Instruction manual ITEM TE550 S.p.A.

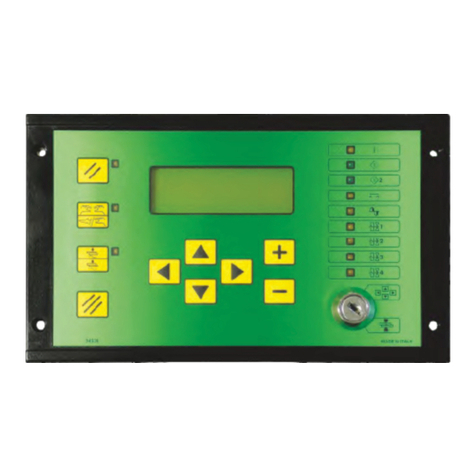

CHAPTER 1 - TE550 WELDING CONTROL UNIT DESCRIPTION

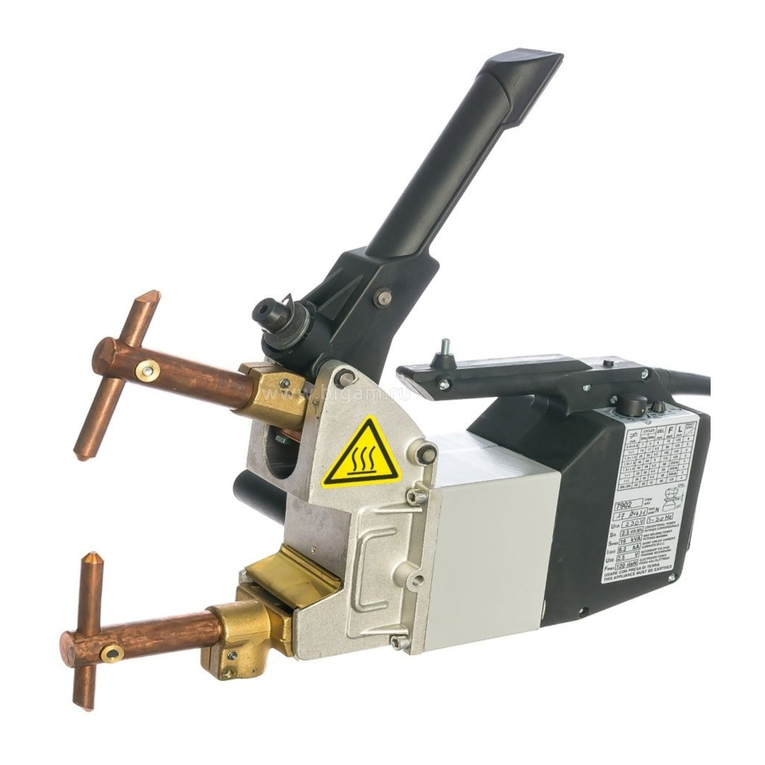

The TE550 is a microprocessor-based welding control unit for resistance welders. The task of

the welding control unit is to manage the welder components, in particular the controlled

diodes that carry out the welding current adjustment.

The TE550 is a particularly versatile welding control unit as it can be adjusted to different

types of welders; it may be installed not only on spot and projection welders but on seam

welders too. It may work with power adjustment: both in constant current and in constant

energy (optional). The number of inputs and outputs may be increased so to better adjust the

welding control unit to automatic machines.

It is possible to store up to 250 different welding programs, 127 of which are recalled directly

from an external device. Each program comprises several programmable parameters that

describe the work cycle. In addition to the plain 4-stage welding cycle, the control unit allows

the running of welding processes with pre-welding current, post-welding current, slope and

pulses.

1.1 - MAIN TECHNICAL FEATURES

Simplified programming via 6 keys and a backlit alphanumeric LCD.

Synchronous control with controlled diodes, phase control current adjustment.

Storage of 250 welding programs, 127 recallable from an external drive.

Up to 33 programmable parameters for each program.

Slope, pulses, pre-weld, post-weld functions and adjustment of the welding times in half-cycles.

Display of the RMS welding current measurement in kA and relative angle of conduction.

3 operating modes: standard, constant current and constant energy (optional).

Weld current, conduction angle, thickness and material indentation limits (optional), on the cylinder

pressure detected by an external sensor (optional).

Double stroke function.

Stepper function to compensate the electrodes wear with programmable curve.

Single and automatic cycle. WELD and NO-WELD function.

Adjustment of first insertion delay.

Control of 5 solenoid valves 24 VDC max. 5 W with self-protected output.

Self-adjustment at mains frequency 50/60 Hz.

Serial data transmission by means of optional insulated RS232 or RS485 ports.

Output for proportional solenoid valve.

Key for selecting foot control or two-hand control.

Selectable languages: Italian, English, French, German, Spanish, Hungarian, Swedish,

Portuguese, Dutch or Polish.

Possibility of upgrading control unit Firmware via appropriate software.

Activation and control of the electrodes dressing (optional)

6/92