Elektron Technology bulgin Buccaneer 900 Series User manual

900 Series

Buccaneer

IP68 and IP69K Waterproof Connectors

Wiring Assembly Instructions

www.bulgin.co.uk

Buccaneer 900 Series Environmentally Sealed Connectors

Mains Wire Connections

Important connect wires

Brown to termina L

B ue to termina N

Green/Ye ow to

termina E

Material:

Body Mouldings: Polyamide

Flammability Rating: UL94V-0

Contacts: Machined Solid Brass, Nickel plated

O Rings: Nitrile

Panel Sealing Gasket: Silicone Rubber

Mechanical:

Sealing: P69K, EN60529

Contact Accommodation: 2.5 to 4mm2 (13-10AWG) conductor, single or

multi stranded

Cable Retention force: 22mm dia, 150N

15mm dia, 150N

7mm dia, 80N

Cable Acceptance and

Gland Tightening Torques:

Cable dia Gland Colour Tightening Torque

PX0 version 13-15mm Yellow (standard)

3.16Nm (28 lb/in)

11-13mm Black

3.16Nm (28 lb/in)

9-11mm White

3.16Nm (28 lb/in)

7-9mm Dark Grey

3.16Nm (28 lb/in)

PXA version 20-22mm Yellow (standard)

3.16Nm (28 lb/in)

18-20mm Black

3.16Nm (28 lb/in)

16-18mm White

3.16Nm (28 lb/in)

14-16mm Dark Grey

3.16Nm (28 lb/in)

Panel mount nut --

2.25Nm

Flange & Bulkhead

fixing screws --

0.9Nm

IMPO TANT - PLEASE EAD

Before usin the connector, it is important that these instructions are carefully

read and understood to ensure the connector system is completely water ti ht

and electrically safe.

IF IN DOUBT CONSULT A QUALIFIED ELECTRICIAN.

NEVER UNMATE OR MATE THE PRODUCT WHILE STILL UNDER LOAD

The 900 Series Buccaneer is available in 2, 3, 4, 5, 7 and 10 pole

versions. The 3, 4, 5 and 7 pole versions have a ‘Leading Earth’ pin

arrangement for added protection.

The socket insert of the connector should always be the live part of the

connector from the supply. The pin insert of the connector should always lead

to the load or electrical device. The pin or socket inserts can be fitted to any

body style to provide the correct arrangement for the application.

To ensure efficient sealing use only smooth, circular cable with appropriate

gland for the cable diameter. The sealing glands supplied with the Flex and

Flex n-line connectors accommodate cables sizes as follows:

Version Cable Dia. Cable Gland Colour

PX0 13-15mm Yellow (standard)

PX0 11-13mm Black

PX0 9-11mm White

PX0 7-9mm Dark Grey

PXA 20-22mm Yellow (standard)

PXA 18-20mm Black

PXA 16-18mm White

PXA 14-16mm Dark Grey

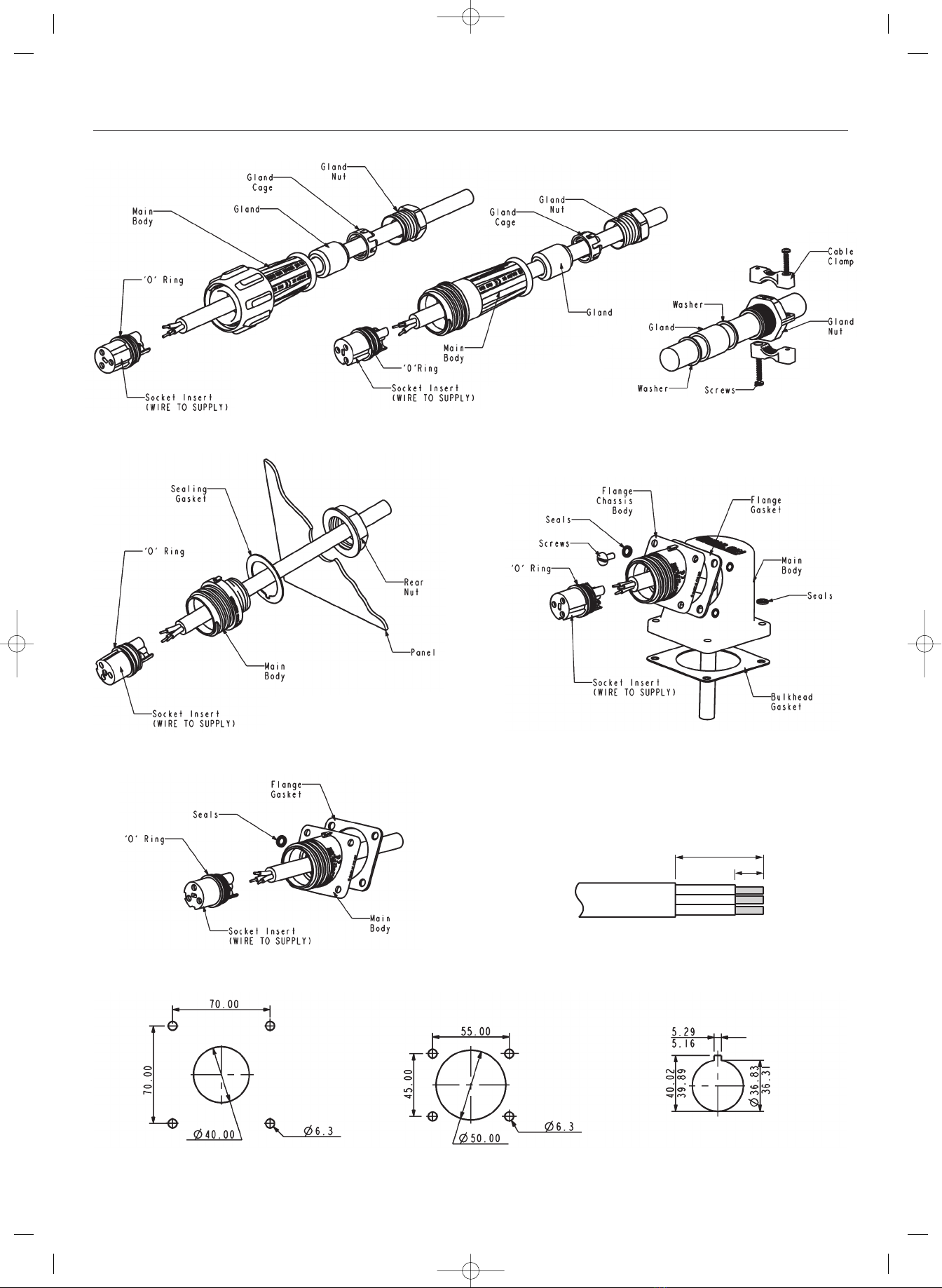

Assembly/Wiring instructions

1. Remove the pin or socket insert from the housing of the connector.

There is a slot for a flat blade screwdriver in the centre of the insert.

NOTE: The inserts have a LEFT HAND THREAD and should be turned

clockwise to remove.

2. For Flex and n-Line connector bodies, remove the gland nut, gland

cage and gland from the rear of the housing and slide onto the

cable. NOTE for PXA version there is no gland cage. Thread the

cable through the connector body. See assembly drawings, figs. 1-5

and 8 for different body styles.

3. Prepare the cable and bare the wire ends as shown in fig. 6, wire

stripping details.

4. nsert the bared wire ends into the terminals on the back of the

pin/socket insert and fully tighten the wire retention screws.

NOTE: f the connector is to be used with ‘mains’ voltages, ensure

the wires are connected in the correct orientation as shown in the

diagram below.

After the wires have been connected securely, pull the cable and

insert back into the housing and tighten with a screwdriver to ensure

the insert is seated correctly.

NOTE: LEFT HAND THREAD, turn the insert anti-clockwise when

assembling.

When assembling the Chassis (fig 3) and Flange (fig 4 and 5)

housing types, the cable should be left free behind the panel to

prevent it twisting.

5. For Flex and Flex n-line housings:

PX0 version: Slide the gland, gland cage and gland nut along the

cable into the body and tighten the gland nut to the appropriate

torque to seal.

Please note change to PXA assembly:

PXA version: Slide 1 washer, the gland, the final washer and gland

nut along the cable into the body and tighten to the appropriate

torque to seal then tighten clamp screws to secure. See fig 8.

6. For the Bulkhead, Flange and Chassis body styles, correctly seat the

gaskets and housing onto the mounting surface and secure with rear

nut or screws/bolts with seals. Ensure all seals and glands are kept

clean during assembly.

NOTE: To ensure that the correct sealing properties of the connector are

achieved it is imperative that all ‘O’ rings are correctly located and

seated before assembly. Please refer to the exploded diagrams for the

locations of these seals.

Part no.: 13672 Issue no: 12

IF IN DO BT SEEK ADVICE

IMPORTANT SAFETY NOTICE

For your protection all mains (250V) equipment

used out of doors, in damp or wet conditions

should be supplied from a correctly fused

source and protected by an approved R.C.D. to

BS7071, BS7288, BS4293, BS EN 61008-1,

BS EN 1008-2-2

900 Series Wiring 13672iss12:900 Series Wiring 13672iss12 19/9/12 16:34 Page 1

Specification

Electrical:

Current Rating: CSA

Current Rating:

Voltage Rating:

Contact Resistance:

Insulation Resistance:

Dielectric strength:

Approvals:

4,5 Poles 7 Pole 10 Pole

32A

30A

600V ac/dc

32A

25A

600V ac/dc

2,3 Poles

32A

30A

415V ac/dc

10A

10A

250V ac/dc

<10m Ohm (initial)

>10M Ohm (@500V dc)

2.2Kv ac min

UL/VDE/CSA/CCC UL/VDE/CCC CCC

CSA Pending UL/VDE/CSA

Pending

ʻCaution not for Interrupting currentʼ

ʻAttention; Ne pas utiliser pour couper le courantʼ

22mm

7mm

Buccaneer 900 Series Environmentally Sealed Connectors

Fig 1. Flex Mounting

(PX0911, PXA911)

Fig 8. Cable retention and

sealing assembly for large

cable entry (PXA911, PXA921)

Fig 3. Chassis/Panel Mounting (PX0931) Fig 4. Flange/Bulkhead Mounting

(PX0941 + PX0950)

Fig 5. Flange Mounting (PX0941)

Fig 6. Wire Striping Details

Fig 7. Panel cut out details

Fig 2. Flex Mounting In-line

(PX0921, PXA921)

BULKHEAD/FLANGE MOUNTING PX0950 FLANGE MOUNTING PX0941 PANEL MOUNTING PX0931

900 Series Wiring 13672iss12:900 Series Wiring 13672iss12 19/9/12 16:34 Page 2

This manual suits for next models

17

Popular Cables And Connectors manuals by other brands

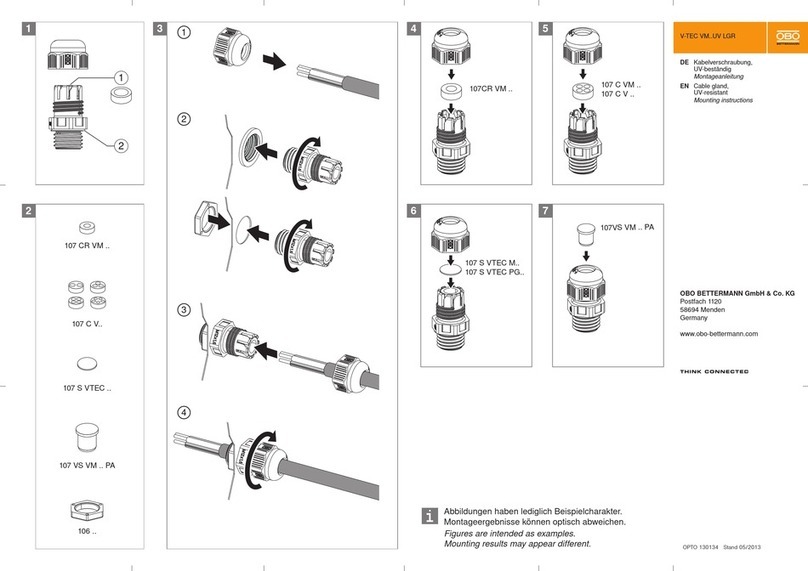

OBO Bettermann

OBO Bettermann V-TEC VM12UV LGR Mounting instructions

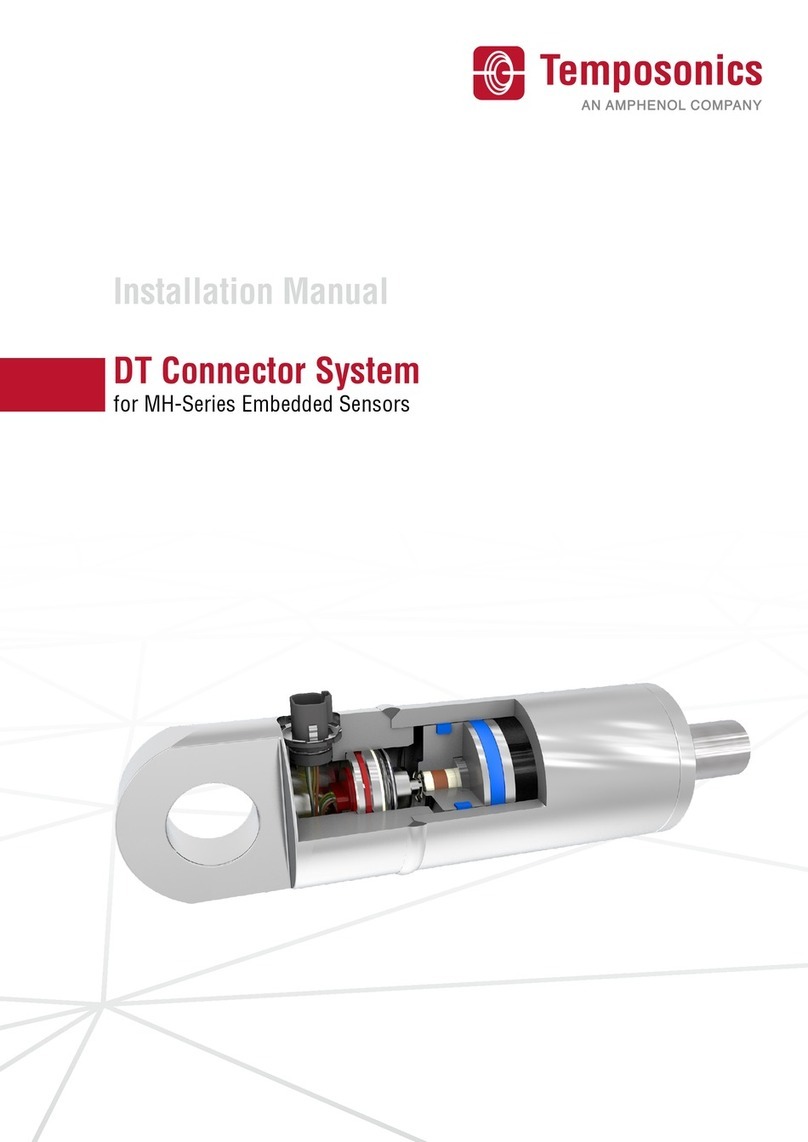

Amphenol

Amphenol Temposonics DT Connector System installation manual

Stihl

Stihl AP instruction manual

Thetford

Thetford Aqua-Magic V quick start guide

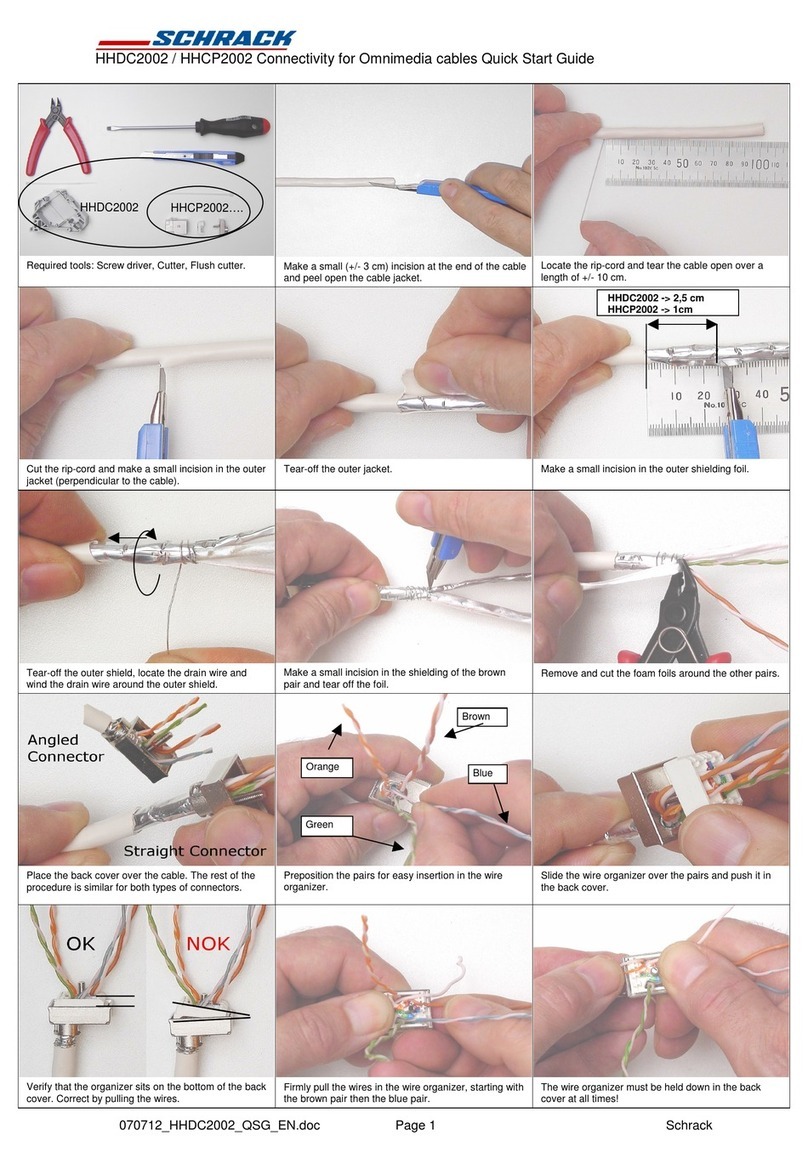

Schrack

Schrack HHDC2002 quick start guide

Renkforce

Renkforce 1407351 operating instructions