ELGO Electric AZ16E Series User manual

E series

Installation manual

AZ16E-000-E_10-06.doc Doku Art. Nr. 799000026

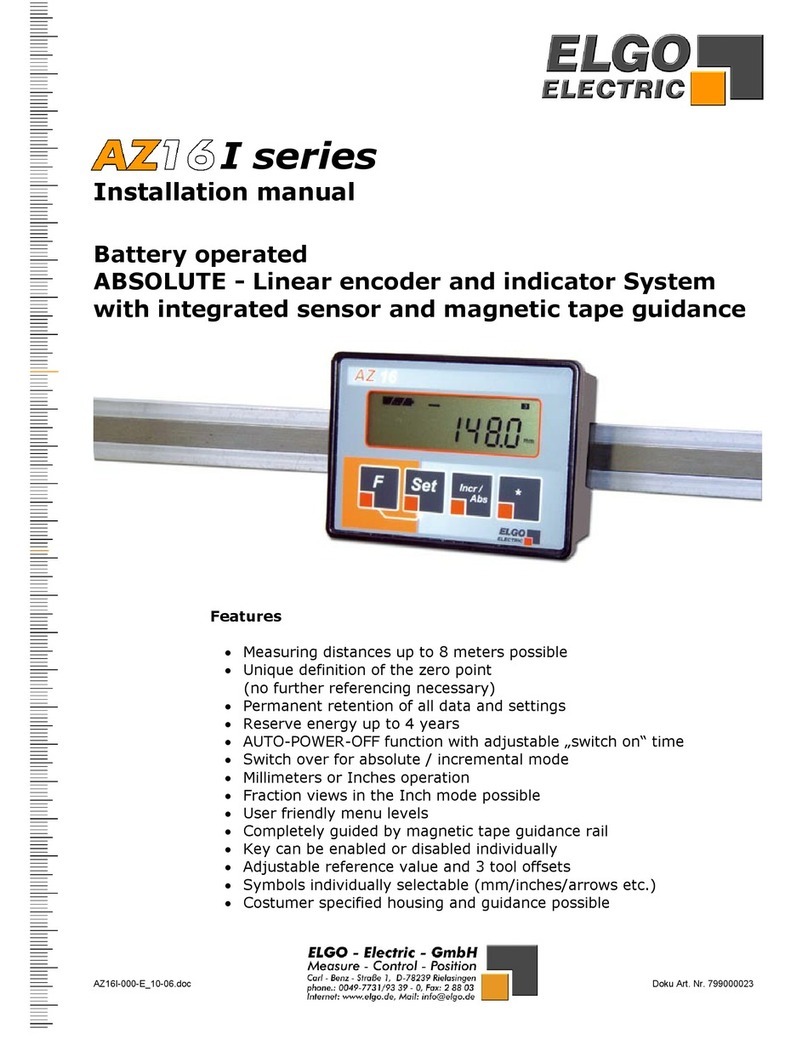

Battery powered Absolute Linear Encoder System

Complete with an Indicator and an external Magnet Sensor with 0.1 mm resolution

Features

• Measuring distances up to 8 meters possible

• Unique definition of the zero point

(no further referencing necessary)

• Permanent retention of all data and settings

• Reserve energy up to 3 years

• AUTO-POWER-OFF function with adjustable „switch on“ time

• Switch over for absolute / incremental mode

• Millimeters or Inches operation

• Fraction views in the Inch mode possible

• User friendly menu levels

• Keys can be enabled or disabled individually

• Adjustable reference value and 3 tool offsets

• Symbols individually selectable (mm/inches/arrows etc.)

2

1. INTRODUCTION 3

2. SAFETY 3

3. DETERMINATION OF THE RAIL AND TAPE LENGTH 4

4. DISPLAY ASSIGNMENT 4

5. THE AZ16E IN OPERATION 4

5.1 Initial operation 4

5.1.1 Detection of measuring direction 4

5.1.2 Referencing 4

5.3 Parameter settings 6

5.4 Parameter list 7

6. BATTERY CHANGE 8

7. MAGNETIC TAPE 9

7.1 Handling 9

7.2 Processing note for sticking 10

7.3 Resistance to chemicals of the magnetic tape 10

7.4 Sticking and cutting 10

8. TECHNICAL SPECIFICATIONS 11

9. DIMENSIONS 12

9.1 Display Unit: 12

9.2 External Magnet Sensor „AZS“: 13

10. INSTALLATION / DISPLAY UNIT 13

11. TYPE DESIGNATION 14

12. LIABILITY EXCLUSION / GUARANTEE 15

3

1. Introduction

The new linear „Absolute“ encoder and indicator unit AZ16 is based on the proven magnetic

measuring principle. According to its battery supply, no wirings are necessary and the systems

is able to operate as a complete stand alone unit. The max. possible measuring distance

amounts to 8 meters. By using the AUTO-POWER-OFF mode the max. service life span of the

battery amounts up to 3 years.

The external magnetic sensor is connected fix to the indicator by a drug chain suitable cable.

Further a version with an internal sensor and a guidance rail is available (AZ16I).

Characteristics of the AZ16E (external Sensor):

The system consists of

- an extensive programmable Display unit

- the external Magnet Sensor "AZS", which its cable length is available up to 20 meters

- an absolute coded Magnetic Tape with a max. measuring Length of 8 meters

The AZS sensor is contactlessly moved over the magnetic tape. It is resistant against abrasion,

dust, dirt and water (protection class IP 67).

The user must provide and guarantee for a suitable mechanical guiding system, to guide the

sensor and keep it along the whole movement in the correct distance (0... 1.5 mm) to the

magnetic tape. The sensor must be installed coplanar to the tape.

2. Safety

Please note: Before first commissioning read this installation manual carefully and

observe absolutely the installation instructions. The measuring system is only dedi-

cated for recording lengths. The type label is intended for exact identification of the

measuring system. The label is situated on the indicator housing. It informs about

the exact type designation (see chapter 9), the delivery date and the production

number. When contacting the company ELGO Electric GmbH please use these

terms.

Attention!

The company ELGO Electric GmbH is not liable for possible damages to machines

and or to persons, which can result from defective material at the measuring sys-

tem and the following circuit. The machine manufacturer is responsible for taking

and realizing the necessary safety precautions.

4

3. Determination of the rail and tape length

Basically the following applies with an order of magnetic tape:

Ordered length of tape = effective measuring distance + 100 mm

For further details see the „Type designation“ at the end of the manual.

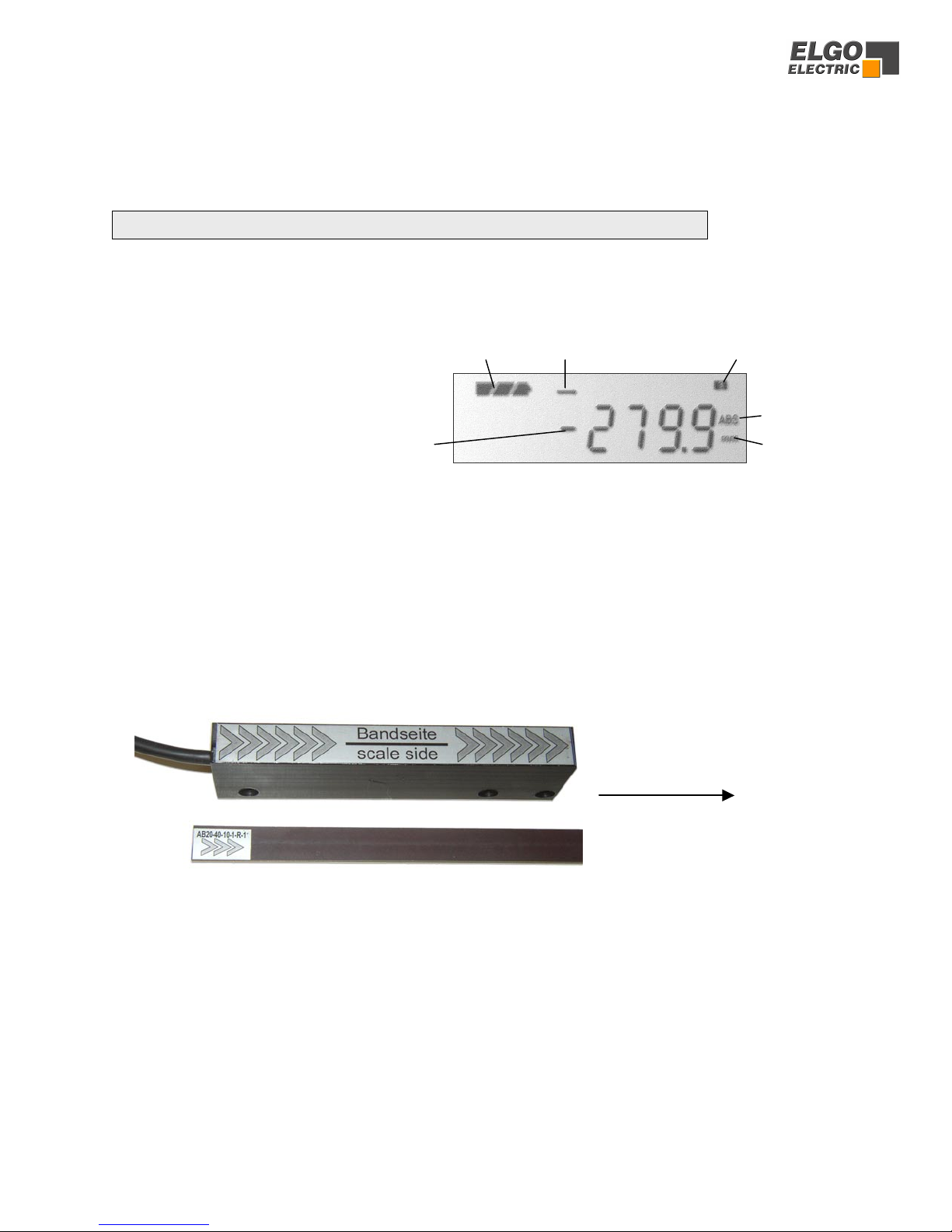

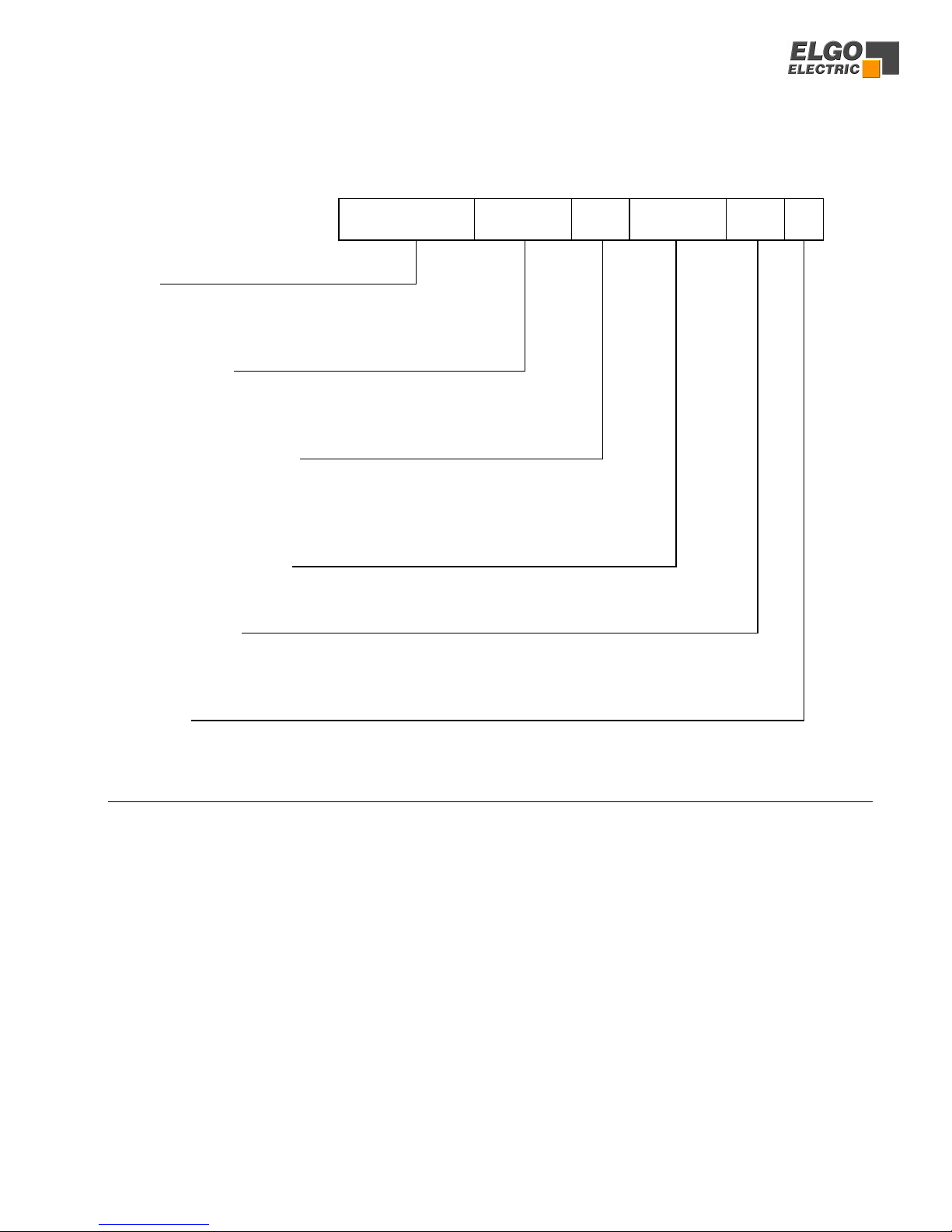

4. Display assignment

5. The AZ16E in operation

5.1 Initial operation

5.1.1 Detection of measuring direction

The Magnet Sensor „AZS“ and the magnetic tape are provided with a marker, in order to signal

the installation direction. The markings of sensor and tape must point to the same direction.

The counting direction (+/-) is reversible in parameter P01 (see chapter 5.4).

5.1.2 Referencing

Setting the zero-point: A new AZ16E unit shows always the absolute value of the magnetic

tape and should be calibrated to the zero point for one time. The reference value default setting in

register P09 is 0. To assign a zero point to an arbitrary position, move to the desired

zero-point and press the buttons F + Set together.

Reference value: Alternatively an arbitrary value can be entered in P09, to set a demanded ref-

erence measurement by pressing F + Set together.

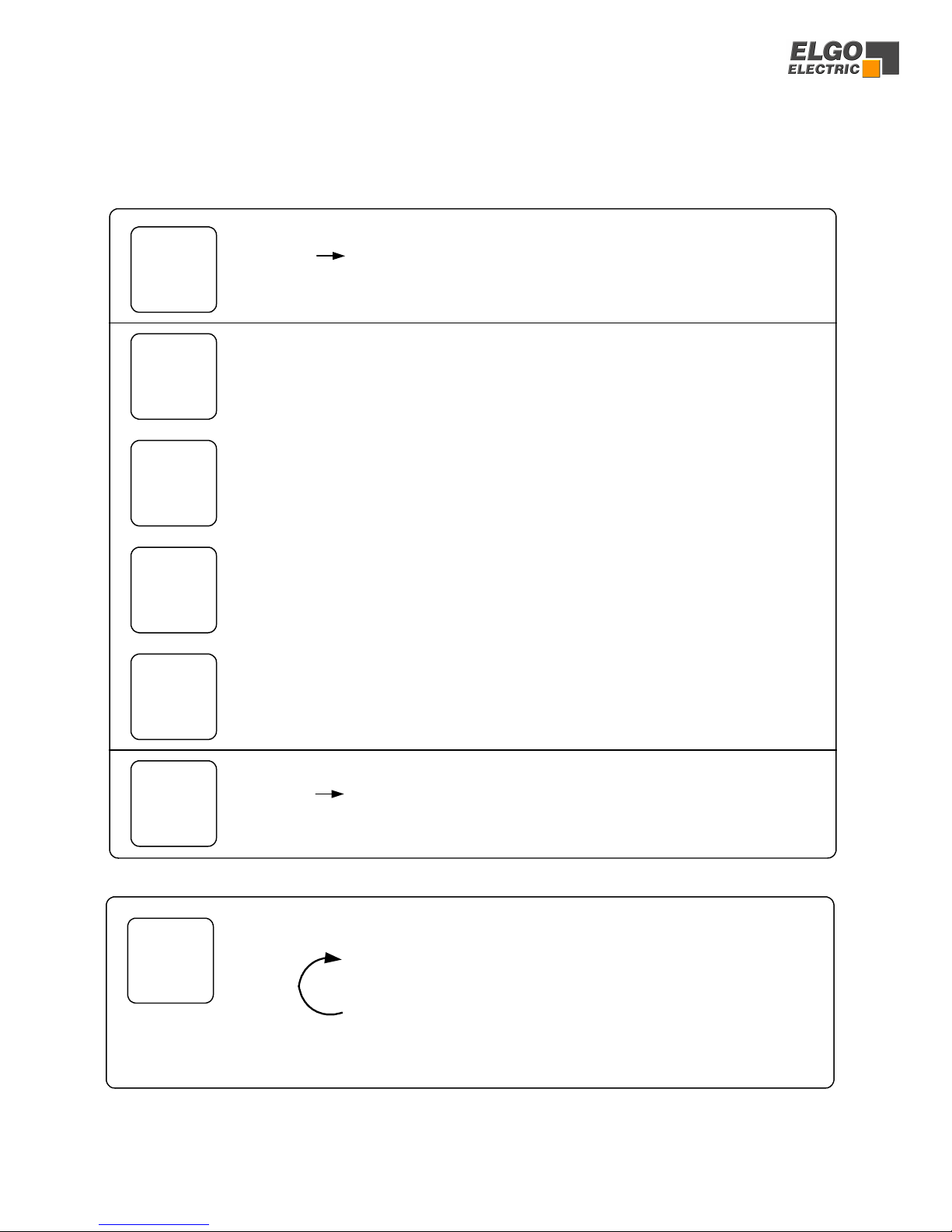

battery condition direction arrow tool offset 3 (1, 2 or 3 possible)

absolute mode

sign measurement unit

Sensor bottom Positive Counting Direction

(if P01 = Default setting)

Tape (top view, scanning side)

5

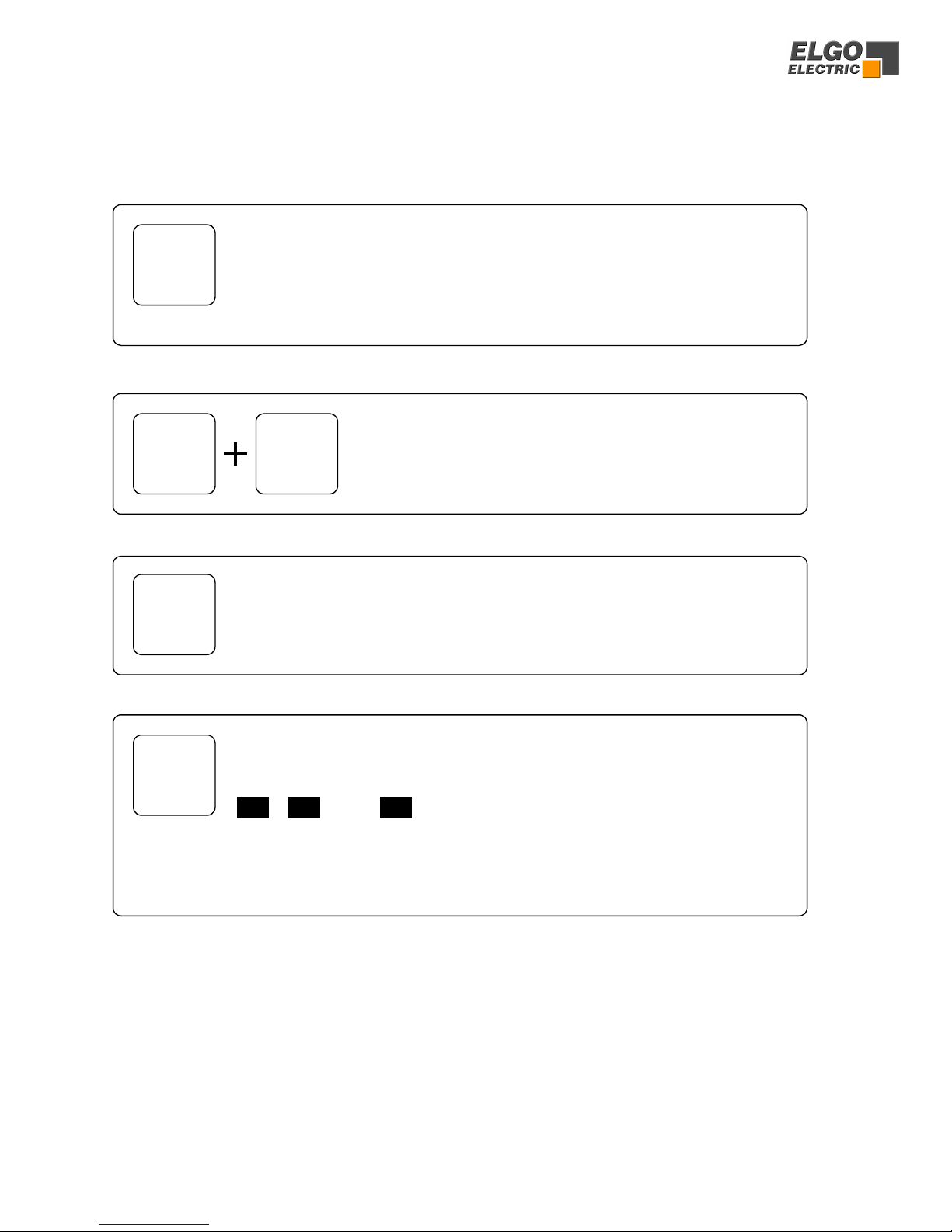

5.2 Basic functions (overview)

Absolute-/ relative measurement

Press Incr/Abs to switch over from „absolute“ to „relative“ measurement:

The actual value shows „0“ and also "INC" appears in the display.

With a renewed pressing of Incr/Abs the display switches back to

„absolute“ measurement and the display shows the real absolute value

again and „ABS“ also.

Incr/

Abs

Reference value

FSet

By pressing F + Set together, the display sets

to the reference value, deposited in register P09.

Switch back from the sleep mode

F

The unit switches into the sleep mode after completion of the adjustable

time in register P04, if there are no changes in the display value and no

key is pressed.

To switch back from the sleep mode, the button Fmust be pressed.

*

Tool offset

Switches over betwee three adjustable Tool Offsets. These can be

depostided in the registers P10/11/12.

The display appears (right above):

, or .

The selectet tool offset will be added to the actual value.

21 3

6

5.3 Parameter settings

Fraction views in Inch- Mode

SET

In the inch mode four different

fraction views can be selected:

Press SET for one time: LSB = 1/64 Inch

Press SET for two times: LSB = 1/32 Inch

Press SET for three times: LSB = 1/16 Inch

Press SET for four times: LSB = 0.001 Inch

F

1) Press button F for 3 seconds.

"P01" (Parameter 01) appears in the display window.

Set

3) Select the desired decade by pressing Set

Incr/

Abs

4) Adjust the desired value by using the Incr/Abs button

F

5) Press F to select the next parameter

Repeat No. 2)... 4) for the next parameter

F

6) Press F for 3 seconds

The display shows the actual value again

F

2) Press button F

The appropriate parameter value appears in the display

3 sec.

3 sec.

7

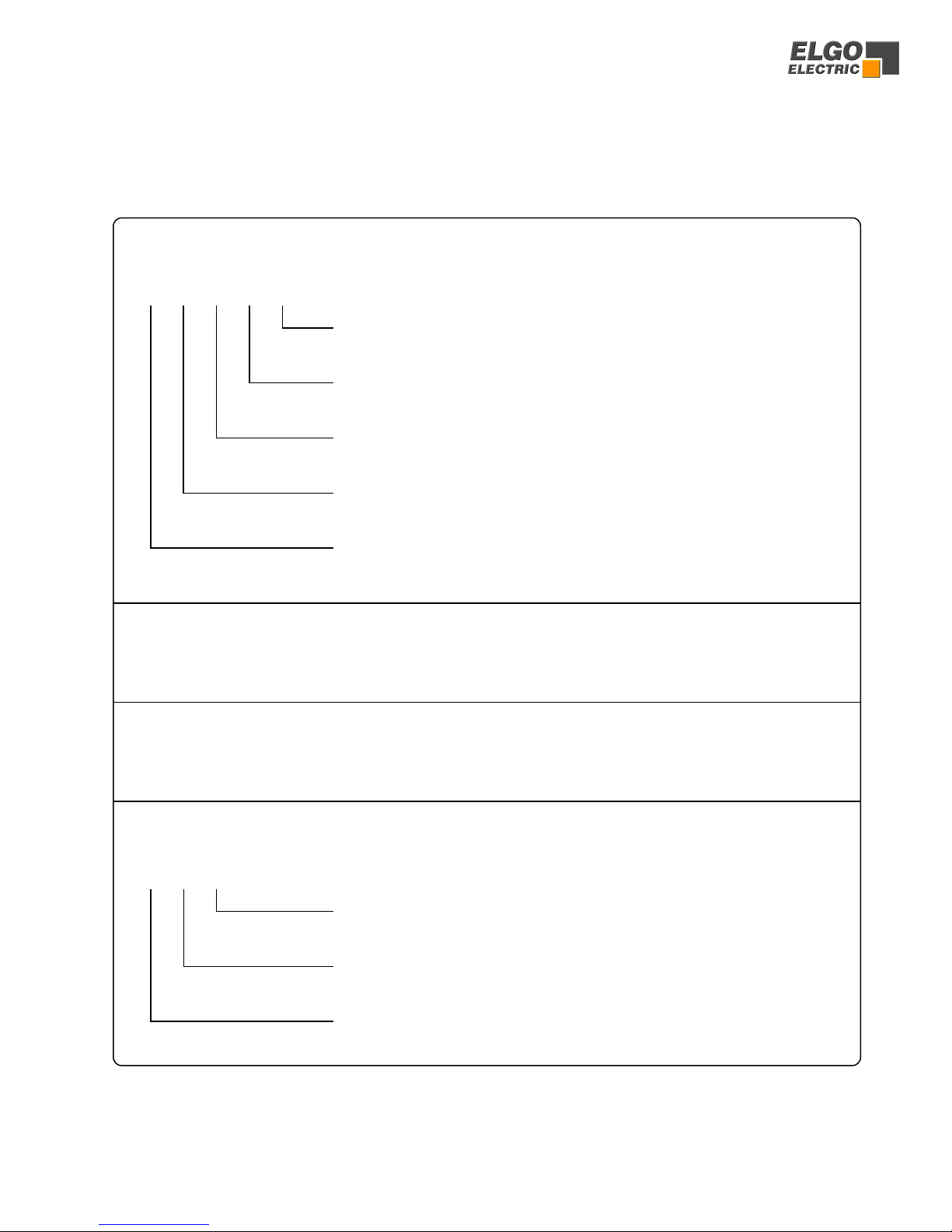

5.4 Parameter list

P 01 / Configuration of system:

0 =

XXXXX

1 =

Positive counting direction

Negative counting direction

0 =

1 =

mm operation (0.1 mm resolution)

Inch operation (0.1 inches resolution)

0 =

1 =

mm/Inch symbol disabled

mm/Inch symbol enabled

( default setting = 11100 )

0 =

1 =

Arrow symbol for „positive direction“ disabled

Arrow symbol for „positive direction“ enabled

0 =

1 =

LCD in standby mode disabled

LCD in standby mode enabled

(Display "OFF" and battery condition)

P 03 / Decimal place: ( default setting = 1 )

X= 0...3 (for mm operation only)

P 05 / keyboard interlock: ( default setting = 111 )

XXX

0 =

1 =

button Set disabled

button Set enabled

0 =

1 =

button Incr/Abs disabled

button Incr/Abs enabled

0 =

1 =

button *disabled

button *enabled

P 04 / Auto power off time: ( default setting = 10 s )

X= 0...99 seconds ( 0 = standby mode disabled)

X

8

Parameter list (continuation)

P 09 / Reference value: ( default setting = 0.0 mm / 0.000 Inch )

- 999999.9 mm ... + 999999.9 mm ( - 9999.999 Inch ... + 9999.999 Inch )

P 10 / tool offset 1: ( default setting = 10.0 mm / 0.100 Inch )

- 999999.9 mm ... + 999999.9 mm ( - 9999.999 Inch ... + 9999.999 Inch )

P 11 / tool offset 2: ( default setting = 20.0 mm / 0.200 Inch )

- 999999.9 mm ... + 999999.9 mm ( - 9999.999 Inch ... + 9999.999 Inch )

P 12 / tool offset 3: ( default setting = 30.0 mm / 0.300 Inch )

- 999999.9 mm ... + 999999.9 mm ( - 9999.999 Inch ... + 9999.999 Inch )

P 99 / Indicates the software version:

1.21 = SW-V1.21

P 08 / Position scaling factor:

0.001 ... 9.999 (the position value is multiplied by the factor adjusted here)

( default setting = 1.000 )

6. Battery change

To change the battery with a standard unit (integrated battery version) remove battery cover

on the rear, by pressing the outer edges gently (like shown on the photo). Useful are commer-

cial battery types, size C, 1.5 V) with good quality. All values and settings remains in case of

changing the batteries.

Please pay attention to the correct polarity!

The polarity is marked inside the housing.

9

7. Magnetic Tape

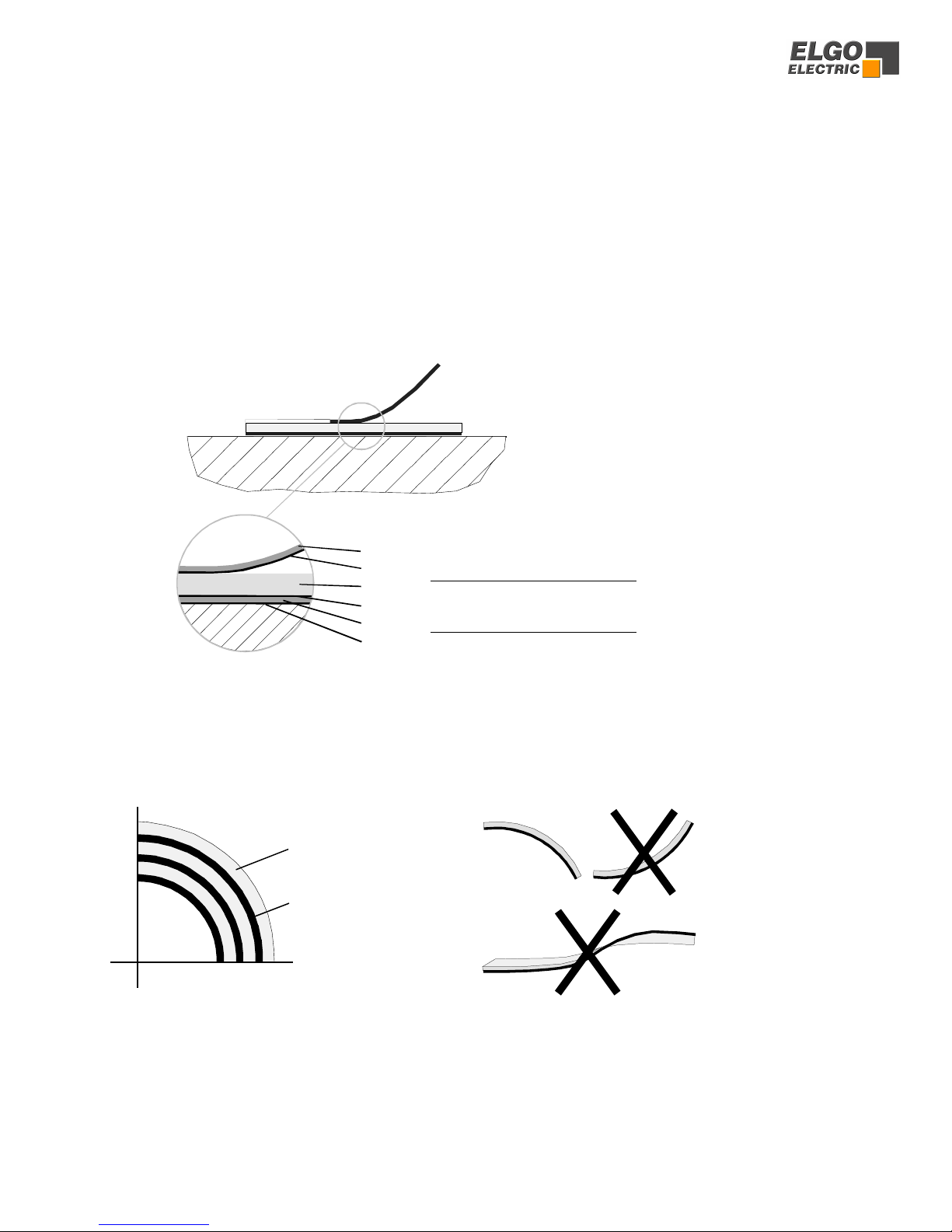

The magnetic tape consists of 3 components (see picture 1)

• a magnetized flexible rubber tape (Pos. 3), which is connected factory made with a

• steel band (Pos. 5) and a

• covering band (Pos. 1) , which is intended for the protection of the rubber tape.

• For mechanical protection of the magnetic tape the covering band must be stuck on. Addi-

tionally it protects the magnetic tape from extreme external magnetic influences.

To reach a complete adhesion between the several materials a special sticky tape is used

(Pos. 2, Pos. 4, Pos. 6).

Pos. 1

–

Coverin

g

band

Pos. 2

–

Sticky tape

Pos. 3

–

Ma

g

netic rubber tape

Pos. 4 - Sticky tape

Pos. 5

–

Steel band

Pos. 6 - Sticky tape

Factory

bonded

Picture 1: Components of the magnetic tape

7.1 Handling

To avoid tension in the magnetic tape, don’t tuck or twist it. Avoid also to store or to handle it

with the magnetic rubber tape to the inside (min. bend radius 150 mm).

Magnetized

synthetic tape

Steel band

Picture 2: Storage and transport

10

7.2 Processing note for sticking

The provided sticky tapes stick well on clean, dry and plain surfaces. The more pollution exists

the more proper the surface has to be. A surface roughness of Ra<= 3,2 (Rz<= 25 / N8) is rec-

ommendable. Typical solvent for cleaning surfaces are a 50/50 - isopropyl-alcohol / water mix-

ture or heptane. The surfaces of materials as copper, brass etc. should be sealed to avoid an

oxidation. The stability of the adhesion is directly depending on the contact, which the adhesive

develops to the stuck surfaces. A high pressure results in a good surface contact.

The optimal sticking temperature is between + 21°C and 38°C.

Avoid colder sticking surfaces than + 10 °C, because in this case the adhesive becomes to hard

and perhaps a sufficient immediate adhesion is hardly to achieve. After proper sticking the sta-

bility of the connection is ensured also when the temperature is below zero. The final tackiness

of a sticking is from experience reached after approximately 72 hours (at + 21 °C). For sticking

use only the provided sticky tape.

7.3 Resistance to chemicals of the magnetic tape

The magnetic tape shows no or only small effects when contacting permanently the following

materials after 2 to 5 years: Formic acid, Glycerol 93°C, Linseed oil, Soy beans oil, Cotton seed

oil, N-hexane, Lactic acid, Formaldehyde 40%, Isooctane, Petroleum.

Poor to medium effects result when contacting permanently the following materials after ap-

proximately 1 year: Acetone, Gasoline, Acetic acid 30%, Olein acid, Acetylene, Steam, Acetic

acid, pure Acetic acid, Sea water, Ammonia, Acetic acid 20%, Isopropyl ether, Stearic acid 70°C

anhydrous, Kerosene.

Strong effects result when contacting permanently the following materials after 1 to 5

months: Benzene, Nitric acid 70%, Turpentine, Toluene, Lacquer solvent, Nitric acid red and

Vitriolic, Carbon Tetrachloride, Trichloroethane, Nitrobenzene, Hydrochloric acid 37% and 93°C,

Tetrahydrofuran, Xylene.

7.4 Sticking and cutting

Attention! When sticking the magnetic tape pay attention to the marks on the mag-

netic tape. A faulty installation delivers incorrect values. An already stuck magnetic

tape is ruined after removing and can't be used again. Observe also the counting

direction of the measuring system.

The magnetic tape and the covering band must be cut to the exact length before sticking:

Magnetic tape length = measuring length + 0.1 m

Preferably the magnetic tape should be stuck into a nut or aligned to an edge.

Procedure for sticking:

1. The magnetic tape is already factory bonded with the steel band, in between is a double sided

sticky tape. Stick the provided sticky tape onto the carrier side (= steel band).

2. Now adjust the magnetic tape and stick it onto the surface. The best way to stick the mag-

netic tape is to do it in two steps. Remove the first half of the adhesive film from the sticky tape

and stick it, then do the rest length.

3. Then stick the sticky tape onto the covering band. It is not important on which side of the

covering band the sticky tape is stuck on.

4. Stick the covering band onto the visible brown magnetic rubber tape

11

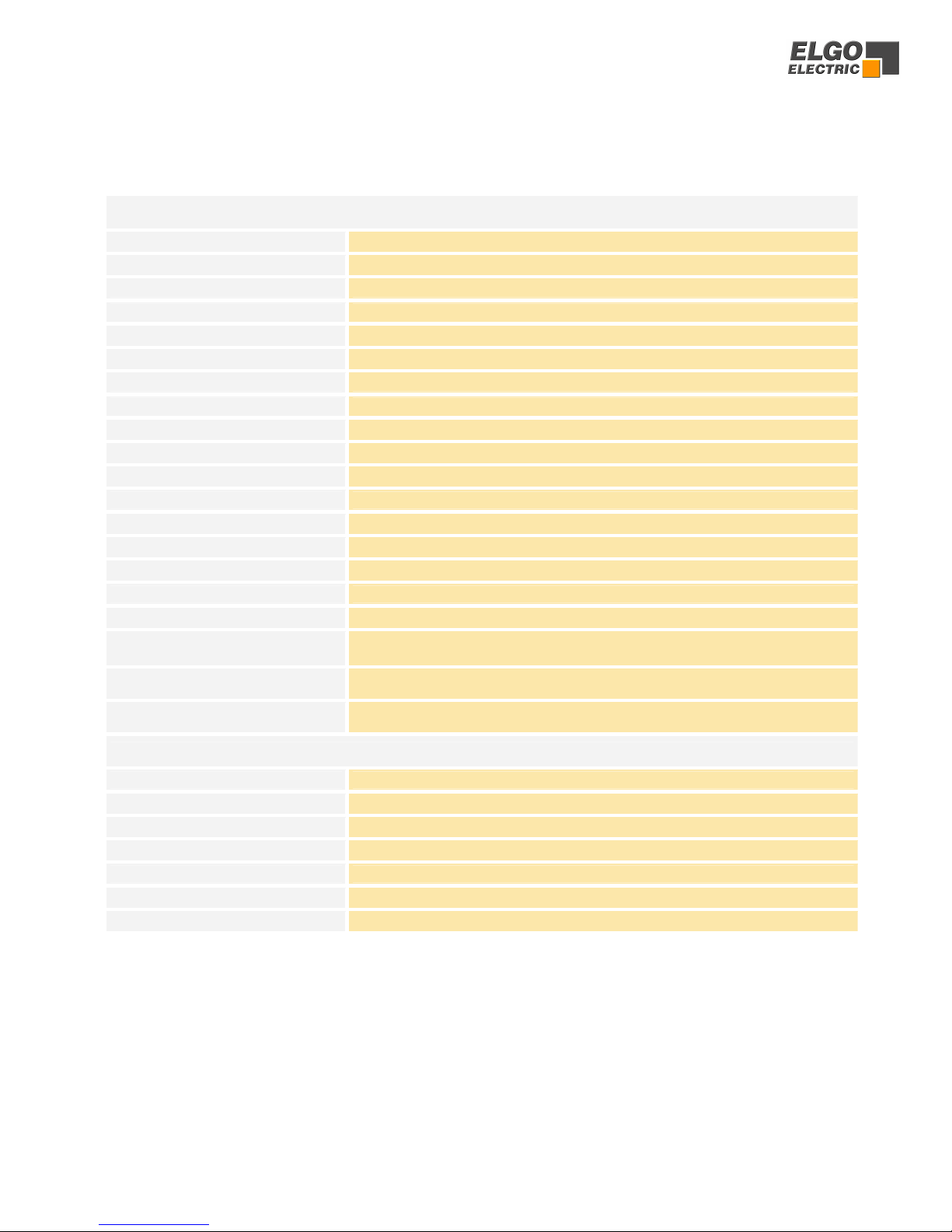

8. Technical specifications

AZ16E (battery powered absolute encoder and indicator system with an external sensor)

POWER SUPPLY 1 commercial battery size C (1.5 V)

Battery service life 1... 3 years (depends on adjusted switch-on time)

Distance Sensor - Tape max. 1.5 mm

Resolution of encoder 0.1 mm

Measuring units mm’s or INCHES

Measuring length max. 8 m

Principle of Measurement Magnetic, absolute

Character of Measurement Linear, no rotative movements possible

LCD-Display 6 Decades, height = 8 mm, with battery condition, signs and symbols

Keypad Membrane keypad

Operating temperature + 5... + 50° C

Stock temperature 0... 70° C

Humidity Not condensing, max. 80 %

Altitude max. 2000 m above sea level

Protection class (display unit) IP 43 (installed state)

Outer dimensions W x H = 96 x 72 mm

Cut out W x H = 93 x 67 mm

Depth (install depth) 37 mm

(total depth) 43 mm

Protection class (sensor) IP 67

Dimensions of sensor (see drawing on page 13)

Magnetic tape for AZ16

Code Absolute, single track system

Extension coefficient a = 16 x 10-6 K-1

Linear extension ∆L = L x αx∆ϑ (L= measuring length in meters)

Dimensions (W x H) 10 mm x ca. 1.8 mm

min. bend radius 150 mm

Operating temperature 0... + 50° C

Protection class IP 67

12

9. Dimensions

9.1 Display Unit:

Panel cut out: B x H = 93 x 67 mm

96

72

63 9

92

6

27

43

34

5.5

37 (Install depth)

66

* minus 9 mm, plug can be bended

34 *

13

9.2 External Magnet Sensor „AZS“:

10. Installation / Display Unit

For mounting into a panel serves 2 small mount-

ing plates with grub screws (included in the deliv-

ery, see image right).

The unit must be pushed from the front into the

cut-out and fixed from the rear by the grub

screws at the instrument panel then.

100

12

1

25

87

174

4

Ø 3.4 Ø 6

R4

14

11. Type designation

AZ16E- 000- 1- X

Type

SN- Number

Power supply (1.5 V)

Cable options

AZ16E: Indicator with external sensor

000 = standard

001 = first special version etc.

0 = fixed cable output

1 = plugable by RJ45 connector (standard)

03.0-

Options

1 = one internal size C battery (standard)

2 = two internal size AA batteries

3 = external battery case

Sensor cable lenght

(max. 20 m possible)

1-

AG = built on housing

Magnetic tape for AZ16E

Type: AB20-40-10-1-R-11 - Desired Length* please indicate in X.XX meters

*) Desired length = measuring length + 0.1 m

15

12. Liability exclusion / Guarantee

We have checked the contents of this instruction manual carefully, to the best of our knowledge and

belief for conformity with the described hardware and software. Nevertheless errors, mistakes or

deviations can not be excluded, therefore we do not guarantee complete conformity. Necessary cor-

rections are included in the subsequent editions.

We appreciate your ideas and improvement suggestions very much.

Reprint, duplication and translation, even in extracts, are only allowed with a written authorization

by the company ELGO Electric GmbH. Our objective is to improve our products constantly, therefore

we keep all rights reserved for any technical modifications without any notice.

ELGO Electric does not assume any liability for possible errors or mistakes.

The guarantee period is one calendar years from the date of delivery and includes the delivered unit

with all its components. ELGO Electric GmbH will at its option replace or repair without charge de-

fects at the unit or the included parts, verifiable caused by faulty manufacturing and/or material in

spite of proper handling and compliance to the instruction manual.

Damages verifiably not caused by ELGO-Electric GmbH and due to improper handling are excluded

from any guarantee e.g. by applying faulty voltage, diffusion of liquid into the interior of the engine,

using force, scratching the surface, chemical influences etc.!

Subject to modifications © ELGO Electric GmbH 2006

Table of contents

Other ELGO Electric Media Converter manuals

Popular Media Converter manuals by other brands

HumanTechnik

HumanTechnik S/PDIF Operation instructions

Belden

Belden GRASS VALLEY KUDOSPRO UHD 1100 user manual

Silex technology

Silex technology LAN 3100 operating manual

Analog way

Analog way BROAD SCAN HD BHD930-AG Preliminary user's manual

TR-Electronic

TR-Electronic CMV582M-4096/4096 PB 36ZB10FL Assembly instructions

Canary

Canary CFT-206X Product specifications