elero VariEco S3/30-K User manual

VariEco S-K

Drive for roller shutters

and textile sun protection

138195501_EN_0116

VariEco S-K

Drive for roller shutters

and textile sun protection

1 Operating and installation instructions

Please keep these operating instructions for later use, to be

available throughout the life of the product!

The German manual is the original version.

All other documents represent the language translations of

the original text.

All rights in the case of a patent, utility model or ornamental

design registration are reserved.

2 General for instructions

The content structure is based on the life cycles of the elec-

tric motor drive (hereinafter referred to as "Product").

The manufacturer reserves the right to make changes to

the Specications stated in these Operating Instructions

at any time. These may, in individual cases, be different

from the respective product version, however the functional

information will not undergo signicant changes or become

invalid. The current version of the Specications may be

requested from the manufacturer at any time. No claims

may be asserted against the manufacturer as a result of the

preceding sentence. Deviations from text or picture state-

ments are possible and depend on the technical develop-

ment, features, and accessories of the products. Deviating

information on special versions will be explained by the

manufacturer in the sales documentation. Other information

shall remain unaffected by these provisions.

2.1 Standards and Directives

During the design process, the basic health and safety

requirements of the applicable laws, Standards and Direc-

tives were complied with. The safety is conrmed by the

declaration of conformity (see "Declaration of Conformity").

All safety information in these Operating Instructions refer

to the laws and regulations currently applicable in Germany.

All instructions in the Operating Instructions shall be ob-

served without limitation and at any time. Beside the safety

instructions contained in these Operating Instructions, the

provisions for accident prevention, environmental protection

and occupational safety, which are applicable for the op-

erating site, must be observed. Provisions and Standards

for the safety rating can be found in the EC Declaration of

Conformity

2.2 Intended use

The product is intended for electrically powering roller shut-

ters and textile sun protection.

The determining factor for the drive is the elero

drive computation program (http://elero.de/

antriebsberechnungsprogramm).

Further elds of application have to be arranged with the

manufacturer, elero GmbH Antriebstechnik (see Address).

The operator will be solely responsible for damages result-

ing from improper use of the product. The manufacturer

cannot be held liable for personal or material damages

caused by misuse or procedural errors, and by improper

operation and commissioning.

The product may be operated only by authorized or trained

personnel under observance of all safety.

Table Of Contents

1 Operating and installation instructions 1

2 General for instructions 1

2.1 Standards and Directives 1

2.2 Intended use 1

2.3 Foreseeable misuse 2

2.4 Warranty and liability 2

2.5 Customer service of the manufacturer 2

3 Safety 2

3.1 General safety instructions 2

3.2 Layout of the safety guidelines 2

4 Product description 3

5 Assembly 3

5.1 Mechanical fastening 3

5.2 Electrical connection 4

5.3 Connection example VariEco 230 V / 50 Hz 4

5.4 Commissioning 5

5.5 Setting the end positions 5

5.6 Checking the end positions 5

6 Troubleshooting 5

7 Maintenance 5

8 Repair 6

9 Manufacturer's address 6

10 Disassembly and disposal 6

11 Notes on the EU declaration of conformity 6

12 Technical data and dimensions 7

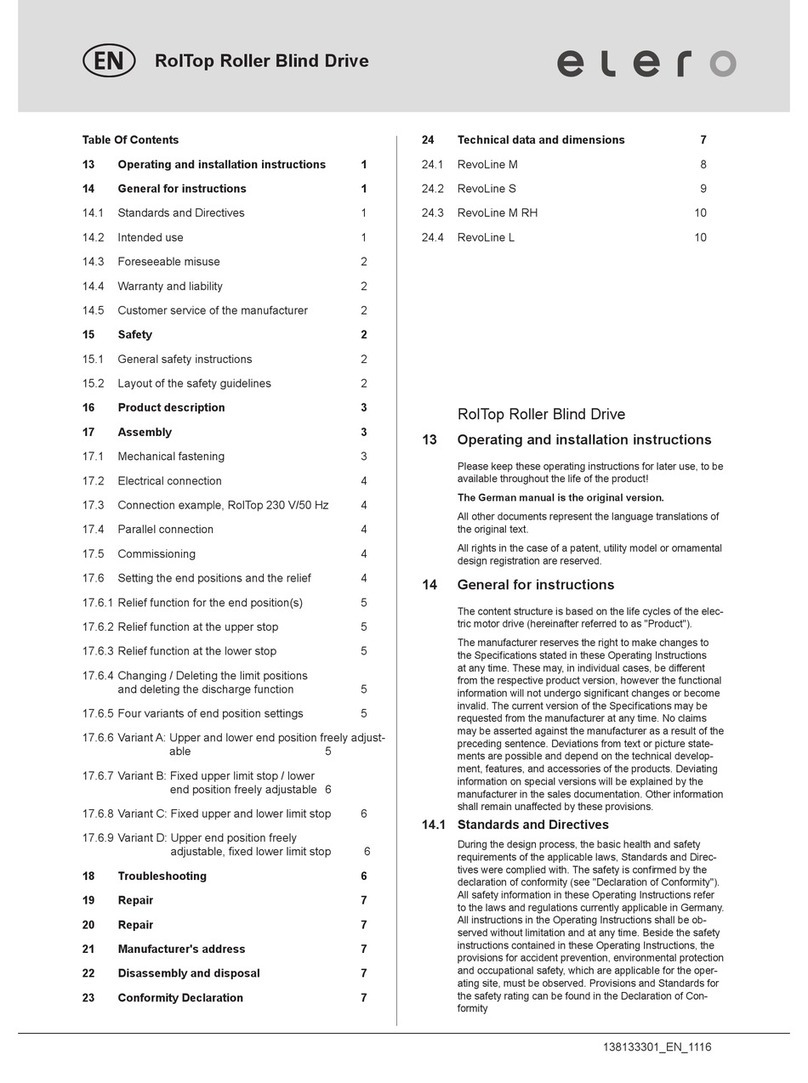

Symbol Signal

word

Meaning

DANGER Warns before an acci-

dent, which will result if

instructions are not fol-

lowed, which can lead to

life-threatening, irreversi-

ble injury or death.

WARNING Warns before an acci-

dent, which can happen

if the instructions are not

followed, which can lead

to serious, possibly fatal,

irreversible injury or death.

CAUTION Warns before an accident,

which can happen if the

instructions are not fol-

lowed, which may lead to

minor reversible injury.

Fig. 1 Notation of personal injury

The following table describes the icons used in these op-

erating instructions that are used for imaging of the dan-

gerous situation in connection with the symbol of the threat

level.

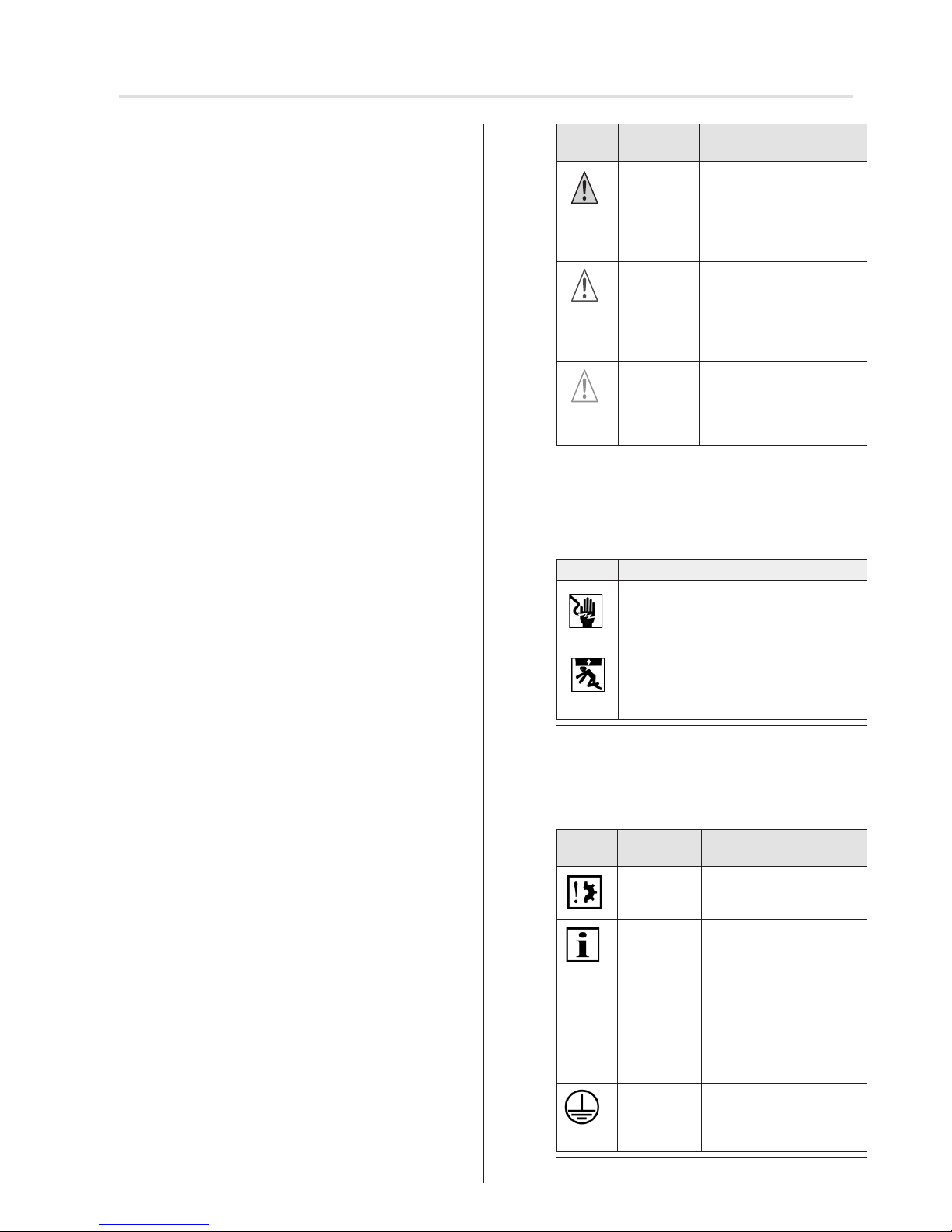

Symbol

Meaning

Danger of electric voltage, electric

shock:

This symbol indicates a risk of electric

shock.

Danger of crushing and striking dead of

persons: This symbol indicates dangers

where the entire body or individual body

parts can be crushed or injured.

Fig. 2 Notation-specic hazard

The following table denes the representation used in the

operating instructions and description of situations where

damage can occur to the product or refers to important

facts, conditions, tips and information.

Symbol Signal

word

Meaning

NOTE This symbol warns of a

possible property dam-

age.

Important: This symbol points out

important facts and con-

ditions as well as to addi-

tional information in these

operating and installation

instructions. It also refers

to certain statements that

give additional information

or help you perform a task

easily.

Symbol for earthing in

protection class I

(protective ground sys-

tem)

Fig. 3 Notation of property damage as well as additional

information

2 | EN © elero GmbH

Intended Use | Security

Only if used according to the specications of these operat-

ing and installation instructions for the safe and proper use

and safe operation of the product are guaranteed.

Intended use includes the observance and compliance with

all safety instructions with regards to this operating manual

and all applicable regulations, and professional associations

of applicable laws for environmental protection. Intended

use includes the observance of prescribed operating rules

in these operating and installation instructions.

2.3 Foreseeable misuse

A use which deviates from the intended use stated by the

manufacturer, elero GmbH Antriebstechnik (see "Address"),

is deemed as foreseeable misuse.

2.4 Warranty and liability

Principally, the General Terms and Conditions of the man-

ufacturer, elero GmbH Antriebstechnik (see "Address"),

apply. The terms and conditions are part of the sales

documents and handed over to the operator upon deliv-

ery. Liability claims for personal or material damages are

excluded when they can be attributed to one or more of the

following causes:

• Opening of the product by the customer

• Unintended use of the product

• Improper installation, commissioning, or operation of the

product

• Structural modications to the product without the written

consent of the manufacturer

• Operation of the product with improperly installed con-

nections, defective safety devices or improperly installed

safeguards

• Non-observance of the safety provisions and instructions

of these Operating Instructions

• Non-compliance with the technical data

2.5 Customer service of the manufacturer

The product should only be repaired by the manufacturer

in case of a failure. The address for sending to customer

service, see the chapter "Address".

If you have not purchased the product directly from elero,

please contact the supplier of the product.

3 Safety

3.1 General safety instructions

The general safety notes when using pipe drives can be

found in the leaet "Instructions on safety" that is enclosed

with each drive"(leaet item no. 138200001). These operat-

ing and installation instructions contain all the safety instruc-

tions that must be observed in order prevent and eliminate

hazards in the handling of the product in the individual life

cycles. The safe operation of the product can only be en-

sured when all given safety instructions are observed.

3.2 Layout of the safety guidelines

The safety instructions in this document are identied by

hazard signs and safety symbols and are designed accord-

ing to the SAFE principle. They contain information on the

nature and source of the danger of possible consequences

and to prevent the danger.

The following table denes the representation and descrip-

tion of hazard levels with possible personal injury, as used

in this manual.

The following example represents the basic structure of a

safety warning:

SIGNAL WORD

Type and source of danger

Explanation of the type and source of the danger

►Measures to prevent the danger.

4 Product description

The VariEco S-K is an electromechanical tubular motor

drive. It performs parallel axial movements.

Commissioning of the VariEco S-K with elero installation

cable for comfortable setting.

5 Assembly

Observe the usual obligation to exercise care with technical

products to minimise other risks.

WARNING

Danger of injury from incorrect assembly

Important safety instructions.

►Observe all assembly instructions, since incorrect assem-

bly may cause severe injury.

CAUTION

Personal injury from hot surfaces.

Drive heats up during operation, the drive housing can be

hot. Possible burning of the skin.

►Wear personal protective equipment (gloves).

►Activation duration and standby times of the drives must

be observed.

Triggered by a possible material errors may occur or

impact shock and injury due to a gearbox break, bud break

or a clutch defect.

►Suitable materials are to be used for the construction as

well as perform a sampling inspection by double load test

according to DIN EN 60335-2-97.

Risk of injury due to impact or shock caused by not prop-

erly mounted or latched motor bearings. Hazards caused

by insufficient stability or stability and stored energy (grav-

ity).

►Selection of engine bearing torque specications.

►Drive must be backed up with all attached backup devic-

es.

►Check for proper latching on engine mounts and correct

tightening torques.

WARNING

Danger of injury due to electric current.

Electric shock possible.

►Electrical work can only be performed by an authorized

electrician.

Danger of injury due to electric current.

Hazardous possibly by parts that have become live in the

error state.

►Electrical connection is described in the operating and

installation instructions included cable bushing.

CAUTION

Risk of injury due to malfunctions due to improper installa-

tion.

Drive over-winds and possibly destroys parts of application.

►For safe operation, the end positions must be set / pro-

grammed.

►Training program of the manufacturer for specialist com-

panies.

NOTE

Loss of power supply, termination of machine parts and

other malfunctions.

►For safe operation, no false mount must be made and the

end position settings must be carried out during commis-

sioning.

Damage to the VariEco S-K due to moisture penetration.

►For devices with protection class IP44, the ends of all

cables or connectors must be protected against the

ingress of moisture. This measure must be implemented

immediately after removal of the VariEco from the original

packaging.

►The drive must be installed in a position in which it is not

sprinkled.

Damage to the application from incorrect assembly.

►Observe the notes in the documents of the manufacturers

of applications and the accessories used.

Important

For best interaction of drive and application, the end posi-

tions must be set at the drive after installation of the

VariEco S-K.

5.1 Mechanical fastening

Important preliminary consideration:

The working space around the built-in drive is usually very

small. Therefore, before the mechanical installation provide

an overview of the implementation of the electrical connec-

tion (see Section 5.2) and make any necessary changes

right away.

NOTE

Damage to the electrical wiring by squeezing or tensile

loading.

►Route all electrical cables so that they are not subjected

to crushing or tensile load.

►Note the bending radius of the connection lines (at least

50 mm).

►Lay the connection line in a loop downwards to prevent

water running into the drive.

Damage to the drive by the action of impact forces.

►Insert the drive into the shaft, never thrust the drive into

the shaft or smash onto the drive!

►Never allow the drive to fall!

Damage or destruction of the drive by drilling.

►Never drill into the drive!

Damage or destruction of the drive by setting the end posi-

tion to the mechanical stop.

►It is not permitted to adjust the end position to a mechan-

ical stop.

© elero GmbH EN | 3

Product description | Assembly

►The motor control must be interlocked in UP/DOWN

direction. A reversing delay of 0.5 seconds must be

ensured.

►Parallel switching of several VariEco S-K drives is only

possible with separating relay.

Damage to the application from incorrect running direction

►The assignment of the running direction UP/DOWN must

be reviewed after the electrical connection has been

established.

Adjustment of the end position at the drive.

►Any adjustment of the end positions that occurs indicates

an electrical connection error. Readjustment of the end

positions is not sufcient in this case, since the end

positions are adjusted often. In this case, the drive needs

to be replaced and the cause removed.

Important

Permanently installed control devices shall be clearly dis-

played.

Important

If the VariEco S-K is used in locations that are not "dry

rooms" (e.g. in the outdoor area, in wet rooms or if it is

excluded that the roller shutter boxes are reliably protected

from moisture by their construction or by roof protrusions

and similar things), the drive must be installed with connec-

tion lines suitable for the installation situation or the con-

nection lines must be protected by conduits. This also

applies to protection from direct solar irradiation.

All applicable standards and provisions must be observed

for the electrical installation.

When connecting the drive to a control, the operating

instructions of the control must be observed.

►Only perform connecting work with the power turned off.

5.3 Connection example VariEco 230 V / 50 Hz

Fig. 4 Circuit diagram VariEco S-K mit 230 V / 50 Hz

5.4 Commissioning

WARNING

Danger of injury from powered parts moving faster than

150 mm/s (application) at VariEco S1,5/70 speed 70

(1/min).

Crushing and striking dead of persons possible.

Standard DIN EN 60335-2-103, part 20.108, is the basis for

impact on an obstacle. It is recommended to limit the

forces by using a catching protection system with sensors

or by switches with off-presettings.

① ② ③ ④

230 V / 50 Hz AC

Junction box

(outside of roller shut-

ter case)

Switch box

1black

2brown

3blue

4green/yellow

4 | EN © elero GmbH

Assembly

Installation in prole tubes / installation in round

tubes

1 Insert drive with matching adapter and limit switch

tappet ring in the prole pipe.

1a Only when installing in the round tube:

On round tubes, cut a slot in the end of the tubes

on the drive side (width 4 mm, length 16 mm)!

1b Push the drive into the round tube and place it so

that the tappet wedge (the inner groove) ts into

the intended cut-out.

2Secure the counterpart support to prevent axial

movement, e.g. screw or rivet on the idler.

3Screw in the coupling (adapter) or rivet it (for round

tube only). Secure the drive in the motor-bearing

against axial movement,

4Attach the roller shutter to the shaft. If the applica-

tion can only be attached to a twisted winding shaft,

switch on the drive in direction downwards until the

drive switches off at the bottom end point (lower

end of the running path reached).

The drive is connected to the prole tube/round tube.

Installation in prole tube/round tube

B

A

C

1

4

2

3

The drive is connected to the prole tube/round tube.

5.2 Electrical connection

WARNING

Danger to life due to faulty electrical connection.

Electric shock possible.

►Before commissioning check the correct connection of

the PE conductor.

NOTES

Damage to the VariEco S-K by faulty electrical connection.

►Before commissioning check the correct connection of

the PE conductor.

Damage or destruction of VariEco S-K by the penetration of

moisture.

►For units with protection class IP 44, the customer con-

nection of the cable ends or connector (cable bushing)

must also be carried out in accordance with protection

class IP 44.

Damage or destruction of VariEco S-K for variants with 230

V AC 1 due to faulty control.

►Switch with OFF setting (Dead man) for drives must be

installed within sight of the VariEco S-K, but away from

any moving parts and amounting to about 1.5 m.

►The motor control must be interlocked in UP/DOWN

direction. A reversing delay of 0.5 seconds must be

ensured.

►Parallel switching of several VariEco S-K drives is only

possible with separating relay.

Damage to the application from incorrect running direction

►The assignment of the running direction UP/DOWN must

be reviewed after the electrical connection has been

established.

Adjustment of the end position at the drive.

►Any adjustment of the end positions that occurs indicates

an electrical connection error. Readjustment of the end

positions is not sufcient in this case, since the end

positions are adjusted often. In this case, the drive needs

to be replaced and the cause removed.

Important

Permanently installed control devices shall be clearly dis-

played.

Important

If the VariEco S-K is used in locations that are not "dry

rooms" (e.g. in the outdoor area, in wet rooms or if it is

excluded that the roller shutter boxes are reliably protected

from moisture by their construction or by roof protrusions

and similar things), the drive must be installed with connec-

tion lines suitable for the installation situation or the con-

nection lines must be protected by conduits. This also

applies to protection from direct solar irradiation.

All applicable standards and provisions must be observed

for the electrical installation.

When connecting the drive to a control, the operating

instructions of the control must be observed.

►Only perform connecting work with the power turned off.

5.3 Connection example VariEco 230 V / 50 Hz

Fig. 4 Circuit diagram VariEco S-K mit 230 V / 50 Hz

5.4 Commissioning

WARNING

Danger of injury from powered parts moving faster than

150 mm/s (application) at VariEco S1,5/70 speed 70

(1/min).

Crushing and striking dead of persons possible.

Standard DIN EN 60335-2-103, part 20.108, is the basis for

impact on an obstacle. It is recommended to limit the

forces by using a catching protection system with sensors

or by switches with off-presettings.

① ② ③ ④

230 V / 50 Hz AC

Junction box

(outside of roller shut-

ter case)

Switch box

1black

2brown

3blue

4green/yellow

►The speed of the driven part must be determined by the

operator depending on the diameter of the winding shaft .

►Always observed the product and safety documentation

of the application supplier.

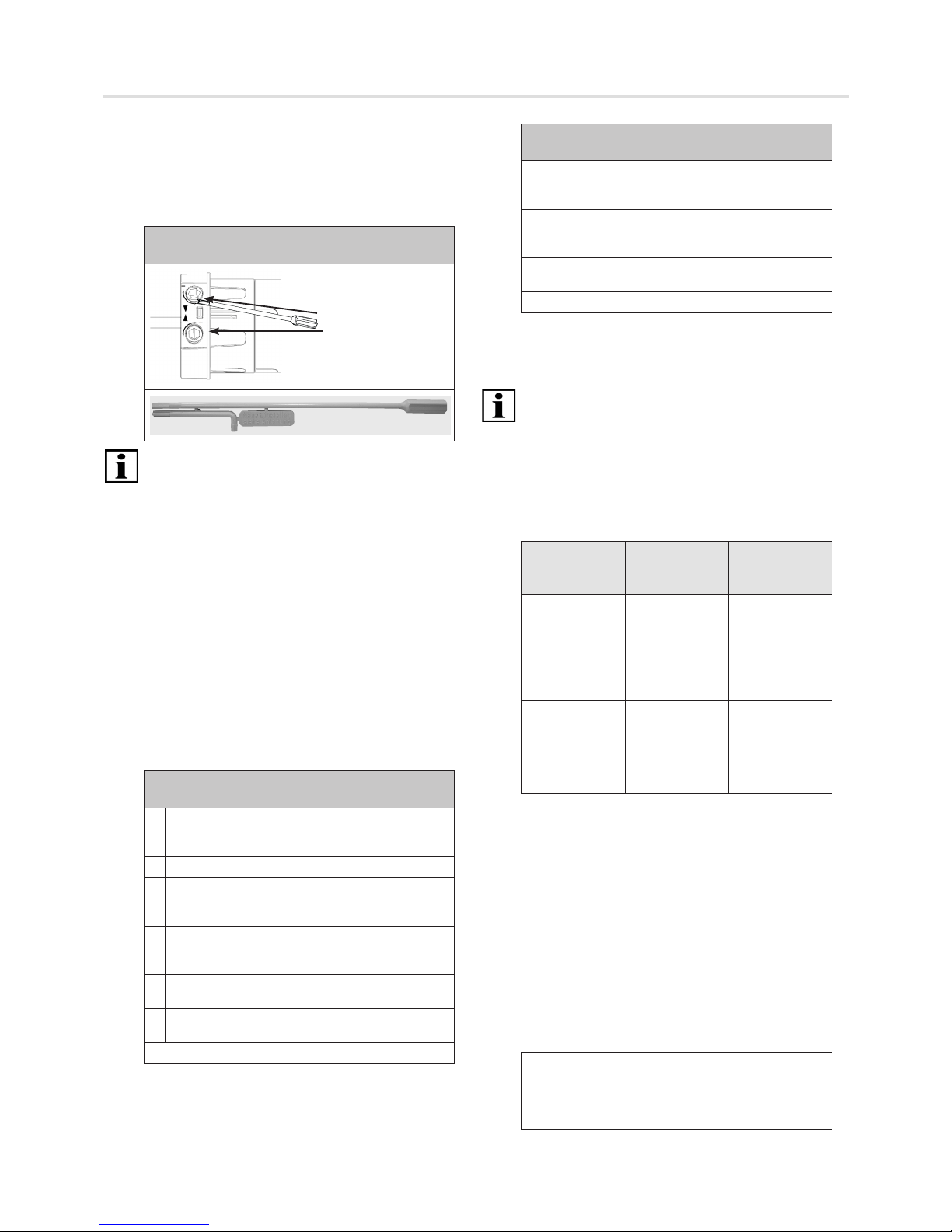

5.5 Setting the end positions

Limit switch: Setting screws

Actuate with setting aid (131163801)

To actuate the limit switch setting screws, use the setting

aid or a Phillips-tip or hexagon socket tool, but never a

power screwdriver.

►6 turns of one of the two limit switch settings crews "UP"

and "DOWN" cause 1 turn of the winding shaft (motor

shaft).

►The maximum limit switch range between the upper and

lower end positions is 32 turns of the motor shaft.

►The assignment of the upper or lower limit switch setting

screw to the upper or lower end position results from the

respective installation situation (right-hand or left-hand

installation) with the corresponding assignment of the

electrical connections for the running direction.

►Turn one limit switch setting screw

from - (minus) to + (plus) to increase the running path

of the application.

►Turn one limit switch setting screw

from + (plus) to - (minus) to reduce the running path

of the application.

Setting the upper end position

(general setting and ne adjustment)

1 Switch on the drive in direction downwards until the

drive switches off at the bottom end point (lower end

of the running path reached)..

2Attach the application to the winding shaft.

3Let the drive run up by pushing the UP button until

it switches off at the upper end point (for small win-

dows, stop rst by pushing the switch if necessary.

4Turn the limit switch setting screw "Top" in the +

(plus) direction or - (minus) direction until you have

reached the nal end position.

5Adjust the upper end position setting with enough

play.

6 Perform a test run and repeat ne adjustment if

necessary.

The upper end position has been set.

2 limit switch setting

screws with running

direction arrows

Adjusting tool

Setting the lower end position

(general setting and ne adjustment)

1 Switch on the drive in direction downwards until the

drive switches off at the bottom end point (lower end

of the running path reached)..

2Turn the limit switch setting screw "Bottom" in the +

(plus) direction or - (minus) direction until you have

reached the nal end position.

3Perform a test run and repeat ne adjustment if

necessary.

The lower end position has been set.

5.6 Checking the end positions

Allow the drive to run alternately in both directions until the

limit switch switches off.

The electrical deactivation at the top and bottom must be

reached before the end position of the mechanical running

path of the application has been reached.

Persistent running "against block" comes with the danger of

damage or destruction of the drive and/or application.

A change to a top or bottom end position is possible at any

time with the limit switch setting screws.

6 Troubleshooting

Problem /

Error

Possible

cause

Cure

Remedy

• The drive does

not switch off

via the limit

switch

• Drive not

responding

• Limit switch

ring is not

being driven

• Limit switch is

not adjusted

• Lock limit

switch ring

• Drive not

responding

• Wrong connec-

tion

• The thermostat

has triggered

• Readjust con-

nection

• Allow drive

to cool down

(minimum 15

minutes)

7 Maintenance

The VariEco S-K is maintenance-free.

8 Repair

If you have any questions, please refer to your specialised

company. Please always state the following information:

• Item number and item designation on the nameplate

• Error type

• Previous and unusual events

• Surrounding circumstances

• Own assumption

9 Manufacturer's address

elero GmbH

Antriebstechnik

Linsenhofer Str. 65

72660 Beuren

Deutschland / Germany

Phone: +49 7025 13-01

Fax: +49 7025 13-212

www.elero.com

Please visit our website if you require a contact outside

Germany.

© elero GmbH EN | 5

Mounting | Commissioning | End position setting | Repair

This manual suits for next models

2

Table of contents

Other elero Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual