20

JAR Venetian Blind Motors

www.elero.com 16 801.9901

We reserve the right to make technical changes 08/04

Adjustment of the working setting:

•Run venetian blind approx. 0.5 m in the “up” direction from the

lower end position. Then close the Venetian blind by means of the

“ZU” (closed) button and press in the “single white” individual

button “Ab2/zu” (down/closed) and keep it pressed for approx.

2 turns of the shaft.

•In inching mode press the “ZU” (closed) button meticulously until

the slats are completely closed.

•By reversing direction (upwards movement) unlatch the “Ab2/ZU”

(Down2/Closed) adjustment button – the working setting is adjusted.

Advice

When making adjustments with the “Ab2/ZU” (Down2/Closed)

adjustment button the lower end position is over-run, see also the

wiring diagram.

Readjustments:

If the respective end position is not accurately set or if the end

positions have changed due to changed winding behaviour of the

venetian blind, then the end positions will have to be reset as

described above.

With the help of the installation cable the venetian blind should be

moved back to about 0.5 m before the desired end position.

The limit switch range is 85 revolutions of the shaft.

Advice

When changing direction the drive must first be dead for at least

0.5 seconds.

Caution!

Due to feedback voltage from the capacitor motors must not be

connected in parallel!

Connection of 2 or more venetian blind drives is only possible with:

– a central or decentral control system or

– a multi-pole interlocking venetian blind switch.

(see elero control system catalogue)

The connecting cable may only be replaced by an authorised elero

service workshop or at the elero works.

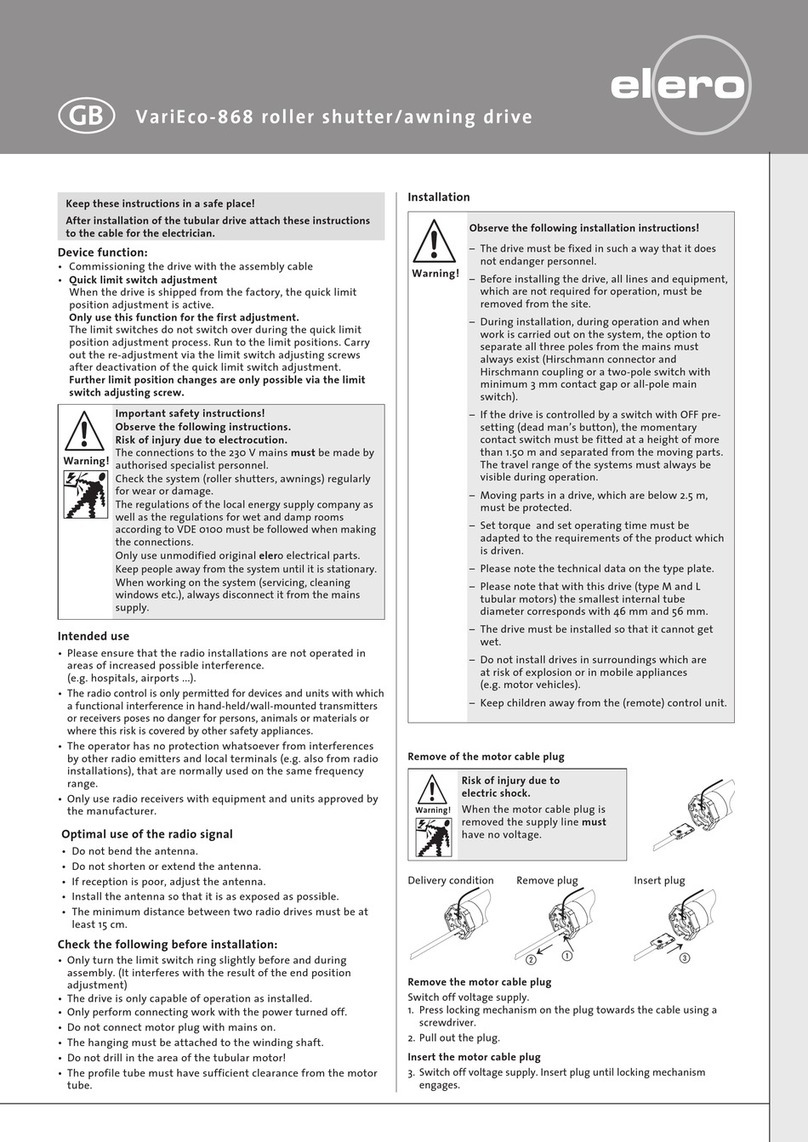

Connection Example

e1 – final end switch “AB1” (Down1)

e2– final end switch “AUF” (Up) with

safety lever

e3– additional final end switch

“AB2/ZU” (Down2/Closed)

During installation provision must be

made for an all-pole disconnection

from the mains supply, e.g. with a

4-pole Hirschmann plug.

Capacitor

Safety cut-

out lever

PE

N

421 3

e3

e1

e2

Ab2

Down2

PE N P

Ab1

Auf

Up

3x1,5

Y

Down1

brown

black 1

black 2

blue

yellow-green

Thermal-

protector

Press switch with separate button

for venetian blind motors with

additional limit switch.

Important safety advices!

Observe the following instructions.

Risk of injury due to electrocution.

The connections to the 230 V mains must be made by

authorised specialist personnel.

The regulations of the local energy supply company as

well as the regulations for wet and damp rooms accor-

ding to VDE 0100 must be followed when making the

connections.

Only use unmodified original elero electrical parts.

This drive is suitable only for interior and exterior

venetian blinds. For other applications please contact

the manufacturer.

Assembly

– The drive must be fixed in such a way that it is not a

danger to personnel.

– Before the drive is installed, make sure that the fuses

are switched off.

– During installation, during operation and when work

is carried out on the system, the option to separate

all three poles from the mains must always exist

(Hirschmann connector and Hirschmann coupling or

a two-pole switch with minimum 3 mm contact gap

or all-pole main switch).

– When installing JA drives in systems, devices or

machines the installer must ensure that

electromagnetic compatibility is maintained.

– The system should be checked at regular intervals

for wear or damage.

– The drive may only be installed in such a way that it

is not directly subject to the influence of the weather.

– Note the technical data for the motor.

– Keep children away from the controller and remote

controller.

– If the drive unit is operated by a pushbutton, it

should be fitted in a position from where the window

can be seen and at a height of not less than 1.5 m.

Advice

The guarantee will lapse if the electrical connections are

incorrect, if the installation work has been carried out

improperly or if repairs, interventions and changes have

been made by unauthorised people!

Warning!

Closed