2.5

General functional description

1910.134 or F.D.A. 21 C.F.R. 178.3570 regulations.

Failure to do so may cause severe injury or death.

Insulate or use protective guards to cover pipes or other

parts that may exceed 80ºC (176ºF). High-temperature

pipes must have a clear marking as potentially

dangerous.

Position the compressor on level surface. In case of

inclined surface, contact ELGi.

Do not allow compressed air to come in contact with

food and related items unless they are compressed air-

treated specifically.

Be aware that this air compressor is intended for

generating only industrial-use compressed air.

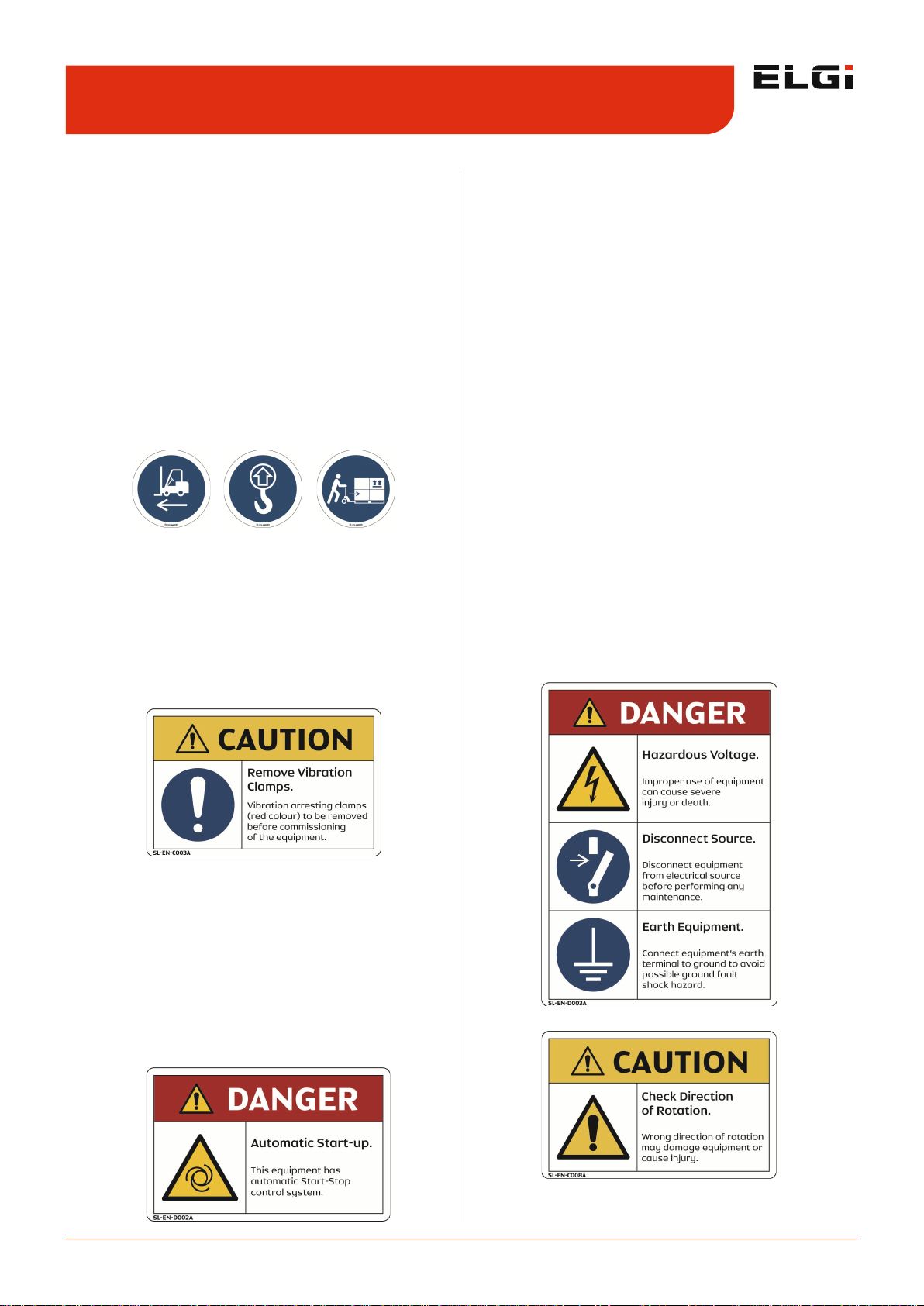

2.3.2 Precautions during operations

When switching on remotely controlled compressors

ensure that no one is checking or working on the

compressor at that time.

Before starting, ensure that no tools or any loose parts

remain inside the compressor.

Do not operate the compressor if a possibility exists

that it could inhale flammable or toxic fumes, vapors or

particles.

Do not operate the compressor below or above its

operating limits.

Wear ear protectors if you work in an environment

where the sound pressure level reaches or exceeds 90

dB (A).

Keep all the compressor doors shut during operation.

For carrying out routine checks, the doors should open

only for short durations not more than 10 minutes.

Wear ear protectors when opening a door.

Keep hands, feet, floors, controls and walking surfaces

clean and free of water or other liquid to minimize the

possibility of slips and falls.

Pressure release

Know that annual servicing of the safety valve is

necessary. It should be checked at the prescribed

pressure for operation.

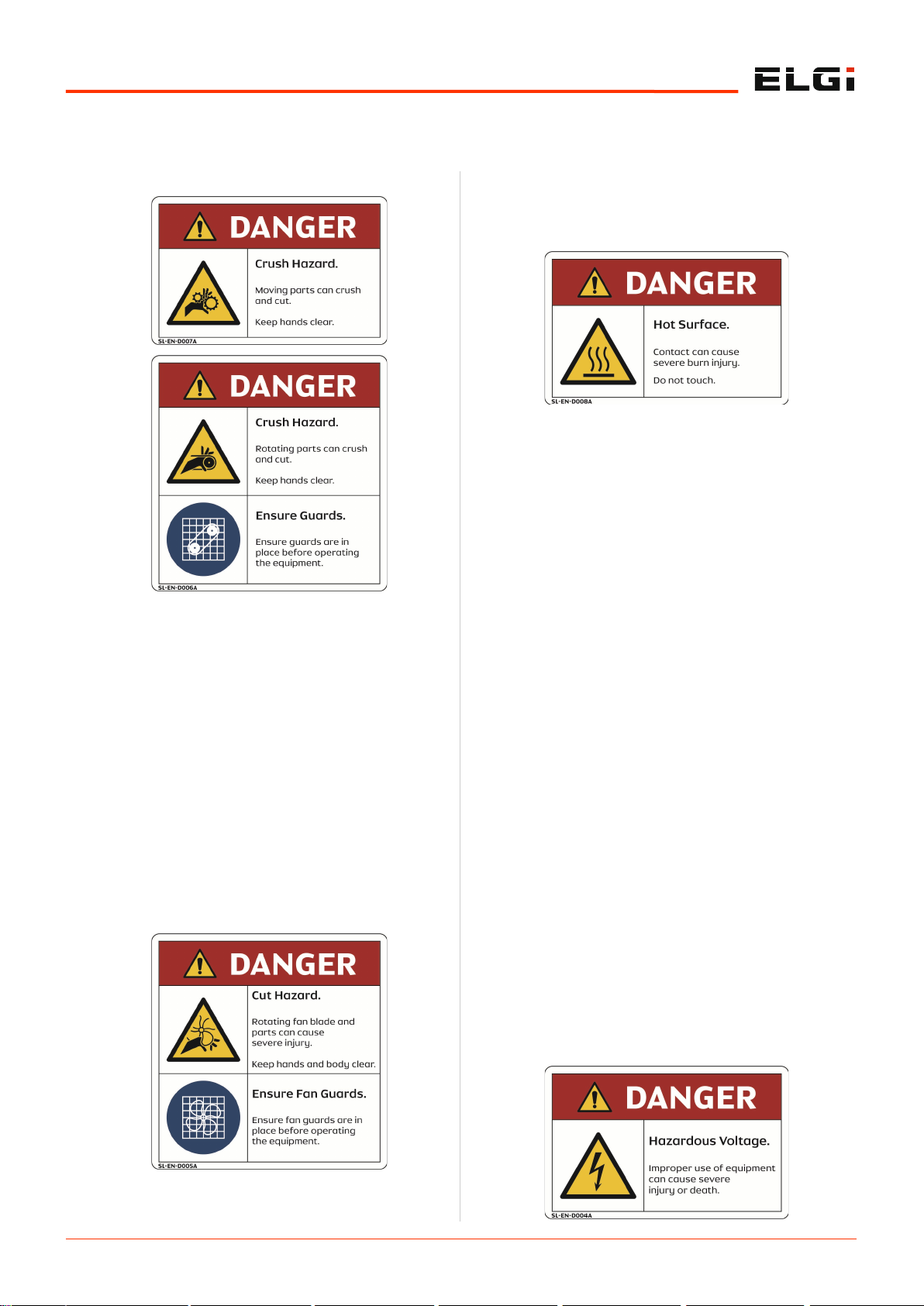

Use correct tools for maintenance and repair work.

Do not allow the manufacturers’ rated safe operating

pressure to exceed for pipes, valves, filters and other

fittings.

It is hazardous to point the compressed air directly

towards any personnel. Keep personnel out of the line

of the discharge air when opening hoses or other points

of compressed air discharge.

Use only the correct type and size of hose end fittings

and connections. When blowing through a hose or

airline ensure that the open end stays securely. A free

end will whip and may cause injury. Make sure to

depressurize a hose fully before disconnecting it.

Release all the pressure in the compressor system

before servicing or performing any maintenance

activity.

Do not engage in horseplay with air hoses. Serious

injury or death may result.

Do not use air at a pressure greater than 2.5 bar.g (36

psi.g) for cleaning purpose.

Open the oil fill cap only when the compressor is not

running and is not pressurized. Shut down the

compressor and bleed the receiver tank to zero internal

pressure before removing the cap.

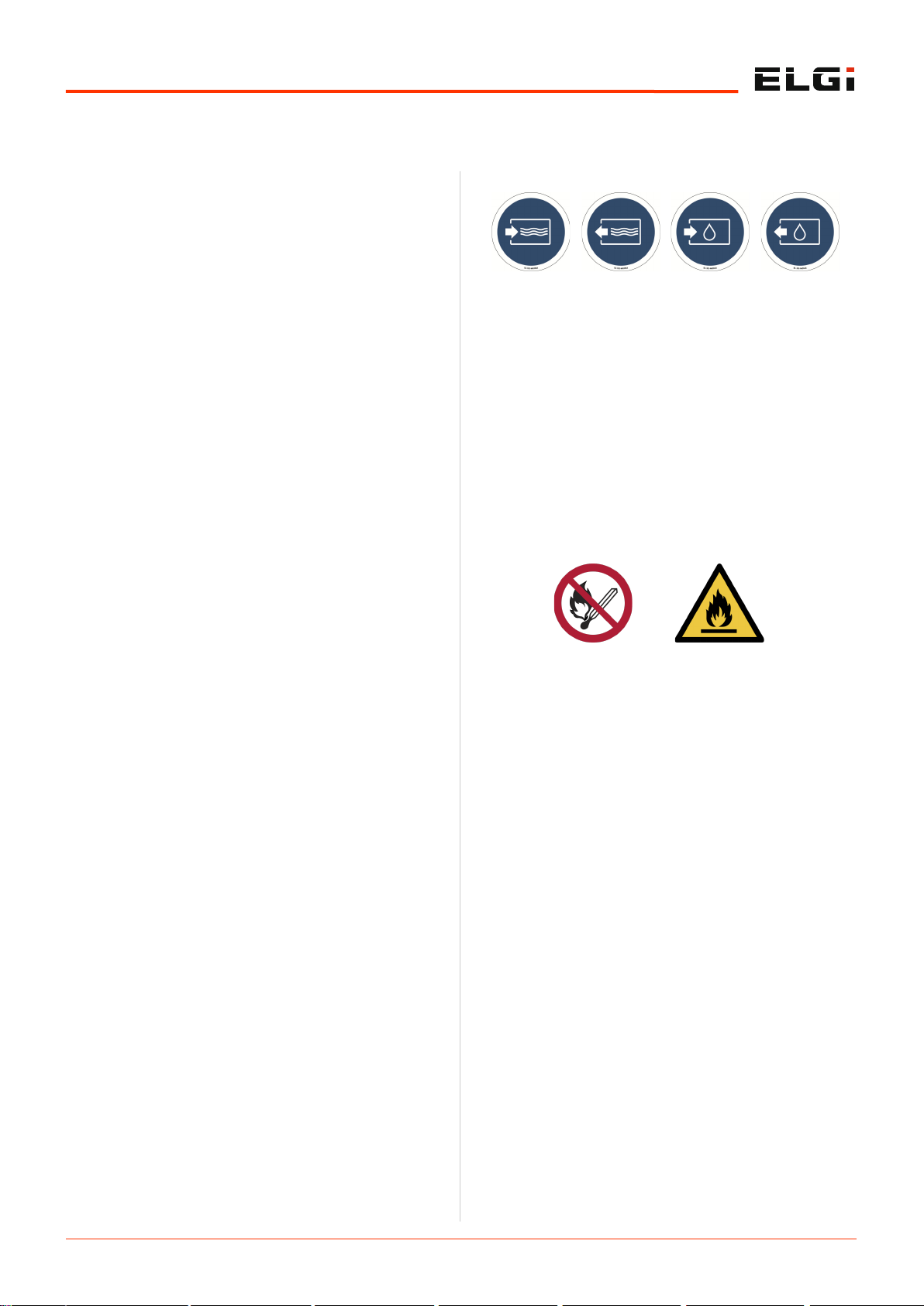

Fire and explosion

Clean up spills of lubricants or other combustible

substances immediately.

Shut down the compressor and allow it to cool down

before checking or adding oil. Remove sparks, flames

and other sources of ignition away from the

compressor.

Do not permit smoking in the vicinity of the compressor.

Do not use flammable solvents for cleaning purposes.

Keep electrical wiring and other terminals in good

condition. Replace any wiring that has cracked, cut,

abraded or otherwise degraded insulation. Keep all

terminals clean and tight.

Keep grounded conductive objects such as tools away

from exposed live electrical parts like terminals to avoid

arcing, which might serve as a source.

Keep oily rags, trash, dry leaves, litter or other

combustibles out of and away from the compressor.

Do not operate the compressor without a proper flow of

cooling air or with an inadequate flow of lubricant or

with a degraded lubricant.

Do not attempt to operate the compressor in a

hazardous environment of any classification unless the

compressor has been specially designed and

manufactured for explosive applications.