Elettrotest HPS/P/200K User manual

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 2

CPS/M Models covered in this manual:

Model

Code

HPS/P/200kVA

99116963

This manual is written from HPS/P firmware version TPSX 09_.

Please check the latest manual version at www.elettrotestspa.it

To consult older manual versions, please contact our support at

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 3

Document list:

This manual is completed by a list of documents, useful to understand all the features of your

HPS/P.

Scan the QR-code or click on the link to directly download the documents.

Documents

Description

Link

QR-code

User Manual

Latest manual version

Manual

Brochure

Brochure for all the TPS-HPS-CPS models

Brochure

TPS Parameters

Describes all the machine modifiable

parameters and the start-up sequence.

TPS

Parameters

TPS protocol

Elettrotest

Describes how the Elettrotest remote

communication protocol works.

Elettrotest

Protocol

TPS protocol

SCPI

Describes how the SCPI remote

communication protocol works with your

HPS/P.

SCPI

Protocol

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 5

Elettrotest Spa

P,zza R.Riello 20/B

45021 Badia Polesine (RO)

Italy

+39 042553567

www.elettrotestspa.it

After sale support

Thank you for purchasing the HPS generator.

HPS is a high-performance variable voltage generator (amplitude and frequency) in order to

simulate and electrical line for test for different application (laboratory, test line, production line)

Responsability:

Elettrotest disclaims any responsibility for damage to people or things

caused by an improper use of its products.

Mandatory

-Verify voltage, power and frequency compatibility between HPS range and electrical

specification of equipment under test (EUT).

-Electrical components of the system must be suitable for the rated voltage and current of

HPS model (paragraph 1.2)

-The electrical components, which by construction cannot support external influences (of

the generator in all its range), can only be used on condition that adequate additional

protection has been provided with automatic disconnection protection.

Notes:

This manual lists precautions and information about operating procedure of device.

The content of this manual is subject to change without prior notice because of continuing

improvements on the instrument’s

Should you have any questions or find any error please contact us by email.

Copying or reproducing all or any part of the contents of this document is strictly

prohibited, without Elettrotest permission

Version:

This manual is written for HPS/P/200kVA firmware version TPSX 09_ and higher

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 6

SAFETY WARNINGS

The manufacturer urges users to read the user manual for our products before installation.

The installation must be carried out by qualified technical staff. The non-observance of the

warnings in this manual can cause electric shocks, even fatal ones.

Please find below some general safety warnings.

•This equipment must be connected to the mains supply using the appropriate safety

devices. Please consult the relevant paragraph 3, in this manual.

•HPS must be connected to safety ground through the correct connections. The non-

observance or the degradation of this earth connection can lead to electric shocks, even

fatal ones. As regards the correct connection modes, please refer to the information

contained in paragraph 3.

•Disconnect HPS from the mains before any work on the equipment and on the connected

power loads.

•Before touching the load or the output connector make sure that the power supply on the

device has been disconnected for at least 5 minutes. This is the time necessary in order for

the capacitors inside the device to discharge. The non-observance of this discharge time

can lead to electric shocks, even fatal ones.

•Avoid heavy shocks to the equipment (especially during transport) or exposure to extreme

weather conditions.

•Any damage to the product due to transportation, incorrect installation or improper use is

not covered by the guarantee supplied by the manufacturer.

•Do not use the equipment in explosive environments or in the presence of dust, acids or

corrosive and/or inflammable gases.

•Tampering with or dismantling any component in the equipment will void the warranty

automatically.

•Do not operate or store under conditions where condensing may occur or where

conductive debris may enter in the case.

The manufacturer declines all responsibility for damage to people or things caused

by an improper use of its products.

ELECTRIC RISK

There are dangerous voltages inside HPS and over the output connector.

The non-observance of the warnings suggest in this manual can lead to electric

shocks, even fatal ones.

OVERHEATING RISK

In the case of a ventilation system failure, the metal parts of the inverter may reach

high temperatures (in some cases higher than 70°C).

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 7

DISPOSAL

INFORMATION FOR USERS ON THE CORRECT HANDLING OF WASTE

ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE)

In reference to European Union directive 2012/19/EU issued on 24 July 2012 and the related

national legislation, please note that:

•WEEE cannot be disposed of as municipal waste and such waste must be collected and

disposed of separately;

•the public or private waste collection systems defined by local legislation must be used. In

addition, the equipment can be returned to the manufacturer at the end of its working life

when buying new equipment;

•the equipment may contain hazardous substances: the improper use or incorrect disposal

of such may have negative effects on human health and on the environment;

•the symbol (crossed-out wheeled bin) shown on the product or on the packaging and on

the instruction sheet indicates that the equipment must be disposed of separately;

•in the event of illegal disposal of electrical and electronic waste, the penalties are specified

by local waste disposal legislation.

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 8

INDEX

1. INTRODUCTION..........................................................................................................................10

1.1. MAIN FEATURES ..................................................................................................................10

1.1.1. Output Voltage.............................................................................................................10

1.1.2. Output frequency.........................................................................................................10

1.1.3. User interface...............................................................................................................10

1.1.4. General performances .................................................................................................11

1.1.5. General specifications..................................................................................................11

1.2. MODELS...............................................................................................................................12

1.3. MAXIMUM OUTPUT CURRENT............................................................................................12

2. NOTES FOR USERS......................................................................................................................13

2.1. SWITCHING ON....................................................................................................................13

2.2. PARAMETERS PROGRAMMING MODE................................................................................13

2.3. VOLTAGE MENU ..................................................................................................................13

2.3.1. SETTING VOLTAGE........................................................................................................14

2.4. RANGE SETTING...................................................................................................................14

2.5. VOLTAGE VISUALIZZATION..................................................................................................15

2.6. FREQUENCY MENU..............................................................................................................15

2.6.1. SETTING FREQUENCY ...................................................................................................16

2.6.2. FREQUENCY REFERENCE SETTING ...............................................................................16

2.7. MODE MENU.......................................................................................................................16

2.7.1. VOLTAGE REACTION.....................................................................................................17

2.7.2. TYPE OF OUTPUT..........................................................................................................17

2.7.3. CONTINOUS OR INRUSH MODE...................................................................................17

2.8. ALARMS ...............................................................................................................................17

2.8.1. SUPPLY ALARMS...........................................................................................................17

2.8.2. SYSTEM ALARMS..........................................................................................................18

2.8.3. CURRENT ALARM .........................................................................................................18

2.8.4. VOLTAGE ALARM .........................................................................................................18

2.9. PARALLEL OPTION ...............................................................................................................18

2.9.1. TURN ON ......................................................................................................................18

2.9.2. CHANGE CONFIGURATION MASTER AND SLAVE.........................................................19

2.9.3. TURN OFF .....................................................................................................................19

3. INSTALLATION............................................................................................................................20

3.1. GENERAL NOTES..................................................................................................................20

3.1.1. POWER CABLING..........................................................................................................20

3.1.2. SIGNAL CABLING ..........................................................................................................21

3.2. FUSES...................................................................................................................................22

3.3. RCD PROTECTION ................................................................................................................22

3.4. MAGNETO-THERMAL PROTECTION ....................................................................................22

3.5. WIRING DIAGRAM...............................................................................................................22

3.5.1. PROTECTION DEVICE....................................................................................................22

3.5.2. Wiring single/three phase diagram of 2 wire configuration .......................................23

3.5.3. Wiring single/three phase diagram of 4 wire configuration .......................................24

3.5.4. Wiring diagram three phase of 2 wire configuration ..................................................25

3.5.5. Wiring diagram three phase of 4 wire configuration ..................................................26

3.5.6. Wiring diagram three phase of 2 wire configuration (MASTER/SLAVE)......................27

3.5.7. Wiring diagram three phase of 4 wire configuration (MASTER/SLAVE)......................28

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 9

4. REMOTE CONTROL.....................................................................................................................29

4.1. SERIAL REMOTE CONTROL ..................................................................................................29

4.1.1. Control software ..........................................................................................................29

4.1.2. Serial cable ...................................................................................................................29

4.2. EXISTENCE TABLE.................................................................................................................29

5. TECHNICAL SPECIFICATIONS ......................................................................................................30

5.1. DATA SHEET.........................................................................................................................30

5.2. MECHANICAL DRAWINGS....................................................................................................31

5.2.1. HPS/T/200K..................................................................................................................31

5.3. DIAGRAM.............................................................................................................................32

5.3.1. MAXIMUM OUTPUT VOLTAGE VS FREQUENCY...........................................................32

5.3.2. INRUSH CURRENT VS TIME ..........................................................................................32

5.4. Internal fuses.......................................................................................................................33

5.4.1. 99116963 HPS200K......................................................................................................33

5.5. Accessory.............................................................................................................................33

5.5.1. 99116963 HPS200K......................................................................................................33

6. SERVICE AND MAINTENANCE ....................................................................................................34

6.1. MAINTENANCE / CLEANING................................................................................................34

6.1.1. Scheduled maintenance...............................................................................................34

6.2. ALARMS DIAGNOSIS AND REPAIRS .....................................................................................34

6.3. BASIC TROUBLESHOOTING..................................................................................................35

6.3.1. Overvoltage / Undervoltage alarms.............................................................................35

6.3.2. Overtemperature.........................................................................................................35

6.3.3. Inverter Alarm..............................................................................................................36

6.3.4. Max DV OUT alarm.......................................................................................................36

6.3.5. Limit IOUT alarm ..........................................................................................................36

7. GUARANTEE ...............................................................................................................................37

8. REVISION INDEX .........................................................................................................................37

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 10

1. INTRODUCTION

HPS is a power source that supplies a sinusoidal and stable voltage. Its output voltage is adjustable

in frequency and amplitude.

1.1. MAIN FEATURES

1.1.1.Output Voltage

The output voltage is guaranteed perfectly sinusoidal, with a distortion of less than 0.6%

regardless of the load. The value of output voltage is kept perfectly stable within 0.1% with linear

load and a full load.

The load that HPS is able to drive can vary from a pure capacity to a pure inductance.

The output voltage is adjustable with continuity from zero to full scale.

Furthermore, HPS is capable to keep the voltage stable with time variable loads, as for example

the pulsating loads. In fact HPS recovers the distortion of the waveform within 0.1% and the

amplitude of the voltage within 0.6% in less than half period.

HPS can in fact provide the nominal power at various full scales and this allows the HPS to adapt

himself to the disparate needs of the user, without having heavy limitations on the output current.

The HPS has only a three phase output, but It is able to supply a single phase load, in this case the

maximum power is 1/3 respect to the nominal power

Furthermore HPS is capable to keep the voltage stable also with time variable loads, as for

example the pulsating loads. In fact HPS recovers the distortion of the waveform within 0.6 % with

linear load and the amplitude of the voltage within 0.1% in less than half period.

Furthermore, HPS can bear a short circuit for an indefinite time without suffering any

consequence.

1.1.2.Output frequency

HPS allows the regulation of the output frequency from 50 to 80Hz at maximum voltage.

This output frequency can be regulated with continuity within the above mentioned range of

frequencies and it has a stability of 0.01% with respect to the set frequency.

HPS also allows to synchronize the output frequency with the frequency of the supply line; this

synchronization is obtained both in frequency with line.

This allows a completely synchronous output, with a zero phase error regard to the supply line,

but with a completely insulated output and with a far superior voltage stability.

1.1.3.User interface

HPS is intended to have an user friendly interface. It is also featured the possibility of an host

computer control, thus allowing to perform tests automatically. HPS allows various usage

selections: working range, wires drop compensation, working frequency, syncronization of the

output frequency with the power line. Furthermore, HPS gives the user clear information on the

status of the output. It is monitored both the set voltage and the set frequency and the output

voltage is read with a precision of 0.3%. The user is also warned in case of over current obtainable

by the HPS, or in case of high loss in the wires, that should not exceed 10% of the set voltage.

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 11

We underline again that HPS automatically limits the maximum allowed current, avoiding damages

to the equipment; the only consequence is that, in this case, it is not guaranteed the precision of

the output waveform neither the accuracy of the output voltage.

The user can set the output voltage through the numeric keyboard, or he can continuously vary

the voltage through specific keys. The same possibility is valid for the setting of the frequency.

The above possibility makes the HPS very flexible in those applications where it is requested a

continuous variation of the two regulated magnitudes, around a given values.

1.1.4.General performances

All the following features are valid within the range of the normal operating limits; they are not

valid during the limitation of the output current.

(1) With linear load.

f.s. stands for Full Scale

s.v. stands for Set Value

1.1.5.General specifications

The voltage is referred phase to neutral, with neutral connected to the earth

PARAMETER

VALUE

Output frequency range (1) (2)

50Hz - 80Hz

Range of synchronization

45Hz - 65Hz

Phase resolution

0.088°(12 bit su 360°)

Frequency resolution

0.02Hz

Frequency precision and time stability

100ppm

Output voltage

300V, 150V

Output voltage resolution

0.025% f.s. (12 bit f.s.)

Operating temperature

0°C - 35°C

(1) Frequency can be increased up to 320 Hz at lower performance than the nominal.

(2) Under 50Hz there is derating of maximum voltage

PARAMETER

VALUE

Distortion of the output waveform (1)

<0.6%

Stability of the output voltage

<0.1% f.s.

Accuracy of the output voltage

<0.5% f.s.

Recovery-time of the output waveform

<200us

Maximum compensated drop on wires

10% s.v.

Recovery time of RMS

<200ms

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 12

1.2. MODELS

The following tables show all the characteristics of both types.

1.3. MAXIMUM OUTPUT CURRENT

Notes:

Output current is continuous RMS current in a linear load, crest factor of output current is 1.41.

To obtain the Peak current, you must multiply the indicated value for 1,41. If you have not linear

load with crest factor bigger than 1.41, the maximum RMS output decrease.

For three phase configurations, all specifications are for L-N. Phase angle specifications are valid

under balanced load conditions only.

MODELS

NOMINAL

OUTPUT

POWER

SUPPLY

VOLTAGE

WEIGHT

INPUT

CURRENT

INPUT

POWER

DIMENSIONS

A, L, P mm

HPS/P 200K

200KVA

400Vac ±10%

3PH

1800 Kg

500A max

230KW

1800 : 1600 : 1000

99116963 HPS 200K 120K360S

Configuration

INRUSH FOR 3 SEC

COUNTINOUS

COUNTINOUS

LOAD

L-N

L-L

Range

300

519

3-PHASE

433.4

A

164.2

A

255.6

A

INDUT.

300

519

3-PHASE

405.5

A

134.5

A

227.0

A

RESIST.

300

519

3-PHASE

379.4

A

110.1

A

201.6

A

CAPAC.

150

259.5

3-PHASE

866.8

A

328.4

A

511.2

A

INDUT.

150

259.5

3-PHASE

811.0

A

268.9

A

454.0

A

RESIST.

150

259.5

3-PHASE

758.8

A

220.3

A

403.2

A

CAPAC.

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 13

2. NOTES FOR USERS

2.1. SWITCHING ON

As soon as HPS switches on, through the switch placed on the control panel of the machine, it

makes different cycles of test, indicated by the progression of the numbers from 0 to 9 on the

displays.

In case of bad working the test stops and the machine indicates on the control panel the type of

alarm checked (see at the voice alarms). When the test ends HPS is set to 0 Volt in the range 300

Volt, 50 Hertz and regulation on the output terminals (2 wires). After the appearing of these

indications HPS is ready to work.

2.2. PARAMETERS PROGRAMMING MODE

HPS/T allows you to change various generator start parameters through the programming mode.

The programming mode allows you to configure a starting profile of the application, different from

the factory one.

The modifiable parameters and how to access the programming mode are illustrated in the

Configure parameters quick guide.

2.3. VOLTAGE MENU

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 14

2.3.1.SETTING VOLTAGE

To set the voltage you can proceed on two ways: through the appropriate buttons UP and DOWN

placed on the left on the control panel or through the numeric keyboard of programming.

The buttons UP and DOWN, respectively indicated with a little arrow upwards and downwards, so

It is possible a continuous variation of the output voltage; the speed of the output voltage

variation depends on time the button is pushed, as time increases, the speed of the output voltage

variation progressively increases. If you want to set a fixed output voltage you can use the numeric

keyboard located on the right of the control panel. To set the voltage proceed in the following

way:

•Push the button PROGRAM (the corresponding led switches on)

•Push the button VOLT (the volt display switches off)

•Digit the required voltage through the numeric keyboard (the numbers are showed on the

display)

•Push ENTER

After pushing ENTER the display begins to blink to indicate that the output is going to the voltage

set up, as soon as the connection takes place , the display stops to flash and the led PROGRAM

shuts off. In case of error you can push the button CLEAR which causes the exit from the

programming routine. The maximum voltage is equal to the set of the range.

Moreover if the set of the voltage is not coherent with the set off range (for example the setting of

a voltage exceeding the range) the datum is not accepted after pushing ENTER.

After pushing ENTER the display begins to blink to indicate that the output is going to the voltage

set up, as soon as the connection takes place , the display stops to flash and the led PROGRAM

shuts off. In case of error you can push the button CLEAR which causes the exit from the

programming routine. The maximum voltage is equal to the set off range.

Moreover if the set off voltage is not coherent with the set off range (for example the setting of a

voltage exceeding the range) the datum is not accepted after pushing ENTER.

2.4. RANGE SETTING

The ranges on HPS allow to make use of the full power output at different voltages. The ranges

are 300 Volt and 150 Volt. The maximum output power changes according to the nature of the

connected load; in case of resistive loads the power is nominal, in case of pure inductive loads

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 15

the power increases, in case of pure capacity load the power decrease. To change the range push

the button corresponding to the requested range placed on the left of the command panel under

the voice RANGE VOLT. When the range is changed, the display showing the set voltage turns off

and the output voltage goes down slowly till zero, then the output power is switched off; after

about 15 seconds the output is switched on again and the Volts display visualizes zero voltage

(0.0); since that moment HPS is ready to receive the setting on the new range.

2.5. VOLTAGE VISUALIZZATION

The display concerning the output voltage can visualize four values: the set voltage or the output

voltage for each phase. At turn on, the display visualizes the set voltage and this is indicated by the

led on the button SET in the DISPLAY VOLT section of the panel.

In order to visualize the actual output voltage, push the corresponding button (OUT); the

visualized voltage indicates a precision of 0.3% full scale range.

If the set voltage is changed, the display returns to show the set value.

In case of 4 wires operation, the display shows the voltage on the sense inputs

2.6. FREQUENCY MENU

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 16

2.6.1.SETTING FREQUENCY

The output frequency of HPS can changed between 50 and 80 hertz.

To set the frequency proceed likewise the setting voltage through the buttons UP and DOWN

(upwards and downwards arrow) and by means of the programming numeric keyboard.

To set the frequency through the programming numeric keyboard you can proceed likewise the

voltage pushing the button HERTZ instead of the button VOLT thus indicating to HPS that you want

to program the frequency.

In this case too after pushing the button ENTER the display concerning the visualization of the

hertz flashes until the output frequency coincides with the set one.

If you plan a frequency exceeding the voltage range, the input value is not accepted pushing the

button ENTER.

2.6.2.FREQUENCY REFERENCE SETTING

The output frequency can have two references: the first one is inner frequency reference with a

precision of 0.01%, the second one is the line of loading frequency. At turn on HPS is connected to

the inner reference and this state is signalled by the led corresponding to the button INT at the

voice FREQ. REF.

To connect the output frequency to the network frequency push the button LINE; in this case the

output frequency is brought at 50 Hertz (this is indicated by the flashing of the visualized

frequency); when the connections with the 50 Hertz takes place, HPS is connected to the network

frequency and the display concerning the frequency switches off. The state of connections to the

network is indicated by the led corresponding to the button LINE. TPS connects itself to the

medium frequency of the network (with a period of integration equal to about 30 seconds) to

eliminate probable line voltage failures or spurious impulses arranged on the same line. To return

to the inner frequency reference push the button INT, after about 10 seconds the display will

visualize 50.00 and the output frequency will be connected to the inner reference.

2.7. MODE MENU

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 17

2.7.1.VOLTAGE REACTION

The stabilization of the output voltage coincides both on the HPS (2 wires) output terminals and

on a possible long distance outlet (4 wires) to eliminate the fall in voltage influence of the

connections. To operate the long distance stabilization first connect the opposite terminals on the

back of the machine following the indications at the voice INSTALLATION. The choice of the kind of

long distance stabilization can be operated by means of the buttons 4 wires and 2 wires at the

voice SENSE.

Notice that HPS corrects falls in voltage on the connections until 10% of the set up voltage to avoid

possible overheating of the same line. After exceeding this limit HPS doesn’t guarantee that the

value of the output voltage is equal to the set up voltage and is visualized a signal of error (see at

voltage alarms).

2.7.2.TYPE OF OUTPUT

There is only the three-phase output.

The output power is variable to type of the load, for resistive load the power is nominal power, for

inductor load is greater than the nominal power, for capacitor load is less than the nominal power.

2.7.3.CONTINOUS OR INRUSH MODE

Using the "Inrush" switch you can select the operation of the machine, in particular you can

change the current limits as shown in the tables. When the LED on the inrush switch is lit the

machine is on Inrush mode and the HPS can give three times the rated current; when the LED is off

the output current continuously is higher. This button is disabled or there is not if the machine has

not the inrush capabilities.

2.8. ALARMS

2.8.1.SUPPLY ALARMS

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 18

HPS can work with network voltage variations of 10%, if these limits are exceeded HPS stops and

the led concerning the occurred alarm blinks, in this case HPS can be unblocked by means of the

button HARDWARE RESET or switching off and switching on the machine.

If the network voltage is too low HPS stops and the led UNDERVOLTAGE is lit.

If the network voltage is too high HPS stops and the led OVERVOLTAGE is lit.

2.8.2.SYSTEM ALARMS

In case of high temperature on the inside of HPS (more than 70°C) this one stops and the led

TMAX is lit; to set again the machine, work as for the loading alarms.

In case of bad operations of the overload sections (inverter) HPS stops and the led INVERTER is lit.

2.8.3.CURRENT ALARM

HPS works a control of the output current and this allows it to support for an indefinite time the

output short circuit. In case of loads that absorb a current superior than the nominal one HPS

works a limitation of the same current.

This limitation is visualized by means of the led LIMIT OUT at the voice CURRENT.

If the machine is in slave configuration this alarms are not significant

In case of current limitation the output sinusoidal wave is no more guaranteed and so it will show

an harmonic distortion.

Not linear loads with an overload less than the nominal one but with a very high crest factor

current allow the current defence. Notice that if someone is working by limitation current HPS

keeps the effective value of the output voltage equal to the set off value until the led concerning

the voltage alarm switches on (see at VOLTAGE ALARM).

2.8.4.VOLTAGE ALARM

HPS, beyond the output distortion control, woks a control of the effective value of the output

voltage either in the configuration 2 wires or in the configuration 4 wires. If the output voltage is

not equal to the set off one a signal of error is visualized by means of the led MAX Vat the voice

VOLTAGE.

This kind of alarm does not cause any block to HPS.

If the machine is in slave configuration this alarms are not significant

2.9. PARALLEL OPTION

2.9.1.TURN ON

Down the steps you have to do to turn on of the system

1. Keep the machines off with the contacts 1.7 and 1.8 of all the machine.

2. Setup the machines master/slave with the contact 1.1 and 1.2 .

3. Close the contacts (1.7 and 1.8), when the machines are ON the change of the command master

slave is disabled.

4. Set the mode of the machines (remote, range, sensing). You have to set only the master

machines.

5. Enable the lines.

6. The system is ready for the voltage frequency ramp.

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 19

2.9.2.CHANGE CONFIGURATION MASTER AND SLAVE

Down the steps you have to do to change the configuration of the system

1. Set 0 on the output voltage of the machines that you need to change the configuration.

2. Disable the lines.

3. Turn off the machines that you need to change the configuration, with the contacts 1.7 and 1.8.

4. Set the configuration Master and Slave with the commands 1.1 and 1.2.

5. Turn on the machine with the commands (1.7 and 1.8)

6. Set the mode of the machines (remote, range, sensing), You have to set only the master

machine.

7. Enable the lines.

8. The system is ready.

2.9.3.TURN OFF

Down the steps you have to do to turn off the system the system

1. Set 0 on the output voltage of the machine.

2. Disable the lines.

3. Turn off the machines, with the command 1.7 and 1.8.

10/02/22 User Manual HPS/P/20kVA 6200591_01_ 20

3. INSTALLATION

3.1. GENERAL NOTES

3.1.1.POWER CABLING

Take off the rear pannel

•Connect a supply cable 3P+T of adequate size to support the current of the model.

•Connect the load cable of correct size to support the maximum current (load 3-phase range 300/150).

•In case connect the sense cable, 3-phase.

•At the end, close the rear panel.

•Remove the internal short circuit OUTPUT NEUTRAL –PE, this short circuits must be made externally on

the star of the output neutral (see schematics)

•The signal part and the power part have not to cabled together.

•The master/slave commands are all 230V, you have to use shielded cable if you cable together with

signal one for example the RS232 connections.

INGRESSO

INPUT

1

2

3

4

L1

L2

L3

PE

AUX MASTER

SENSE

OUT 3-FASE

AUX SLAVE

AUX MASTER

SENSE

OUT 3-PHASE

AUX SLAVE

1.

1

1.

2

1.

3

1.

4

1.

5

1.

6

1.

7

1.

8

12

13

14

15

16

17

18

19

20

2.

1

2.

2

2.

3

2.

4

2.

5

2.

6

L1

L2

L3

N

L1

L2

L3

N

PE

This manual suits for next models

1

Table of contents

Languages:

Popular Industrial Equipment manuals by other brands

ABB

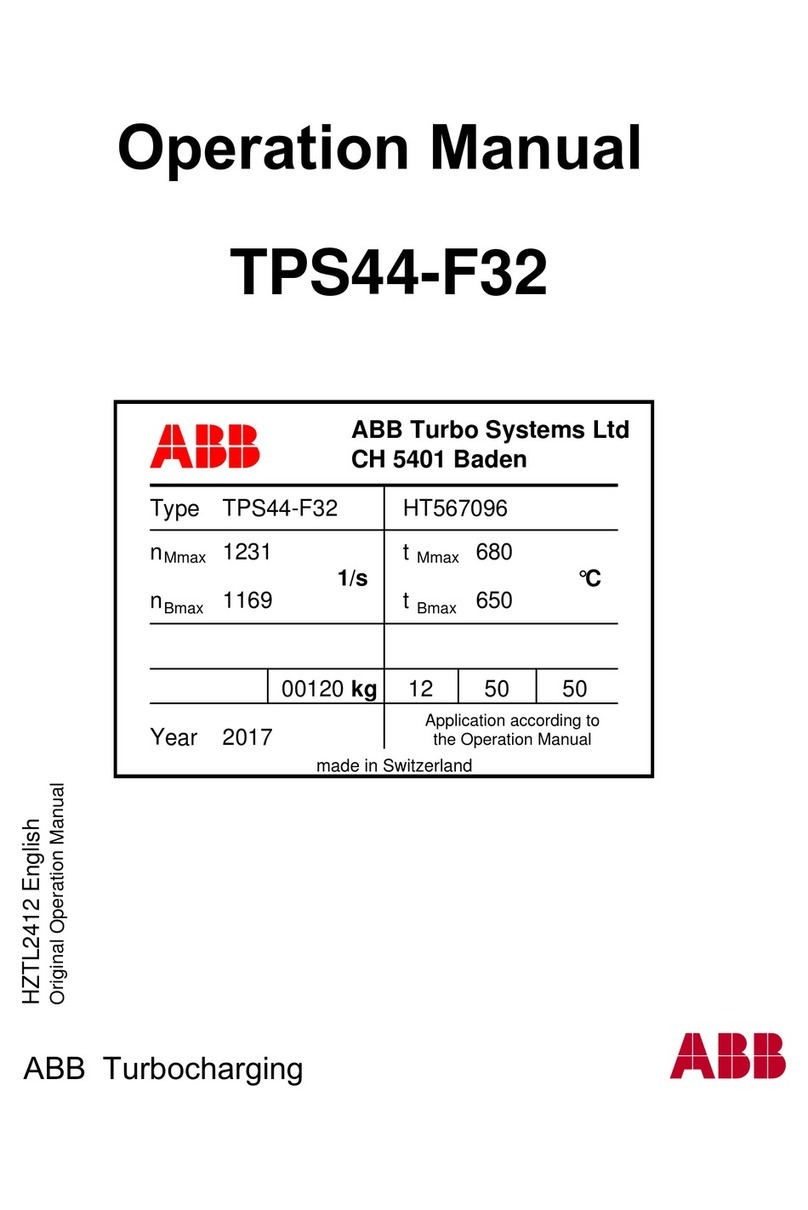

ABB HT567096 Operation manual

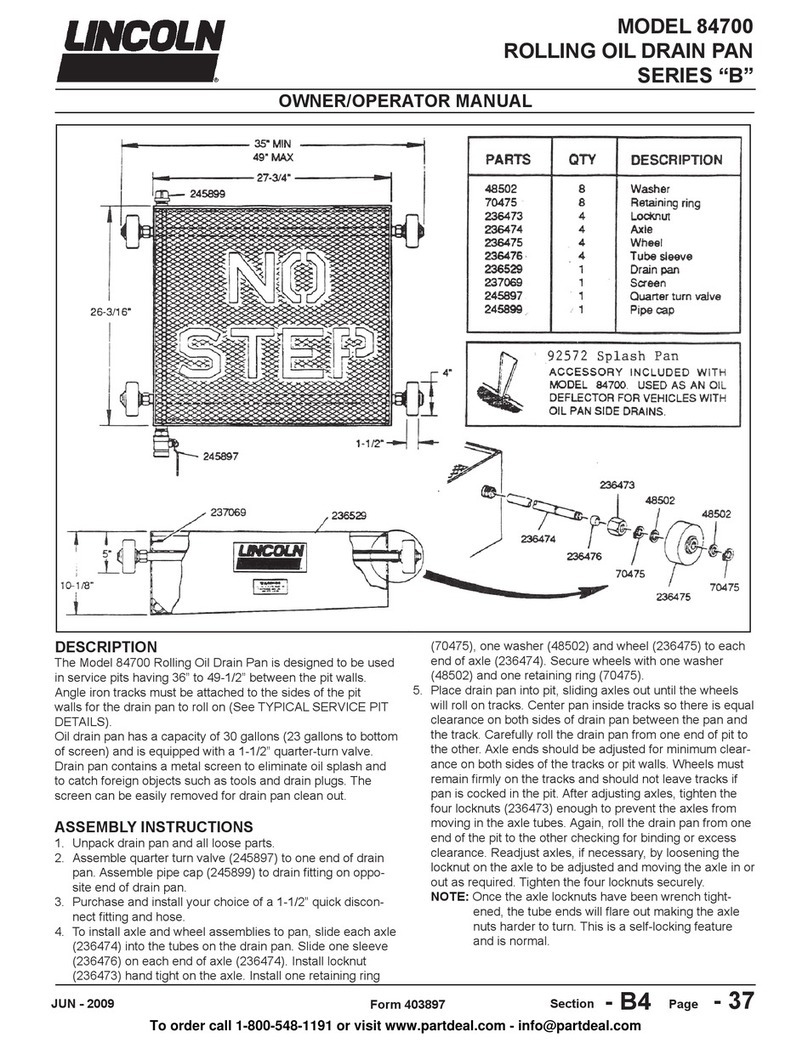

Lincoln

Lincoln 84700 Owner's/operator's manual

Reversomatic

Reversomatic RHRV-C100PECM Operation instructions

Leibinger

Leibinger CANVASA Series Original operating manual

GRUNDFOS ALLDOS

GRUNDFOS ALLDOS Oxiperm C 164 Series Operation and service manual

Best

Best ZS-BA20120 Operational Instruction