elero VariEco-868 User manual

VariEco-868 roller shutter/awning drive

GB

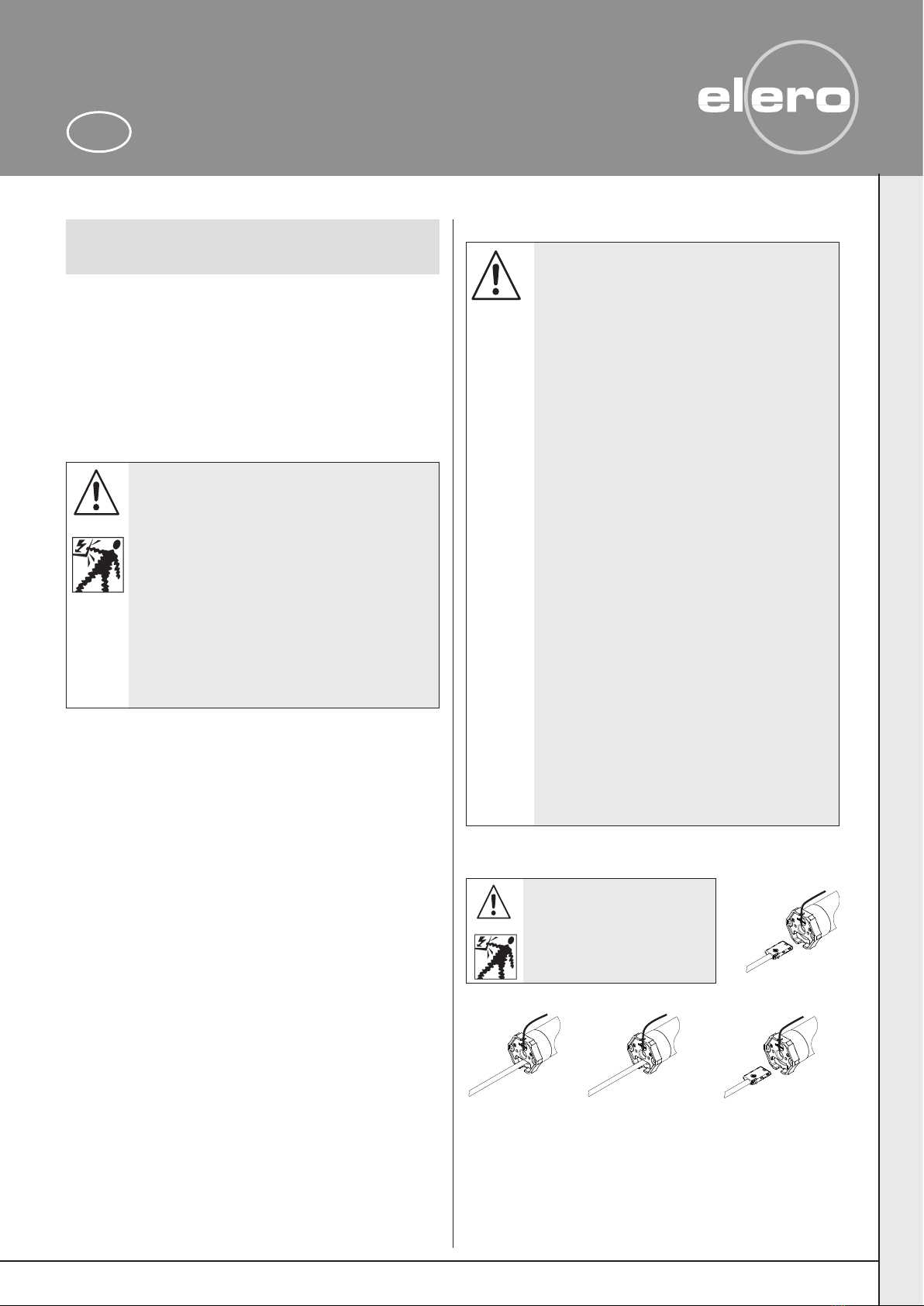

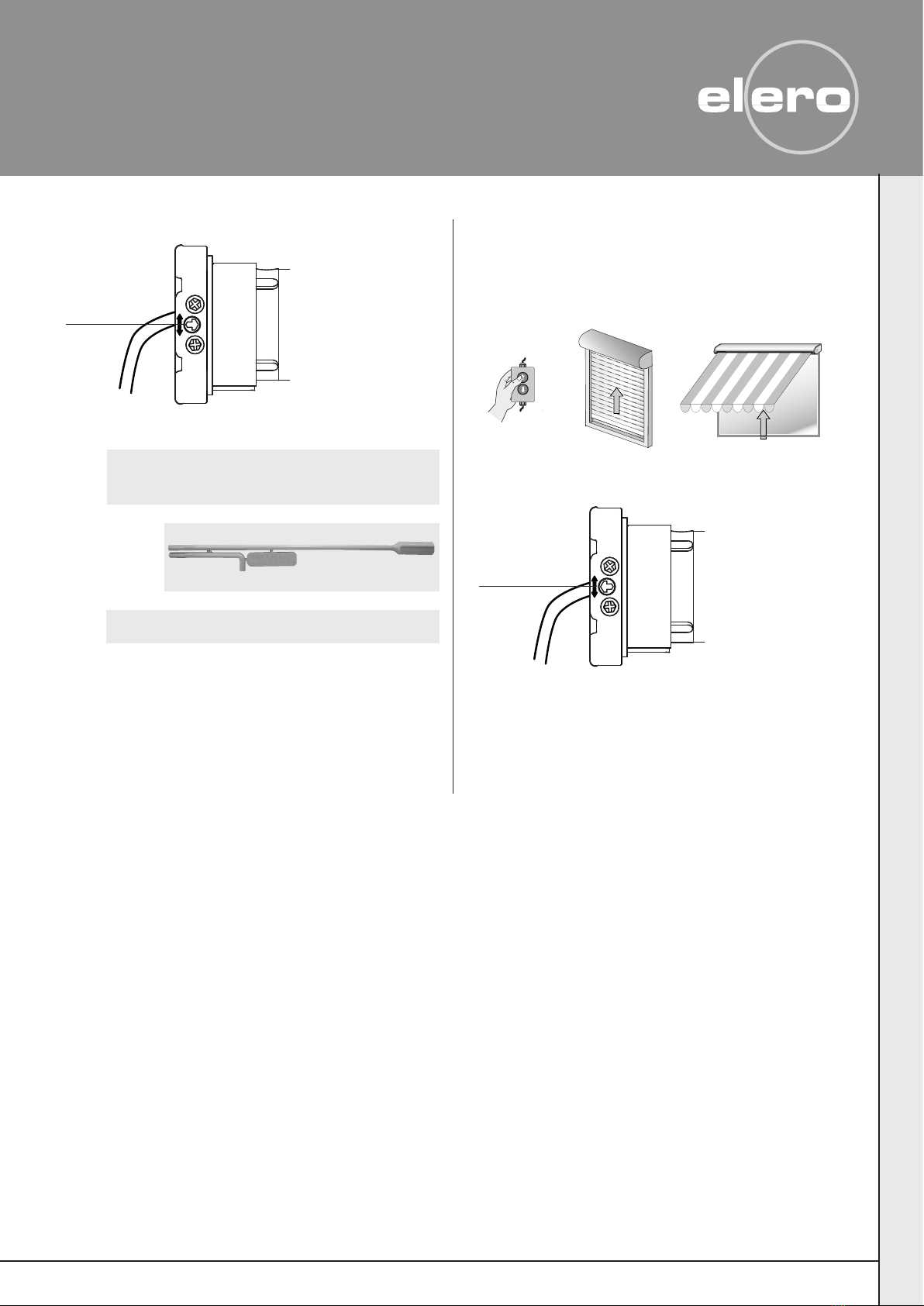

Remove the motor cable plug

Switch off voltage supply.

1. Press locking mechanism on the plug towards the cable using a

screwdriver.

2. Pull out the plug.

Insert the motor cable plug

3.

Switch off voltage supply. Insert plug until locking mechanism

engages.

Delivery condition

2

Insert plugRemove plug

13

S

S

S

Check the following before installation:

• Only turn the limit switch ring slightly before and during

assembly. (It interferes with the result of the end position

adjustment)

• The drive is only capable of operation as installed.

• Only perform connecting work with the power turned off.

• Do not connect motor plug with mains on.

• The hanging must be attached to the winding shaft.

• Do not drill in the area of the tubular motor!

• The profile tube must have sufficient clearance from the motor

tube.

Warning!

Important safety instructions!

Observe the following instructions.

Risk of injury due to electrocution.

The connections to the 230 V mains must be made by

authorised specialist personnel.

Check the system (roller shutters, awnings) regularly

for wear or damage.

The regulations of the local energy supply company as

well as the regulations for wet and damp rooms

according to VDE 0100 must be followed when making

the connections.

Only use unmodified original elero electrical parts.

Keep people away from the system until it is stationary.

When working on the system (servicing, cleaning

windows etc.), always disconnect it from the mains

supply.

Device function:

• Commissioning the drive with the assembly cable

•Quick limit switch adjustment

When the drive is shipped from the factory, the quick limit

position adjustment is active.

Only use this function for the first adjustment.

The limit switches do not switch over during the quick limit

position adjustment process. Run to the limit positions. Carry

out the re-adjustment via the limit switch adjusting screws

after deactivation of the quick limit switch adjustment.

Further limit position changes are only possible via the limit

switch adjusting screw.

Keep these instructions in a safe place!

After installation of the tubular drive attach these instructions

to the cable for the electrician.

Intended use

• Please ensure that the radio installations are not operated in

areas of increased possible interference.

(e.g. hospitals, airports ...).

•

The radio control is only permitted for devices and units with which

a functional interference in hand-held/wall-mounted transmitters

or receivers poses no danger for persons, animals or materials or

where this risk is covered by other safety appliances.

• The operator has no protection whatsoever from interferences

by other radio emitters and local terminals (e.g. also from radio

installations), that are normally used on the same frequency

range.

• Only use radio receivers with equipment and units approved by

the manufacturer.

Optimal use of the radio signal

• Do not bend the antenna.

• Do not shorten or extend the antenna.

• If reception is poor, adjust the antenna.

• Install the antenna so that it is as exposed as possible.

• The minimum distance between two radio drives must be at

least 15 cm.

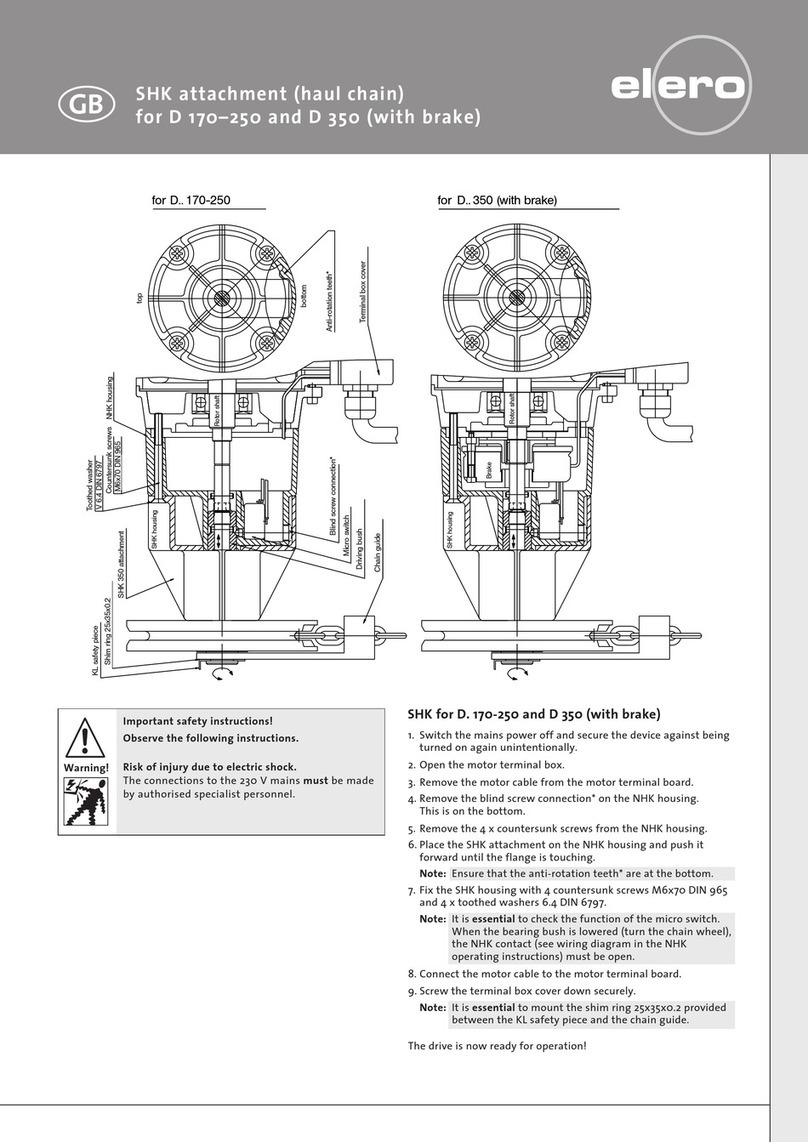

Installation

Observe the following installation instructions!

–

The drive must be fixed in such a way that it does

not endanger personnel.

– Before installing the drive, all lines and equipment,

which are not required for operation, must be

removed from the site.

– During installation, during operation and when

work is carried out on the system, the option to

separate all three poles from the mains must

always exist (Hirschmann connector and

Hirschmann coupling or a two-pole switch with

minimum 3 mm contact gap or all-pole main

switch).

– If the drive is controlled by a switch with OFF pre-

setting (dead man’s button), the momentary

contact switch must be fitted at a height of more

than 1.50 m and separated from the moving parts.

The travel range of the systems must always be

visible during operation.

– Moving parts in a drive, which are below 2.5 m,

must be protected.

– Set torque and set operating time must be

adapted to the requirements of the product which

is driven.

– Please note the technical data on the type plate.

– Please note that with this drive (type M and L

tubular motors) the smallest internal tube

diameter corresponds with 46 mm and 56 mm.

– The drive must be installed so that it cannot get

wet.

– Do not install drives in surroundings which are

at risk of explosion or in mobile appliances

(e.g. motor vehicles).

– Keep children away from the (remote) control unit.

Warning!

Remove of the motor cable plug

Risk of injury due to

electric shock.

When the motor cable plug is

removed the supply line must

have no voltage.

Warning!

Mounting and initial operation

Explanation of ProLine buttons

Hand-held/wall transmitter

elero

Auto

LR03 (AAA)

--

Programming button P

(Back of unit)

Programming

button P

Back of wall transmitter

3

2

1

3

2

1

Mains

Assembly cable connection

(only permissible for commissioning or setting procedures)

1.

Commissioning

Mains

2.Switch on mains.

Radio connection (transmitter operation)

3

2

1

3

2

1

2. Switch on mains.

2

Note: Before you put the drive into the radio mode, you must set

the ent position.

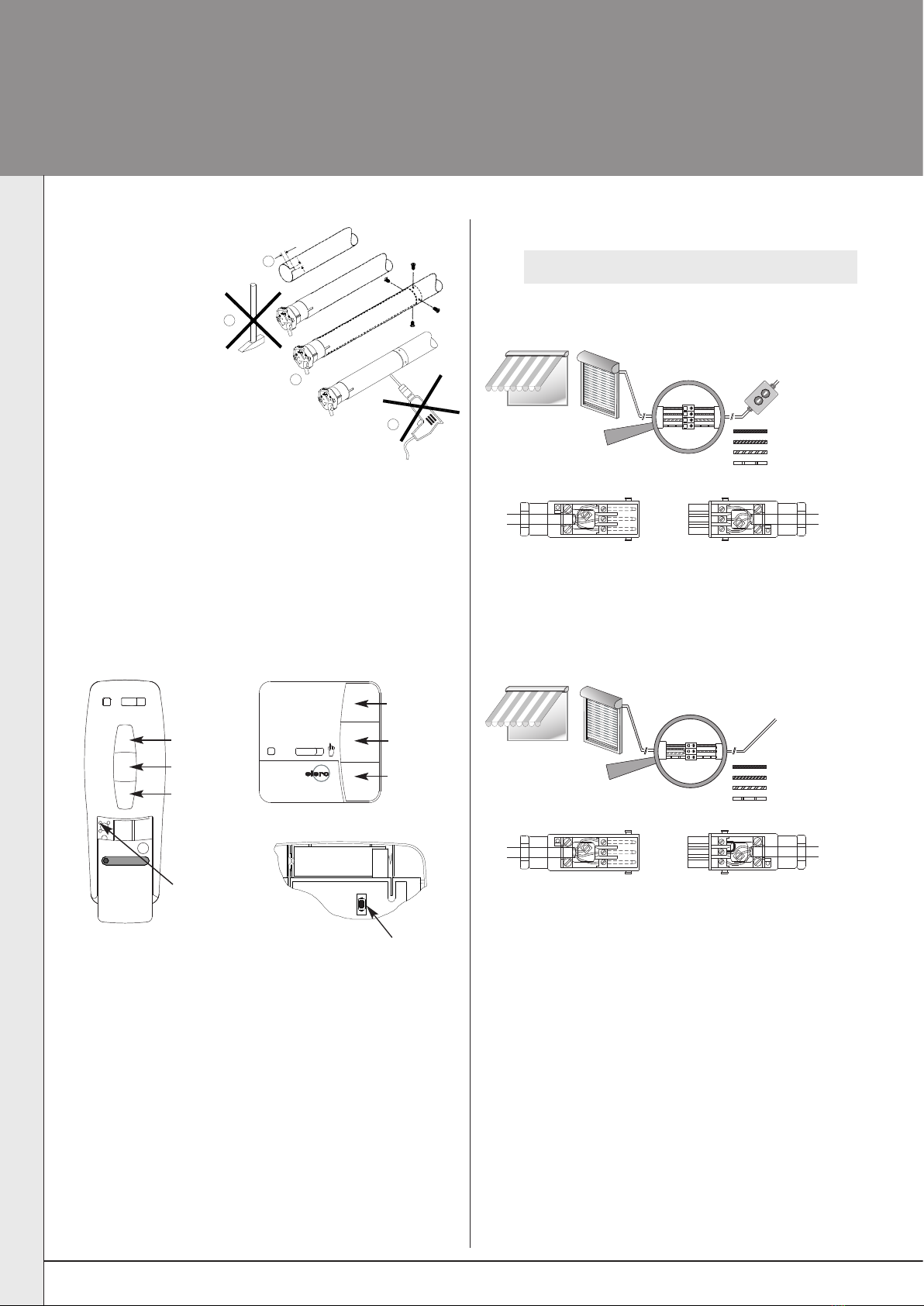

Shaft assembly

Installation in profile tubes

X

1

On round tubes, cut

a slot in the end of

the tubes on the drive

side (width 4 mm,

length 6 mm)!

X

2Push the drive

(do not knock in)

so that the drive lug

engages in the slot.

X

3

Screw on or rivet on the coupling

(adaptor)!

X

4

Attach the hangings to the shaft!

Run in the DOWN direction if it is necessary to install

the hangings on the winding shaft.

Secure the abutment against axial shifting by riveting or bolting

the cross member.

1

4

2

3

UP button

STOP button

DOWN

button

UP button

STOP button

DOWN

button

elero

Blue (neutral wire) (1)

Black (2)

Brown (3)

Green-yellow

elero

Blue (neutral wire) (1)

Black (2)

Brown (3)

Green-yellow

Mounting and initial operation

3

Note: The maximum limit switch range is 35 revolutions of the

shaft.

Use the adjusting tool for carrying out the adjustment.

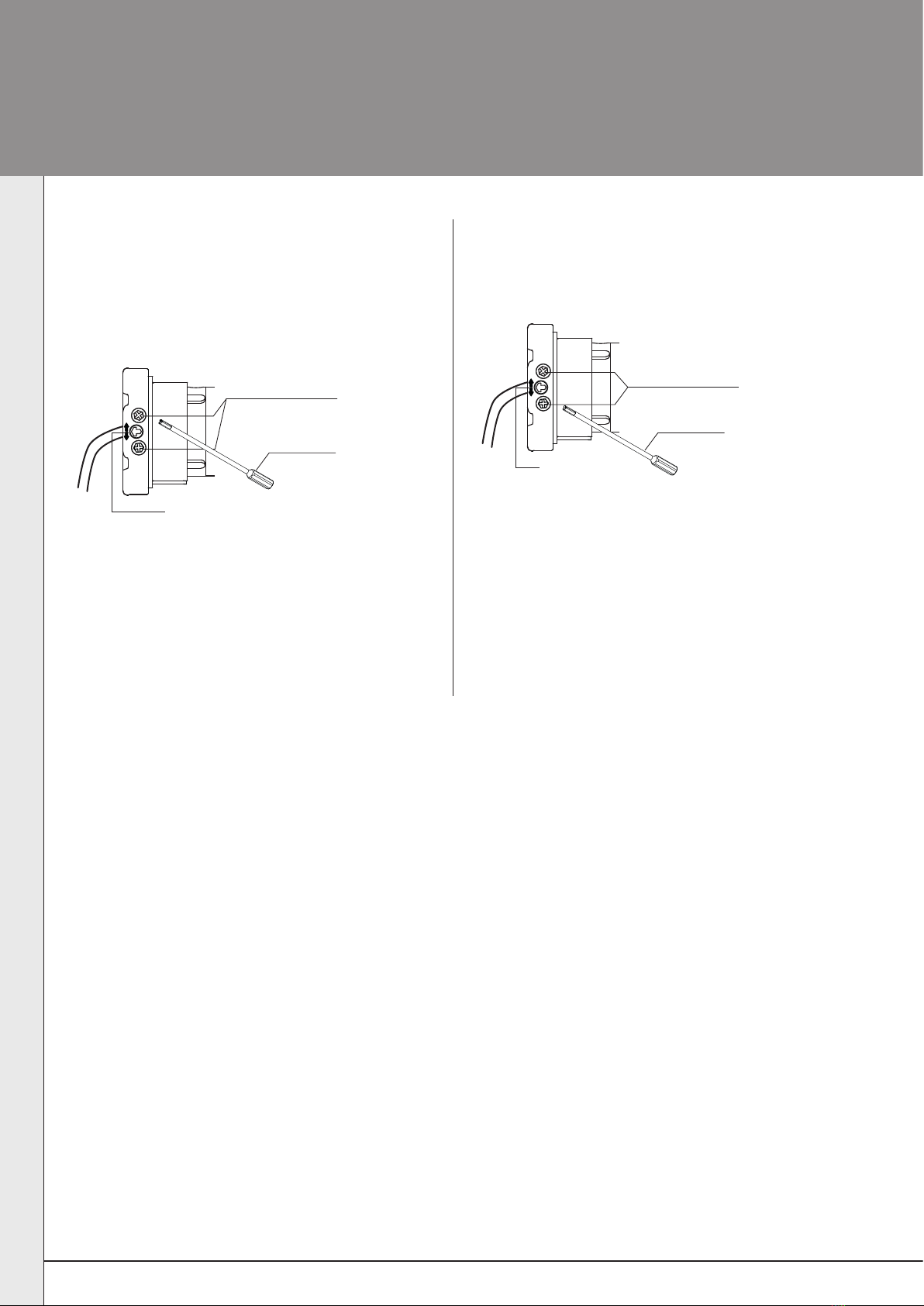

Delivery status/factory setting

-

+

-

+

Quick limit switch

adjustment

position „On“

The quick limit switch

adjustment is activated at

the factory.

Releasing screw is in the

"On" position.

The arrow of the releasing

screw points in the direc-

tion of the crown adaptor.

Limit switches are not

active in the quick limit

switch adjustment.

Adjusting tool

Adjusting tool

13 116.3801

Note: The limit switches will only work after the motor has been

installed in the shaft.

Quick limit switch adjustment

1. Attach the hangings to the shaft.

Run in the DOWN direction if it is necessary to move the

winding shaft.

2. Use the motor cable to move the hangings in the UP direction

until you reach the desired limit position.

3. Turn the releasing screw to the "Off" position.

The arrow of the releasing screw points in the direction of the

cable.

Use an adjusting tool to do so.

4. Both limit positions are now roughly pre-set.

The fine adjustment must be carried out using the individual

adjusting screws.

Only at commissioning

-

+

-

+

Quick limit switch

adjustment

position ”Off“

4

Adjustment of the end positions

Checking the end positions

Allow the drive to run alternately in both directions until the limit

switch switches off.

-

+

-

+

Limit switch

adjustment screws

1. Allow the drive to run fully in the "Down" direction.

2. Attach the roller shutter to the shaft.

3. Press the UP button on the assembly cable and keep it

depressed.

Setting of the upper end position

(Fine adjustment or end position changes) Setting the lower end position

(Fine adjustment or end position changes)

4. Turn the adjusting tool of the UP limit switch adjustment screw

in the +or –direction until the end position is reached.

One turn of the limit switch adjustment screw represents

approx. 60° of turning of the winding shaft.

Limit switch

adjustment screws

1. Press the DOWN button on the assembly cable and keep it

depressed.

-

+

-

+

2. Turn the adjusting tool of the DOWN limit switch adjustment

screw in the +or –direction until the final end position is

reached.

One turn of the limit switch adjustment screw represents

approx. 60° of turning of the winding shaft.

The directional arrows show the corresponding travel direction of

the limit switch screws (4 mm Allen screws).

minus (–) = shorter travel

plus (+) = longer travel

Directional arrow

Adjusting tool

Adjusting tool

Directional arrow

5

Stopping the radio programming mode

Qsee transmitter instructions

STOP

elero

elero

elero

3. Press the UP button immediately after the start of upward

travel.

4. Press the DOWN button immediately after the start of

downward travel.

The drive will stop.

The transmitter is now programmed.

LR03 (AAA)

--

Auto

Auto

2. Press programming switch Pon your transmitter.

The drive runs up and down for 2 minutes.

STOP

elero

elero

elero

3. Press the UP button immediately after the start of upward

travel.

4. Press the DOWN button immediately after the start of

downward travel.

The drive will stop.

The transmitter is now programmed.

LR03 (AAA)

--

Auto

Auto

2. Press simultaneously:

UP and DOWN buttons and programming button Pon the

programmed transmitter for min. 3 sec.

The drive runs up and down for 2 minutes.

Auto

min. 3 sec.

Programmed transmitter

New transmitter

New transmitter

+

STOP

STOP

Deletion of individual transmitters

Qsee instructions for the control unit

Deletion of all transmitters

Qsee instructions for the control unit

STOP STOP

STOP

STOP

Programming the transmitter/

Programming further transmitters

Programming the transmitter

Condition: The drive is in radio mode.

The end positions must have been programmed.

If the end positions have not been programmed,

remove the blind from the shaft.

When the mains has been switched off for a short time,

the drive is ready to be programmed for 5 minutes.

1. Switch off/on mains.

Programming procedure for other transmitters

Programming procedure possible for max. 16 transmitters.

In order to program further transmitters, start with the new

transmitter at 1

or

1. Switch off/on mains

6

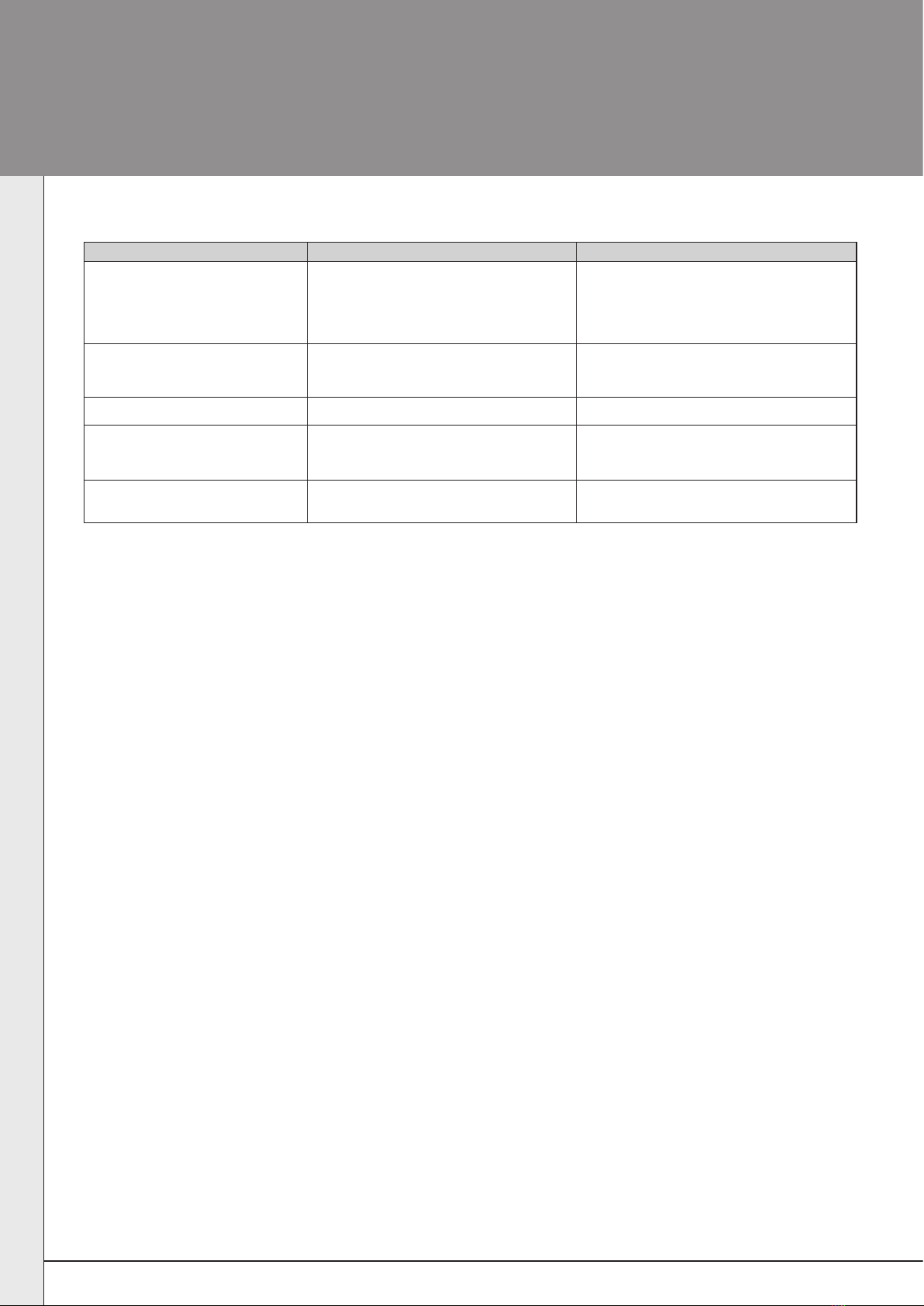

Notes on troubleshooting

Fault Possible cause Remedy

• Radio programming mode • Faulty connection • Check connection

does not start • Drive not connected to mains • Check mains voltage

• Time frame already expired (5 min) • Interrupt mains voltage briefly

• Thermostat has triggered • Allow drive to cool down

• Radio transmitter has no battery • Check transmitter (LED must be illuminated)

• Radio transmitter not in • UP/DOWN button pressed too late. • Restart radio programming mode

programming mode Note time frame (1 sec.)

• Sender ist bereits eingelernt • Push STOP button

• Drive runs only in one direction • Faulty connection • Check connection

• The drive does not switch off • Limit switch ring is not being driven • Readjust installation and limit switches via

via the limit switch the limit switch adjusting screws

• Drive does not react • Limit switch is not adjusted • Set limit switch

• Drive is no longer reacting • Wrong connection • Readjust connection

• Thermostat has triggered • Allow drive to cool down

Troubleshooting

7

Technical parameters subject to change

08/09

20

NRG Automation Ltd.

Foundry Lane – Halebank

Widnes, Cheshire WA8 8TZ

Tel. (44) 87024042 19

Fax (44) 87024040 86

www.elero.com

elero GmbH

Antriebstechnik Linsenhofer Straße 59–63

D-72660 Beuren

Telefon (070 25) 13-01

Telefax (07025) 13-212

www.elero.com

Table of contents

Other elero Engine manuals

Popular Engine manuals by other brands

Vanguard

Vanguard Series 432447 Operating and maintenance instructions

VOGELS

VOGELS VGI Hardware manual

Corsair

Corsair M25 manual

Oriental motor

Oriental motor BLM operating manual

E-MAG

E-MAG LYCOMING 200-6XL Series Installation and operating guide

Oriental motor

Oriental motor K II S Series operating manual

Power Fist

Power Fist 8714040 user manual

AOK

AOK AM24 PLUS manual

Hobby King

Hobby King XYZ 53 STS Service manual

woodmizer

woodmizer D17 Safety, Operation, Maintenance & Parts Manual

Crestron Electronics

Crestron Electronics CSM-QMTDC Series quick start

Sea-doo

Sea-doo Rotax 1503 4-Tec 2005 Engine shop manual