Elektron MULTISPOT M80 User manual

Operating instructions

MULTISPOT M80

Resistance Welder

Item no. 322921

Revision: 3.0 - Translation

Version: 09th, March 2010

Be sure you have read and understood

this operating manual before you carry

out any works on and/or with this

equipment.

Contents page

1.0 Warning notes – explanation of symbols 1

2.0 Description of equipment and overview 3

3.0 Start-up 5

3.1 Assembly of power supply unit and trolley 5

3.2 Compressed air connection 5

3.3 Mains power supply connection 6

3.4 Checking the mains voltage drop during welding 6

3.5 Malfunction indicator 7

4.0 Applications 8

5.0 Technical data 9

6.0 Working with spot-welding tongs 11

6.1 Preparation of welding area 11

6.2 Spot-welding with the tongs 13

6.3 Pulse welding 15

7.0 Operating the welding gun 17

7.1 Push spot welding 19

7.2 Pulling-out dents with washer 21

7.3 Pulling-out dents with high-speed planishing hammer “SAH" 23

7.4 Pushing-in dents 25

7.5 Shrinking sheet metal 25

7.6 Welding-on threaded studs 27

7.7 Welding-on T-pins 29

7.8 Positioning/fixing sheet metal (tacking) 31

8.0 Operating QUICKSPOT 31

9.0 Connection of AIRPULLER 32

10.0 Practical hints 32

11.0 Appendix/self-test and troubleshooting 33

11.1 Self-test 33

11.2 Checking LED displays and the solenoid valves 33

11.3 Mains-supply test and troubleshooting 33

11.4 Manual tool selection 35

11.5 Operating panel malfunction 35

- 1 -

1.0 Warning notes – explanation of symbols

Caution!

Please note the following when using resistance welding units:

The power supply unit and leads of the welding gun and the spot

welding tongs generate a powerful electromagnetic field when in use.

Electromagnetic fields can cause irritations of sense organs, nerve

and muscle cells as well as malfunctions in physical aids (hearing aid,

pacemaker etc.), electronic devices and data storage units.

To prevent these effects, avoid a direct body contact with the welding

cable. A safe distance of 15 cm between cable and body is

recommended.

Caution! Danger!

Ignoring this warning may result in injury!

Observe the notes!

This is the only way to achieve satisfactory welding results.

Work on the power supply unit may ONLY be performed by qualified

electricians.

Wear protective goggles and gloves!

- 2 -

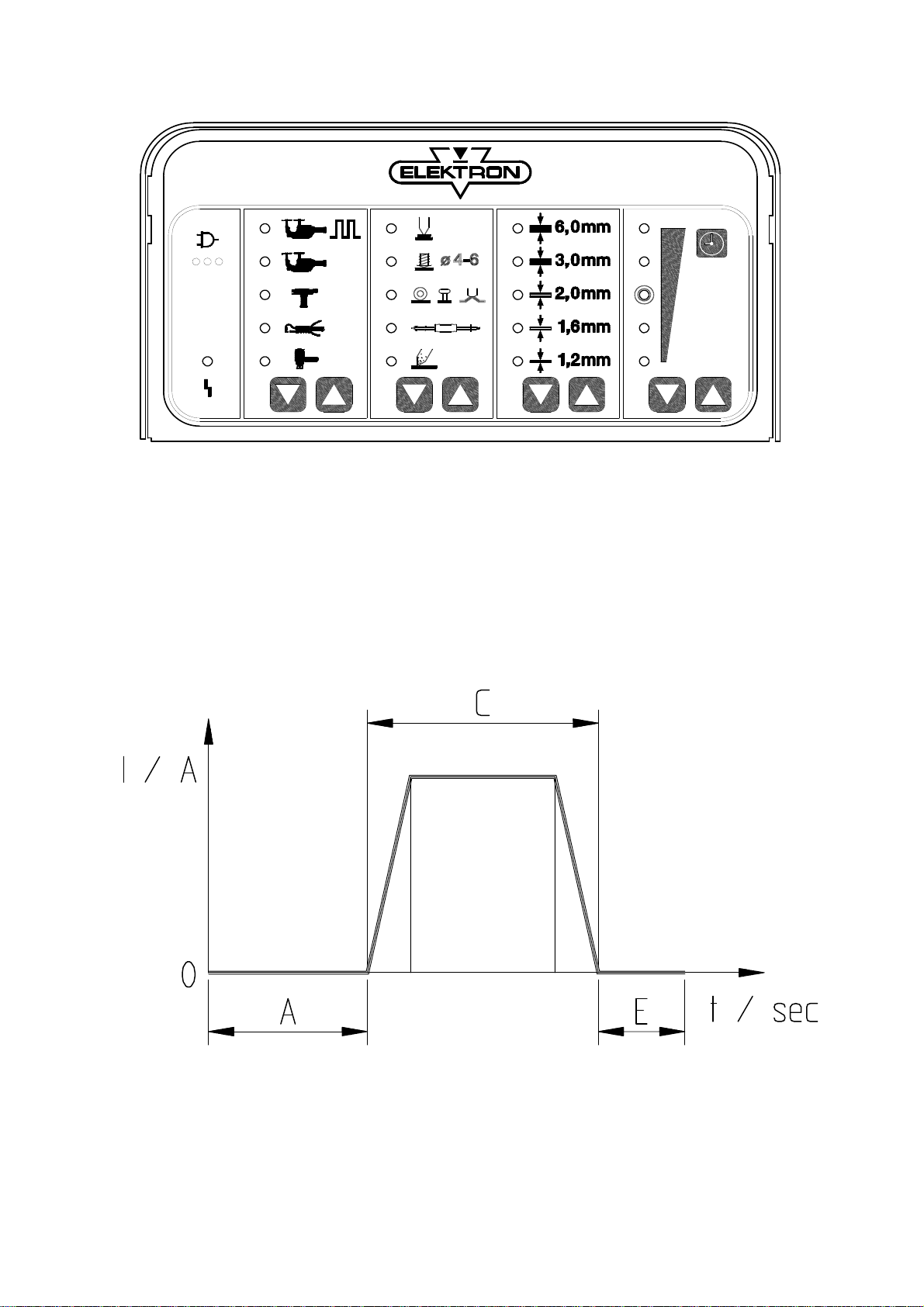

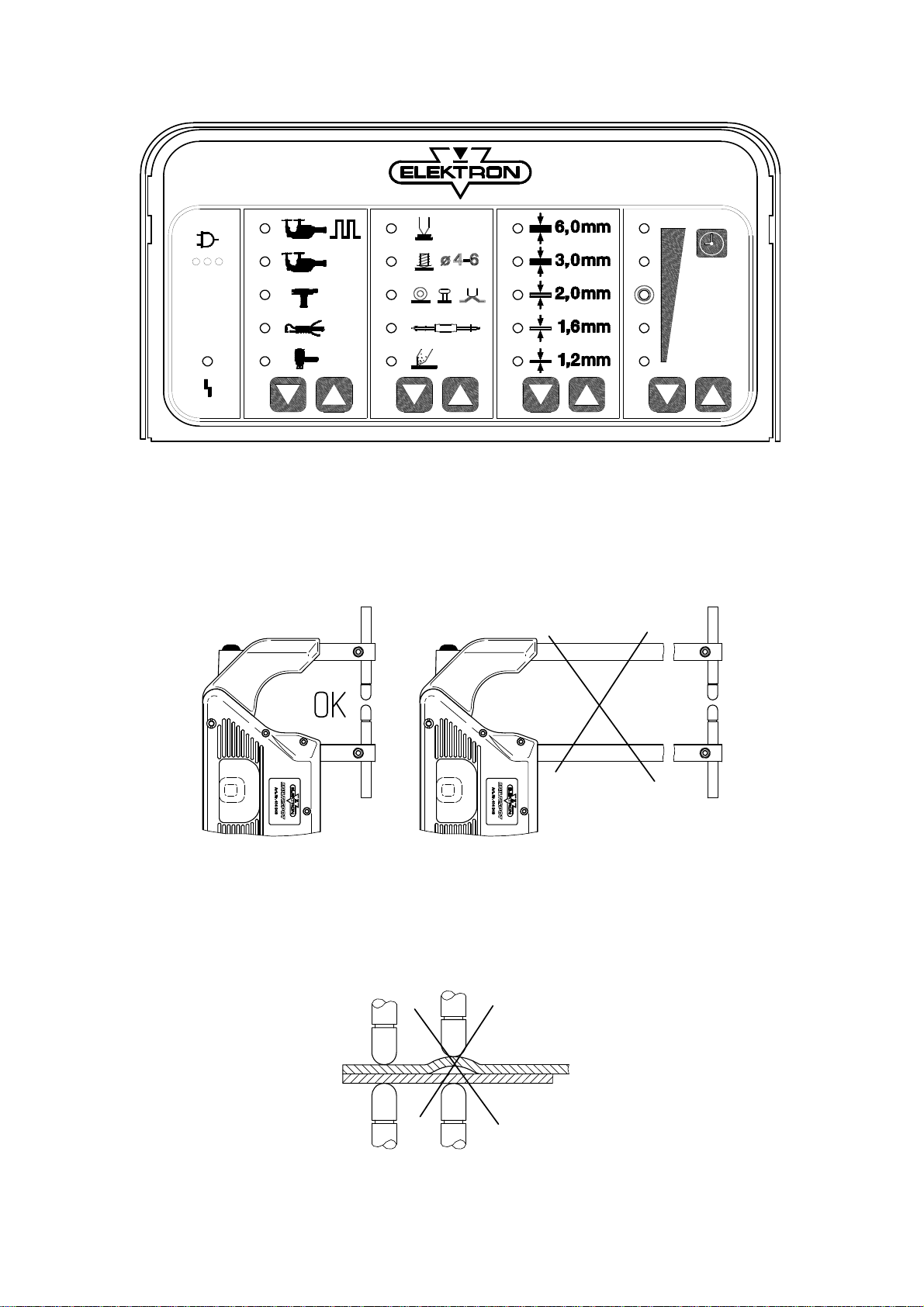

AB Tool selecting keys (manual) see Appendix

CD Gun functions selecting keys

EF Sheet thickness selecting keys

GH Fine adjustment keys time +/–

Tools

1 Tongs, pulse welding

2 Tongs, spot welding

3 Gun

4 QUICKSPOT

5 AIRPULLER

Working with gun

6 Push spot welding

7 Stud welding

8 Beat-out with washers, T-pins, riveting dies

9 High-speed planishing hammer

10 Anneal/shrink

11 Sheet thickness selector

12 Fine adjustment +/–

13 Mains plug symbos with LED “control mains voltage drop” (15, 16, 17)

14 LED malfunction

- 3 -

2.0 Description of equipment and overview

The MULTISPOT M80 resistance welding unit is designed for the

special requirements of motor vehicle body repair.

The power source is controlled by a micro-processor. After selecting the operating

mode and the sheet steel thickness, the current and weld time will be assigned

automatically and – where necessary and advisable – corrected accordingly. An

audible alarm is performed, if the welding current is too low.

Further functions:

– Automatic tool recognition

– Integrated mains monitor recognises undervoltage

– Automatic current rise, welding, current recognition and repressing

– Easy and distinct operation by means of foil keyboard

– Thermal probe controlled air-cooling for gun and tongs

– Central connection for welding current, compressed air, cooling and control

wiring

– Closed box for accessories in power supply unit

– Sturdy trolley with basin for tools and accessories and electrode arms

60 Tongs holder * * in connection with spot

61 Cable holder welding tongs

62 Trolley frame **special accessories (item no.

63 Central connection socket pls. see from accessories list)

64 Balancer **

65 Filter pressure reducer

66 Mains switch

67 Service box

68 Power supply unit

69 Screws 8 x 16

70 Screws 8 x 16

71 Trolley base

72 Roller

73 Guide wheel

74 Receptacle for pulling tool + SAH

75 Receptacle for electrode arms

76 Fastening screws

77 Electronics / operation panel

- 4 -

- 5 -

3.0 Start-up

3.1 Assembly of power supply unit and trolley

– Screw frame (62) to the trolley base with the screws provided (70)

– Put power supply unit (68) on the trolley and fasten with screws

provided (76).

– Screw tongs holder* (60), cable holder (61), balancer** (64)

to the frame.

– (*= in connection with spot welding tongs

**= special accessories)

item number please see from accessories list).

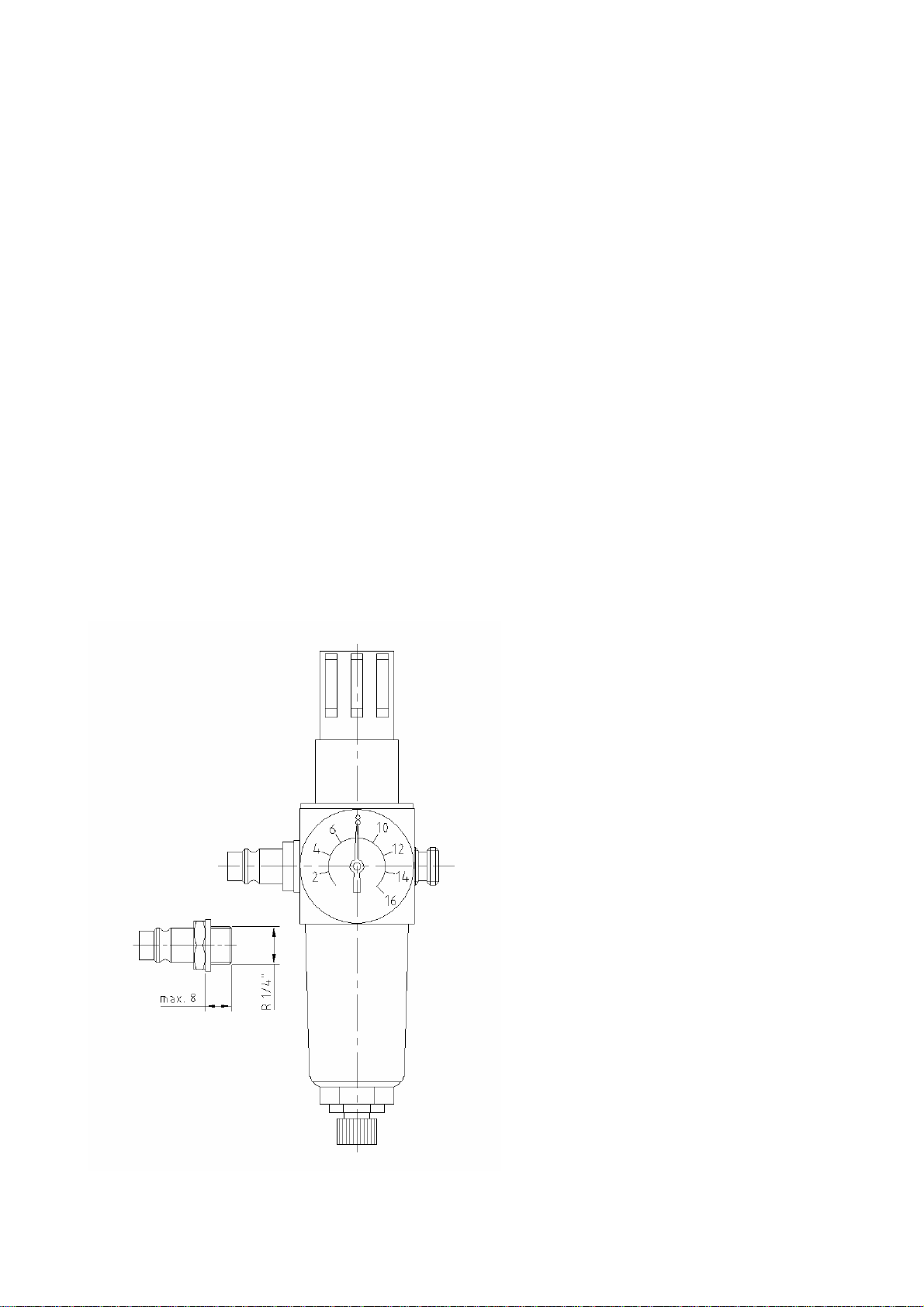

3.2 Compressed air connection

Connection to a compressed air supply is necessary for operation of the

MULTISPOT M80 in conjunction with the spot welding tongs! The connection with

adjustable filter/pressure reducer (65) is located on the back of the power supply

unit (68). The operating pressure is 8 bar!

Insufficient pressure reduces the electrode contact pressure and increases

electrode wear. Excessive pressure can cause poor welding quality and

damage to the tongs.

When installing another air

connection, ensure that the thread of

the plug connector is screwed into the

filter pressure reducer no deeper than

8 mm, as otherwise the air supply will

be interrupted.

Seal the thread with Loctite.

- 6 -

3.3 Mains power supply connection

400 V 50/60 Hz (automatic switch-over)

Connection to a 32 A Cekon socket

Fuse: 32/35 A slow fuse

or

32 A automatic circuit-breaker

230 V (190-240 V) 50/60 Hz (automatic switch-over)

Connection to a 63 A Cekon socket

Fuse: 63 A slow fuse

or

63 A automatic circuit-breaker

3.4 Checking the mains voltage drop during welding

If the full performance of the MULTISPOT M80 is to be obtained, the mains

voltage drop during welding must be kept as small as possible.

The full test is described on Page 35, Chapter 11.3:

Information about the mains drop during welding

Display with 3 LEDs (15, 16, 17) under the mains plug symbol:

Green = mains OK

Green/yellow = mains drop within tolerance range.

Only yellow = considerable mains drop – welding performance

impaired

If necessary, check mains cord, extension cables etc. or use thicker cables.

Red and = large mains drop with large drop in performance.

warning tone: Welding is not possible. Welding current too low.

If necessary, check mains cord, extension cables etc. or use thicker cables.

After 2 seconds, the display automatically reverts to green.

After each welding operation, any mains voltage drop is displayed

for 2 seconds.

- 7 -

3.5 Malfunction indicator

The red LED (14) indicates

thermal overloading of the

spot-welding tongs/spot-

welding gun. While the LED

(14) is glowing, it is not

possible to continue welding

with the tool connected. The

unit is ready for use again

after the LED (14) has

extinguished.

- 8 -

4.0 Applications

Welding capacity:

Compressed-air pressure 8 bar

Electrode arm 120 mm

Programme switch Material Sheet thickness

Function in mm

Pulse welding with pneu-

matic spot welding tongs sheet steel 3.0 + 3.0

Spot welding with sheet steel 2.0 + 2.0

spot welding tongs pneumatic galvanized steel 1.5 + 1.5

Spot welding with

QUICKSPOT sheet steel 1.0 + 1.0

Push spot welding sheet steel 1.25 + 1.25

Setting for the following functions:

e. g. for sheet thickness 0.8 mm – choose range 1.6 mm

= 2 x 0.8 mm

Straightening out

with washer sheet steel 1.2

Airpuller sheet steel 1.0

Straightening out with

high-speed

planishing hammer sheet steel 0.8

Shrinking sheet steel 0.6 – 1.0

Stud welding Steel bolts Æ 4 – 6 mm

on sheet steel 2.0 mm

- 9 -

5.0 Technical data

Power supply unit

Supply voltage 400 V (380-415 V) 230V (190-240 V)

Slow fuse 32/35 A* 63 A*

Mains frequency 50/60 Hz 50/60 Hz

Power supply cord 14.7 kVA 14.7 kVA

Max. welding capacity 45 kVA 45 kVA

Open-circuit voltage 12 V 12 V

Welding current 6400A, 6400A,

3% duty cycle 3% duty cycle

Welding time** 0.03 – 0.9 s 0.03 – 0.9 s

automatic automatic

adjustment adjustment

Pulse welding time** 0.1 – 1.5 s 0.1 – 1.5 s

automatic automatic

adjustment adjustment

Ambient temperature 40° C 40° C

Type of protection IP21 IP21

Dimensions H/W/D mm 375/265/535 375/265/535

Weight power supply unit 54.5 kg 54.5 kg

Dimensions of power supply

unit in trolley H/W/D in mm 1020/517/600 1020/517/600

Total weight inc. accessories approx. 97.1 kg approx. 97.1 kg

Spot welding tongs (pneumatic)

Weight (without cable) 3.5 kg 3.5 kg

Weight (with cable) 11.5 kg 11.5 kg

Operating pressure 8 bar 8 bar

Electrode arms 20 x 20 mm 20 x 20 mm

Electrode contact pressure 1800 N 1800 N

Welding cable Ø/length 120 mm²/2.5 m 120 mm²/2.5 m

Electrodes Ø 12 mm

Push spot welder

Welding cable Ø /length 120 mm² / 2.2 m 120 mm² / 2.2 m

Earth cable Ø /length 120 mm / 1.5 m 120 mm / 1.5 m

Weight 6.15 kg 6.15 kg

Electrodes Ø 10 mm 10 mm

**Operation with a lower rating fuse at reduced power is possible.

**+ automatic correction

- 10 -

24 Spot welding tongs

25 Electrode arm, stationary, 20 x 20 mm (square)

26 Electrode arm, movable, 20 x 20 mm

27 Welding electrodes with caps

28 Momentary contact button

29 Handle groove

30 Release button for movable electrode arm

31 Welding cable

32 Electrode arm receptacle

- 11 -

6.0 Working with the spot-welding tong

Caution! Switch off power supply unit or set to “push spot

welding” mode during breaks or when changing electrodes

or adjusting electrode spacing!

Otherwise danger of crushing!

– Insert the central plug of the spot welding tongs – with arrow

pointing upwards – into the central socket (63) of the power

supply unit until limit stop.

– The unit will switch over to symbol “tongs” automatically.

– When using uncoded tongs, set to “tongs” symbol with keys

AB.

– Tighten the sleeve nut of the central connection by turning

clockwise.

– Insert electrode arms (25 and 26) in tongs.

– Make sure the movable electrode arm (26) clicks home.

– Insert and adjust electrodes (27).

– Electrode spacing 6 to max. 8 mm.

– Check with size 6 Allen key.

– Tighten socket-head cap screws.

– Re-check electrode spacing after the initial spot welding

procedures and re-adjust, if necessary!

The condition of the electrode caps is essential for proper weld-

ing results! Change or grind worn caps!

For item no. of the cutter please see Accessory List!

The electrode caps can easily be changed by turning with pliers.

Simply place fresh electrode caps on the taper of the electrode

and press in position.

In order to accommodate bulky body parts, such as door sills and

posts, the movable electrode arm (26) can be released by

pressing the release button (30). When the electrode arms (25)

and (26) are pressed together manually, the arm will engage

automatically.

6.1 Preparation of the welding area

The area of the sheets to be welded should be ground to a bright

metal finish.

Important! The contact points of electrode cap to sheet and

sheet to sheet must be absolutely free of grinding swarf,

paint residues and rust. Otherwise welding will cause

- 12 -

A B C D E F G H

- 13 -

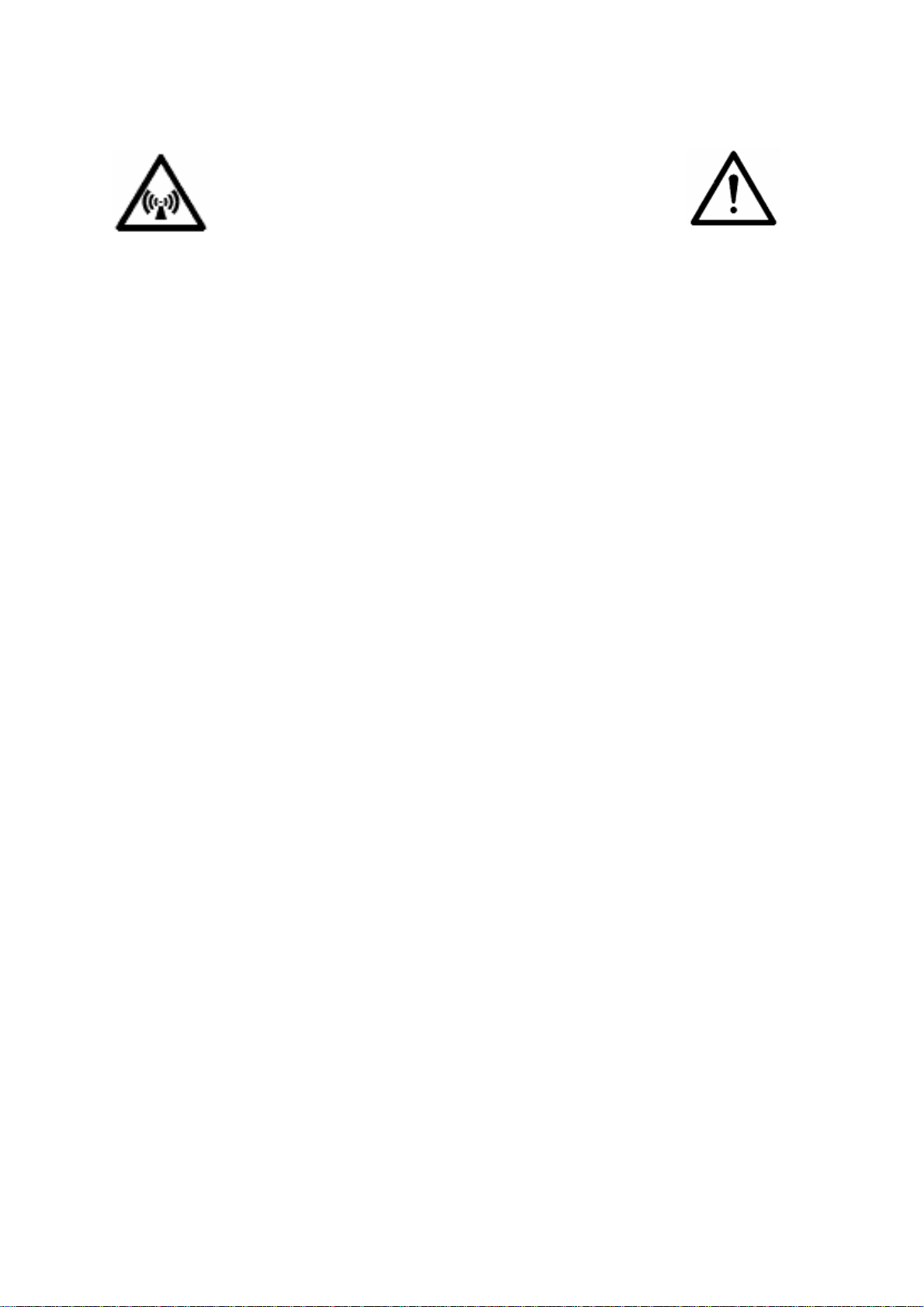

6.2 Spot-welding with the tongs

Caution:

Electromagnetic fields!

Wear protective goggles and gloves!

Electrodes heat up!

Flying sparks!

– Switch on unit with mains switch (66).

– Connect unit to the compressed air supply.

Ensure sufficient compressed air pressure, operating

pressure is 8 bar! If necessary, adjust pressure with the

filter pressure reducer (65). Insufficient compressed air

will lead to excessive splatter and the weld spot may

burn out.

When the spot-welding tongs have been connected, the unit

will switch automatically to the “tongs” symbol.

In the case of uncoded tongs, select the “tong spot-welding”

function with the program key AB, set sheet thickness with

key EF; if necessary fine-adjust with key GH, e. g. galvanized

sheets +, stainless steel sheets –.

During welding procedures, keep hold of button of the tongs

until welding process is automatically cut-off.

Sequence of the welding program (see diagram on LHS):

A – Pre-pressing 0.75 sec

C – Welding with automatic timer-setting 0.03 to 0.45 sec

E – Re-pressing 0.5 sec.

Releasing key (28) prematurely will interrupt the

functions “Pre-pressing” and “Welding”. Continued

pressure on key (28) can extend the function “Re-press”.

- 14 -

A B C D E F G H

- 15 -

6.3 Pulse welding

Caution:

Electromagnetic fields!

Wear protective goggles and gloves!

Electrodes heat up!

Flying sparks!

This mode is used for spot-welding sheet metal of 2 x 1.5 mm

or more, such as e.g. frame parts and gusset flanges.

Preparations:

– Ensure precise fitting of the sheets to be welded – no air

gap!

– Clean sheets.

– Electrode arms no longer than 250 mm.

– Stable mains power supply.

– Air pressure minimum 8 bar at filter pressure reducer.

Welding:

– Select mode “Tongs – pulse welding” with keys AB.

– Select sheet thickness with keys EF.

– Keep hold of key (28) of the tongs until welding process is

cut-off automatically.

– Observe intervals of approx. 10 secs. Between spots to

prevent electrode caps from annealing.

– The pulse welding option should only be used in the

exceptional cases mentioned above.

– Overload: Continue welding once the red LED has

extinguished.

- 16 -

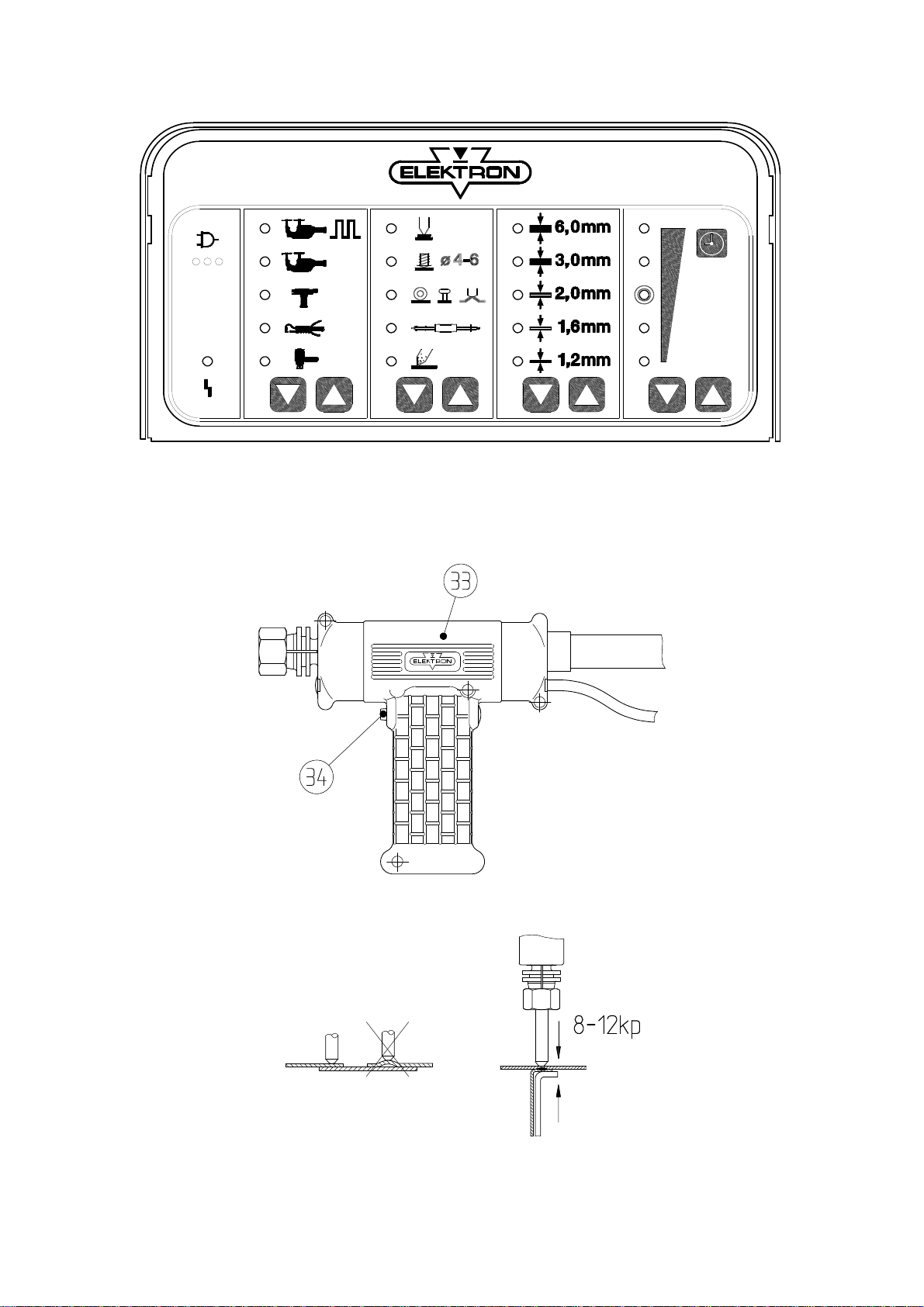

33 Welding gun

34 Button of welding gun

35 Grounding cable

36 Copper shoe

37 Lever clamp

38 Connection piece

- 17 -

7.0 Operating the welding gun

Preparation:

– Insert the central plug of the welding gun (33) into the

central socket (63) until limit stop. Arrow on the plug pointing

upwards.

– The unit will switch automatically to the “gun” symbol.

– Select the “gun” tool with key AB (uncoded gun only).

– Tighten the sleeve nut of the central connection by turning

clockwise.

– Operating pressure at the filter pressure reducer min. 8 bar!

– Connect the copper shoe (36) of the grounding cable (35) to

a bare point on the bodywork to be welded. Use lever clamp

(37) provided or a mole wrench.

Before using the lever clamp (37), you have to weld on two

8 mm washers as close to the point of weld as possible, see

section 7.2! In this case, press the copper shoe (36) of the

grounding cable (35) firmly onto the metal sheet. This is the

only way to obtain a good current transfer.

Attention!

The copper shoe (36) must always be connected to the metal

sheet below the metal part of the body to be worked on. In

any case avoid current transfer via hinges, door and bonnet

locks, as these might otherwise be damaged!

- 18 -

A B C D E F G H

Table of contents

Other Elektron Welding System manuals

Elektron

Elektron MULTISPOT MI-100control User manual

Elektron

Elektron MULTIMIG 400puls User manual

Elektron

Elektron MULTISPOT MI-90 T User manual

Elektron

Elektron MULTIMIG 200 User manual

Elektron

Elektron MULTISPOT MI-100 User manual

Elektron

Elektron MULTISPOT M20 User manual

Elektron

Elektron MULTISPOT MI-100-3 User manual

Elektron

Elektron KERCOMET 170 User manual

Popular Welding System manuals by other brands

Feider

Feider FPSI140A Original instructions

Shengzao Mechanical & Electrical Equipment

Shengzao Mechanical & Electrical Equipment SZ-1800 operating manual

Helvi

Helvi SPOT CAR ALU 33 operating manual

Telwin

Telwin NORDIKA 1800 instruction manual

ESAB

ESAB ESP-50 instruction manual

Miller

Miller Big Blue 500 Pro owner's manual