eletor SC-12 User manual

SPEED CONTROL-12 v2a Instruction Manual

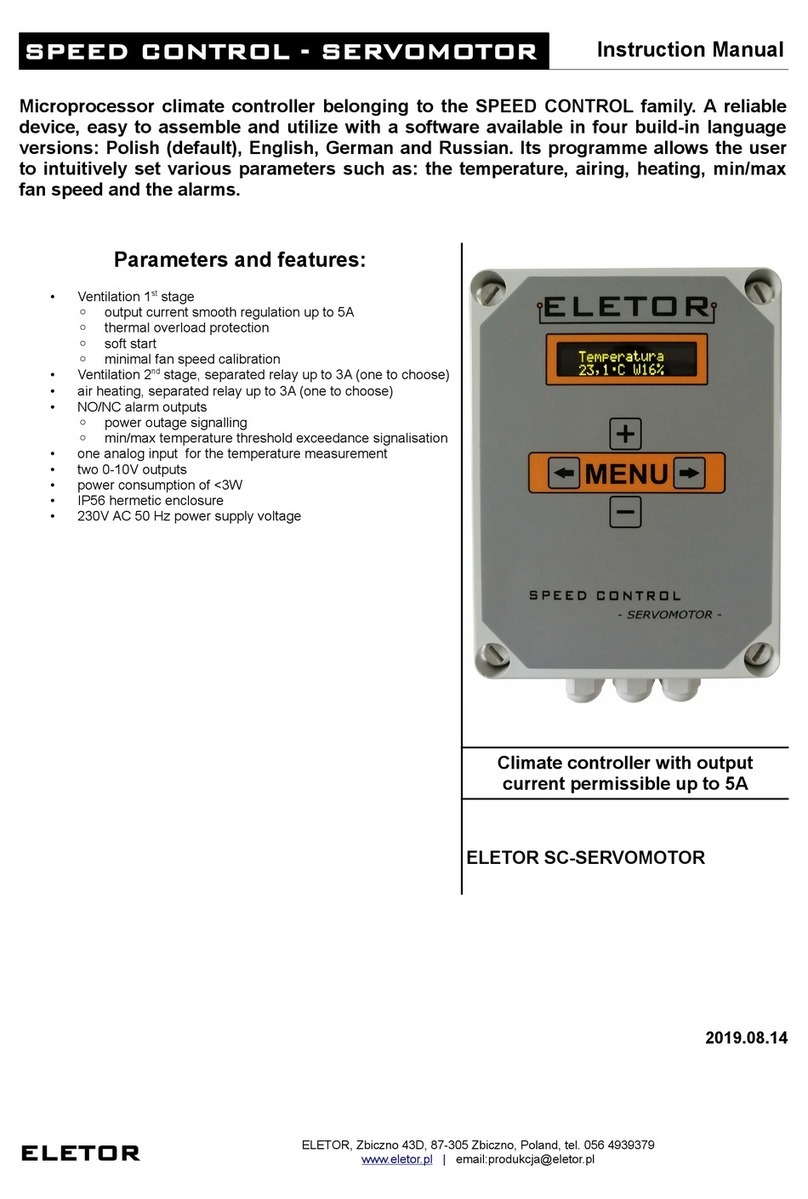

Microprocessor climate controller belonging to the SPEED CONTROL family The device

versatility is guaranteed by the variety of its inputs/outputs and the intuitive software that

is available in two languages: Polish and English Apart from some basic functions such

as: adjusting the temperature, heating, min/max fan speed and the alarms, the device

also allows to test and maintain calibration records of the actuators cooperating with the

controller

Parameters and features:

1. Ventilation 1st stage:

•output current smooth regulation up to the maximum of 12A

•thermal overload protection

•soft start function

•bypass relay full calibration

•minimal fan speed calibration

•energy saving programme with inlet flaps opened in advance

2. Ventilation 2nd stage, separated relay up to 6A:

. Heating, separated relay up to 6A

4. NO/NC alarm outputs:

•power outage signalisation

•max/min temperature threshold exceedance signalisation

•built-in acoustic alarm

5. Three independent 0-10V outputs:

•cooperation with the extension modules

•inlet flaps and chimney damper control

•variable-capacity heating control

6.Two analog inputs for the temperature measurement

7. Digital port for the temperature measurement (up to four sensors)

8. Two function-relay outputs (to choose):

•cooperation with linear actuators

•stage and stage 4 ventilations

9. Two analog 0-10V inputs

10. Potentiometer DC10V power supply

11. Additional DC12V power supply

12. PC cooperation up to 1200 m

1 . Power consumption of <10W

14. IP65 hermetic enclosure

15. Power supply voltage 2 0VAC 50Hz Climate controller with output

current permissible up to 12A

ELETOR SC-12

2019 08 16

ELETOR ELETOR, Zbiczno 4 D, 87- 05 Zbiczno, Poland tel. 056 49 9 79

www.eletor.pl | email:produkcja@eletor.pl

SPEED CONTROL-12 v2a Instruction Manual

Controller installation

Warning! While installing the device it must be cut off from any power supply, because the

voltage on some of the components is highly hazardous to your health and life. It is advised

to entrust a qualified and skilled personnel to carry out this installation.

Choosing a place for the installation

The place for the installation have to be chosen rationally, taking into account easy access to such

device for the persons concerned, and at the same time having a spot inaccessible for children or

animals. Climate conditions should be also concerned, which means that the device ought to work within

the temperature range from -10°C to 40 °C, in a place not exposed to direct sunlight. Free air flow

around the device is also essential. The temperature sensor is an integral part of the device. There are a

few rules to be followed in order to install such sensor:

•the sensor should not be installed in a place with no free air flow, or in a spot directly exposed to

sunlight

•the sensor should not be installed on the load-bearing wall of the building

•presence of nearby heat-emitting devices such as radiators or lamps should be avoided

•the sensor should not be placed directly by the door or ventilation holes

•the sensor should not be placed in spots accessible for animals

•it is advised to arrange the wire connected to the sensor away from the power cords

The installation

The device works in rough climate conditions. If properly installed, the controller and the sensor are both

resistant to the harmful influence of the environment.

Bear in mind the following comments while installing the device:

•the cover gasket should be checked before screwing

•the cover should be fully tightened by all the screws

•the wires used to connect the sensor should be round

•after connecting a wire, the cable gland should be tightened up in such a way to seal and

immobilize the wire, the use of silicone is advised

•unused cable glands should be closed (sealed)

•the controller (from its bottom part) should be attached on a flat wall using four rawlplugs

Plugging in

Warning! Be sure that the power supply is cut off before you plug in the device!

Before connecting the controller for the first time, the front panel should be unscrewed and then

removed. Depending on the work mode, the adequate number of holes for the cable glands should be

made (cut out from the bottom part). The wires should be inserted into the rubber cable glands and then

connected. The illustration below presents the arrangement of the connectors of this device.

ELETOR ELETOR, Zbiczno 4 D, 87- 05 Zbiczno, Poland tel. 056 49 9 79

www.eletor.pl | email:produkcja@eletor.pl

SPEED CONTROL-12 v2a Instruction Manual

Connector labelled as AC 230V should be connected to the power supply (switching station). Using the

circuit breaker 1P-B6 and overvoltage limiters of T1 and T2 type is obligatory. It is worth grouping the

controllers on different phases (L1,L2,L ) while connecting multiple devices, in order to equally load the

power line.

Connector labelled as FAN should be directly connected to the ventilator. In case of controlling multiple

ventilators the aggregated load cannot be higher than 12A. Every ventilator should be separately

secured. PE and N outputs should not be guided from the power supply (the switching station). Instead,

they ought to be connected to the connectors of the controller.

Connector labelled as FAN 2 may be used for connecting 2nd stage ventilators or the spraying systems.

The output is separated with max relay current of 6A (the circuit breaker 1P-B6 is required, when

controlling the load directly). The relay activates when the measured temperature is higher than the total

amount of value set previously by the user and the band ventilation value.

Connector labelled as HOT may be used to connect the heater. The output is separated with max relay

current of 6A (the circuit breaker 1P-B6 is required, when controlling the load directly). The relay

activates when the temperature drops below the value set by the user.

Connector labelled as ALARM – NC,C and NO outputs that should be connected to the alarm control

panel. The alarm activates automatically when:

•the temperature is too low or too high,

•the controller or the temperature sensor is damaged,

•the power blackout occurs,

•the controller malfunction occurs (e.g the device is overheated)

Connectors labelled as FUNC1 and FUNC2 help to connect the elevator to opening the air inlets using

the left/right motor. FUNC1 relay provides current for the servo motor, while FUNC2 relay switches the

direction of the motor rotation. The exemplary scheme of connecting the elevator is presented below -

(the circuit breaker 1P-B6 is required).

By deactivating the elevator function, FUNC1 and FUNC2 outputs work respectively as the relays of the

rd and 4th stage ventilation.

ELETOR ELETOR, Zbiczno 4 D, 87- 05 Zbiczno, Poland tel. 056 49 9 79

www.eletor.pl | email:produkcja@eletor.pl

SPEED CONTROL-12 v2a Instruction Manual

Connector labelled as 12V is intended to provide power for the external sensors.

Connector labelled as V1 0-10V is intended to connect the expansion modules. The voltage on this

connector is proportional to the level of ventilation.

Connector labelled as V2 0-10V is intended to connect the servo motor that opens the inlet flaps.

Connector labelled as V3 0-10V is intended to connect the smooth speed heating system. The voltage

of this output increases proportionally to the decrease in the temperature, starting from the heating temp.

value.

Connector labelled as 10V is intended to power the potentiometer of the elevator, or other 0-10V type

components.

Connector labelled as SENS1 (SENS2) should be connected to one TS- or TS-5 temperature sensor,

the polarity is not relevant. If connecting two sensors at the same time, the temperature measured

values are averaged. It is advised to arrange the test leads away from the power cords.

Connector labelled as 1-WIRE may be used to connect higher number of the digital temperature

sensors to the maximum of 4, connected in parallel (with the appropriate polarisation maintained). The

maximum length of the wire connecting the sensors is 150 m (the length of the wire has no influence on

the temperature measurement). Using the screened cable is advised.

Connector labelled as RS-485 may be used to build ventilation systems and for the PC communication.

Connector labelled as IN1 0-10 is intended to implement the feedback signal to the air inlets -

determining current inlets position.

Connector labelled as IN2 0-10 is intended to connect the controller with other sensors, e.g. the humidity

or CO2 sensors or the sensor working as the power extending module.

Working principle

The primary function of the controller is to maintain the temperature in the breeding room at the level set

by the breeder. Please note that the controller is only a tool that helps to provide the optimal climate

conditions in the room. The breeder plays the main role in the whole process by adjusting the settings on

the device based on current weather conditions outside the building, as well as (and most importantly)

based on the observation of the behaviour of all animals. The user should also monitor the device work

status using the alarm control panel.

First controller start-up

aution! While starting the sensor up for the first time the settings of the minimal

fan speed must be adjusted immediately.

The sensor cooperates with the ventilators equipped with the single-phase induction motor, capacitor

start-up and the maximum current consumption of 12A. After the attachment of a given ventilator, the

user has to adapt it to the cooperation with the controller. In other words, it is necessary to set the

minimal fan speed. Such function is similarly called “Minimal speed” and it can be set after entering

ELETOR ELETOR, Zbiczno 4 D, 87- 05 Zbiczno, Poland tel. 056 49 9 79

www.eletor.pl | email:produkcja@eletor.pl

SPEED CONTROL-12 v2a Instruction Manual

“Advanced setup” option. To perform such action properly, it is advised to cooperate with another person,

who can set the value of “Minimal speed” (the default value is 0μs). Not having this setting adjusted, the

device may not work properly.

The value of “Minimal speed” may be considered as valid ,as soon as the flaps of the ventilation stack

start to lift slightly.

If a new ventilator is being attached to the controller, the whole activity of setting the “Minimal speed” has

to be repeated.

Periodical airing

Airing is one of the functions performed by the controller, which activates when the temperature in the

room drops below the temperature value set by the user. Such function guarantees a constant air

circulation inside the breeding room to provide a regular air supply for the animals, at the same time

extracting already used air. There are three parameters available in the airing mode:

•“Time airing” - indicates the time duration of the activated ventilator (in minutes)

•“Break time” - determines the amount of time during which the ventilator is not working

•“Airing level” - indicates the power value of the ventilator in “Time airing”

All of the parameters above can be set by the user. However, there are some rules to be remembered

while adjusting the values in the airing process:

•airing is turned on only when the temperature in the piggery drops below the value previously set

by the user,

•the primary function of airing is to provide a constant fresh air supply for the animals, and not

maintaining the temperature that had been set in the room,

•airing the room frequently for short periods is strongly recommended,

•longer airing periods should be avoided, because they can lead to major temperature variations,

•the parameters must be adjusted properly according to the behaviour of animals in the breeding

room and all the conditions that occur not only inside, but also outside of the building.

Device working scheme

The controller smoothly regulates the ventilation

from “Min 1” to “Max1” within the range of

“Setting temp.” and “Airing band 1”. “Vent 2nd

stage” will be active above that range and “Level

min. 1” will immediately change to “Level min. 2”.

As the temperature continues to grow, it will

change to “Level max. 2” at the end of “Airing

band 2” range. If “Airing band 2: equals “0”, but

“Level max.1” is enabled, “Vent. 2nd stage” will be

activated, causing further increases in the

temperature to have no effect on changes in the

ventilation process (dotted part of the graph). In

the case of the temperature in the room dropping

below the “Setting temp.”, the controller turns on

the airing process periodically and if it continues to drop, heating is additionally activated. Every action is

based on the adjustments that the user had implemented before. When the temperature in the piggery

has different parameters than those set by the user, the programme of the controller may connect with

the alarm control panel and activate the alarm.

ELETOR ELETOR, Zbiczno 4 D, 87- 05 Zbiczno, Poland tel. 056 49 9 79

www.eletor.pl | email:produkcja@eletor.pl

SPEED CONTROL-12 v2a Instruction Manual

Controller programming

The controller has a built-in set of default settings entered to the non-volatile device memory in two

cases:

•during the first device start-up

•when the memory data error occurs

In case of the power outage, the controller is not losing any of the settings that had been adjusted earlier

by the user.

Front panel – indicator lights, buttons and the display

1. Red indicator light signalling that the maximal permitted temperature threshold had been

exceeded.

2. Red indicator light signalling that the

minimal permitted temperature threshold

had been exceeded.

. Yellow indicator light signalling the

process of heating.

4. Yellow indicator light signalling “Vent. 2nd

stage”.

5. Green indicator light signalling manual

ventilation level adjustment.

6. Green indicator light signalling the work of RS485 communication.

7. Display menu in normal work mode showing the temperature on the screen

8. Bargraph signalling the level of the Ventilation

9. “up” menu button or the value change button

10. ESC button – exiting the menu or the given parameter without saving its value

11. OK button – entering the menu or confirming (saving) the given parameter value

12. “down” Menu button or the value change button

sing the menu (setup)

Rich in a wild range of functions, the controller allows to adjust the settings to the specific circumstances.

After entering the menu (by pressing one those buttons “+”, “-” or “OK”), access to the grouped functions

section is granted. Pressing “+” or “-” button allow to choose one of the functions, editing, saving or

entering further function options may be triggered by pressing “OK” button. To go back to the main menu

or cancel the adjustment of the given value “Esc” button should be pressed.

Main menu (setup) functions

MENU PARAMETR OPIS

Setting temp Setting temp.

20.0o C Displays the temperature value from which the smooth ventilation process

will start. This parameter should be based on the type of animals inside the

breeding room.

Airing time Active time

0 min Indicates the length of the airing process (in minutes).

Break time

5 min Indicates the length of the breaks between the airing process work cycles

(in minutes).

Airing level

30 % Indicates the power of the ventilation during the airing process (in

percentage).

ELETOR ELETOR, Zbiczno 4 D, 87- 05 Zbiczno, Poland tel. 056 49 9 79

www.eletor.pl | email:produkcja@eletor.pl

SPEED CONTROL-12 v2a Instruction Manual

Alarm Active alarm

YES The Alarm relay activation/deactivation. Press “NO” to block the connector

from transmitting the alarm input signal ( to the alarm control panel).

Min. alarm

15.0o C Indicates the minimal absolute temperature value signalling the alarm

activation.

Max. alarm

25.0o C Indicates the maximal absolute temperature value signalling the alarm

activation.

Alarm signal

YES Activation/deactivation of the acoustic signal inside the controller.

Airing Airing Ban 1

5.0o C Indicates the reaction time of the controller (the change of the ventilation

level from min 1 to max 1) on the growing temperature.

Level min. 1

1 % Indicates the ventilation level corresponding to the setting temperature.

Level max. 1

100 % Indicates the constant ventilation level for the temperature exceeding the

range of smooth regulation, when “Airing Band 2” = 0. Otherwise the

maximum regulated ventilation level for the temperature will be the sum of

the Setting temperature and the Airing Band 1.

Airing Ban 2

0.0o C Indicates the reaction time of the controller (the change of the ventilation

level from min 2 to max 2) on the growing temperature of the 2nd stage. The

function is not active when the band value equals 0.

Level min. 2

1 % Indicates the minimal level of the 1st ventilation stage, at the moment when

the ventilation 2nd stage relays are activated.

Level max. 2

100 % Indicates the constant ventilation level for the temperature exceeding the

smooth regulation range when the ventilation 2nd stage is active.

Stage 3

5.0o C Indicates the current temperature of the stage based on the setting temp.

(the elevator function must be deactivated).

Stage 4

7.0o C Indicates the current temperature of the stage 4 based on the setting temp.

(the elevator function must be deactivated).

Heating Heating temp.

15.0o C Indicates the temperature threshold at which the heating process is

activated.

Heating Ban

5.0o C Indicates the proportion of the heating systems (on 0-10V V output) in

accordance to the current temperature.

Advanced menu (setup) functions

Menu intended mainly for the installers, that allows to adapt the controller to the ventilator and the

installation process, test the circuits or choose the menu language.

MENU PARAMETER DESCRIPTION

Testing This function allows to check the specific controller circuits. All of the

settings in this mode are temporary, until cancelling the menu. After pressing

the OK or ESC button, every parameter will change back to its previously set

value.

Airing

0 % Allows to adjust the ventilation level manually, in order to check the

ventilation system. After confirming the function, the green indicator light

(hand shape) should light up.

Alarm

No The activation lights up two red indicator lights, activates the sound signal

and the alarm circuit.

Heating

No The activation lights up the yellow indicator light (the flame shape) and

activates the heating circuit.

Stage 2

No The activation lights up the yellow indicator light (the ventilator) and activates

the 2nd stage circuit.

Output V1

0.0 V Testing the 0-10V outputs. By pressing “+” and “-” buttons it is possible to

adjust the voltage value on: the expansion modules, inlet flaps and smooth

heating. This function is especially useful during the calibration of inlet flaps

ELETOR ELETOR, Zbiczno 4 D, 87- 05 Zbiczno, Poland tel. 056 49 9 79

www.eletor.pl | email:produkcja@eletor.pl

SPEED CONTROL-12 v2a Instruction Manual

Output V2

0.0 V V2 output.

Output V3

0.0 V

Elevator

0 Allows to check the inlet flaps system “+” button opens the inlets, while “-”

button closes them. The display shows a current actuator position measured

by the potentiometer.

Stage 3

No The activation enables the Stage ventilation circuit to start (the elevator

function must be deactivated).

Stage 4

No The activation enables the Stage 4 ventilation circuit to start (the elevator

function must be deactivated).

Language English Choosing the language of the menu. Currently there are two options

available: Polish or English.

Fan Minimal spee

0 The calibration of the minimal fan speed directly attached to the controller.

The parameter determines the level of ventilation of “1%”. The positive value

of this parameter increases the fan speed, while the negative value

decreases that speed.

Min. exten

1.9 V Minimal voltage supplied to the power extending module (0-10V V1 output).

Max. exten

10.0 V Maximum voltage supplied to the power extending module (0-10V V1

output).

Cut exten

No Cutting off the power extending module. When selecting “Yes”, the (V1 0-

10V) output voltage of the control extending modules will drop to 0V and not

to to the minimal set value - when the ventilation level reaches 0%.

Inversion

No The activation triggers the inversion of the V1 output characteristics. The

voltage value will be dropping, as the ventilation level in min-max range

increases. The signal on the V1 output during the inversion is 10-0V.

Flaps Offset

0.0o C Early inlet flaps opening. The adjusted value determines the temperature

before the “Setting temp, at which the inlet flaps will open.

Closure

No The activation results in the (V2 0-10V) output voltage value of the inlet flaps

dropping to level of 0V and not to the minimal set value - in case of no

ventilation = ventilation level 0%.

Flaps min.

1.9 V Minimal voltage supplied to the inlet flaps (0-10V V2 output).

Flaps max.

10.0 V Maximum voltage supplied to the inlet flaps (0-10V V2 output).

Inversion

No The activation triggers the inversion of the V2 output characteristics. The

voltage value will be dropping, as the ventilation level in min-max range

increases. The signal on the V2 output during the inversion is 0-10V.

Measurements T Calibration S1

23.0o C -> 23.5o CThe calibration for the the analog inputs, allowing to rescale the temperature

measured from S1 and S2 sensors.

Calibration S2

23.0o C -> 23.2o C

Averaging time

60 s This parameter indicates the period, during which the temperature

measurement values are being averaged. The value of the averaged

temperature is the primary parameter of this controller function. The changes

of outputs statuses (airing, heating, inlets, ventilation stages and alarms), are

strictly connected with this parameter and cannot occur more often than

within the time adjusted in this option.

Elevator Calibration Ope

1024 -> 853 The calibration of the elevator is vital for the proper inlet flaps system work.

The “+” button opens the inlets, the “-” button closes the inlets. While

opening the inlets, the position parameter should grow and drop while

closing them – if not, verify the connection of the actuator (power supply and

the potentiometer). In “Calibration Ope” the inlets should be opened to the

maximum and then the parameter should be confirmed by pressing the “OK”

button. In “Calibration Clo” the inlets should be closed and then the

Calibration Clo

0 -> 324

ELETOR ELETOR, Zbiczno 4 D, 87- 05 Zbiczno, Poland tel. 056 49 9 79

www.eletor.pl | email:produkcja@eletor.pl

SPEED CONTROL-12 v2a Instruction Manual

parameter should be confirmed by pressing the “OK” button. The “ESC”

button allows to cancel the function mode without saving. Różnica między

The difference between the values of these two positions should be of at

least 100 units.

Deactivation

No The deactivation option cuts off the elevator from the FUNC1 and FUNC2

relays, at the same time changing their functions to the ventilation of Stage

and 4.

Soft Start All the parameters on this group are responsible for the ventilation start-up.

The start of the ventilation in the smooth group is always preceded by the

smooth fan movement up to 100%, working on that level for some time and

then dropping to the ventilation level that had been previously set. Such

action creates the blow while this process begins, allowing the butterfly

valves to open. The values are presented in the power supply voltage

periods on the ventilation of 1%.

Start time

5 A parameter indicating the speed of the ventilation level changes from zero

to maximum – smooth fans start-up. Setting the value to 0, turns the smooth

start-up off.

100% time

100 A parameter indicating the starting work time of the ventilation level on

100%. Adjusting the start-time and changing the value from 100 to 0, turns

off the blows completely during the ventilation start.

Stop time

5 A parameter indicating the speed of the ventilation level changes.

Heating Inversion relay

No The activation triggers the inversion of HOT output characteristics. The relay

will be opened wider, as the measured temperature value drops.

Hysteresis

0.5o C Indicates the level of the temperature hysteresis for the heating relay.

Relative work

No The activation triggers the relative heating temperature adjustment against

the temperature set previously. Basic heating menu is changed, showing the

differences from the setting temp.

Heating min.

1.9 V Minimum voltage of the smooth heating system – the heater with variable fan

efficiency ( V 0-10V output).

Heating max.

10.0 V Maximum voltage of the smooth heating system – the heater with variable

fan efficiency ( V 0-10V input).

Software ver. 2.4

Apr 13 2018 Information about the software version and the date of its compilation.

Error messages and warnings

Error messages inform the user about the potential malfunctions of the device. Possible error messages

that may appear on the screen are listed below:

ERROR DESCRIPTION

Cut of power The overload alarm, activating at 75°C. The device stops working until it cools

down.

Sensor failure Signals that the sensor is not connected to the device or that the

sensor/connecting cable is damaged.

ELETOR ELETOR, Zbiczno 4 D, 87- 05 Zbiczno, Poland tel. 056 49 9 79

www.eletor.pl | email:produkcja@eletor.pl

SPEED CONTROL-12 v2a Instruction Manual

Comments and warnings

Caution! While installing the device it must be cut off from any power supply,

because the voltage on some of the components is highly hazardous to health and

life. It is advised to entrust a qualified and skilled personnel to carry out this

installation.

To avoid problems with the utilisation of the device it is necessary to familiarise with the Instruction

Manual before installation and further usage. The user should not interfere with the device construction

or perform any repairs. This applies in particular to modifying various elements or components.

Maintenance and service works should be only performed by the authorised staff (the installer or the

authorised service). The controller requires proper adjustments of the parameters in accordance with the

conditions that occur inside the breeding room. Such adjustments are the matter of breeder’s choice.

The alarm system is required in rooms with artificial ventilation. The producer of this product is not

responsible for the damage/losses caused by the abnormal installation, improper programming of the

functions, repercussions of random events, or other external factors.

The producer reserves all the rights to modification of the construction, or software of the device.

The product should not be thrown away with unsorted municipal waste after being

used for the last time Instead, it should be reprocessed in accordance with current

requirements ( EU Commission WEEE directive 2012/19/EU)

The product was manufactured in compliance with RoHS EU directive (also known as Directive

2011/65/EU).

ELETOR ELETOR, Zbiczno 4 D, 87- 05 Zbiczno, Poland tel. 056 49 9 79

www.eletor.pl | email:produkcja@eletor.pl

SPEED CONTROL-12 v2a Instruction Manual

Technical data

Power supply voltage 2 0VAC 50Hz

Max FAN power output 12A

Range of operating output voltage 70V ÷ 2 0V

Max FAN 2 (relay) output current 6A

Max HOT (relay) output current 6A

Max ALARM (relay) output current 4A

Max FUNC1 and FUNC2 (relay) outputs current 4A

Operating temperature range -10 +40oC

Temperature measurement range 0 +50oC

Temperature measurement resolution 0,1oC

Temperature sensor damage detection YES

Maximum number of analog sensors 2

Temperature measurement accuracy – analog input 1oC

Dependence of wire resistance on the measurement – analog input 15.8Ω/oC

Maximum number of digital sensors 4

Temperature measurement accuracy – digital input 0.5oC

Dependence of wire resistance on the measurement – digital input none

Max wire length connecting digital sensors 150m

Surge protection (max E) 210J

Overload protection 75oC

Dimensions 4x29x12 [cm]

Enclosure class IP65

The controller SPEED CONTROL-12 v2 comes with:

•one temperature sensor

•four rawlplugs

•two PG1 .5 cable glands

•three PG11 cable glands

•four PG9 cable glands

ELETOR ELETOR, Zbiczno 4 D, 87- 05 Zbiczno, Poland tel. 056 49 9 79

www.eletor.pl | email:produkcja@eletor.pl

Table of contents

Other eletor Controllers manuals