elero RevoLine M RolTop M6 User manual

RolTop Roller Blind Drive

138133301_EN_1116

RolTop Roller Blind Drive

13 Operating and installation instructions

Please keep these operating instructions for later use, to be

available throughout the life of the product!

The German manual is the original version.

All other documents represent the language translations of

the original text.

All rights in the case of a patent, utility model or ornamental

design registration are reserved.

14 General for instructions

The content structure is based on the life cycles of the elec-

tric motor drive (hereinafter referred to as "Product").

The manufacturer reserves the right to make changes to

the Specications stated in these Operating Instructions

at any time. These may, in individual cases, be dierent

from the respective product version, however the functional

information will not undergo signicant changes or become

invalid. The current version of the Specications may be

requested from the manufacturer at any time. No claims

may be asserted against the manufacturer as a result of the

preceding sentence. Deviations from text or picture state-

ments are possible and depend on the technical develop-

ment, features, and accessories of the products. Deviating

information on special versions will be explained by the

manufacturer in the sales documentation. Other information

shall remain unaected by these provisions.

14.1 Standards and Directives

During the design process, the basic health and safety

requirements of the applicable laws, Standards and Direc-

tives were complied with. The safety is conrmed by the

declaration of conformity (see "Declaration of Conformity").

All safety information in these Operating Instructions refer

to the laws and regulations currently applicable in Germany.

All instructions in the Operating Instructions shall be ob-

served without limitation and at any time. Beside the safety

instructions contained in these Operating Instructions, the

provisions for accident prevention, environmental protection

and occupational safety, which are applicable for the oper-

ating site, must be observed. Provisions and Standards for

the safety rating can be found in the Declaration of Con-

formity

Table Of Contents

13 Operating and installation instructions 1

14 General for instructions 1

14.1 Standards and Directives 1

14.2 Intended use 1

14.3 Foreseeable misuse 2

14.4 Warranty and liability 2

14.5 Customer service of the manufacturer 2

15 Safety 2

15.1 General safety instructions 2

15.2 Layout of the safety guidelines 2

16 Product description 3

17 Assembly 3

17.1 Mechanical fastening 3

17.2 Electrical connection 4

17.3 Connection example, RolTop 230 V/50 Hz 4

17.4 Parallel connection 4

17.5 Commissioning 4

17.6 Setting the end positions and the relief 4

17.6.1 Relief function for the end position(s) 5

17.6.2 Relief function at the upper stop 5

17.6.3 Relief function at the lower stop 5

17.6.4 Changing / Deleting the limit positions

and deleting the discharge function 5

17.6.5 Four variants of end position settings 5

17.6.6 Variant A: Upper and lower end position freely adjust-

able 5

17.6.7 Variant B: Fixed upper limit stop / lower

end position freely adjustable 6

17.6.8 Variant C: Fixed upper and lower limit stop 6

17.6.9 Variant D: Upper end position freely

adjustable, xed lower limit stop 6

18 Troubleshooting 6

19 Repair 7

20 Repair 7

21 Manufacturer's address 7

22 Disassembly and disposal 7

23 Conformity Declaration 7

24 Technical data and dimensions 7

24.1 RevoLine M 8

24.2 RevoLine S 9

24.3 RevoLine M RH 10

24.4 RevoLine L 10

15 Safety

15.1 General safety instructions

The general safety notes when using pipe drives can be

found in the leaet "Instructions on safety" that is enclosed

with each drive"(leaet item no. 138200001). These operat-

ing instructions contain all the safety instructions that must

be observed in order prevent and eliminate hazards in the

handling of the product in the individual life cycles. The safe

operation of the product can only be ensured when all given

safety instructions are observed.

15.2 Layout of the safety guidelines

The safety instructions in this document are identied by

hazard signs and safety symbols and are designed accord-

ing to the SAFE principle. They contain information on the

nature and source of the danger of possible consequences

and to prevent the danger.

The following table denes the representation and descrip-

tion of hazard levels with possible personal injury, as used

in this manual.

Symbol

Signal

word

Meaning

DANGER Warns before an acci-

dent, which will result if

instructions are not fol-

lowed, which can lead to

life-threatening, irreversi-

ble injury or death.

WARNING Warns before an acci-

dent, which can happen

if the instructions are not

followed, which can lead

to serious, possibly fatal,

irreversible injury or death.

CAUTION Warns before an accident,

which can happen if the

instructions are not fol-

lowed, which may lead to

minor reversible injury.

Fig. 1 Notation of personal injury

The following table describes the icons used in these op-

erating instructions that are used for imaging of the dan-

gerous situation in connection with the symbol of the threat

level.

Symbol

Meaning

Danger of electric voltage, electric

shock:

This symbol indicates a risk of electric

shock.

Fig. 2 Notation-specic hazard

The following table denes the representation used in the

operating instructions and description of situations where

damage can occur to the product or refers to important

facts, conditions, tips and information.

2 | EN © elero GmbH

Warranty and liability | Safety

14.2 Intended use

The product is intended for use in façade engineering to

drive electrically powered sun protection devices.

The determining factor for the drive is the elero drive com-

putation program (http://elero.de/

antriebsberechnungsprogramm).

Further elds of application have to be arranged with the

manufacturer, elero GmbH Antriebstechnik (see Address).

The operator will be solely responsible for damages result-

ing from improper use of the product. The manufacturer

cannot be held liable for personal or material damages

caused by misuse or procedural errors, and by improper

operation and commissioning.

The product may be operated only by trained and author-

ized personnel under observance of all safety.

Only if used according to the specications of these operat-

ing and installation instructions for the safe and proper use

and safe operation of the product are guaranteed.

Intended use includes the observance and compliance with

all safety instructions with regards to this operating manual

and all applicable regulations, and professional associations

of applicable laws for environmental protection. Intended

use includes the observance of prescribed operating rules

in these operating and installation instructions.

14.3 Foreseeable misuse

A use which deviates from the intended use stated by the

manufacturer, elero GmbH Antriebstechnik (see "Address"),

is deemed as foreseeable misuse.

14.4 Warranty and liability

Principally, the General Terms and Conditions of the man-

ufacturer, elero GmbH Antriebstechnik (see "Address"),

apply. The terms and conditions are part of the sales

documents and handed over to the operator upon deliv-

ery. Liability claims for personal or material damages are

excluded when they can be attributed to one or more of the

following causes:

• Opening of the product by the customer

• Unintended use of the product

• Improper installation, commissioning, or operation of the

product

• Structural modications to the product without the written

consent of the manufacturer

• Operation of the product with improperly installed con-

nections, defective safety devices or improperly installed

safeguards

• Non-observance of the safety provisions and instructions

of these Operating Instructions

• Non-compliance with the technical data

14.5 Customer service of the manufacturer

The product should only be repaired by the manufacturer

in case of a failure. The address for sending to customer

service, see the chapter "Address".

If you have not purchased the product directly from elero,

please contact the supplier of the product.

Symbol Signal

word

Meaning

NOTE This symbol warns of a

possible property dam-

age.

Important: This symbol points out

important facts and con-

ditions as well as to addi-

tional information in these

operating and installation

instructions. It also refers

to certain statements that

give additional information

or help you perform a task

easily.

Fig. 3 Notation of property damage as well as additional

information

The following example represents the basic structure of a

safety warning:

SIGNAL WORD

Type and source of danger

Explanation of the type and source of the danger

►Measures to prevent the danger.

16 Product description

The RolTop is an electromechanical tubular motor drive. It

performs parallel axial movements.

Commissioning of the RolTop with elero assembly cable

for setting dierent functions.

Venetian blind with free ride (torque deactivation)

Relief function for the Venetian blind (Venetian blind

protection).

• The variant-dependent values of your RolTop can be

removed from the type label.

• The dierent versions of the RolTop contain dierent

types of brake systems depending on size and torque.

The result may yield dierent performance e.g. regarding

access to end positions.

17 Assembly

CAUTION

Personal injury from hot surfaces.

Drive heats up during operation, the drive housing can be

hot. Possible burning of the skin.

►Wear personal protective equipment (gloves).

Triggered by a possible material errors may occur or

impact shock and injury due to a gearbox break, bud break

or a clutch defect.

►Suitable materials are to be used for the construction as

well as perform a sampling inspection by double load test

according to DIN EN 60335-2-97.

Risk of injury due to impact or shock caused by not prop-

erly mounted or latched motor bearings. Hazards caused

by insufficient stability or stability and stored energy (grav-

ity).

►Selection of engine bearing torque specications.

►Drive must be backed up with all attached backup devices.

►Check for proper latching on engine mounts and correct

tightening torques.

WARNING

Danger of injury due to electric current.

Electric shock possible.

►Electrical work can only be performed by an authorized

electrician.

Danger of injury due to electric current.

Hazardous possibly by parts that have become live in the

error state.

►Electrical connection is described in the operating and

installation instructions including cable bushing.

CAUTION

Risk of injury due to malfunctions due to improper installa-

tion.

Driven by winds and possibly destroyed parts of the appli-

cation.

►For safe operation, the end positions must be set / pro-

grammed.

►Training program of the manufacturer for specialist com-

panies.

NOTE

Loss of power supply, termination of machine parts and

other malfunctions.

►For safe operation, no false mount must be made and the

end position settings must be carried out during commis-

sioning.

Damage to the RolTop due to moisture penetration.

►For devices with protection class IP44, the ends of all

cables or connectors must be protected against the

ingress of moisture. This measure must be implemented

immediately after removal of the RolTop from the original

packaging.

►The drive may only be installed so that it is not irrigated.

Important

In the delivery status (factory setting), the RolTop in com-

missioning mode.

►You have to set the end positions (see chapter 5.6).

17.1 Mechanical fastening

Important preliminary consideration:

The working space around the built-in drive is usually very

small. Therefore, before the mechanical installation provide

an overview of the implementation of the electrical connec-

tion (see Section 5.2) and make any necessary changes

right away.

NOTE

Damage to the electrical wiring by squeezing or tensile

loading.

►Route all electrical cables so that they are not subjected

to crushing or tensile load.

►Note the bending radius of the cables (at least 50 mm).

►Lay the connection cable in a loop downwards to prevent

water running into the drive.

Damage to the drive by the action of impact forces.

►Insert the drive into the shaft, never thrust the drive into

the shaft or smash onto the drive!

►Never allow the drive to fall!

Damage or destruction of the drive by drilling.

►Never drill into the drive!

© elero GmbH EN | 3

Product description | Assembly (mechanical attachment)

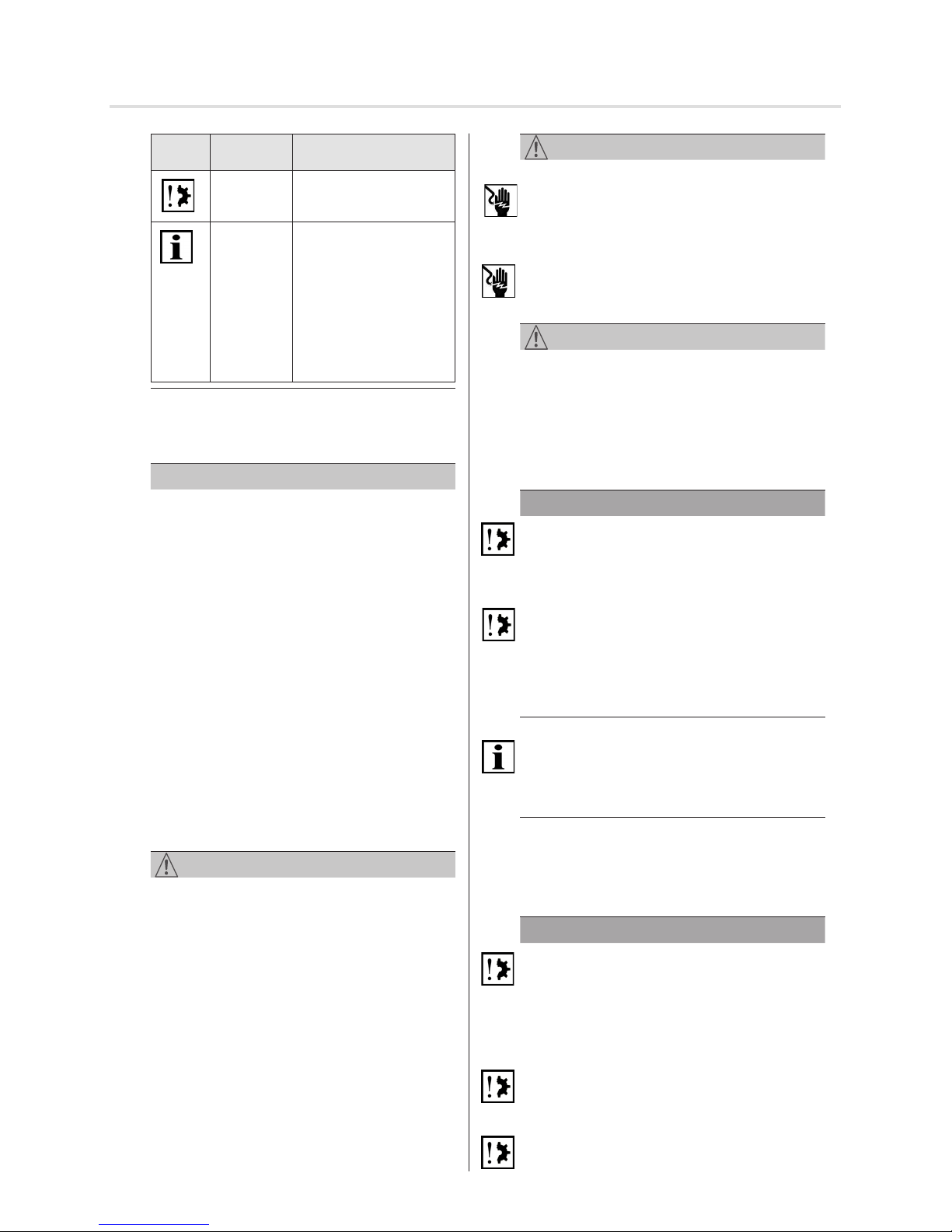

Removal and insertion of the device plug

Delivery status Remove plug Insert plug

Fig. 4 Removal and insertion of the device plug

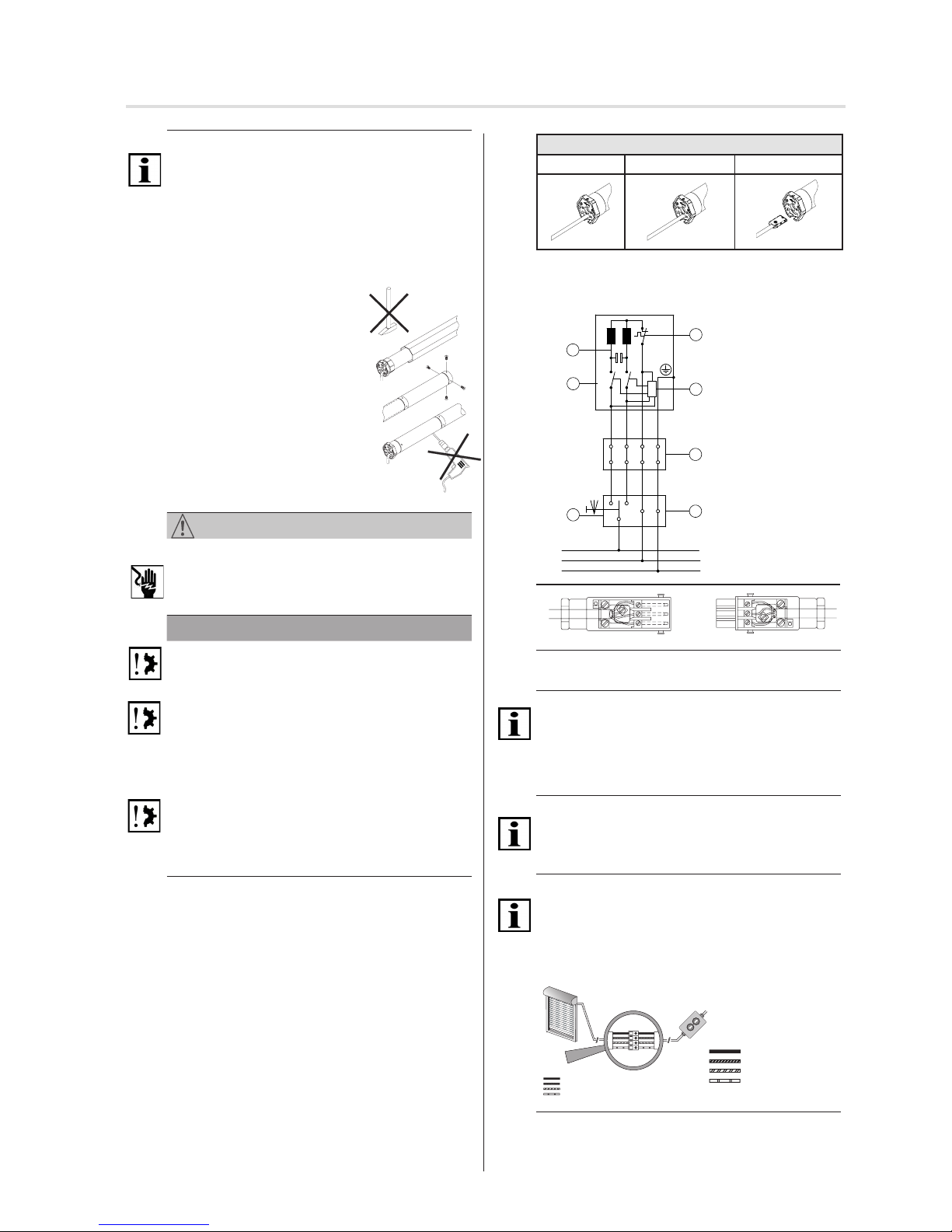

17.3 Connection example, RolTop 230 V/50 Hz

PE

N

L1

102

sw

br

bl

gr/ge

1

2

3

4

7

6

Wicklungsthermostat

Geräteschalter

Abzweigdose

Schalterdose

Jalousieschalter/Jalousietaster

Elektronik

Kondensator

sw schwarz

br braun

bl blau

gr/ge grün/gelb

L1,N,PE Netz 230V/50Hz

1

2

3

4

5

6

5

7

3

2

1

3

2

1

Fig. 5 Circuit diagram RolTop 230 V / 50 Hz and

wiring when used with Hirschmann plug STAS 3

Important

The motor control must be interlocked in up / down direc-

tion.

A reversing delay of at least 0,5 seconds must be ensured.

17.4 Parallel connection

Important

You can connect several parallel RolTop. Note the maxi-

mum switching capacity of switching.

17.5 Commissioning

Important

The drive is in the delivery in commissioning mode.

►You have to set the end positions with the elero assem-

bly cable.

►Connection of the assembly cable is only admissible for

commissioning of the drive and the setting processes.

%ODX1HXWUDOOHLWHU

6FKZDU]

%UDXQ

*UQJHOE

HOHUR

%ODX1HXWUDOOHLWHU

6FKZDU]

%UDXQ

*UQJHOE

Fig. 6 Connection for cable assembly

►Switch on mains.

►You can now set the end positions with the elero assem-

bly cable.

→

1

→

2

→

3

1Winding thermostat

2Appliance switch

3Junction box

4Switch box

5Blind switches/

blind push buttons

6Electronics

7Capacitor

sw black

br brown

bl blue

gr/ge green yellow

4 | EN © elero GmbH

Assembly (Electrical connection) | Commissioning

Important

Attach the RolTop only at the appropriate fasteners.

Permanently installed control devices shall be clearly dis-

played.

• The curtain must be fastened to the winding shaft.

• The prole tube must have enough distance to the motor

tube.

• Look for an axial clearance (1-2 mm).

Installation in prole tubes

ⒶInsert the drive with a suitable adapt-

er and traction ring into the prole

tube.

Lay the motor cable protected in or-

der to prevent damage by the driven

component.

ⒷSecure the counter bearings against

axial displacement, e.g. screw shaft

spider or rivet.

Secure drive in axial storage!

ⒸSecure hanging on the shaft!

17.2 Electrical connection

WARNING

Danger to life due to faulty electrical connection.

Electric shock possible.

►Before commissioning check the correct connection of

the PE conductor.

NOTE

Damage to the RolTop by faulty electrical connection.

►Before commissioning check the correct connection of

the PE conductor.

Damage or destruction of RolTop by the penetration of

moisture.

►For units with protection class IP 44, the customer con-

nection of the cable ends or connector (cable bushing)

must also be carried out in accordance with protection

class IP 44.

Damage or destruction of RolTop for variants with 230 V

AC 1 due to faulty control.

►Switch with OFF setting (Dead man) for drives must be

installed within sight of the RolTop, but away from any

moving parts and amounting to about 1.5 m.

Important

For electric connection no transmission and retransmission

of the access line or connector is required as a rule.

Depending upon used mounting plate and/or adapter plate

it is necessary in particular with the RolTop Type S to

remove this screwed plate before a cable exchange.

Connection only in free of tension status, in addition

drive line without tension

1 Using a suitable screwdriver, press out the lock of the

device connector to the line.

2Disconnect the plug.

3Insert connector until the latch engages.

17.6 Setting the end positions and the relief

Important preliminary consideration:

Decide on a specic relief function before setting the end

positions (dierent combination options according to the

following statements):

This will save unnecessary setting eort!

Press the travel key until the drive signals the transition into

the setting mode, by a short automatic stop. You can now

program the end positions. After setting the two end posi-

tions, the setting mode is completed.

17.6.1Relief function for the end position(s)

If an end position is set to stop, an additional relief for the

Venetian blind can be released.

Important

Activation of the relief function (in the versions B to D) takes

place in one work step when the end positions are pro-

grammed (see chapter 5.6.7 to chapter 5.6.9)!

17.6.2Relief function at the upper stop

For variant C (see chapter 5.6.7)

and variant D (see chapter 5.6.8):

Activate relief function at the upper stop.

1 Push and hold the UP button ▲ from instruction ①

(chapters 5.6.7 and 5.6.8) and actuate the DOWN

button ▼ with the assembly cable (at the same time).

Keep both buttons pushed until the Venetian blind

stops.

The relief function at the upper stop is activated.

17.6.3Relief function at the lower stop

For version C (see chapter 5.6.8)

and version D (see chapter 5.6.9):

Activate relief function at the lower stop

1 Push and hold the DOWNP button ▼ from instruction

③(chapters 5.6.8 and 5.6.9) and actuate the UP

button ▲ with the assembly cable (at the same time).

Keep both buttons pushed until the Venetian blind

stops.

The relief function at the lower stop is activated.

17.6.4Changing / Deleting the limit positions

and deleting the discharge function

A change or deletion of a single end position is not possible.

This is always done in pairs (upper and lower end position

simultaneously).

By the deletion of the end positions and the adjustment of

the optional discharge function is lost.

Important

The Venetian blind is adjusted only after a complete and

uninterrupted access and exit to the blind.

Changing / Deleting the end positions

1 From a middle Venetian blind position with the as-

sembly cable , push and hold both direction buttons

(▲ and ▼) at the same time until the drive briey

moves up and down.

The deletion of the setting of end position is completed.

The end positions can be programmed again.

17.6.5Four variants of end position settings

Four dierent combinations of end position settings are

possible. They must be selected sensibly according to the

technical requirements of the Venetian blind.

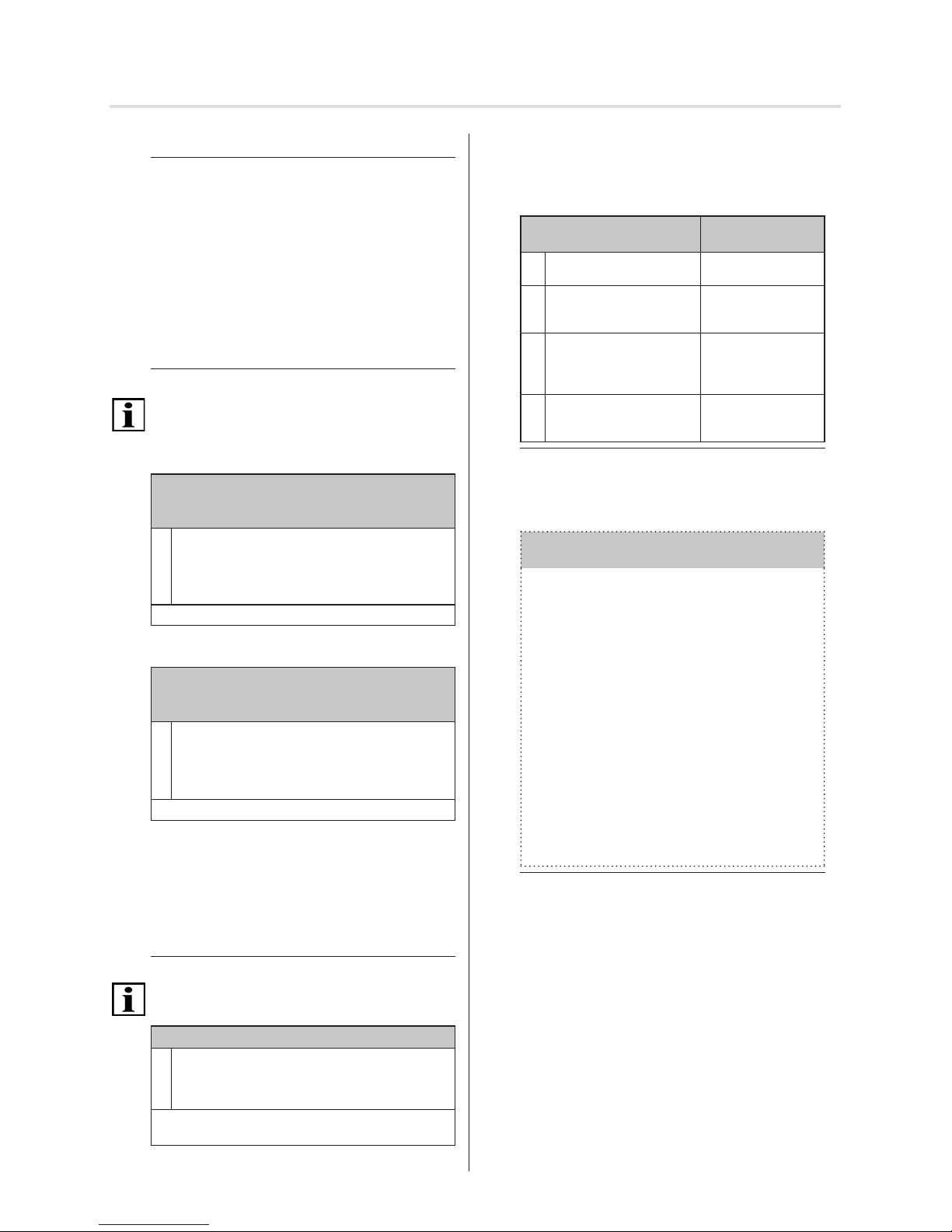

End position settings

(4 versions)

possible with

AUpper and lower end posi-

tion freely adjustable

T-strap, tapes,

belt

BFixed upper limit stop /

lower end position freely

adjustable

T-strap, tapes,

belt, limit plugs,

angle bracket

CFixed upper and lower limit

stop

Anti push-up device,

sti shaft connector,

limit plugs, angle

bracket

DUpper end position freely

adjustable, xed lower limit

stop

Anti push-up device

Fig. 7 Versions of the end position settings in the RolTop

17.6.6Variant A: Upper and lower end position

freely adjustable

Variant A:

Upper and lower end position freely adjustable

①From a middle Venetian blind position with the as-

sembly cable, push the UP button ▲ until the Vene-

tian blind has reached the desired end position.

The drive starts, stops briey and then moves on

(while the UP button ▲ is pushed).

Correction is possible with the buttons ▲ and ▼ .

②Press the AB button ▼ until the drive stops auto-

matically.

The upper end position has been set.

③Press the AB button ▼ again until the Venetian

blind has reached the desired lower end stop.

The drive starts, stops briey and then moves

on (while the AB button ▼ is pushed).

Correction is possible with the buttons ▲ and ▼ .

④Press the AUF button ▲ until the drive stops

automatically.

The lower end position has been set.

Setting of the end positions variant A is now complete.

Fig. 8 End position setting Variant A:

© elero GmbH EN | 5

Commissioning | Setting the end positions and the relief

17.6.9Variant D: Upper end position freely

adjustable, xed lower limit stop

Variant D: Upper end position freely adjustable,

xed lower limit stop

① From a middle Venetian blind position with the as-

sembly cable, push the UP button ▲ until the Vene-

tian blind has reached the desired end position.

The drive starts, stops briey and then moves on

(while the button is pushed).

Correction is possible with the buttons ▲ and ▼ .

② Press the DOWN button ▼ until the drive stops

automatically.

The upper end position has been set.

③ Press the DOWN button ▼ again until the Venetian

blind has reached the lower end stop (run to lower

end stop).

The drive starts, stops briey and then moves on

(while the DOWN button ▼ is pushed).

The drive switches o automatically when the lower

limit stop is reached.

④ Press the UP button ▲ until the drive stops

automatically.

The lower end position has been set.

Optional: Activation of the relief function for the

lower stop; see chapter 5.6.3

Setting of the end positions variant D is now complete.

Fig. 11 End position setting Variant D:

18 Troubleshooting

Problem /

Error

Possible

cause

Cure

Remedy

• Drive stops

during travel

• End positions

are not set

• Drive is in

setting mode

• Set end posi-

tions

• Drive stops

after a short

time

• End position

programmed

• Sluggish

shutter

• Set second

end position

• Check smooth

running of the

Venetian blind

• Drive runs only

in one direction

• Connection

error

• Check connec-

tion

• Drive not

responding

• No mains

voltage

• Temperature

limiter has

tripped

• Check mains

voltage

• Allow drive to

cool

• Drive does not

learn any end

positions

• Random travel

• Travel to end

position or limit

stop too short

• Delete end

positions

Reset end

positions

• Drive must run,

stop briey

and run on

(while a button

is pushed at

the assembly

cable).

Fig. 12 Error search at the RolTop

6 | EN © elero GmbH

Setting the end positions and the relief | Troubleshooting

17.6.7Variant B: Fixed upper limit stop / lower

end position freely adjustable

Variant B: Fixed upper limit stop / lower end posi-

tion freely adjustable

① From a middle Venetian blind position with the

assembly cable, push the UP button ▲ until the

Venetian blind has reached the desired end position

(run to the upper stop).

The drive starts, stops briey and then moves on

(while the UP button ▲ is pushed).

The drive switches o automatically when the upper

limit stop is reached.

② Press the AB button ▼ until the drive stops auto-

matically.

The upper end position has been set.

Optional: Activation of the relief function for the

upper stop; see chapter 5.6.2

③ Press the AB button ▼ again until the Venetian blind

has reached the desired lower end stop.

The drive starts, stops briey and then moves on

(while the button is pushed).

Correction is possible with the buttons ▲ and ▼ .

④Press the AUF button ▲ until the drive stops auto-

matically.

Setting of the end positions variant B is now complete.

Fig. 9 End position setting Variant B:

17.6.8Variant C: Fixed upper and lower limit stop

Variant C: Fixed upper and lower limit stop

①From a middle Venetian blind position with the

assembly cable, push the UP button ▲ until the

Venetian blind has reached the desired end position

(run to the upper stop).

The drive starts, stops briey and then moves on

(while the UP button ▲ is pushed).

The drive switches o automatically when the upper

limit stop is reached.

② Press the AB button ▼ until the drive stops auto-

matically.

The upper end position has been set.

Optional: Activation of the relief function for the

upper stop; see chapter 5.6.2

③ Press the AB button ▼ again until the Venetian blind

has reached the lower end stop (run to lower end

stop).

The drive starts, stops briey and then moves on

(while the DOWN button ▼ is pushed).

The drive switches o automatically when the lower

limit stop is reached.

④ Press the AUF button ▲ until the drive stops auto-

matically.

The lower end position has been set.

Optional: Activation of the relief function for the

lower stop; see chapter 5.6.3

Setting of the end positions variant C is now complete.

Fig. 10 End position setting Variant C:

19 Repair

The RolTop is maintenance free.

20 Repair

Please contact your dealer if you have any questions.

Please always provide the following information:

• Item number and name on the type plate

• Type of fault

• Previous and unusual events

• Surrounding circumstances

• Own assumption

21 Manufacturer's address

elero GmbH

Antriebstechnik

Maybachstr. 30

73278 Schlerbach

Deutschland / Germany

Phone: +49 7021 9539-0

Fax: +49 7021 9539-212

www.elero.com

Please visit our website if you require a contact outside

Germany.

22 Disassembly and disposal

Dispose of the packaging according to current regulations.

Dispose the product after previous use in accordance with

applicable regulations.

Environmental information

No unnecessary packaging was used. The packaging can

be easily divided into three material types: Cardboard (box),

Styrofoam (padding) and polyethylene (bag, foam material

protective foil).

The device is made up of materials that can be reused if it

is disassembled by a specialist operation. Please observe

the local provisions on disposal of packaging material and

old devices.

Always expect additional danger that does not occur in

operation during disassembly.

WARNING

Danger of injury due to electric current.

Electric shock possible.

►Physically disconnect power supply lines and discharge

charged energy storage. Wait for at least 5 minutes after

deactivation for the motor to cool down and the capaci-

tors to lose their voltage.

►Use suitable, tested and stable climbing aids when per-

forming disassembly work above body height.

►All work at the electrical system must only be performed

by the sta described in the chapter "Safety instructions

for electrical installation".

Scrapping

During the scrapping of the product, the international,

national and regional-specic laws and regulations are to be

complied with.

Please make sure to consider material recyclability, ease of

dismantling, and separability of materials and components

as well as environmental and health hazards during recy-

cling and disposal.

CAUTION

Environmental damage at incorrect disposal

►Electronic scrap and electronic components are subject

to the hazardous waste rules and must only be disposed

of by approved specialist operation.

►Groups of materials such as plastics and metals of vari-

ous kinds are sorted for recycling and disposal process.

Dispose electrical and electronic components

Disposal and recycling of electric and electronic compo-

nents must comply with the applicable national laws and

regulations.

23 Conformity Declaration

elero GmbH hereby declares that this product corresponds

to the applicable directives. The complete declaration of

conformity can be found under www.elero.com.

24 Technical data and dimensions

The indicated technical data are subject to tolerances (ac-

cording to the respective applicable standards).

© elero GmbH EN | 7

Relief function | End position settings

Technical data and dimensions

24.1 RevoLine M

Build / Type RolTop

M6

RolTop

M7/23

RolTop

M10

RolTop

M12/23

RolTop

M20

RolTop

M30

RolTop

M40

RolTop

M50

Rated voltage (V) 1 ~ 230 1 ~ 230 – 240 1 ~ 230

Rated frequency (Hz) 50

Noiseless soft brake • –

High-speed door – • – • –

Rated torque (Nm) 6 7 10 12 20 30 40 50

Rated speed (rpm) 14 23 14 23 14

Rated current (A) 0.52 0.6 0.9 1.2 1.3

Rated power consumption (W) 118 140 200 270 300

Shaft diameter (mm) 50

Protection class (IP) 44

Limit switch range (turns) 40

Operating duration (min S2) 5 4 5 4

Length A (mm) 478 480 530 540 530 540 560

Length B (mm) 460 462 513 523 512 522 542

Weight (kg) 1.5 1.9 2.2 2.3 2.6 3.1

Operating environment temperature

(°C) – 20 to +60

Conformity

Emission sound pressure level

(dBA) < 70

Protection class I •

Plug-in connecting cable (m) 2.0

Item number 34 301.0001 34 225.0001 34 221.0001 34 235.0001 34 231.0001 34 241.0001 34 251.0001 34 261.0001

8 | EN © elero GmbH

33

D

C

E

Stator FE C D E Motorrohr

Rol/Sun/Vari

381 364 elero=14 339

391 374 RH=12 349

456 439 SH=19 414

466 449 424

486 469 444

526 509 484

546 529 504

RolTop M1,8/138 RH Neher 384493401 120 556 539 514

RolTop M1,8/138-868 RH Nehe r 384403406 120

D= C-17mm (halbe Kupplung)

Baugröße Typ

55

C

D

E

E

45O

55O52,7

C

D

33

33

C

D

33

E

45O45O45O

O52,7

C

D

33

45O

O57,5

E

C

D

33

45O

O57,5

E

Build / Type RolTop

M6

RolTop

M7/23

RolTop

M10

RolTop

M12/23

RolTop

M20

RolTop

M30

RolTop

M40

RolTop

M50

Rated voltage (V) 1 ~ 230 1 ~ 230 – 240 1 ~ 230

Rated frequency (Hz) 50

Noiseless soft brake • –

High-speed door – • – • –

Rated torque (Nm) 6 7 10 12 20 30 40 50

Rated speed (rpm) 14 23 14 23 14

Rated current (A) 0.52 0.6 0.9 1.2 1.3

Rated power consumption (W) 118 140 200 270 300

Shaft diameter (mm) 50

Protection class (IP) 44

Limit switch range (turns) 40

Operating duration (min S2) 5 4 5 4

Length A (mm) 478 480 530 540 530 540 560

Length B (mm) 460 462 513 523 512 522 542

Weight (kg) 1.5 1.9 2.2 2.3 2.6 3.1

Operating environment temperature

(°C) – 20 to +60

Conformity

Emission sound pressure level

(dBA) < 70

Protection class I •

Plug-in connecting cable (m) 2.0

Item number 34 301.0001 34 225.0001 34 221.0001 34 235.0001 34 231.0001 34 241.0001 34 251.0001 34 261.0001

24.2 RevoLine S

Technical data and dimensions

© elero GmbH EN | 9

C

E

D

33

CDE

Drehzahl

RolTop/V ari Eco S1,5 70/84 534 517 11

RolTop/V ari Eco S3 30/36 534 517 11

RolTop/V ari Eco S5 (17)/19/20 534 517 11

RolTop S7 30

RolTop/V ari Eco S8 (17)/-/- 534 517 11

RolTop/V ari Eco S12 (17)/19/20 534 517 11

RolTop/V ari Eco S10 514 497 11

Baugröße Typ

Maße mit und ohne Funk

C

E

D

33

35

O

35

O

O

39

O

39

Baugröße / Typ S1,5/70 S3/30 S5/30 S5 S8 S10 FL S12 FL S12/11 FL

Roller shutter ■ ■ ■ ■ ■ ■

Roller blind ■ ■ ■ ■ ■ ■ ■ ■

Noiseless soft brake ■ ■ ■ ■ ■ - - -

Rated voltage [V] 1 ~ 230 1 ~ 230 1 ~ 230 1 ~ 230 1 ~ 230 1 ~ 230 1 ~ 230 1 ~ 230

Rated frequency [Hz] 50 50 50 50 50 50 50 50

Rated torque [Nm] 1,5 3 5 5 8 10 12 12

Rated speed [1/min] 70 30 30 17 17 17 17 11

Rated current [A] 0,55 0,55 0,73 0,55 0,73 0,55 0,73 0,55

Rated power consumption [W] 130 130 168 130 168 130 168 130

Shaft diameter [mm] 38 38 38 38 38 38 38 38

Limit switch range (turns) 160 80 80 40 40 40 40 40

Protection class (IP-Code) 44 44 44 44 44 44 44 44

Operation duration (min S2) 5 5 4 5 4 4 4 4

Length C [mm] 534 534 534 534 534 514 534 514

Length D [mm] 517 517 517 517 517 497 517 497

Length E [mm] 11 11 11 11 11 11 11 11

Weight [kg] 1,3 1,2 1,2 1,2 1,3 1,2 1,4 1,2

Operating environment

temperature [°C] -20 ... 60 -20 ... 60 -20 ... 60 -20 ... 60 -20 ... 60 -20 ... 60 -20 ... 60 -20 ... 60

Protection class I

■ ■ ■ ■ ■ ■ ■ ■

Conformity

■ | ■ | ■ ■ | ■ | ■ ■ | ■ | ■ ■ | ■ | ■ ■ | ■ | ■ ■ | ■ | ■ ■ | ■ | ■ ■ | ■ | ■

Artikel-Nr. (Rundkopf /

Sternkopf) 302210001 302110001 302310001

302330001

302530001

308230001

308130001

30815001

We reserve the right to make technical changes

elero GmbH

Antriebstechnik

Maybachstr. 30

73278 Schlierbach

www.elero.com

Phone: +49 7021 9539-0

Fax: +49 7021 9539-212

Technical data and dimensions

24.3 RevoLine M RH

Build / Type RolTop

M4/60 RH

RolTop

M7/23 RH

RolTop

M10 RH

RolTop

M12/23 RH

RolTop

M20 RH

RolTop

M30 RH

Rated voltage (V) 1 ~ 230

Rated frequency (Hz) 50

Noiseless soft brake –

High-speed door • – • –

Rated torque (Nm) 4 7 10 12 20 30

Rated speed (rpm) 60 23 14 23 14

Rated current (A) 0.9 0.6 0.9

Rated power consumption (W) 200 140 200

Shaft diameter (mm) 50

Protection class (IP) 44

Limit switch range (turns) 40

Operating duration (min S2) 4 5 4

Length A (mm) 540 480 530 540 530

Length B (mm) 523 462 513 523 512

Weight (kg) 2.2 1.9 2.2 2.3

Operating environment temperature

(°C) – 20 to +60

Conformity

Emission sound pressure level

(dBA) < 70

Protection class I •

Plug-in connecting cable (m) 2.0

Item number 38 469.0001 38 225.0001 38 221.0001 38 235.0001 38 231.0001 38 241.0001

Build / Type RolTop

L60

RolTop

L80

Rated voltage (V) 1 ~ 230

Rated frequency (Hz) 50

Noiseless soft brake –

Application protection up and down

and reversion on obstacle •

Rated torque (Nm) 60 80

Rated speed (1/min) 14

Rated current (A) 1,9 2,0

Rated power consumption (W) 430 470

Shaft diameter (mm) 63

Protection class (IP) 44

Limit switch range (turns) 40

Operating duration (min S2) 4

Length A (mm) 589,4

Length B (mm) 572,4

Weight (kg) 3,3 3,6

Operating environment temperature

(°C) – 20 bis +60

Conformity

Emission sound pressure level

(dBA) < 70

Protection class I •

Plug-in connecting cable (m) 2,0

Item number 36 731.0001 36 741.0001

24.4 RevoLine L

This manual suits for next models

22

Table of contents

Other elero Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual