elero VariEco M NHK Series User manual

RevoLine VariEco NHK

Assembly instructions

138164001_EN_0519

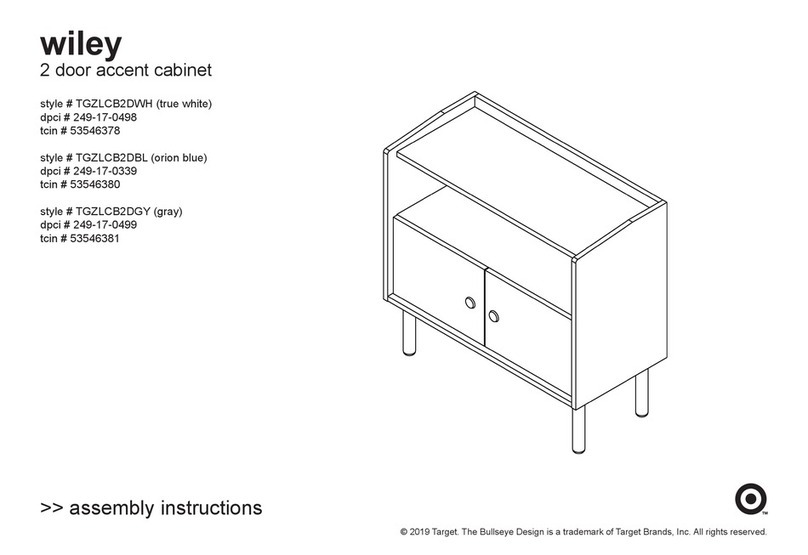

General

Application: Tubular drive for small rolling doors, roller shut-

ters and textile sun protection

Limit stop: Mechanical

Special feature: Emergency manual operation, noiseless

soft brake (up to 20 Nm)

Shaft size: Type M from Ø 50 mm, type L from Ø 63 mm

Standard scope of delivery

•2 m connecting cable, assembly instructions

Accessories

•Adapter sets, motor bearing, control units

Safety instructions

General safety instructions for use including installation of

drives for roller shutters, awnings and textile sun protection

can be found in the “Safety instructions” leaet supplied with

each drive. Please read the general safety instructions and

this installation manual carefully as the procedure in this

manual is a prerequisite for correct use of the product. Any

intervention by unqualied personnel or failure to comply with

warnings may lead to personal injuries or material damage.

Figures included are for illustration purposes only. The illus-

trations may dier from your product with respect to minor

details and are provided for general information only.

elero GmbH continuously strives to improve all products. As a

result, the specications, features and technology of this prod-

uct may be changed at any time. The information provided is

based on current information at the time of publication.

No claims can be derived from the technical data, images and

information provided in this manual.

&$87,21

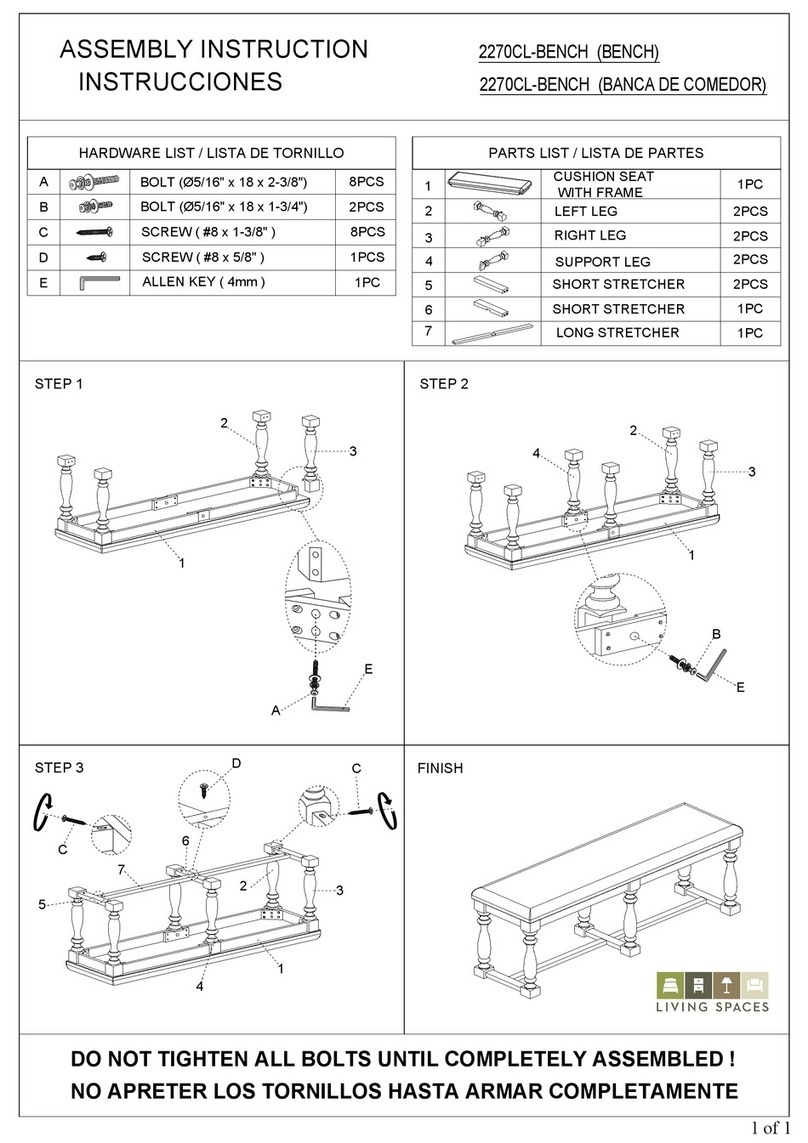

Assembly

•Only connect the drive with the power turned o.

•Only insert the drive's plug with the power turned o.

•The drive is only capable of operation while installed.

•Never adjust the end position to a mechanical stop.

•The length of the winding shaft is determined for each

specic installation depending on the drive head and motor

bearing used at the installation site.

•Do not drill holes in the area of the tubular drive.

Installation in prole tubes

•Push drive with the suitable drive adapter and limit switch

crown into the prole tube. Install the shaft with drive and

counterpart support so that the limit switch setting mechanism

is accessible.

•Secure the counterpart support to prevent axial movement

(screw on the idler or rivet it on).

•Connect the drive to the elero assembly cable, matching up

the core colours.

•Allow the drive to run in DOWN/CLOSED direction until the

limit switch cuts out.

•Attach the blind to the shaft.

Installation in round tubes

•On the round tube, cut a slot in the end of the tube on the

drive side.

•Push the drive in so that the lug of the drive engages in the

slot.

•Screw in the drive adapter or rivet it.

•Allow the drive to run in DOWN/CLOSED direction until the

limit switch cuts out.

•Attach the blind to the shaft.

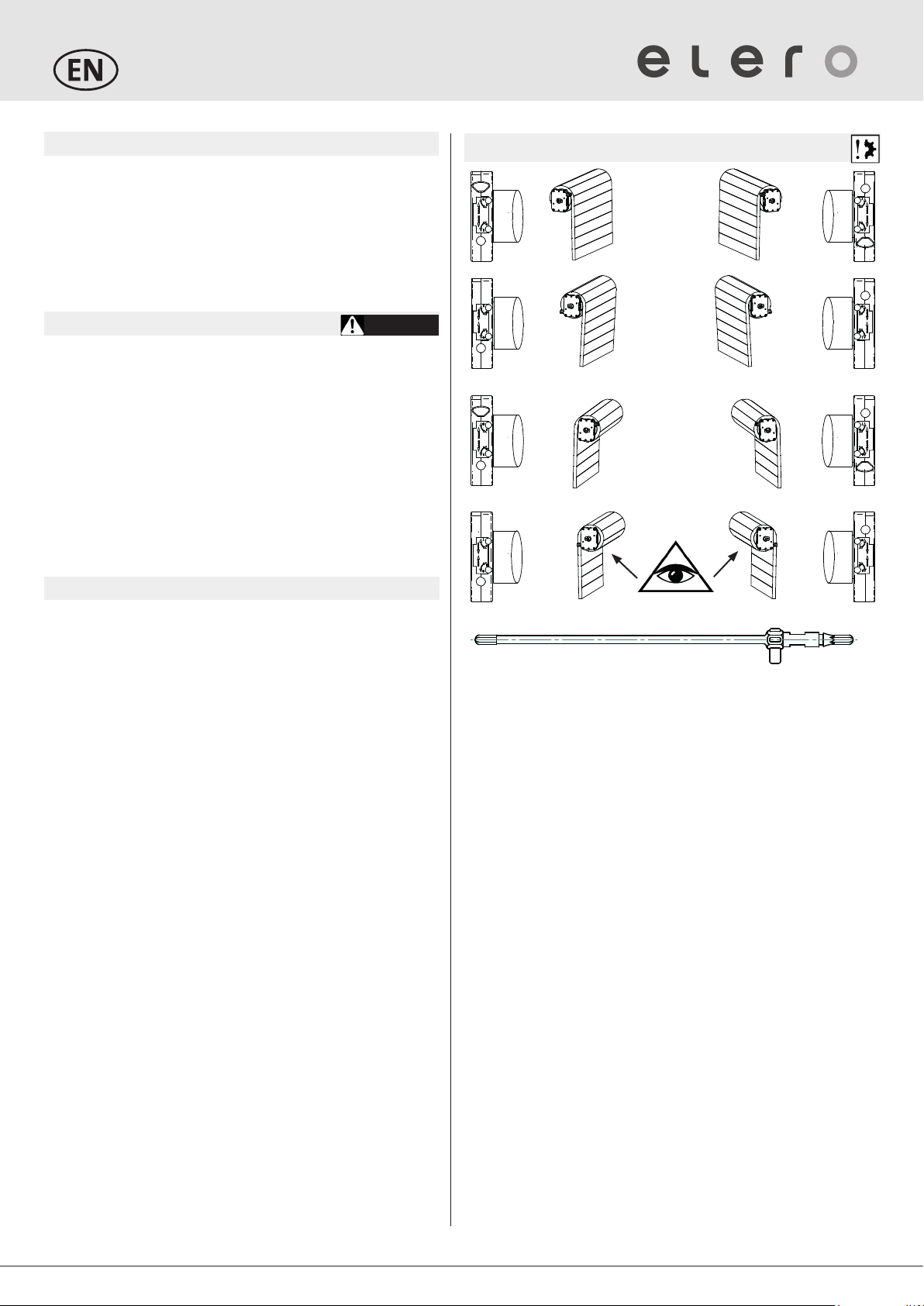

Adjustment of end positions

Adjusting key: item number 13 109.6401

NOTE: For activation of the limit switch setting screws, use the

setting tool or Phillips/hexagon socket tool. Never use an electric

screwdriver!

Important: The limit switch setting screws for the upper end posi-

tion and lower end position are assigned depending on the paral-

lelism of the rotating limit switch crown with the running direction

arrow.

Upper end position

1. Allow the drive (without blind) to run fully in DOWN/CLOSED

direction.

2. Attach the rolled-down blind to the shaft.

3. Push the [OPEN ▲] button and keep this held down.

4. Using the setting tool, turn the limit switch setting screw in posi-

tive or negative direction until you reach your desired upper

end position.

Lower end position

5. Push the [DOWN/CLOSED ▼] button and keep this held down.

6. Using the adjusting key, turn the DOWN limit switch setting

screw in positive or negative direction until you reach your

desired lower end position.

Checking the end positions

Allow the drive to run into the relevant end position until the limit

switch cuts out. The electric cut-out must take place before the

blind has reached the end position of its mechanical travel path.

If the blind is constantly operated as far as its end position, there

is a risk of damage to the drive and/or blind or even a danger it

will be destroyed.

Take into account any possible changes to the length of the blind

due to temperature uctuations or weather inuences. Allow for a

safety margin.

UP

DOWN/

CLOSE

DOWN/

CLOSE

UP

DOWN/

CLOSE

UP

UP

DOWN/

CLOSE

UP

DOWN/

CLOSE

DOWN/

CLOSE

UP

DOWN/

CLOSE

UP

UP

DOWN/

CLOSE

Technical data and dimensions

The technical data specified is subject to tolerance factors

(according to applicable standards).

All illustrations are non-binding.

EU Conformity

elero hereby declares that this product is in compliance with the

essential requirements and other relevant provisions of Europe-

an directives 2006/42/EG that are applicable in Europe. A decla-

ration of conformity is available at the website

www.elero.com/downloads-service/

Notes on troubleshooting

Fault

Cause

Remedy

•The drive does

not switch o in

the end position

via the limit

switches

•Drive does not

react

•Limit switch

crown is not

being driven

•Readjust instal-

lation and limit

switches via the

limit switch ad-

justment screws

•Set limit switch

•Drive does not

react

•Incorrect

connection

•Readjust

connection

Manufacturer's

address

Service

elero GmbH

73278 Schlierbach

GERMANY

www.elero.de

If malfunctions have occurred or the

device has been damaged despite

proper handling, please contact your

contractor or dealer.

RevoLine VariEco NHK

Assembly instructions

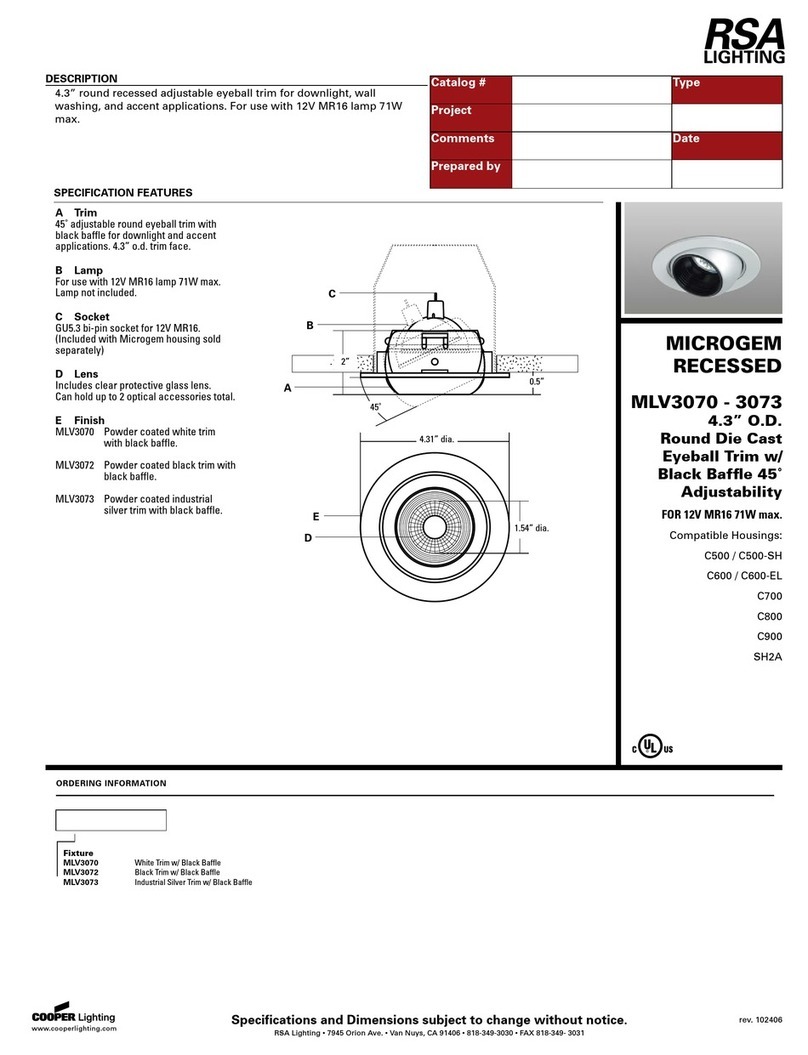

Electrical connection

Note:

Due to feedback voltage from the installed capacitor, never

connect several drives in parallel.

The motor controls in UP/DOWN direction must be inter-

locked with one another. A reversing delay of at least 0.5 sec.

must be ensured.

102

reseau electrique

L

N

PE

230V/50Hz

vert-jaune

brun

noir

bleu

de volet

M

1~

102

rete

L

N

PE

230V/50Hz

verde/giallo

marrone

nero

blu

M

1~

102

Netz

L

N

PE

230V/50Hz

grün/gelb

braun

schwarz

blau

oder -taster

M

1~

102

power grid

L

N

PE

230V/50Hz

green/Yellow

brown

black

blue

junction box

M

1~

boiter de scatola di

derivatione

26E=

D

C

33

F

Stator FE C D E Motorrohr

M10-17 N HK 120V 621 604 26 565

M20 NHK/ M16-17 NHK 120V 661 644 26 605

M30 NHK/ M36-12 NHK 120V 651 634 26 595

M50 NHK 681 664 26 625

Rol TopD+ M6 NHK 524 507 26 468

Rol TopD+ M10 NHK 544 527 26 488

Rol TopD+ M20 NHK 604 587 26 548

Rol TopD+ M30 NHK 594 577 26 538

Baugröße Typ

100

74

91,5

O

60

90

30°

M6

16

q

2 | EN

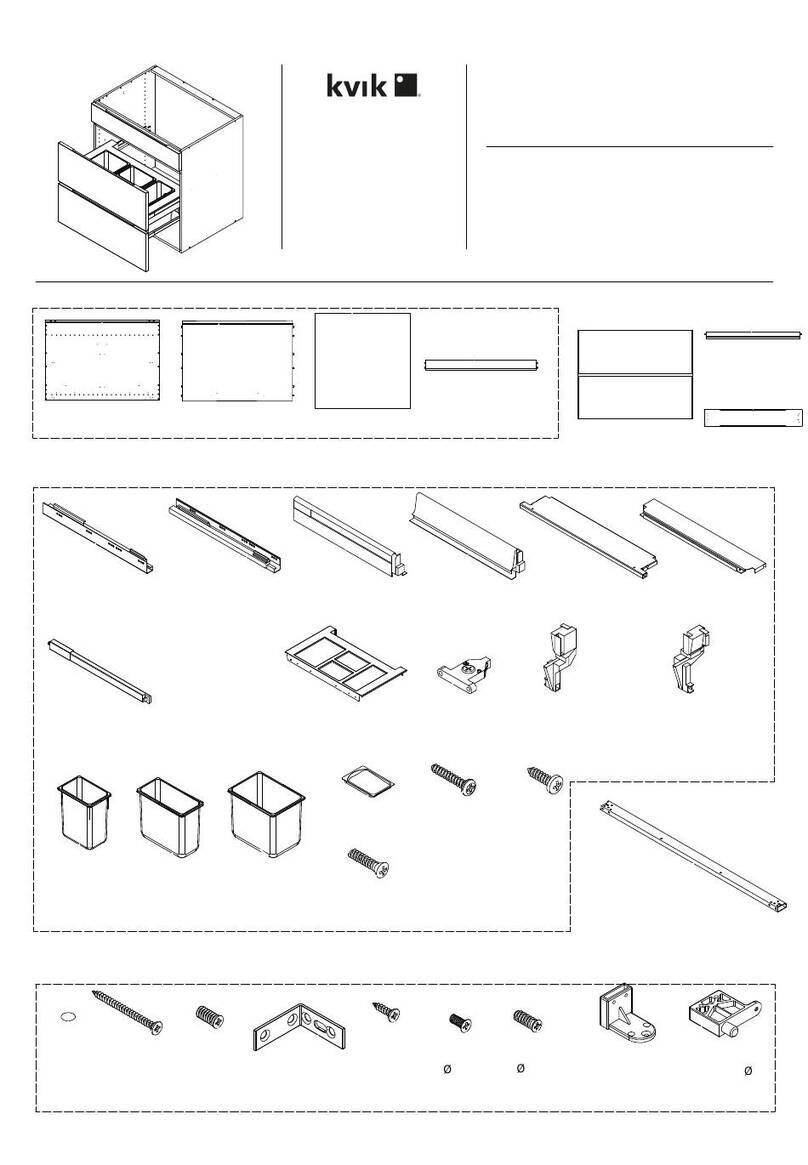

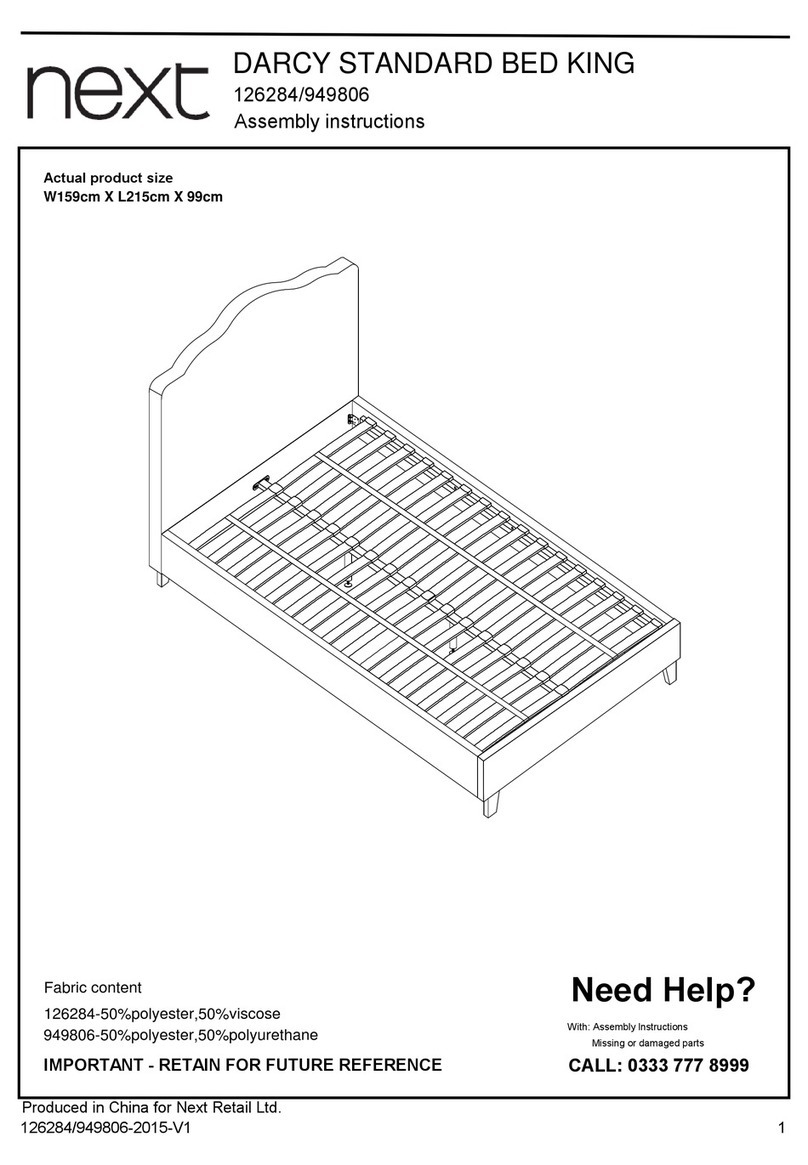

Emergency crank handle

Note:

Tubular drive versions with the additional code NHK are tted

with an emergency unlocking device.

The emergency unlocking device ensures that the blind can be

opened or closed in case of an emergency. Examples of emer-

gencies might be blackouts or a defect to the tubular drive.

The emergency unlocking device is not intended to be used

on regular basis as otherwise the tubular drive may become

damaged.

Emergency release of the tubular drive via the manual

override/emergency crank handle

CAUTION

•Hands, loose items of clothing or long hair may become

entrapped and crushed.

•Disconnect the tubular drive from the mains power prior to

emergency unlocking (switch should not be operated).

•Attach the manual override/emergency crank handle to the

tubular drive.

•Open or close the blind slowly by turning the manual override/

emergency crank handle.

•Ensure that you do not go past the limit switches set.

wall anchors

13 106.3501

wall anchors

13 301.0801

7 mm 6-edge

with awning loop

23 771.0002

front element

Spherical bearing for coupling funnel 23 772.0002

articulated crank with spherical bearing and

7 mm hexagonal 23 764.0002

Spherical bearing with awning eyelet 23 731.0002

ø 12.5 x 18.5 tief

for front elements

with ø 12 bolts

Connecting

cable pluggable

334488443300000011

348430001.asm

31.07.2014 fleischerd

-

VVaarriiEEccooMM3300NNHHKK

1:2

-

Diese Maße werden besonders geprüft

This dimensions are particularly examined

Kanten gebrochen

Edges broken

Allgemeintoleranzen

General Tolerances:

DIN ISO 2768-1 m-E

DIN ISO 2768-2 K-E

Maßstab / Scale:

Werkstoff / Material:

Datum / Date: Name:

A-EW

geprüft

proofed:

Benennung / Title:

Zeichnungsnummer / Drawingnumber:

Werkzeug-Nr

Tool-Number:

GGeemmääßßRRooHHSS--RRiicchhttlliinniiee22001111//6655EEGG//aaccccoorrddiinnggttooRRooHHSSddiirreeccttiivvee220000//1111//EEUU

Index: Kurzbeschreibung / Short Comment: Name:

Datum / Date:

elero GmbH

Antriebstechnik

Linsenhofer Str. 65, D-72660 Beuren

Fon: (0049) 7025 / 13-01

Fax: (0049) 7025 / 13-390

Verwendung , Kennzeichnung / Used in, Spezification:

Gewicht / weight: 2510 g

Solid Edge

a

b

c

d

-

-

-

-

-

Rohrindex erhöht, Schraube war 101010907.

Typenschild geä.

MiniPlug entfernt

Drehmomentangaben hinzu gekommen.

-

-

-

-

-

20.06.2017

24.10.17

06.12.17

30.10.2018

-

-

-

-

-

FLD

HEC/WAT

HEC/WAT

FLD

-

-

-

-

-

-

Blatt / Sheet: Blattanzahl / Number of sheets: -

CAD-Nr / CAD-No:

231290001

1233941201

1231620002

1

138066003

1

133092102

1

Menge Mengeneinheit Dokumentnummer Titel Material Kommentar

1 STK 233941201 Motor M H90 Fl

1 STK 231620002 Endschalter kpl. 6F

1 STK 231290001 Getriebe

1 STK 138200001 Sicherheitshinweis -

1 STK 138164001 Einstellanleitung

1 STK 138066003 Aufkleber Typenschild -

1MM 138037103 Transferfolie 110x450 lfm.TMX Super Pr.

CAB

1 STK 133092102 Motorrohr 595 Präz. St-Rohr 45 x 1,5 DIN 2393

4 STK 101014701 Senkschraube EJOT Altracs Plus 4x10

Torx 20

St verzinkt

2 STK 101013621 Schraube WN 1552 - DG35x7 St verzinkt EJOT Nr.:441 0383

801

101014701

4

101013621

2

677

629

91,5

74

100

90

45

O

Lauffläche muß mit PD1 gefettet werden./

Bearing surface has to be lubricated whith PD1.

26

63

+7

-3

60

LK

Schrauben mit 4,3

u

0,3 Nm anziehen./

Tighten the screws whith 4,3

u

0,3 Nm.

a

a

Link für Typenschildabstand

b

Excelstückliste

Drehmoment nach Arbeitsanweisung./

Torque according to work instruction.

Drehmoment nach Arbeitsanweisung./

Torque according to work instruction.

d

d

d

Rear cable

outlet

Size / Type VariEco

M20 NHK

VariEco

M30 NHK

VariEco

M40 NHK

VariEco

M50 NHK

VariEco

L40 NHK

VariEco

L60 NHK

VariEco

L80 NHK

VariEco

L100 NHK

VariEco

L120 NHK

Rated voltage [V] 1 ~ 230 1 ~ 230 1 ~ 230 1 ~ 230 1 ~ 230 1 ~ 230 1 ~ 230 1 ~ 230 1 ~ 230

Noiseless soft brake • - - - - - - - -

Rated torque [Nm] 20 30 40 50 40 60 80 100 120

Rated speed (1/min) 14 14 14 14 14 14 14 11 11

Rated current [A] 0,90 0,90 1,05 1,30 1,45 1,55 1,80 1,70 2,00

Rated power

consumption [W]

200 200 242 300 333 356 415 390 460

Shaft diameter 50 50 50 50 63 63 63 63 63

Protection class (IP) 44 44 44 44 44 44 44 44 44

Limit switch range

(revolutions)

29 29 29 29 29 29 29 29 29

Operating time

(min S2)

4 4 5 4 4 4 4 4 4

Length C [mm] 661 651 682 682 730 730 760 760 760

Length D [mm] 644 634 665 665 713 713 743 743 743

Length E [mm] 27 27 27 27 27 27 27 27 27

Ø F [mm] 45 45 45 45 58 58 58 58 58

Weight [kg] 2,2 2,5 2,7 3,1 5,76 576 6,2 6,2 6,2

Ambient operating

temperature [

°C

]

-20 to 60 -20 to 60 -20 to 60 -20 to 60 -20 to 60 -20 to 60 -20 to 60 -20 to 60 -20 to 60

Protection class I • • • • • • • • •

Plug-in connection

cable [m]

2.0 2.0 2.0 2.0 2.0 2.0 2.0 2,0 2,0

Item number 34 833.0001 34 843.0001 34 853.0001 34 863.0001 36 925.0002 36 935.0002 36 945.0001 36 955.0001 36 965.0001

RevoLine VariEco NHK

Assembly instructions

Technical data and dimensions:

VariEco M NHK / VariEco L NHK

EN | 3

elero GmbH

Antriebstechnik

Maybachstr. 30

73278 Schlierbach

www.elero.com

Subject to technical changes

This manual suits for next models

10

Other elero Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Next

Next DARCY 126284 Assembly instructions

Naterial

Naterial LYRA II 2022R09P01-0103 Assemby - Use - Maintenance Manual

Rapidline

Rapidline AM100 Assembly instructions

Touchstone

Touchstone Whisper Lift II PRO owner's manual

WIEMANN

WIEMANN WIEMANN 991404 manual

Contender

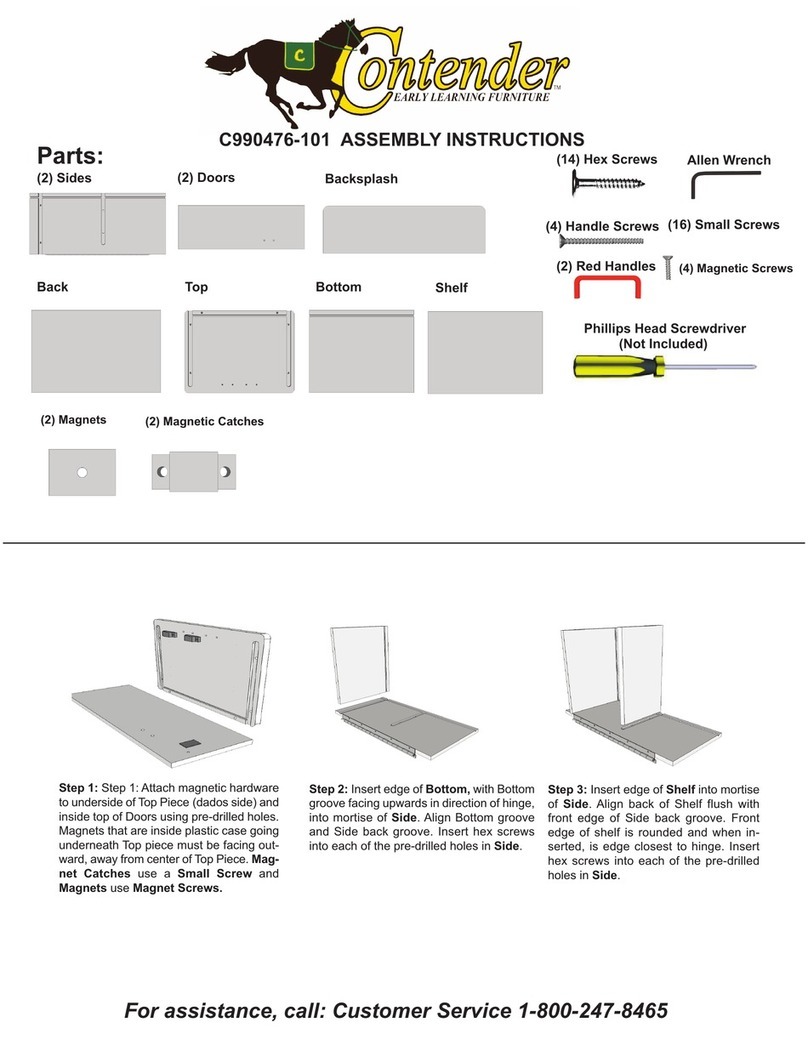

Contender C990476-101 Assembly instructions