Electronics SP44 User manual

Table of contents

Other Electronics Controllers manuals

Popular Controllers manuals by other brands

Vetus

Vetus AFSTTOP Installation instructions and operation manual

Riverside Hydronics

Riverside Hydronics TempTrac user manual

Nibe

Nibe AXC 40 Installer manual

Anaheim Automation

Anaheim Automation MDC151-024031 Series user guide

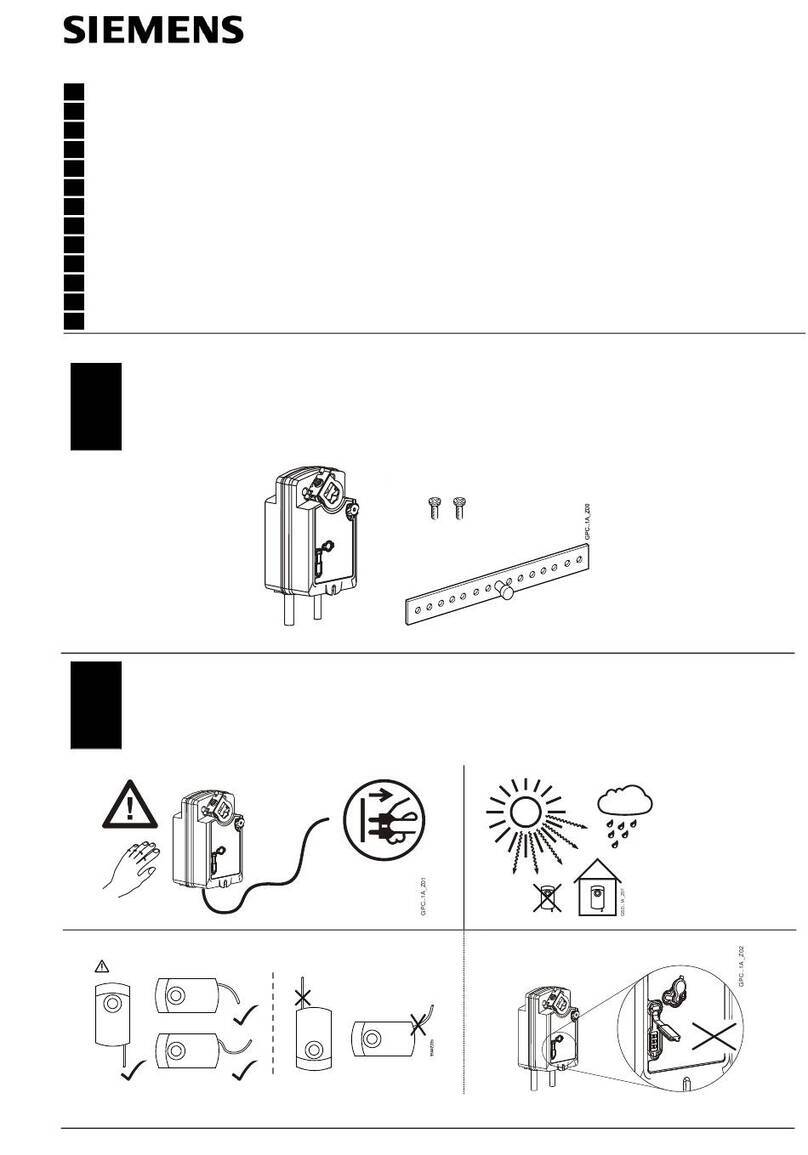

Siemens

Siemens GPC 1A Series Mounting instructions

Emerson

Emerson Dixell WING XW264K Installing and operating instructions

Ingersoll-Rand

Ingersoll-Rand SE Basic Manual

Ubisys

Ubisys J1 manual

Armacost Lighting

Armacost Lighting ProLine 13421 manual

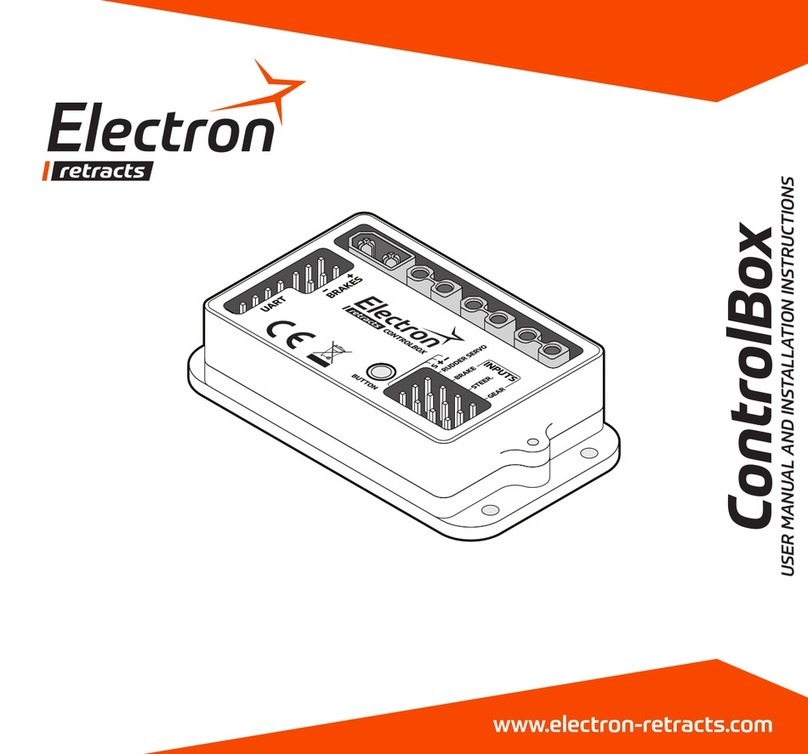

Electron retracts

Electron retracts ControlBox User manual and installation instructions

Reer

Reer MOSAIC Master M1 Installation and use

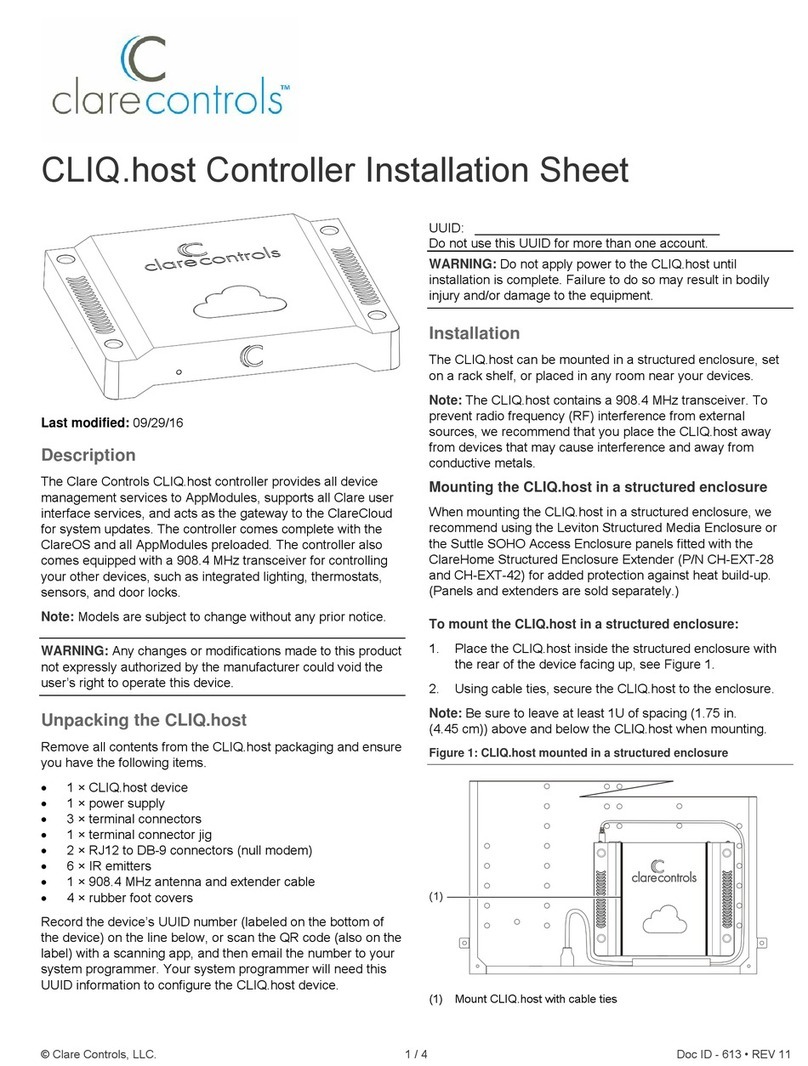

Clare Controls

Clare Controls CLIQ.host Installation sheet

Rosslare

Rosslare AC-F Series Installation and programming manual

LEGRAND

LEGRAND 5739 12 Technical sheet

Emerson

Emerson Dixell Wing XW570L Installing and operating instructions

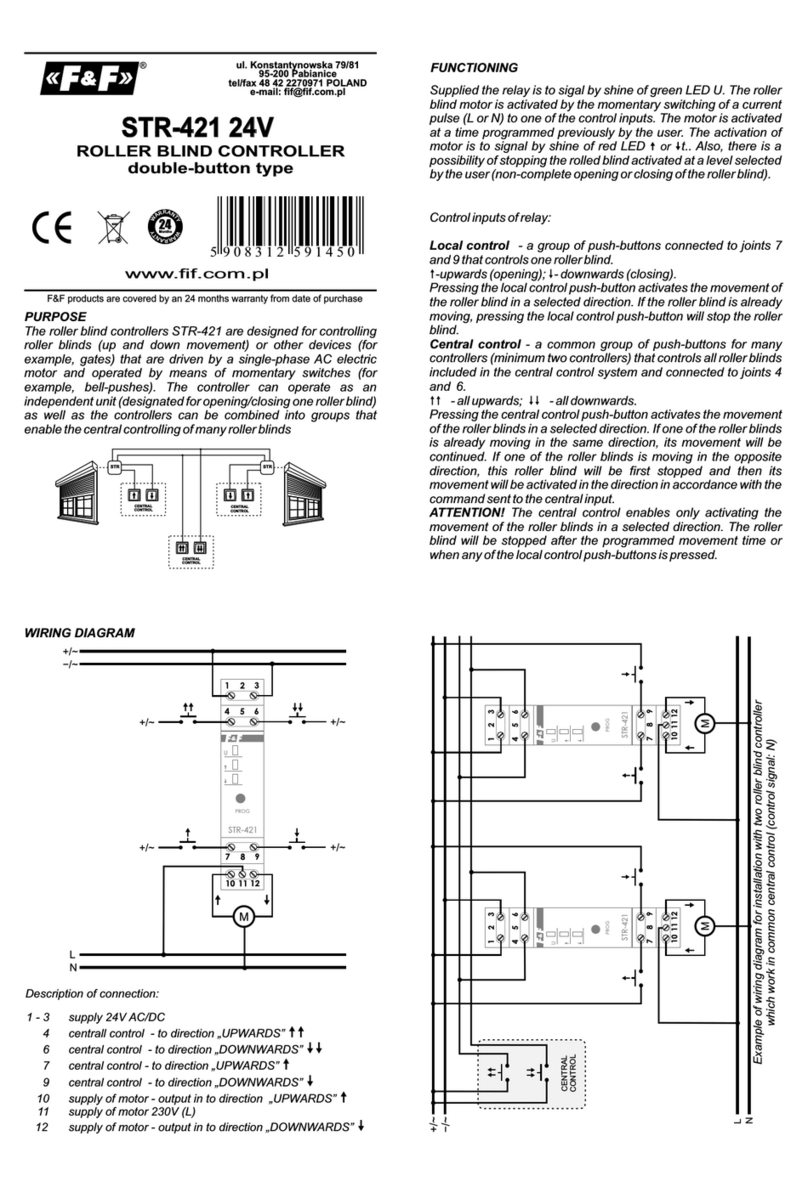

F&F

F&F STR-421 quick start guide

Woodward

Woodward easYgen-3000 Operation

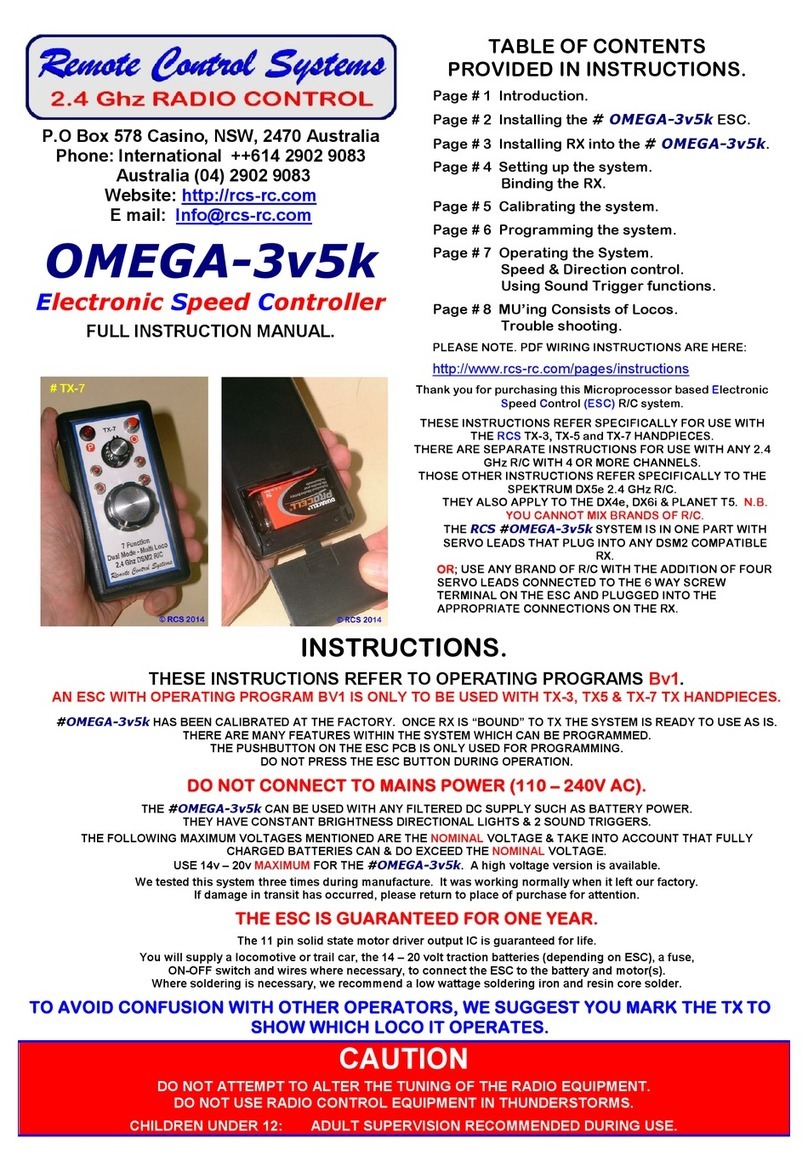

Remote Control Systems

Remote Control Systems OMEGA-3v5k FULL INSTRUCTION MANUAL