Elektron KERCOMET 170 User manual

Made in Germany

Operation Manual

KERCOMET 170 and 210

MULTIMIG 150

MIG / MAG - Welding ma hine

Item-No: 327 972

Revision: 1.0 - Original

Version:

31.01.2013

Be sure you have read and understood this operating

manual before you arry out any works on and/or with this

equipment!

2

© litzRotary GmbH

ranch remen

Hinterm Sielhof 22

D-28277 remen

Germany

Phone: +49 (0)421 / 54 90 6 - 906

Fax: +49 (0)421 / 54 90 6 - 19

E-Mail: [email protected]

Internet: www.elektron-bremen.de

Release:

litzRotary GmbH ranch remen

KERCOMET 170

und

210, MULTIMIG 150

Table of ontents

3

Table of ontents

1

Ma hine elements 4

2

Explanation of symbols 5

2.1

Meaning of the symbols in the operation

manual 5

2.2

Meaning of the symbols on the machine 5

3

Safety pre autions 5

4

General regulation of use 6

5

Unit prote tion 6

6

Noise emission 6

7

Ambient onditions 7

8

UVV inspe tion 7

9

Ele tromagneti ompatibility

(EMC) 7

10

Setup and transport 8

11

Brief operating instru tions 9

12

Before start-up 10

12.1

Connecting the torch 10

12.2

Connecting the ground cable 10

12.3

Select mains voltage 10

12.4

Fastening the ground clamp 10

12.5

Insert the welding wire spool 11

12.6

Thread the wire electrode in 11

12.7

Connecting the inert gas cylinder 12

12.8

Changing the wire electrode 14

13

Start-up 16

13.1

Control console KERCOMET 170 and

MULTIMIG 150 16

13.2

Control console KERCOMET 210 18

13.3

Current/voltage display 19

13.4

Characteristic connection 20

13.5

Main parameters 21

13.6

Secondary parameters 21

13.7

Special functions 22

13.8

Reset setting 22

14

Messages 23

15

Troubleshooting 24

16

Repair and maintenan e 26

16.1

Check regularly 26

16.2

Torch care 26

17

Te hni al data 27

18

Options and a essories 28

18.1

Torch holder 28

19

Disposal 28

20

Servi e 28

21

S hemati KERCOMET 170 29

22

S hemati KERCOMET 210 30

23

S hemati MULTIMIG 150 31

KERCOMET 170

and

210, MULTIMIG 150

Ma hine elements

4

1 Ma hine elements

Fig. 1: Machine elements

1 Safety chain for gas

2 Hoisting points

3 Mains cable

4 Mains voltage changeover-switch

(on switch able units only)

5 Gas hose

6 Tray area

7 Handle

8 Control panel

9 Main switch

10 Socket for ground cable

11 Central socket

Some depicted or described acces-

sories are not included in the

scope of delivery.

Subject to change.

KERCOMET 170

and

210, MULTIMIG 150

Explantion of symbols – Safety pre autions

5

2 Explanation of symbols

2.1 Meaning of the symbols in the

operation manual

Danger to life and limb!

If the danger warnings are disre-

garded, this can cause slight or

severe injuries or even death.

Danger of property damage!

Disregarding danger warnings can

cause damage to w

ork pieces,

tools, and equipment.

General note!

Designates useful information

about the product and equipment.

2.2 Meaning of the symbols on the

ma hine

Danger!

Read the user information in the

operation manual.

Dis onne t the mains plug!

Pull out th

e mains plug before

opening the housing.

3 Safety pre autions

Hazard-free working with the ma-

chine is only possible if you read

the operating and safety instruc-

tions completely and strictly ob-

serve them.

Please obtain practical training be-

fore u

sing the machine for the first

time. Follow the accident preven-

tion regulations (UVV

1

)).

efore starting any welding work,

clear away any solvents,

degreasing agents, and other

flammable materials from the

working area. Cover flammable

materials wh

ich can not be moved.

Only weld if the ambient air

contains no high con

centrations of

dust, acid vapours, gases or

flammable substances. Special

care must be taken during repair

work on pipe systems and tanks

which contain or have con

tained

flammable liquids or gases.

Never touch live parts inside or

outside of the housing. Never touch

welding electrodes or live welding

current parts in a machine that is

on.

Do not expose the machine to rain,

do not spray water on it or steam

blast it.

Always use

a welding shield. Warn

other persons in the welding area

about arc-rays.

1

) Only for Germany.

Available at Carl Heymanns-Verlag,

Luxemburger Str. 9, 50939 Köln.

KERCOMET 170

and

210, MULTIMIG 150

General regulation of use

6

Please use a suitable extrac

tion

system for gases and cutting

fumes. Always wear breathing ap-

paratus whenever there is a risk of

inhaling welding or cutting vapours.

If the mains cable is damaged or

severed in use, do not touch the

cable but unplug the mains plug

immediately. Never use a machine

if the mains cable is damaged.

Keep a fire extinguisher near the

welding area.

Check the welding area for fire af

ter

welding (see UVV

1

)).

Never try to disassemble the pres-

sure reducer. Replace the defec

tive

one.

The machine must be transported

or set up only on firm, leve

l

surfaces. The maximum admissible

angle of inclination for setting up or

transporting is 10°.

Service and repair work may only be carried

out by a trained electrician.

Ensure that the ground cable has good and

direct contact near the welding location. Do

not allow welding current to pass through

chains, ball bearings, steel cables or

grounding equipment; this may melt them.

Secure yourself and the welding machine

when working in elevated or inclined areas.

The machine may only be connected to a

properly grounded mains supply. (Three-

phase four-wire system with grounded

neutral conductor or single phase-three-wire

system with grounded neutral conductor)

socket and extension cable must have a

functional protective conductor.

Wear correct protective clothing, leather

gloves and leather apron.

Protect the welding area with curtains or

mobile screens.

Do not use this machine to thaw frozen

water pipes or cables.

In closed containers, under cramped con-

ditions, and in high electrical risk areas, only

use machines with the S sign.

Switch off the machine during breaks and

close the valve of the gas cylinder.

Secure the gas cylinder with a chain to

prevent it falling over.

Disconnect the mains plug from the mains

before changing the place of installation or

making repairs to the machine.

Please heed the safety regulations which apply

to your country.

Subject to change.

4 General regulation of use

This unit is for welding of steel, aluminium and

their alloys as well as for brazing with CuSi

wires for commercial as well as for industrial

use.

5 Unit prote tion

This machine is protected electronically

against overloading. Do not use fuses of higher

amperage than printed on the identification

plate.

Close the side cover before starting any

welding work.

6 Noise emission

The noise level of the unit is less than

70 d (A), measured under standard load in ac-

cordance with EN 60974-1 in the maximum

working point.

KERCOMET 170

und

210, MULTIMIG 150

Ele tromagneti ompatibility (EMC)

7

7 Ambient onditions

Temperature range of ambient air:

In operation:

-10 °C … +40 °C (+14 °F … +104 °F)

Transport and storage:

-25 °C … +55 °C (-13 °F … +131 °F)

Relative humidity:

up to 50 % at 40 °C (104 °F)

up to 90 % at 20 °C (68 °F)

Operation, storage and transport

may only be carries out within the

ranges indicated! Use outside of

this range is c

onsidered not used

with its intended purpose. The

manufacturer is not liable for dam-

ages cause by misuse.

Ambient air must be free of dust, acids, cor-

rosive gases or other damaging substances!

8 UVV inspe tion

Operators of commercially-operated welding

systems are obliged to have safety inspections

of the equipment carried out regularly in

accordance with VDE 0544-4. ELEKTRON

recommends inspection intervals of 12 months.

A safety inspection must also be carried out

after alterations or repair of the system.

Improper UVV inspections can

destroy the system

9 Ele tromagneti ompatibility

(EMC)

This product is manufactured in conformance

with the current EMC standard. Please note

the following:

The machine is intended for welding in both

commercial and industrial applications

(CISPR 11 class A). Use in other

surroundings (for example in residential

areas) may disturb other electronic devices.

Electromagnetic problems during start-up

can arise in:

• Mains cables, control cables, signal and

telecommunication lines near the welding or

cutting area

• TVs / radios

• Computers and other control equipment

• Protection equipment such as alarm

systems

• Pacemakers and hearing aids

• Equipment for measurement and calibration

• Equipment with too little protection against

disturbances

If other equipment is disturbed it may be

necessary to provide additional shielding.

The affected area can be bigger than your

premises/property. This depends on the

building, etc.

Please use the machine in compliance with the

manufacturer's instructions. The machine

operator is responsible for installation and use

of the machine. Furthermore, the owner is

responsible for eliminating the disturbances

caused by electromagnetic fields.

KERCOMET 170

und

210, MULTIMIG 150

Setup and transport

8

10 Setup and transport

Danger of injury du

e to the de

-

vi e falling over and rashing!

When transporting using mechani-

cal lifting equipment (e.g. crane,

etc.), only the hoisting points shown

here may be used. Use suitable

load-carrying equipment.

Each lifting point must be loaded

separately. Do NOT,

for example

put one load strap through both

handles, as this could lead them to

be pulled together and cause

breakage!

Do not use a fork-lift truck or simi

lar

device to lift the machine by its

housing.

Remove the gas cylinder from the

welding machine before transpor-

tation .

The machine must be transported

or set up only on firm, level sur-

faces. The maximum admissible

angle of inclination for setting up or

transporting is 10°.

Fig. 2: Lifting point for 4-point hoisting

KERCOMET 170

and

210, MULTIMIG 150

Brief operating instru tions

9

11 Brief operating instru tions

A detailed description can be found

in chapter. „ efore start up“

Page 10

and chapter. „Start up“

Page 16.

Place the inert gas cylinder on the unit and

secure it with the chain 1.

Remove the screw cap from the inert gas

cylinder and open the valve 32 briefly (blow-

out).

Connect the pressure reducer 13 to the inert

gas cylinder.

Connect the insert gas hose 5 from the unit

to the pressure reducer and open the

cylinder valve.

Insert the mains plug in the socket.

Connect welding return cable to connector

10 and the clamp to the work piece.

Insert wire feed rollers 25 into wire feed unit

in accordance with the type of welding wire

selected, set contact pressure to 2.

Connect the torch to central connector 11

and insert the relevant contact tip to se-

lected welding wire.

Insert welding wire.

Keep torch switch pressed and set main

switch 9 ON. Magnetic valve will be ac-

tivated!

Adjust gas quantity at pressure reducer.

(Rule: wire diameter x 10 = gas quantity).

Hold down the wire feed switch 29 until the

welding Wire projects from the torch neck to

the gas nozzle by approx. 10 mm.

Set required material-wire-gas combination

using characteristic line switch 65.

Select the 2-stroke mode using the button

60.

Select the thickness of material to be

welded using step switch 57.

Torch switch pressed and held = welding.

Release the torch switch = welding process

completed.

KERCOMET 170

and

210, MULTIMIG 150

Before start-up

10

12 Before start-up

12.1 Conne ting the tor h

Connect the central connector 17 of the

torch to the central socket 11.

Fig. 3: Connecting the torch

12.2 Conne ting the ground able

Connect welding return cable 18 to con-

nector 10 and secure it by turning it clock-

wise.

Fig. 4: Connecting the ground cable

12.3 Sele t mains voltage

(Only for machines with mains voltage switch-

over, refer to technical data)

Set the required voltage by using mains

voltage switch 4.

For 230 V operation, the adapter CEE 16 on

shock proof plug (incl. in delivery) may be

used.

Performance values are lim

ited in

230

V mode, i.e. max welding

power is limited to 2/3 of the values

stated in technical data.

12.4 Fastening the ground lamp

Fig. 5: Correct

Attach the ground clamp immediately be-

side the welding point so that the welding

current will not try to find its own return path

through machine parts, ball bearings or

electric circuits.

Connect the ground clamp firmly to the

welding bench or the work piece.

Fig. : Incorrect

Do not place the ground clamp on the

welding machine or the gas cylinder; oth-

erwise the welding current will be carried via

the protective conductors and it will destroy

these.

KERCOMET 170

and

210, MULTIMIG 150

Before start-up

11

12.5 Insert the welding wire spool

Danger to life and limb and fire

hazard due to glowing welding

wire or parts!

Wire excess length of the wire

spool can

cause short circuits with

the side panel or bottom of the unit.

When inserting the welding wire

spool, please pay attention to the

correct winding and make sure that

there are no wire excess lengths.

Set the wire brake in such a way

that the wire spool doesn't con

tinue

running when pressing the torch

key.

Open side panel and turn the retaining nut

20 off from the wire spool holder 22.

Place the welding wire reel on the decoiler

mandrel and ensure that the carrier mandrel

23 locks in position.

For small welding wire reels, use an adaptor

(order number 420 922).

Set the wire brake 21 so that, when the

torch switch is released, the welding wire

spool just does not run on.

Fig. 7: Decoiler mandrel

12.6 Thread the wire ele trode in

Unscrew the contact tip of the torch.

Open side panel.

The diameter of the wire electrode must

agree with the legible embossed figure on

the wire feed rollers 25.

Swing the tilt levers 27 to the side and

thread the wire electrode through the inlet

nozzle 26 and central socket 11.

Fig. 8: open 2-roll wire feed

Fig. 9: open 4-roll wire feed

Swing the lever back 28 and secure in po-

sition with the tilt levers 27.

KERCOMET 170

and

210, MULTIMIG 150

Before start-up

12

Fig. 10: close 2-roll feed

Fig. 11: close 4-roll feed

Turn on the machine at mains switch 9.

Fig. 12: Wire feed button

Press wire feed button 29.

Adjust the contact pressure using the reg-

ulation screws 27 so that wire feed rollers

25 just slip when the welding wire spool is

stopped. The wire must not be jammed or

deformed.

A B C

Correct Contact pressure

too high

Wrong wire feed

roller

Fig. 13: Wire feed rollers

Note for wire feed unit with 4 rollers:

Adjust the contact pressure of the wire feed

rollers 25 on the side of the inlet nozzle 26

to be less than on the side of the central

socket 11 in order to keep the wire

electrode under tension in the wire feed

unit.

Push the wire feed button 29 until the wire

protrudes from the torch neck by about 20

mm.

Screw the contact tip matching the wire

thickness into the torch and cut off the

protruding end of the wire.

12.7 Conne ting the inert gas ylinder

Set the insert gas cylinder 14 down on the

carrier plate and secure it with the chain 1.

riefly open the gas cylinder valve 32

several times in order to blow out any dirt

particles present.

Connect the pressure reducer 13 to the inert

gas cylinder 14.

Screw the inert gas hose 5 to the pressure

reducer.

Open valve 32 of shielding gas bottle 14.

Turn the machine off at main switch 9.

Press torch key and keep it pressed.

Turn on the machine at mains switch 9.

Solenoid valve will be switched on for 10

seconds.

KERCOMET 170

and

210, MULTIMIG 150

Before start-up

13

Set the gas quantity using adjusting screw

35 of the pressure reducer 13. The gas

quantity will be displayed on the flow meter

34.

Rule of thumb:

Gas volume = wire diameter x 10 l/min.

The cylinder content is indicated on the

content manometer 33.

Fig. 14: Connecting the inert gas cylinder

KERCOMET 170

and

210, MULTIMIG 150

Before start-up

14

12.8 Changing the wire ele trode

Change the wire feed rollers. Select the

most suitable rollers for the application.

Fig. 15: Wire feed rollers

A Steel feed roller

B Aluminium feed roller

C Knurled feed roller (for flux-cored wire)

Fig. 1 : Marking of wire feed rollers

Replace the steel torch with an appropriate

torch, or change the wire feed spiral.

Wire feed spiral: (for steel or flux- ored

wire)

Remove the existing wire feed spiral or

plastic core and insert the new wire feed

spiral. (Refer to the operating manual for the

torch)

Insert the guide tube 85 into the central

connection.

Plasti ore: (for aluminium, stainless steel

or CuSi wire)

Remove the existing wire feed spiral or

plastic core and insert the new plastic core.

(Refer to the operating manual for the torch)

Remove the guide tube 85 from the central

connection.

Shorten the protruding plastic core so that it

is tight up against the wire feed roller, and

slide the appropriately shortened support

tube over the protruding plastic core for

stabilisation.

All:

Tighten the torch and thread the wire elec-

trode in.

The order numbers of the replace-

ment part

s depend upon the type of

torch used and the diameter of the

wire, and can be obtained from the

torch spares lists.

KERCOMET 170

and

210, MULTIMIG 150

Before start-up

15

Fig. 17: Wire feed

7 Central socket

17 Central connection (torch)

25 Wire feed roller

38 Retaining nipple (=clamp) of the plastic

liner for 4.0 mm and 4.7 mm outside

diameter

39 O-ring

40 Union nut

41 Plastic liner

42 Support tube for plastic cores with 4 mm

OD Support tube not required with OD of

4.7 mm.

43 Guide tube

44 Wire feed spiral

KERCOMET 170

and

210, MULTIMIG 150

Start-up

16

13 Start-up

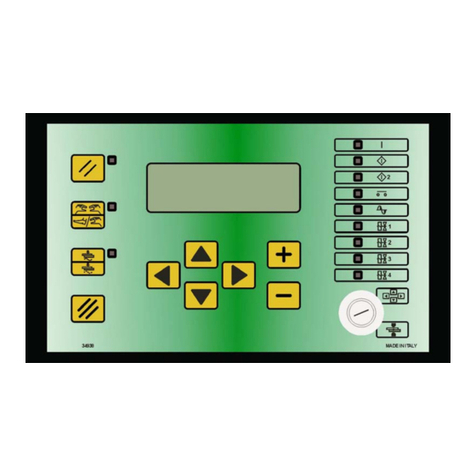

13.1 Control onsole KERCOMET 170 and MULTIMIG 150

Fig. 17: Control console KERCOMET 170 and MULTIMIG 150

KERCOMET 170

and

210, MULTIMIG 150

Start-up

17

45 Symbol wire feed

lights up in the 7-segment display 47 if the

wire feed is displayed in m/min or as

correction value in %.

47 7-segment display wire feed / material

thickness

depending on the mode, wire feed,

material thickness, welding step or (al-

ternating) secondary parameter code and

value are displayed.

49 Symbol 4-stroke

lights up if 4-stroke mode is set.

50 Symbol 2-stroke

lights up if 2-stroke mode is set.

51 Symbol Spot welding

lights up if spot welding mode is set.

52 Symbol Interval

lights up if interval mode is set

53 Symbol material thickness

lights up if the 7-segment display 47

displays the material thickness in mm.

56 Main switch

for turning the welding machine ON and

OFF.

57 Step switch material thickness / welding

step

by setting the step switch, for approx. 2

seconds the material thickness alt. welding

step will be displayed in the 7-segment-

display 47.

58 Symbol 230 V

lights up if 230 V is selected (applicable for

units with voltage changeover switch)

59 Symbol 400 V

lights up if 400 V is selected.

60 Trigger Mode

to select 2-stroke, 4-stroke, spot welding

or interval mode.

61 Turning knob wire feed

for adjustment of wire feed. y activation

of the turning knob, the wire feed will be

displayed as correction value in % on the

7-segment display 47, after setting the

speed will be displayed in m/min.

KERCOMET 170

and

210, MULTIMIG 150

Start-up

18

13.2 Control onsole KERCOMET 210

Fig. 19: Control console KERCOMET 210

KERCOMET 170

and

210, MULTIMIG 150

Start-up

19

45 Symbol wire feed

lights up in the 7-segment display 47 if the

wire feed is displayed in m/min.

46 Symbol welding current

lights up if the 7-segment display 47

displays the welding current in Ampere.

47 7-segment display welding current / wire

feed depending on set mode, either wire

feed, welding current or secondary

parameter value will be displayed.

49 Symbol 4-stroke

lights up if 4-stroke mode is selected.

50 Symbol 2-stroke

lights up if 2-stroke mode is selected

51 Symbol spot-welding

lights up if spot welding mode is selected.

52 Symbol interval

lights up if interval mode is selected.

53 Symbol material thickness Display 55

lights up if the material thickness is

displayed in mm.

54 Symbol welding voltage

lights up if the 7-segment display 55

displays the welding voltage in V.

55 7-Segment display material thickness /

welding voltage

according to set characteristic line (see

chapter characteristic setting) or mode

either the material thickness, welding

voltage or secondary parameter codes will

be displayed.

56 Main switch

for switching the welding unit ON and

OFF.

57 Step switch material thickness / welding

voltage

for adjusting the material thickness alt. the

welding voltage, values will be displayed in

the 7-segment display 55.

58 Symbol 230 V

lights up if 230 V welding voltage is set.

(machines with changeover switch only).

59 Symbol 400 V

lights up if 400 V welding voltage is set.

60 Mode selection key

for setting of mode, either 2-stroke, 4-

stroke, spot welding or interval.

61 Turning knob wire feed for wire feed

adjustment.

y activating the turning knob, the wire

feed is displayed in the 7-segment display

47 as correction value in %, after setting in

speed m/min.

13.3 Current/voltage display

47 Current indicator

55 Voltage display

The actual values of welding voltage and

welding current are displayed during and after

welding. If any changes of the set values by

the operator (i.e. step switch, turning knob,

key) take place, the main parameter wire feed

and material thickness will be displayed.

KERCOMET 170

and

210, MULTIMIG 150

Start-up

20

13.4 Chara teristi onne tion

Fig. 20: Characteristic table and selection knob

The characteristic selection knob 65 and the

corresponding table are in the wire feed

casing.

The table content may differ from

your welding machine. The char-

acterist

ic lines are set individually

for each machine type.

Select the required material-wire-gas

combination from the characteristic table.

Read the corresponding characteristic

number off from the right hand column.

Set the corresponding number from the

table using selection knob 65.

elow the characteristic number 0 (manual

mode)

• Is the material-wire-gas combination

nullified. Wire feed and welding voltage can

be set manually.

• The welding step ( asic Plus) instead of

material thickness will be displayed.

• The must-value for welding voltage (Control

Pro) instead of material thickness will be

displayed.

If an unassigned number is set with

the characteristic selection knob 65,

the 7-segment-

display 47 will

display the error message „noP“.

This manual suits for next models

2

Table of contents

Other Elektron Welding System manuals

Elektron

Elektron MULTISPOT MI-100control User manual

Elektron

Elektron MULTISPOT M20 User manual

Elektron

Elektron MULTISPOT MI-100 User manual

Elektron

Elektron MULTISPOT M80 User manual

Elektron

Elektron MULTIMIG 200 User manual

Elektron

Elektron MULTISPOT MI-100-3 User manual

Elektron

Elektron MULTIMIG 400puls User manual

Elektron

Elektron MULTISPOT MI-90 T User manual