INSTALLATION, OPERATIONS AND MAINTENANCE MANUAL 5

Device specific

Warning: SmartRack™ MV remote

racking device incorporates

components, such as the DC power

supplies, which could contain stored

energy. Under no circumstances

should the protective covers on any

component of the device be removed.

Never tamper with, modify, or otherwise alter

the mechanical components, electronics, or control

software of the racking device. Failure to comply

could cause the device to fail resulting

in equipment damage or personal injury.

Never disconnect any of the cables from connected

components while the device is powered. Always

turn off the device and disconnect it from its power

source before attempting to unplug the data cables.

Do not open a cabinet door with SmartRack™ MV

attached. This could damage the racking device

coupling or circuit breaker truck. Always properly

remove the Motor Box using the rotary latch before

attempting to open the cabinet door.

SmartRack™ MV remote racking device is only

intended for use with switchgear breakers,

auxiliary devices such as PT or CPT drawout truck

and Model 2 MCC contactors listed in the

Compatible Devices section of this instruction

manual. ABB makes no claims to compatibility

regarding unlisted devices.

General

Always follow your company’s safety guidelines.

Wear appropriate Personal Protective

Equipment (PPE).

This product is intended to be operated and

maintained by qualified persons thoroughly trained

and knowledgeable of the hazards involved. This

publication is written only for such qualified

persons and is not intended to be a substitute for

adequate training and experience in the safety

procedures for this device.

Detailed descriptions of standard repair

procedures, safety principles, and service

operations are not fully elaborated in this

instruction book. It is important to note that this

document contains some warnings and cautions

against some specific service methods that could

cause personal injury to service personnel, or could

damage equipment or render it unsafe. These

warnings do not cover every conceivable method in

which service (whether or not recommended

by ABB) may be performed.

Secondly, ABB cannot predict or investigate all

potential hazards resulting from all conceivable

service methods. Anyone using service procedures

or tools, whether or not recommended by ABB, must

satisfy himself thoroughly that neither personal

safety nor equipment safety will be jeopardized by

the service method or tools selected.

All information contained in this manual is based

on the latest product information available at the

time of printing. ABB reserves the right to make

changes at any time without notice.

—

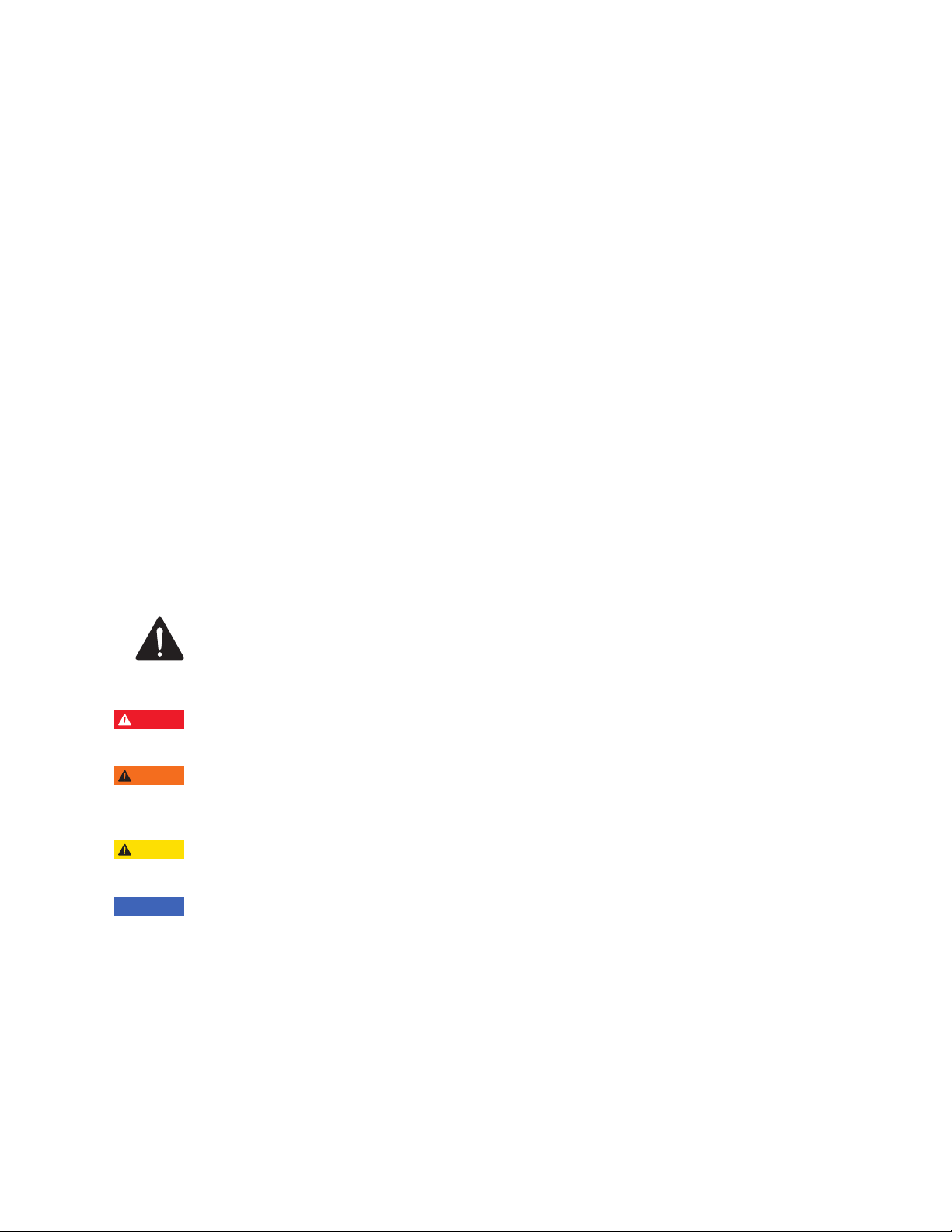

Safety notices

—

01

Personal Protective

Equipment

—

01

WARNING