© Zennio Avance y Tecnología S.L. Edition 3 Futher information www.zennio.com Page 1/4

ALLinBOX 1612

Multifunction device with KNX power supply, KNX-IP Interface, 16 outputs, 12 inputs and logical module

ZPR1612 TECHNICAL DOCUMENTATION

FEATURES

•640mA KNX power supply with 29VDC auxiliary output.

•110-240VAC 50/60Hz power input.

•KNX system voltage supply and monitorization.

•Short-circuit and overvoltage protection.

•Reset button and overload status LED.

•KNXnet/IP tunneling protocol (up to 5 connections).

•Maximum APDU length of 254bytes.

•Ethernet 10/100 BaseT IP with RJ45 socket.

•8 different configurable channels: shutter channels (up to 8),

individual outputs (up to 16) and 2/4-pipe fan coil controls (up to 2).

•Outputs suitable for capacitive loads, maximum 140µF.

•Manual output operation through remote control.

•12 analog/digital inputs.

•Output timing.

•20 logic functions.

•Total data saving on KNX bus failure.

•Integrated KNX BCU.

•Dimensions 69 x 96 x 210mm (12 DIN units).

•DIN rail mounting (EN 50022), with fixing clamp.

•Possibility of connecting different phases in adjacent outputs.

•Conformity with the CE directives (CE-mark on the right side).

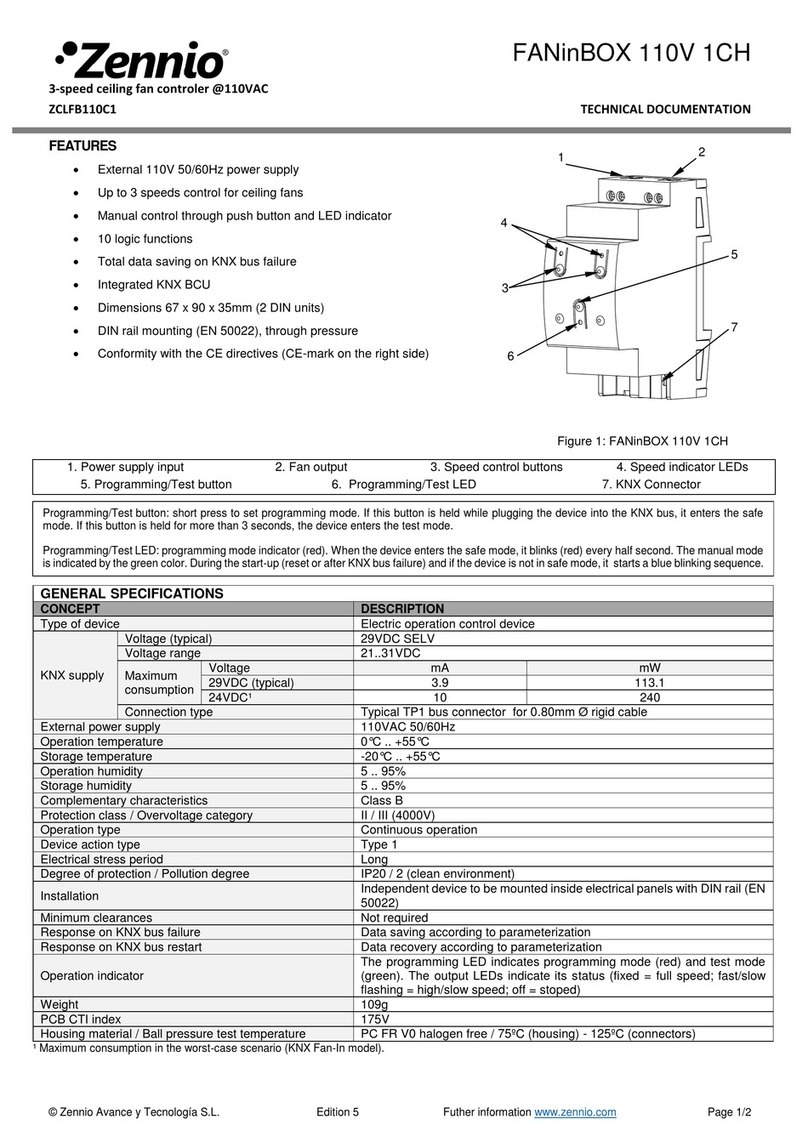

PROGRAMMING/TEST BUTTON: short press to set programming mode. If this button is held while providing main power supply to the device, it enters

the safe mode. If this button is held for more than 3 seconds, the device enters the test mode.

PROGRAMMING/TEST LED: programming mode indicator (red). When the device enters the safe mode, it blinks (red) every half second. The manual

mode is indicated by the green color. During the start-up (reset or after providing main power supply) and if the device is not in safe mode, it starts a

blue blinking sequence.

POWER SUPPLY STATUS LED: it indicates the status of the power supply (green color: the device is working properly; off LED: power supply failure;

green blinking: short-circuit on KNX bus and/or auxiliary power output).

OVERLOAD STATUS LED: it indicates an overload on the KNX line or on the auxiliary power output (red blinking: cut-off due to overload/short circuit

on the KNX bus and/or the auxiliary power output*; red color: overload on bus and/or auxiliary power output line *).

*Reduce the load on the bus and/or the auxiliary power output lines until its total consumption does not exceed the maximum current specified.

KNX BUS LED: it indicates that the device is powering up the KNX bus (green color).

ETHERNET LED: it indicates that the device is connected to Ethernet and has an IP address assigned (green color).

RESET INDICATOR LED: it indicates that a reset of the KNX system has been performed by using the corresponding reset button (red blinking). To

reset the bus power supply, the Reset button should be pressed (it is recommended to hold it for at least 5 seconds to verify the reset of all the devices

in the line). The reset LED will blink slightly in red while the Reset button is pressed.

IP FACTORY RESET INDICATOR LED: it indicates that the device has just performed an IP factory reset (red color). To reset the KNX IP Interface,

the IP Factory reset button must be pressed for at least 3 seconds.

MANUAL CONTROL: Inorder to perform manualcontrol of the device, an IR remote control is necessary(Ref. 9900024) not includedwith the ALLinBOX

1612. When the device is in Test On mode, the manual control can be done by pressing the corresponding buttons on the IR remote control (please,

be sure that the remote IR emitter is pointing to the IR input of ALLinBOX 1612).