power supply :230VAC, +/-10% ,50 Hz

Ambient Temp. range : 0 to 55 oC

Sensor break indication : Up scale [ ]

Sensor break protection :Relay‘Off’(Relay ‘On’by demand)

RelativeHumidity : 90 % Non Condensing

Power consumption :6VA

Weight :900grams

Mounting : Flush panel mounting

Dimensions :96(W) x96(H)x 120(D)mm

Cutout :92x92mm,+1,-0mm

Communication :RS232/ RS485

Protocol : Modbus RTU

Device Address : Programmablebetween1 to 247

Baud Rate : Selectable between 1200 to 9600 kbps

Programming protection : Password protected. Default password is 191.

Specifications

16 5

Starting

Address

0000

0001

0002

Contents of the location

Process Value

Value of Setpoint No - 1

Value of Setpoint No - 2

Modbus Protocol

Communication : RS 232 or RS 485 2 wire

Protocol : MODBUS RTU

Device Address : Programmable from 1 to 247

Baud Rate : Selectable between 1200, 2400, 4800 or 9600 kbps

Parity : None

Data bits : 8

Stop bits : 1

Functions supported :

1. Read Input Registers ( 03 or 04 )

2. Preset Multiple Registers ( 16 )

Exception Codes :

1. Invalid Function Code ( 01 )

2. Invalid Start Address ( 02 )

3. Invalid Data Value ( 03 )

ESD

ESD

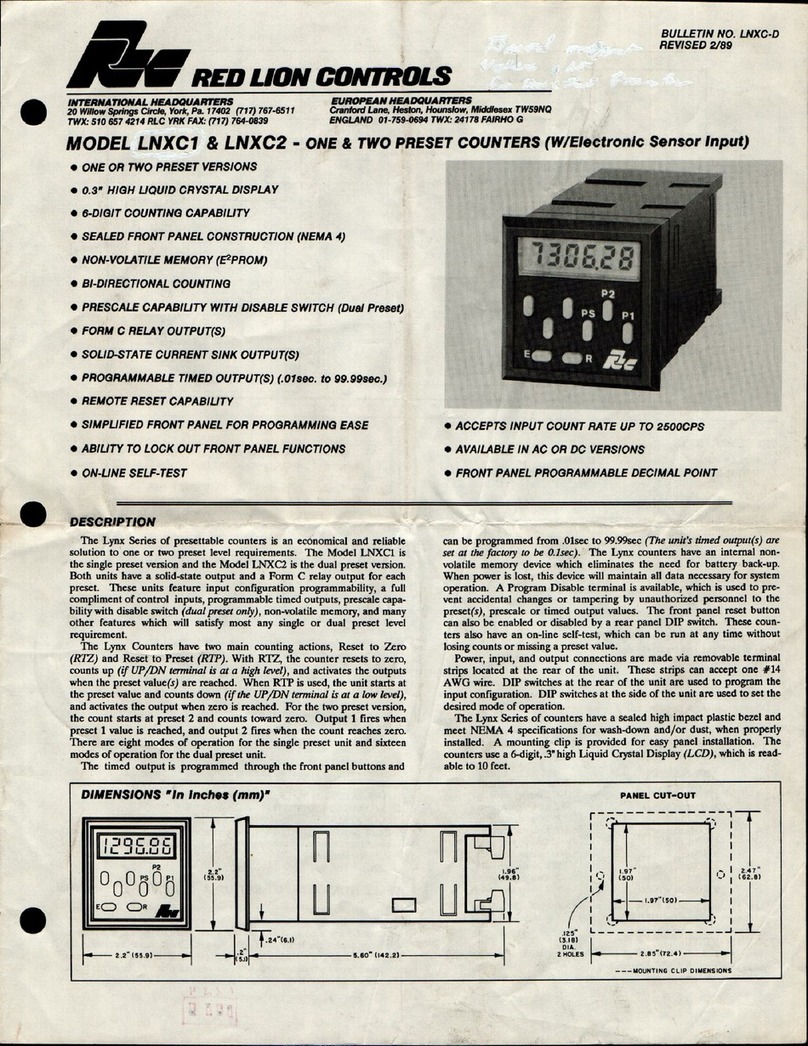

B)RearView

Illustrations

A)Front view

615

92

92

NP

E

230 V AC

1 2 3

13 14

15

PNO

RL - 1

NC

16 17 18

P

NO

RL - 2

NC

F

FLOW INDICATOR TOTALISER

FIT 7223

OUTPUT

1

2

Flow: 400. 0 kg/hr

Totl: 3454545302

E L E C T R O N I C S

SYSTEMS AND DEVICES

Output Calibration procedure

Warning :This procedure is to be carried out strictly by

technicallyqualifiedpersonnelonly.

Theinstrumentiscalibrated atthefactoryusing0.05%accurate cali-

bratinginstruments.Nocalibrationshouldberequiredinnormalcase,

howeveriftheinstrument requiresre-calibration,the proceduretobe

followedisgivenbelow.

$$

$$

$

When display show span message then by using

increment and decrement key set 20 mA on the

multimeter. Display shows output count.

Press enter key.

When display show zero message then by using

increment and decrement key set 4 mA on the

multimeter. Display shows output count.

Press enter key.

Calibration Mode

F

RUN MODE

Note :

1. All values followed by Enter key will be stored,

else the value will be discarded.

2. All modes have password protection.

Default password is 191.

For output calibration connect a multimeter

at the mA output terminals. The password for

output calibration is191.

ESD

ESD

Operation

BlockDiagram

1. Transducer:This isexternallyconnectedtothe instrument.

Typesavailableare 4-20/ 0-20 mAcurrentsignal

2. Signalconditioner: This circuit accepts the process signal

fromthe sensor performs thenecessarycompensation

(AmbientcompensationforT/Cand lead wire compensation

forPT- 100)andconvertsit into suitable signal levelforADC.

3. ADC: Thisis a 12 bit SuccessiveApproximationtypeADC

inbuiltthemicrocontroller. Itacceptstheanaloginputsignal,

convertsit into digital data and feeds it tothe processor for

further action.

4. Microcontroller: Thisistheheartoftheunitandis inter

facedto all otherperipherals.Thetransducers, membrane

keypad,display,memory andoutputrelaysfunctionunder

thecommandof themicrocontroller.

5. Memory: Therearetwo memory elements provided in the

circuit.One istheEPROMfor monitor(main)program storage

andtheotheristheNVRAMforstorageofvarioususer

Signal

Conditioner

Field

Field

Control

through

Contactor

Transducer

&

Transmitter

Amplifier Display

Keyboard Micro-

controller Relay

14 7

Input Calibration procedure

Warning :This procedure is to be carried out strictly by

technicallyqualifiedpersonnelonly.

Theinstrumentiscalibrated atthefactoryusing0.05%accurate cali-

bratinginstruments.Nocalibrationshouldberequiredinnormalcase,

howeveriftheinstrument requiresre-calibration,the proceduretobe

followedisgivenbelow.

$$

$$

$

Feed 20 mA from a stable source. Unit

displays the ADC count corresponding

input given.

Feed 4 mA from a stable source. Unit

displays the ADC count corresponding

to input.

Calibration Mode

D

RUN MODE

Note :

1. All values followed by Enter key will be stored,

else the value will be discarded.

2. All modes have password protection.

Default password is 191.

ESD

ESD

programmedparameters andprocessvariables(even in events

ofprolongedpowerfailure).

6. Keypad: Feather touch membrane keys are providedon

thefront panelforuser programming.Thesekeys have

featureslikelonglife, negligible contact bounce, ease of

operation.

7. Display: The front panelcarriesalltheindications. These

arecontrolledbythe CPU. 16 column x 2 rowsAlfa numeric

LCDdisplayisused forindicatingvariousmessagesand

parametervalues.2 LED's indicate the relay status of 2 corre

sponding setpoints. Thisactsas aninterfacebetweenuser and

CPU.

8. Outputrelays: There are tworelays, one for each setpoint.

9. RS 232 : Serial port is for communication with a PC. For

modedetails on this, pls refer themodbusprotocolsection.

Modes of Operations :

1. ProgramMode:

Inthis mode the user can programallthesetpoints, control

actionetc.

2. Run Mode :

Inthis mode the display shows the process value.

Forprogramming sequence pleasereferprogramflow chart.

813

Installation procedure :

The instrument should be mounted in a place where it is clearly

visibleandaccessible.

1. Inserttheinstrumentinasuitable cutout andfixitusingthe

bracketpair provided on the sides.

2. Make the connectionsasshownin RearView diagram.

3. Allconnectionsshouldbefirm.

4. Connect the positive of the transmitterto'+' terminaland

negativeofpowersupplyto' - ' terminal. i.e Connet the

terminalsinserieswiththetransmitter.

5. Ensureproperearthingtotheinstrument.

6. Connect the RS 485 2 wires to the master instrument.

Alsoobserve "Precautions"asgiven inthismanual

%%

%%

%

RUN MODE

E

ESD

ESD

12 9

Display Process

Value & function

in accordance

with parameters

set in

Configuration mode

RUN MODE

Power On

Func

key pressed?

F

No

1. Enter will take the

program to

respective Modes.

2. Increment and

Decrement keys are

used to select between

the modes.

3. Function key will take

back to

RUN mode.

B

C

D

A

Configuration Mode

C

E

NN

ESD

ESD

10 11

Program the hysterisys of setpoint no. 1

between 2 to 255 counts

Program the relay logic

high or low logic

of setpoint no. 1

between

Program the setpoint no. 1 value.

Setup Mode

B

RUN MODE

Program the hysterisys of setpoint no. 2

between 2 to 255 counts

Program the relay logic

high or low logic

of setpoint no. 2

between

Program the setpoint no. 2 value.

Note :

1. In program mode if function key is pressed at any point, unit will branch to

auto mode.

2. All values followed by Enter key willbe stored, else the value will be discarded.

3. All modes have password protection. Default password is 191.

F

User can stop the totalizer action

by selecting "YES"

User can reset the totalizer value

over here by selecting "YES".

A

RUN MODE

Note :

1. In program mode if function key is pressed

at any point, unit will branch to auto mode.

2. All values followed by Enter key will be stored,

else the value will be discarded.

3. All modes have password protection.

Default password is 191.

F

Table of contents

Other Electronics Controllers manuals