Elgas TRZ User manual

Radial-blade turbine gas meter TRZ

Radial-blade turbine Quantometer EQZ/EQZK

Installation and operating instructions

May 2018

Rev. 1

Index

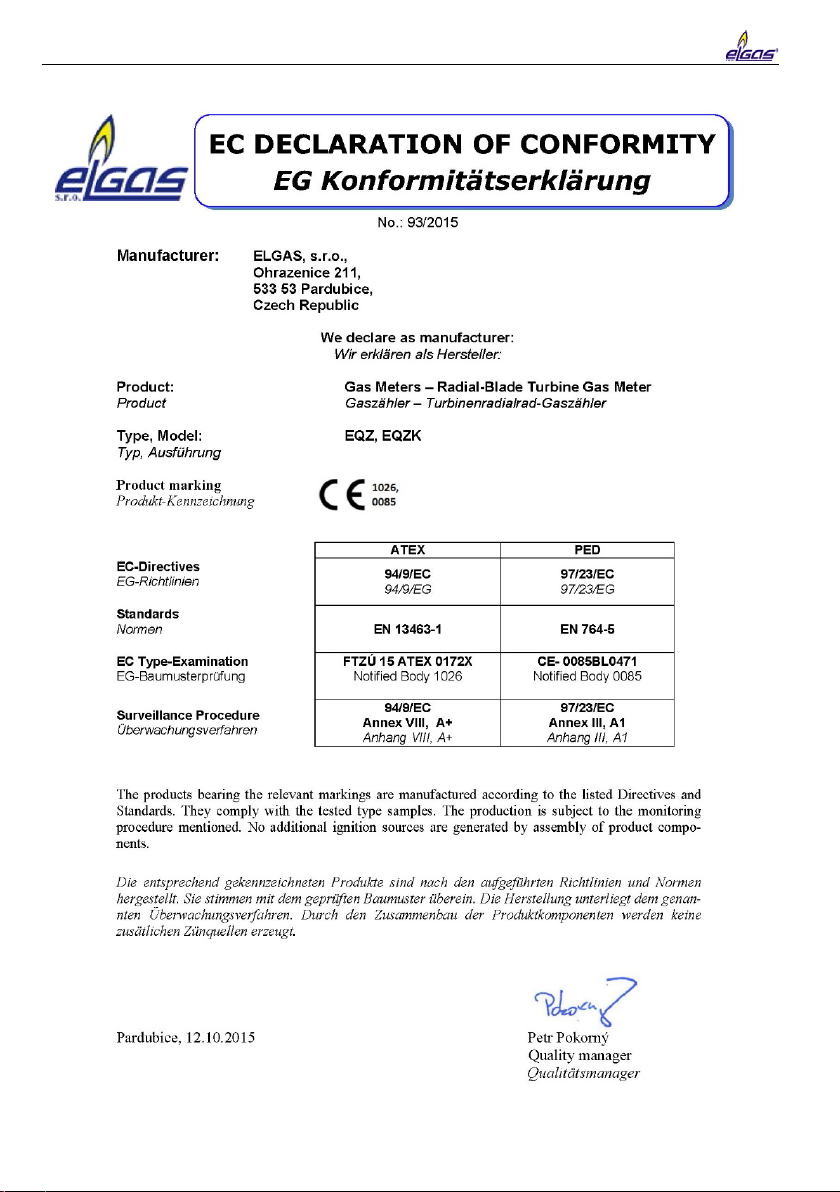

1 Field of application.............................................................................................. 3

2 Installation conditions ........................................................................................ 3

2.1 Installation of the monopipe adapter into the pipeline ............................. 4

2.2 Cleaning of the pipeline prior to measuring insert installation .................. 4

2.3 Installing the meter onto the monopipe adapter EAS................................ 5

2.4 Pulse generators.......................................................................................... 6

2.5 Electrical connection of pulse generator.................................................... 7

3 Commissioning.................................................................................................... 7

3.1 Maintenance and service centre ................................................................ 8

4 Disassembly and disposal ................................................................................... 8

5 Information for installation in explosive areas.................................................... 8

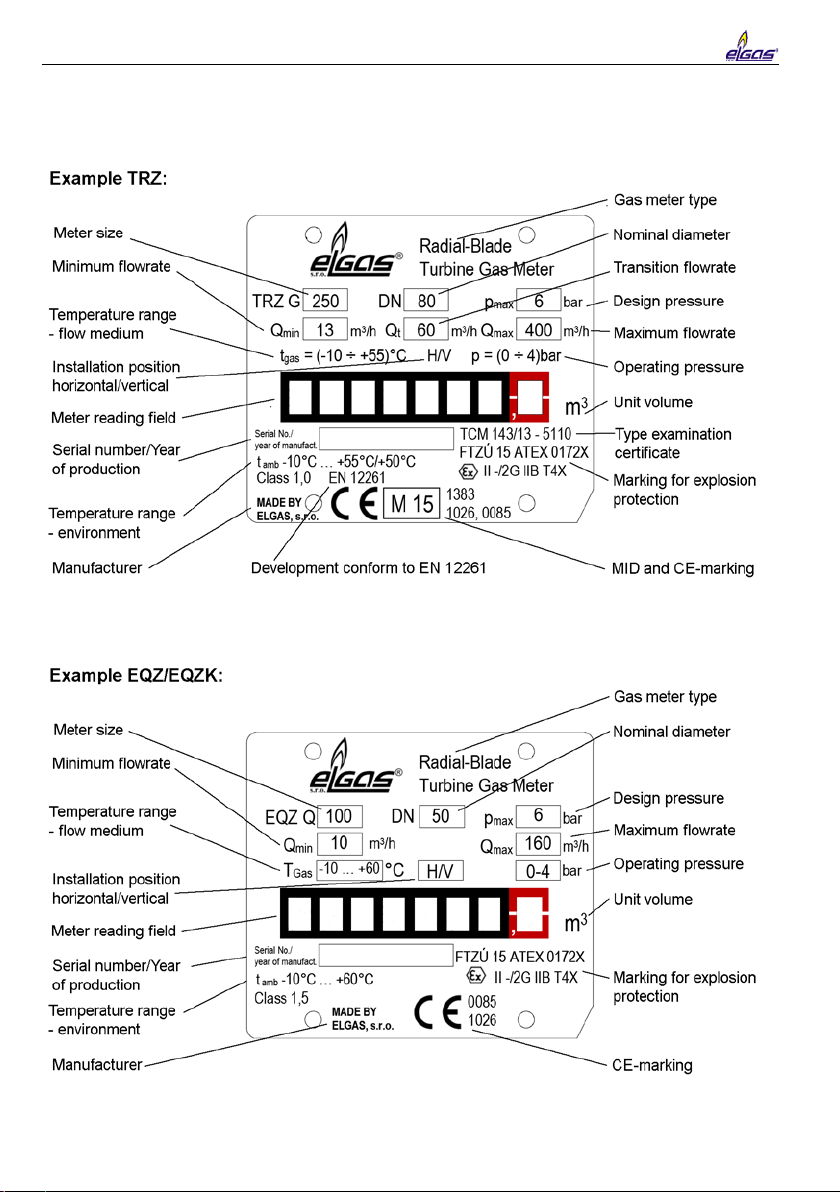

6 Detailed description - type plate ........................................................................ 9

7 Declaration of Conformity ................................................................................ 10

3

1 Field of application

Type

TRZ /EQZ /EQZK

Size

G/Q 16 - G/Q 400

Nominal diameter

DN 40 - DN 100

Maximum pressure (Design):

Flange

Screwed

6 bar

4 bar

Maximum operating pressure

4 bar

Temperature range - gas

-10 °C ... +55 °C /+60 °C/+60 °C

Temperature range - ambient

-10 °C ... +55 °C /+60 °C/+60 °C

Turbine flow meters are suitable for custody transfer and Quantometers for internal

and industrial measurements of clean and dry natural gas, town (city) gas, propane,

butane, nitrogen (gas), air and inert gases.

Installation, connection, commissioning and maintenance must only be carried out by

expert technicians who, first of all, have read and understood the operating

instructions. These operating instructions include all important information required

for the installation and operation of Radial-blade turbine gas meters type TRZ and

Quantometer type EQZ/EQZK. They supplement the relevant national regulations

with respect to the manufacturing and equipment of measuring systems as well as

with respect to maintenance activities. For the installation in explosion sensitive areas

please refer to section 5 in this manual.

2 Installation conditions

If possible, the TRZ/EQZ should be installed in a closed area.

When installing a meter outdoors, it should be protected from the direct effects of

the weather. The meter has a protection rating of IP65 and is UV-resistant.

Valves installed in front or after the gas meter should be opened slowly.

Regulators, valves and armatures should be installed with a minimum distance of 2 x

DN up-stream of the meter. (EN12261)

The gas flow should be free of pulsations and vary only in a modulating way.

Strong external vibrations (e.g. feed pumps) on the meter can damage it.

4

The injection of odorants must be effected at a sufficient distance downstream of the

meter.

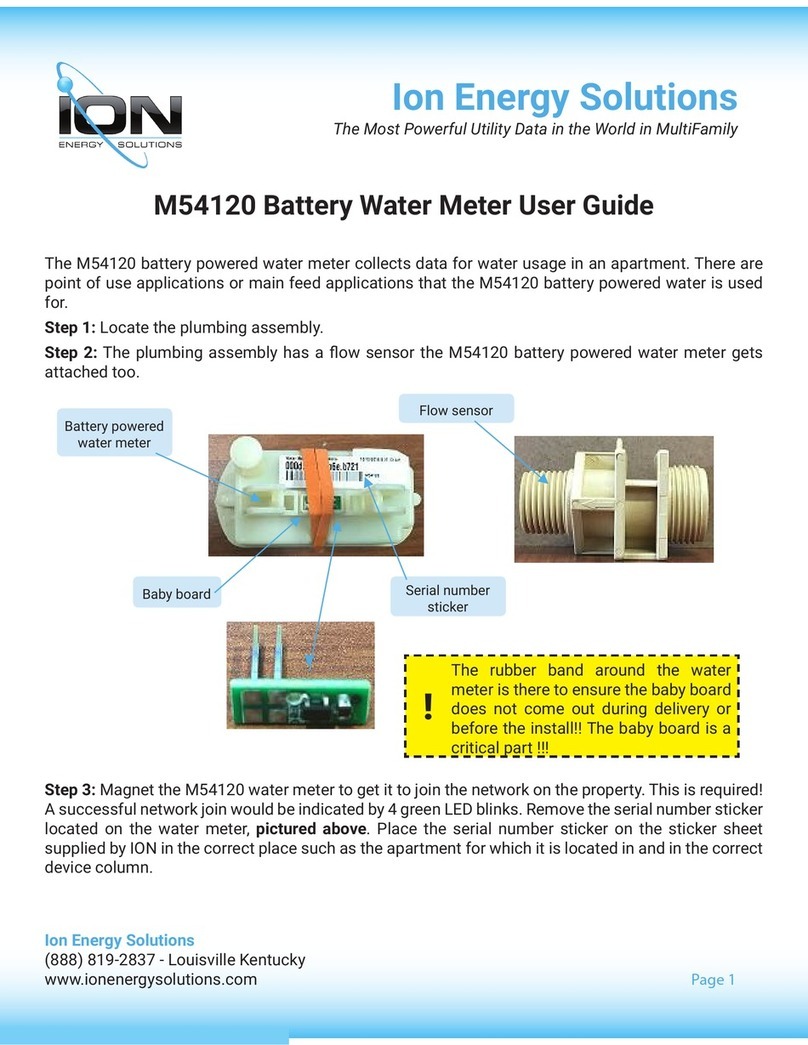

2.1 Installation of the monopipe adapter into the pipeline

Prior to the installation of the meter, the monopipe adapter should be inspected to

ensure that no damage has been inflicted to the meter during transportation. Faulty

components should be replaced.

The flow direction is indicated on the monopipe adapter EAS by means of

an arrow

and must correspond with the flow of gas in the pipeline. Never operate the meter

in reverse flow.

Use only approved types of flat gaskets. The gaskets must be aligned

concentrically and must not protrude into the inside of the pipeline.

Only screws, which correspond to the correct flange size, may be used. The screws

must be tightened in a diagonal (crosswise) manner and to the correct torque rating.

No screws can be left out.

The preferred installation position is horizontal with the roller counter ontop. (Remark:

Inthecasethatgasmeterisprovidedwithover-runbreak,onlythisinstallationposition

is available). The meter can also be installed vertically, axes of roller counter should

be positioned horizontal.

The EAS is subjected to a leak test:

PN16 (Flange):

Test pressure = 24 bar

PN 4 (Threaded):Test pressure = 6 bar

The EAS is a component of the pipework and is to be regarded and maintained /

examined accordingly.

2.2 Cleaning of the pipeline prior to measuring insert installation

Before installing the meter onto the EAS, the pipeline must be cleaned so that no

foreign objects, dust or fluids remain inside.

On request ELGAS, s.r.o. can supply an overflow cap, which allows the gas to flow

through the meter in place of the measuring insert.

The installation of a filter upstream of the meter is recommended.

The pipework can now be flushed, so that excess dirt is expelled without damaging

5

the measuring insert.

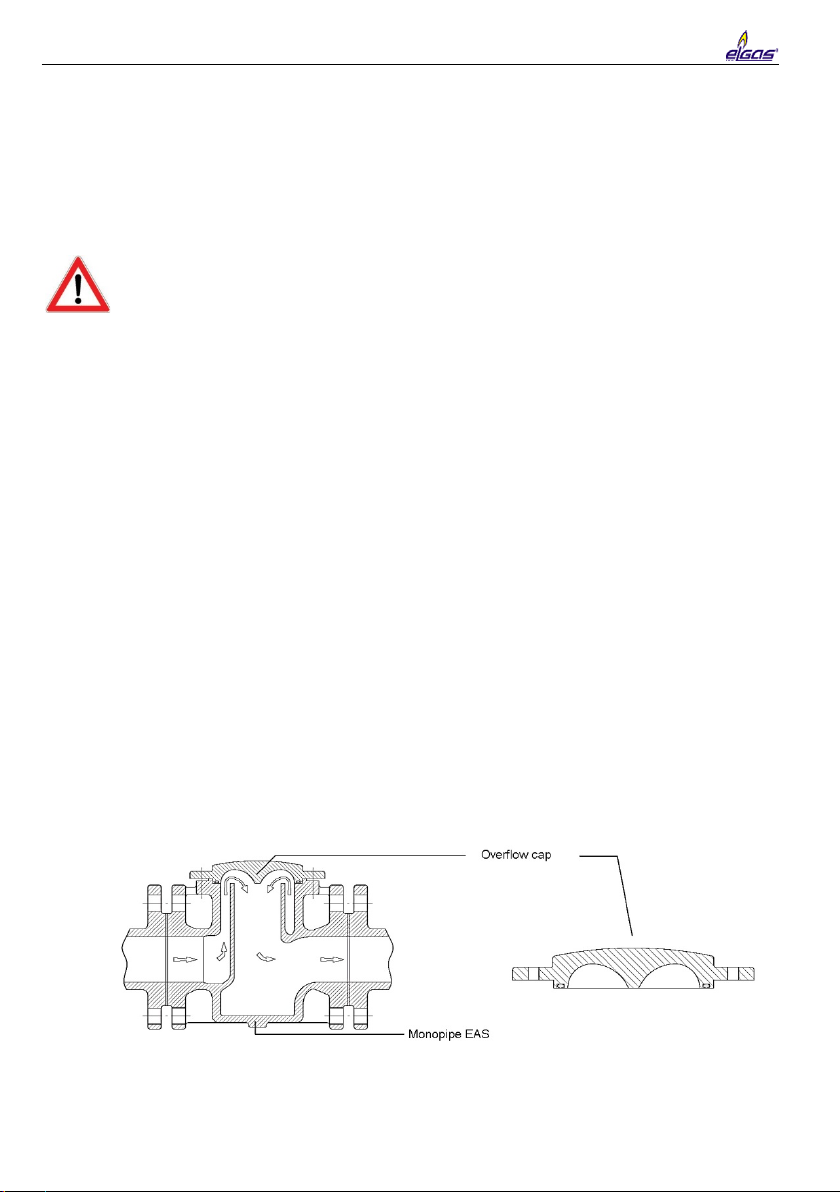

2.3 Installing the meter onto the monopipe adapter EAS

Prior to the installation of the meter, the measuring insert should be inspected to

ensure that no damage has been inflicted on the meter during transportation.

Accessories should be inspected for completeness (e.g. Pulse generator). Faulty

components should be replaced.

The measuring insert is delivered in special protective packaging. This should only

be removed shortly before installation.

Installationof the meteris possible horizontallyor vertically (if over-run brakeis applied,

only horizontal position with counter on top is allowed); the meter head can be rotated

in 90° steps. It should however, always be ensured that the axis of the roller counter is

horizontal (i.e. volume value can be read). The meter must not be installed upside

down.

Before mounting the meter onto the EAS, make sure that the pipeline has been

flushed and is clean. If not please refer to section 2.2 "Cleaning of the pipeline prior

to measuring insert installation".

The gas should be dry and free of dirt and dust. Particles may not be larger than

5Microns. Otherwise, we urgently recommend the installation of a dust-moisture trap.

In case of new systems, the temporary installation of a filter or cone screen (mesh

width: 0,5 mm) is recommended in order to protect the meter. The cone screen

should be removed after 4 weeks.

The O-rings mounted on the meter must be firmly seated and must not be damaged

during installation.

The meter is mounted to the EAS by tightening the cylinder screws is a crosswise

manner. Please keep to the recommended tightening torque:

Nominal Diameter DN 50 = 40 Nm

Nominal Diameter DN 80 = 65 Nm

Nominal Diameter DN 100 = 100 Nm

Only the ELGAS, s.r.o. delivered screws may be used for this purpose.

6

After installation of the meter a leak test must be carried out on the entire unit.

To prevent sabotage and leakage through the loss of screws the meter can be

sealed.

2.4 Pulse generators

For the remote transmission of operating volume, the following

pulse generators are available:

•NF (IPG-NF1/2) Reed-contact (Standard)

pulse value = 1m3 per pulse

For use within explosive sensitive areas with gas, steam and mist

II 2G EEx ia IIC T6

The intrinsic safety can only be guaranteed with the correct operating materials,

together with the written confirmation/proof of intrinsic safety and the verified

following maximum values.

Umax = 24 VDC

Imax = 10 mA Pmax

f

max

=

=

120 mW

0.18 Hz

Ci

effective internal capacity

= negligibly small

Li

effective internal inductivity

= negligibly small

•MF Namur Sensor (optional)

pulse value = 1m3 per 100 pulses

For use within explosive sensitive areas with gas, steam and mist

II 2G EEx ia IIC T6

The intrinsic safety can only be guaranteed with the correct operating materials,

together with the written confirmation/proof of intrinsic safety and the verified

following maximum values.

U

max

=

25 VDC

I

Mark

=

>2.2 mA

f

max

=

18 Hz

U

Nom

=

8 VDC

I

Space

=

<1.0 mA

Ci

effective internal capacity

=

<=30 nF

I

max

=

4 mA

P

max

=

100 mW

Li

effective internal inductivity

=

<=100 µH

•NF Reed-contact IN-Z61 (optional)

pulse value = 1m3per pulse

This reed pulser can be retrofitted at later time without

breaking the meter seal.

Note: This pulser is only designed for an ambient

temperature of -10 °C to 50 °C.

For use within explosive sensitive areas with gas, steam and mist

EEx ia IIC/IIB/IIA EEx ib IIC/IIB/IIA

7

The intrinsic safety can only be guaranteed with the correct operating materials,

together with the written confirmation/proof of intrinsic safety and the verified

following maximum values.

2.5 Electrical connection of pulse generator

The electrical connections for the two pulse generators NF Reed-contact and MF

Namur Sensor in the register area is made possible by a 6-pole circular plug.

The NF Reed-contact and MF Namur Sensor (if installed) are indicated by a sticker,

which is positioned on the outer casing of the measuring insert.

Pulse generator sticker for NF-Reed contact

(Low

frequency)

Pulse generator sticker for MF-Namur Sensor (Middle

frequency)

In addition to the type description on each sticker, information about the number of

pulses per m3 (pulse value), the Ex-identification number of the pulse generator and

the permissible maximum electrical values are displayed.

The cable is correctly connected when the circular plug is inserted into the socket

and is fastened by tightening the coupling ring.

The NF Reed-contact IN-Z61 has its own direct connection point and is indicated on

the sensor. The plug is pushed as far into the opening of the housing, until the

connecting point engages. With an additional pin, the plug is secured before

removing it again. The pin has a diagonal hole in it through which wire is placed to

seal the pulse generator.

Only the original supplied plug connection may be used for this purpose.

3 Commissioning

Fill the measuring section slowly by opening valves gradually(at least 1 minute) until

the operating pressure is reached.

Note: Pressure surges (shocks) and / or excessive start-up flowrates may damage

the meter.

Umax = 25 VDC

Imax = 50 mA Pmax = 250 mW

fmax = 0.18 Hz

Ci

effective internal capacity

= negligibly small

Li

effective internal inductivity

= negligibly small

8

The maximum flowrate Qmax of the meter may not be exceeded.

Carry out a leak test.

Please take note of the maximum and minimum flowrates indicated on the typeplate

of the meter.

3.1 Maintenance and service centre

TRZ, EQZ and EQZK have permanently lubricated bearings. Lubrication of the

bearings is not necessary.

Service centre:

ELGAS, s.r.o., Provozovna Chrudim, Pardubicka 199, 537 01 Chrudim,

Czech republic, Tel.: +420 469 623 087, Email.: sales@elgas.cz

4 Disassembly and disposal

To disassemble the gas meter measuring insert from the monopipe adapter the

4 cylinder screws must be unscrewed. Until such time that a new measuring insert

can be installed, use can be made of the over-flow cap which is fastened to the

EAS. The flow is therefore ensured during the interim.

For revisions, it is advisable to return these to the manufacturer in the original

packaging or to the closest service centre.

Meters, which are to be retired from service, can be sent to ELGAS, s.r.o. or the

nearest service centre or in addition be sent for scrap metal use.

5 Information for installation in explosive areas

Markings on the complete meter as an explosion proof operating device:

for TRZ: Ex II -/2G IIB T4X Tamb -10 °C ... 55 °C

for EQZ/EQZK: Ex II -/2G IIB T4X Tamb -10 °C ... 60 °C

The regulations for explosion proof applications for the pulse generators are

described in detail in this manual in Chapter 2.4.

If the optional pulse generator IN-Z61 is used, then the ambient temperature

may

not fall outside the stipulated range of -10 °C ... 50 °C.

Cleaning of the register cover with a dry tissue/cloth

must be strictly avoided. Danger of contact -

brush discharge i.e. sparks may occur during contact.

Where the danger exists of falling objects the pressure connection pr, the connection

plug for the electrical connection and the optional pulse generator INZ-61 should

be protected by a protective covering. Otherwise the danger exists that an impact

on the pressure connection pr, a leak could be caused. By impact on the register

covering, the danger exists that the mounted plug or IN-Z61 electrical components

could be destroyed leading to

sparks. Such protective coverings for each nominal

size can be sourced from ELGAS, s.r.o.. Other protective coverings may also be

9

used provided that they meet the above mentioned requirements.

6 Detailed description - type plate

10

7 Declaration of Conformity

11

Radial-blade turbine gas meter TRZ

Radial-blade turbine quantometer EQZ/EQZK

Installation and operating instructions

Prepared by:

Collective of authors

Issued by:

ELGAS, s.r.o

Ohrazenice 211

533 53 Pardubice

Czech republic

Phone: +420 466 414 500. 511

Fax: +420 466 411 190

http://www.elgas.cz

e-mail: sales@elgas.cz

Issued on:

May 2018

Rev. no.:

Rev. 1

This manual suits for next models

2

Table of contents

Popular Measuring Instrument manuals by other brands

Microsensor

Microsensor MPM480 Operation manual

Rapsodo

Rapsodo HITTING 2.0 quick start guide

Bender

Bender RCMB-35-30 Series quick start guide

Tektronix

Tektronix KEITHLEY 4200A-SCS-PK2 quick start guide

VIDA TECH

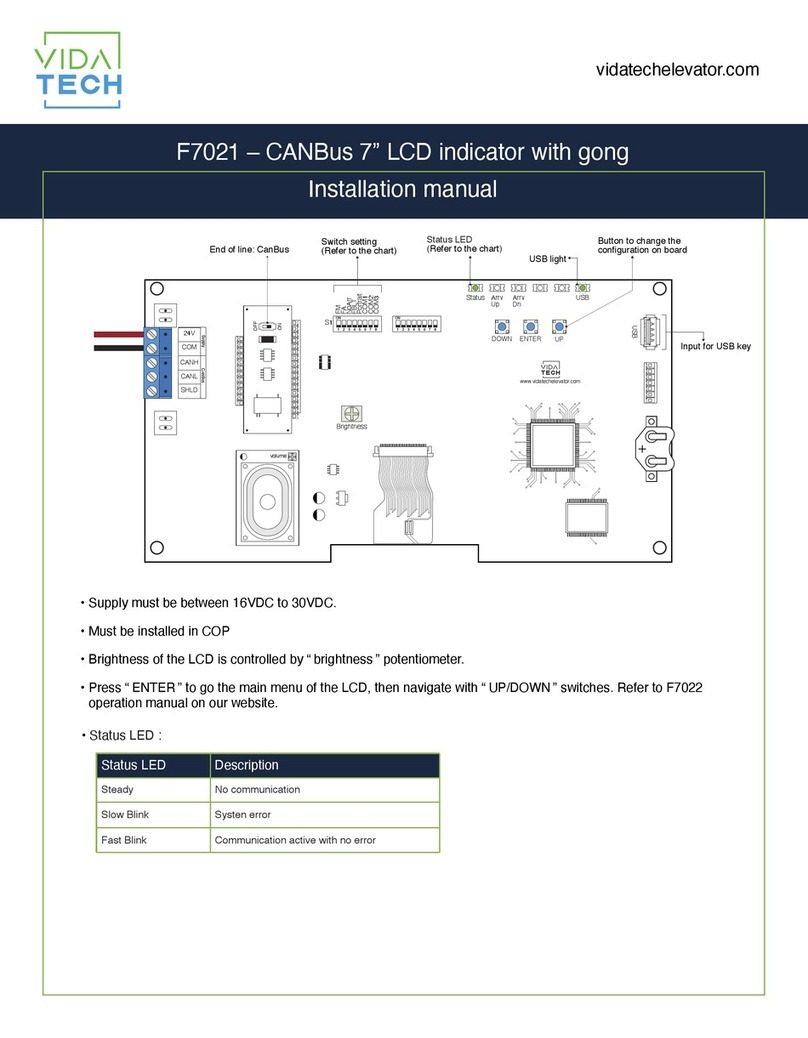

VIDA TECH F7021 installation manual

Keysight Technologies

Keysight Technologies UXA N9040B manual