elero JA Venetian User manual

Setting instructions:

Venetian blind drives are supplied from the factory already set to the

lower end position. Connect installation cable to venetian blind drive.

Setting the upper end position:

• Move venetian blind upwards with the

corresponding push button.

• Press in the orange adjustment button while it

is moving up and hold it in for at least 5 seconds

(adjustment button stays latched in).

Advice:

This must have taken place at latest 0.5 m before reaching the

end position. After pressing the adjustment button it must stay

latched in.

• With the help of the installation cable

travel directly to the upper end position

(fine adjustment by means of inching

operation with the installation cable).

• By changing the direction of travel the

adjustment button is automatically

unlatched and the upper end position

is then set.

Installation in headpiece

Installation instructions:

• Install drive without restraint, in correct

position (safety cut-out showing

downwards), and properly aligned with

the shafts in the venetian blind head.

• Impacts (e.g. hammer blows) are not

permitted on drive, shaft or coupling.

• The axle height of the drive is 27.5 mm.

See JA accessories for dampers for different

bearing blocks axle heights.

• Make sure that the shaft is not radially loaded.

• Make electrical connection with installation cable and

check the turning direction of the drive shaft according

to the direction advice on the front of the limit switch

housing. Travel to the lower end position again with the

DOWN pushbutton.

• Couple drive to shaft.

Advice:

• Valid only with right hand installation.

• In the case of left hand installation the colour assigment is exactly

reversed.

After the venetian blind motor has been installed, attach these

instructions to the cable for the use of the electrician.

Advice: The drive may only be operated with an safety cut-out.

Mounting instructions

Mounting of the safety cut-out „right hand installation“

Remove label on the bottom side of the limit switch housing and

insert the safety cut-out with orange or black cap in the openings

and engage it in such a way that the orange or black pressure pin

points towards the side of the orange adjustment push-button UP.

If the supplied safety cut-out cannot be used, e.g. due to lack of

space, then the label must not be removed since it protects the

inside of the limit switch against dirt.

Please check the function of the safety cut-out. Incorrect

installation may lead to damage.

If the safety cut-out is not long enough,

it can be extended by 10 mm at a time

with the safety cut-out extension

(article number 16 101.4501).

(Maximum of 3 safety cut-out

extensions can be plugged on).

Insert the blade of a small flat

screwdriver into one of the grooves

on the orange cover and by pressing the blade towards the middle

of the safety cut-out, lever off the cover. Clip on the extension and

then clip on the cover again.

Mounting of the safety cut-out „left hand installation“

(special Accessory)

When installing the JA drive as a left-hand system

the arrangement of the microswitches inside the

limit switch housing automatically swaps over the

UP and DOWN movments.

This means that the safety cut-out with the white

cap (article number 26 200.1101) must be used.

This safety cut-out must be inserted and clipped

into the openings of the limit switch housing so

that the „white“ pressure pin points to the side of

the „white“ adjustment push button. The label L provided with the

directional advice, should then be stuck over the existing label on

the front.

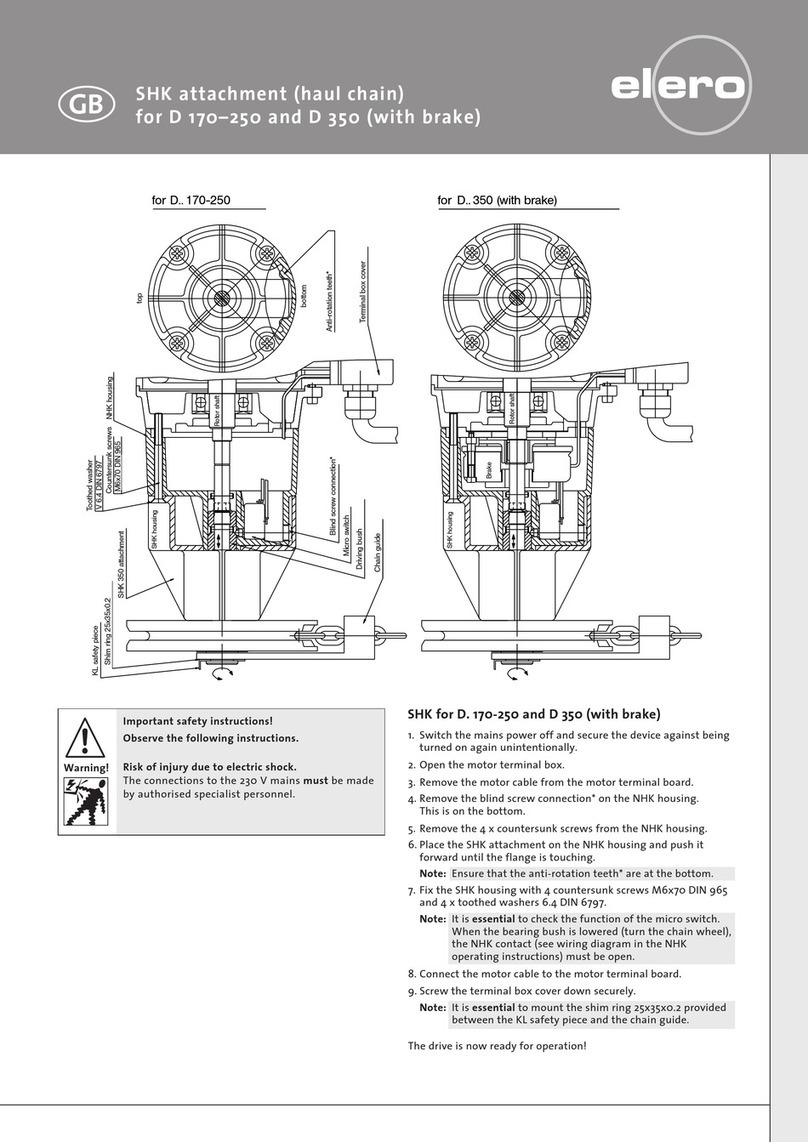

Mounting of the QuickSnap coupling for JA

1. Apply coupling at an angle whilst observing the position of the

coupling with respect to the shaft: The stop spring should slide

on the upper surface of the hexagonal shaft.

2. Push coupling a little further until the spring audibly latches

into the groove. (Click).

3. If the groove is covered by a bearing or lockwasher, the

hexagonal shaft can be correspondingly pushed back until the

coupling spring latches into place.

4. By pulling it by jerks check that the coupling is securely seated.

Dismantling of the QuickSnap coupling for JA

Do not forcibly remove the coupling.

1. Lift up the motor coupling retaining spring on the shaft with a

small screwdriver.

2. Pull off the coupling.

JA Venetian Blind Motors

removable label

damper countersunk bolt with

cross recess H no. 3

Safety cut-

out

Adjustment push

button (orange)

UP

Adjustment

push button

(white) DOWN

Setting the lower end position:

It is not normally necessary to set the lower end position since the

ventian blind drives are set to the lower end position in the factory.

If it is necessary however the setting takes place in the same way as

for the upper end position.

• Move venetian blind downwards with the corresponding push

button.

• Simultaneously press the white adjustment button and hold it

down for at least 5 seconds.

Advice:

This must have taken place at latest 0.5 m before reaching the end

position. After pressing the adjustment button it must stay latched in.

• With the help of the installation cable travel directly to the lower

end position (fine adjustment by means of inching operation

with the installation cable).

•

By changing the direction of travel the adjustment button is

automatically unlatched and the lower end position is then set.

Readjustments:

If the respective end position is not accurately set or if the end

positions have changed due to changed winding behaviour of the

venetian blind, then the end positions will have to be reset as

described above.

With the help of the installation cable the venetian blind should be

moved back to about 0.5 m before the desired end position.

The limit switch range is 85 revolutions of the shaft.

USA

CA

JA Venetian Blind Motors

Important safety advices!

Observe the following instructions.

Risk of injury due to electrocution.

The connections to the 120 V mains must be made by

authorised specialist personnel.

The regulations of the local energy supply company as

well as the regulations for wet and damp rooms

according to NFPA must be followed when making the

connections.

Only use unmodified original elero electrical parts.

This drive is suitable only for interior and exterior

venetian blinds. For other applications please contact

the manufacturer.

Keep people away from the system until it is stationary.

When working on the system (servicing, cleaning windo-

ws etc.), always separate it from the mains supply.

It the venetian blind motor is fitted as part of a

machine or any other installation, the user has to

make sure that the EMC regulations continue to be

observed.

elero venetian blind motors are approved:

• UL 1004 electric motors

• UL 2111 overheating protection for motors

CSA C22.2 No. 100 motors and generators

CSA C22.2 No. 77 overheating protection

Connection of 2 or more motors is possible only

• with a central or decentral control system or

• with a multipin interlocking venetian blind switch.

(send for the according elero control system

catalogue).

Assembly

– The drive must be fixed in such a way that it is not a

danger to personnel.

– Before installing the drive, all lines and equipment,

which are not required for operation, must be removed

from the site.

– Before the drive is installed, make sure that the fuses

are switched off.

–

During installation, provision must be made for an

all-pole disconnection from the mains supply, e.g.

with male Hirschmann plug, Item No. 23 846.0001,

and female Hirschmann plug, Item No. 13 701.5301, a

with at two-pin interlocked switch with at least

3 mm contact opening distance or all-pole mains

switch.

– If the drive is controlled by a switch with OFF pre-

setting (dead man’s button), the pushbutton must be

fitted at a height of more than 1.50 m and separated

from the moving parts.

The travel range of the systems must always be visible

during operation.

– Moving parts in a drive, which are below 2,5 m, must

be guarded.

– For drives supplied without a driven part the design

torque and the design operating time must agree with

the properties of the driven parts.

Please note the technical data on the type plate.

– When installing JA drives in systems, devices or

machines the installer must ensure that

electromagnetic compatibility is maintained.

–The system should be checked at regular intervals for

wear or damage.

–The drive may only be installed in such a way that it is

not directly subject to the influence of the weather.

Warning!

Connection Example

Do not use switches, push-button, switching systems which allow

to give an “Up” and “Down” command at the same time.

When reversing direction of travel, ensure a volt free period of at

least 0,5 sec.

1 venetian blind motor 2 venetian blind motors

Warning!

Do not connect 2 or more motors in parallel! Due to

feedback voltage the limit switches could be damaged!

Caution!

Wrong connection

PE

Thermal

protector Thermal-

protector

Capacitor

Capacitor

Safety

cut-out

lever

Safety cut-

out lever

green

red

black

white

green

red

black

white

green

red

black

white

Mains 120 V / 60 Hz

Mains 120 V / 60 Hz

Only use 2-pin interlocked

venetian blind switches or

push-buttons!

Only use interlocked

venetian blind switches

or push-buttons

123

PE NVU

123

PE NVU

123

PE NVU

Capacitor

Thermal-

protector

Safety cut-

out lever

Up

Down

Up

Down

Up

Down

Thermal

protector

Safety cut-

out lever

Capacitor

Thermal

protector

Safety

cut-out

lever

green

white

black

red

green

white

black

red

Mains 120 V / 60 Hz

123

PE NVU

123

PE NVU

Up

Down

Up

Down

– Note the technical data for the motor.

– Keep children away from the controller and remote

controller.

– When installing JA drives in systems, devices or

machines the installer must ensure that electro-

magnetic compatibility is maintained.

–If the drive unit is operated by a pushbutton, it should

be fitted in a position from where the window can be

seen and at a height of not less than 1.5 m.

–Do not install drives in surroundings which are at risk of

explosion or in mobile appliances (e.g.motor vehicles).

Advice

The guarantee will lapse if the electrical connections are

incorrect, if the installation work has been carried out

improperly or if repairs, interventions and changes have

been made by unauthorised people!

13 805.4602

Technical parameters subject to change 08/06

Other elero Engine manuals

Popular Engine manuals by other brands

dunkermotoren

dunkermotoren BG 65 PN Series Operation manual

Tecumseh

Tecumseh AH-HSK600 - quick reference

Nice

Nice Era Mat A Series Instructions and warnings for installation and use

fakro

fakro ZWS12 user manual

Tecumseh

Tecumseh Snow King HMSK80 Operator's manual

Grundfos

Grundfos ML Installation and operating instructions