elgris HYBRID BASIC User manual

Hybrid Controller

“Diesel – PV Off the shelve”

Manual

Version 2.5

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 2 of 25

Table of Contents

1. INTRODUCTION___________________________________________________________________________ 4

1.1 Version overview_____________________________________________________________________ 5

2. INSTALLATION____________________________________________________________________________ 6

2.1 Safety instructions____________________________________________________________________ 6

2.1 Device overview______________________________________________________________________ 6

2.2 Pin description _______________________________________________________________________ 7

2.3 General connection overview GRID and FUEL SAVING_______________________________________ 8

2.4 RS 485 pin out _______________________________________________________________________ 9

2.5 Dipswitches _________________________________________________________________________ 9

3.0 SOFTWARE ____________________________________________________________________________ 11

3.1 Settings reading _____________________________________________________________________ 11

3.2 Settings changing____________________________________________________________________ 11

3.3 Parameter overview _________________________________________________________________ 12

3.4 Output selection type ________________________________________________________________ 12

3.5 Grid feed in protection modus _______________________________________________________ 13

3.6 Fuel Saving mode with generator _____________________________________________________ 14

4COMMISSIONING________________________________________________________________________ 14

4.1 First time power on __________________________________________________________________ 14

5GRAPHICAL USER INTERFACE ________________________________________________________ 15

5.1 Overview __________________________________________________________________________ 15

5.2 Inverter settings_____________________________________________________________________ 15

5.3 elgris cloud _________________________________________________________________________ 16

5.4 System settings _____________________________________________________________________ 17

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 3 of 25

5.5 Multiple generators with elgris SMART METER ___________________________________________ 18

5.5.1 Grid and dual generator application example with optional storage _________________________ 19

6ADJUSTING THE PID SETTINGS_______________________________________________________ 20

6.1 Manual tuning ______________________________________________________________________ 20

6.2 Ziegler–Nichols method ______________________________________________________________ 21

7MODBUS GATEWAY FUNCTION_______________________________________________________ 21

8MODBUS SERVER _______________________________________________________________________ 22

8.1 Register mapping Common Model______________________________________________________ 22

8.2 Register mapping WYE connect Meter Model ____________________________________________ 23

8.3 Custom mapping ____________________________________________________________________ 25

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 4 of 25

1. Introduction

Dear customer, thank you for purchasing this product. The HYBRID BASIC controller is the first series

produced control system which enable you to control a PV system connected with a Diesel generator

in an intelligent way. With the modern HYBRID BASIC series Diesel - PV controller you can control

your PV system in a way that Diesel load is minimised, and fuel saving is maximized. The modern

controllers offer the following functions:

•Multiple Generator set control

•Prime mover and generator protections

•Engine data measurement (optional trough external bus):

oOperating hours

oRunning hours

oStart attempts

oOil pressure

oCoolant temperature

oBattery voltage

oFuel level measurement

oEngine speed

oService hours

oEtc.

•Generator voltage, current and power measurement

•GRID control and GENERATOR control with one device

•Ethernet based web interface for remote control (optional)

•2x MODBUS RS-485 for engine control and easy expanding

Specializing in products for generators and hybrid power solutions, the HYBRID BASIC offers the

following features standard:

•Wide range power supply input from 85 - 265 VAC (50 - 60 Hz)

•Small footprint.

•Intuitive software.

•Wide temperature range of -25° –+85°.

•Industrial PUR protection coating for extra rugged environment.

•IP-68 on request.

If you have any questions or if something is unclear, you can contact us in several ways:

Per E-Mail : support@elgrispower.com

By Phone : +49 (0) 2423 9086501

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 6 of 25

2. Installation

2.1 Safety instructions

Before installing the product in the end-installation, ensure that the device is not damages during

transport and everything looks in a normal way.

All the connecting cables must not be bent or squeezed. This can result in malfunctions, short circuits

and defects in the device and/or sensor connected.

Make sure that cables are not damaged when drilling or bolting in place.

The module may only be commissioned after it has been installed contact-free in a casing. This

product generates high frequency. Never operate it in the vicinity of medical devices (e.g.

pacemakers) and/or medical equipment (e.g. in hospitals). Look for a suitable installation site.

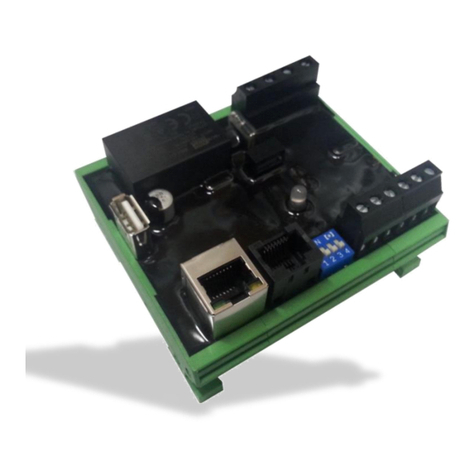

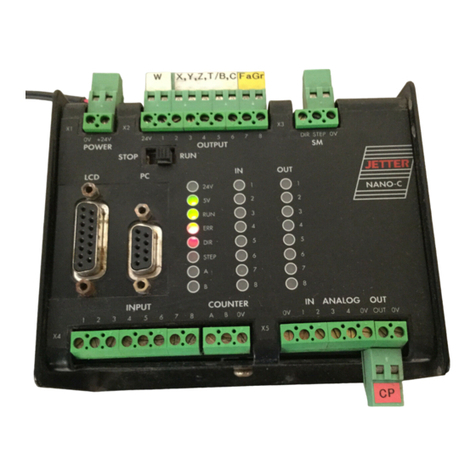

2.1 Device overview

Before wiring the device, be sure that the voltage is switched off.

+

-

OK

on

1 2

on

1 2 3 4 5 6

13 14 15 16

1

2

3

4

5

6

7

8

9

10

11

12

21

20

19

18

17

Ethernet

RS 485 A

RS 485 B

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 7 of 25

2.2 Pin description

Signal connector

Pin

Description

Minimum

Maximum

1

Analogue input 1 positive

0 V / 0 mA

10 V / 20 mA*

2

Analogue input 2 positive

0 V / 0 mA

10 V / 20 mA*

3

Input common level

0 V

0 V

4

Digital input 1

Open

Closed

5

Digital input 2

Open

Closed

6

Input common level

0 V

0 V

Power input

7

K input current transformer L3

0 Aac

5 Aac

8

L input current transformer L3

0 Aac

5 Aac

9

K input current transformer L2

0 Aac

5 Aac

10

L input current transformer L2

0 Aac

5 Aac

11

K input current transformer L1

0 Aac

5 Aac

12

L input current transformer L1

0 Aac

5 Aac

13

Phase L1 voltage input

85 Vac

250 Vac

14

Phase L2 voltage input

85 Vac

250 Vac

15

Phase L3 voltage input

85 Vac

250 Vac

16

Neutral input of voltage

Control

input

17

Level 1 (0 % limitation)

2 A @ 250 VAC / 30 VDC

18

Level 2 (30 % limitation)

2 A @ 250 VAC / 30 VDC

19

Level 3 (60 % limitation)

2 A @ 250 VAC / 30 VDC

20

Level 4 (100 % limitation)

2 A @ 250 VAC / 30 VDC

21

Relay signal common

Check inverter specifications

Dipswitch

1

1

IP address selection

OFF = DHCP

ON = static

2

System frequency

OFF = 50 Hz

ON = 60 Hz

3

Single or Three phase

OFF = Three phase

ON = Single phase

4

Not used

Must be OFF

5

Analog selection channel 1

ON = 0 –20 mA

OFF = 0 –10 V

6

Analog selection channel 2

ON = 0 –20 mA

OFF = 0 –10 V

Dipswitch

2

1

120 Ohm termination RS-485 A

ON = 120 Ohm

OFF = Open

2

120 Ohm termination RS-485 B

ON = 120 Ohm

OFF = Open

* Depending on dipswitch 5 and 6

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 9 of 25

2.4 RS 485 pin out

Pin

Description

1

Not connected

2

RS-232 TX (Only on A)

3

RS-232 RX (Only on A)

4

RS-485 B (D-)

5

RS-485 A (D+)

6

GND

7

Not connected

8

Not connected

2.5 Dipswitches

There are 2 dipswitches on the controller. The 2 switch is for the termination resistors of the RS 485

A and B and the 6 switches if for settings.

on

1 2

Dipswitch

Description

OFF

ON

1

No termination A

120 Ohm A

2

No termination B

120 Ohm B

on

123456

Dipswitch

Description

OFF

ON

1

DHCP

Static IP

2

50 Hz

60 Hz

3

Three phase

Single phase

4

Not used must be OFF

5

0 –10 Vdc

0 –20 mAdc

6

0 –10 Vdc

0 –20 mAdc

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 10 of 25

2.6 LED status

The LED on board informs the user about the internal status.

LED colour

Meaning

Action

Off

No power or internal error

Contact support

Internal Error

Contact support

Date and time not set, no USB data

logging possible

Update date and time or check

internet connection for SNTP

Standby, no inverter online

Check inverter settings

Controller is throttling the PV

Normal operation

Power management active

Normal operation

Controller is not throttling PV

Normal operation

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 11 of 25

3.0 Software

The software on the controller enables the user to change all relevant settings and adjust the system

to local needs for example during commissioning.

The HYBRID BASIC controller has an integrated menu which can be selected by pressing the OK

button. When the menu is active, the outputs are disabled and no control is possible. After leaving

the menu, the new settings will be stored in EEPROM and the controller automatically loads the new

parameters and start working.

When the system is working, you can read the actual power on the top display. The bottom display

shows error or other parameters, depending on the firmware version and type of HYBRID controller.

Availability of the settings and display screen depends on the firmware version.

3.1 Settings reading

To read out the actual parameters of the HYBRID BASIC controller press the OK button. The led will

start flashing green and by pressing UP and DOWN you can scroll through the parameters.

On the top screen you can read the parameter number and on the bottom screen you can read the

actual parameter value.

+

-

OK

LED solid green

3.2 Settings changing

You can change the settings by pressing the OK button when the parameter which needs to be

changed is selected and displayed on the screen.

+

-

OK

LED solid orange

The led will lid orange to indicate that the parameter can be changed.

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 12 of 25

3.3 Parameter overview

The following parameters are available. Not all paramters can be changed. Parameters which can not

be changed are marked with a * and are read only. Most parameters which can not be changed are

for measurements only.

Parameter 4 and 9 are used for the power calculations. Parameter 4 holds the secundairy value of

the CT and parameter 9 the primairy.

Number

Description

Default

Minimum value

Maximum value

Symbol

P1

Generator power*

0

0

999

kW

P2

CT current*

0

0

1 –5

A

P3

CT current in % of maximum

0

0

100

%

P4

CT type (1A –5A)

1

1

5

A

P5

Minimum setpoint generator

50

0

100

%

P6

Ramp up speed

30

0

60

Seconds

P7

Ramp down speed

5

0

60

Seconds

P8

Power correction

1

0.00

2.00

P9

CT ratio (P4:P9)

100

1

1000

A

P10

Output type

1

1

5

See table

3.4 Output selection type

The 4 relays on the controller can be programmed with different functionality. There are 3 main

output modes, the BAR mode, the DOT mode and the BINAIR mode each having the possibility to set

a minimum value rather than having all the relays off.

When the time set with P7 is elapsed, the next output type is selected. When the value is below 0 %

either no output will be selected (without minimum) or the lowest possible value is selected (with

minimum).

Parameter 10

Mode

Limitation

Relay output

1

2

3

4

1

BAR without minimum

0 %

X

30 %

X

X

60 %

X

X

X

100 %

X

X

X

X

2

BAR with minimum after

delay of P7

0 %

X

0 %

X

X

30 %

X

X

X

60 %

X

X

X

X

100 %

X

X

X

X

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 13 of 25

Parameter 10

Mode

Limitation

Relay output

1

2

3

4

3

DOT without minimum

0 %

X

30 %

X

60 %

X

100 %

X

4

DOT with minimum after

delay of P7

0 %

X

0 %

X

30 %

X

60 %

X

100 %

X

Parameter 10

Mode

Limitation

Relay output

1

2

3

4

5

Binair output

0

1

X

2

X

3

X

X

4

X

5

X

X

6

X

X

7

X

X

X

8

X

9

X

X

10

X

X

11

X

X

X

12

X

X

13

X

X

X

14

X

X

X

15

X

X

X

X

3.5 Grid feed in protection modus

The HYBRID BASIC controller can also be used to set a specific feed in limit, prevent the inverter from

feeding into a (public) grid (zero export) or have a minimum consumption from the grid.

The controller accepts two different setpoints which can be selected with digital input 1 (pin 4).

When the digital input 1 is open, the controller uses the grid setpoint.

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 14 of 25

3.6 Fuel Saving mode with generator

In the “Fuel Saving” mode the controller automatically determines the optimum production point of

the solar system to archive maximum savings for the Diesel. Further the controller ensures that the

generator will not be running under the minimum load specified by the engine manufacturer.

The controller accepts two different setpoints which can be selected with digital input 1 (pin 4).

When the digital input 1 is open, the controller uses the grid setpoint.

4 Commissioning

Before starting with the commissioning of the HYBRID controller all safety precautions must be taken

which apply to the rules in your country and general safety rules. Never work on a system with a

running generator and short the output of the generator before working on the power system.

Only a few settings are needed to commissioning the HYBRID system. Most important is the settings

of the current transformer and the setpoints for grid mode and Fuel Saving mode.

4.1 First time power on

Follow the following steps when the system is first time being powered.

When using TCP for communication, all components needs to have static IP settings.

Switch off the PV inverter, disconnect the PV inverter from the system and start the

controller by applying power to L1 and N in case you use a single-phase system or L1, L2 and

L3 with N for three phase systems. When the HYBRID controller is working properly, the LED

is blinking green.

Connect to the embedded webserver by typing the default address 192.168.1.100 in a web

browser.

On the Menu select Settings to adjust the CT ratio. The CT ratio is defined as 1: value. For

example, when you have a CT 5:200 the value is 40.

When the CT ratio is changed the power readings on the overview page should match the

actual power. More detailed information can be obtained with 192.168.1.100/Meter

A positive value is consumption from the grid, a negative value means exporting to the grid.

When this is not correct, check the wiring of K and L of the CT.

Switch on the DC side of the PV system to commission the PV inverters. The steps to add an

inverter to the system is explained on page 15.

End

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 15 of 25

5 Graphical User Interface

The HYBRID BASIC controller includes a webserver to adjust the system parameters and see the

status of the system.

By default, the webserver can be reached by typing the IP address 192.168.1.100 in a web browser.

Supported web browsers are Microsoft Edge, Google Chrome and Mozilla Firefox.

5.1 Overview

5.2 Inverter settings

After selecting the brand of the inverter which needs to be controlled, the type of communication

needs to be selected. Not all communication options are available for all inverters. Please refer to the

inverter support list on the website www.elgrispower.com

When selecting TCP as communication, the IP address and MODBUS TCP port (Default 502) must be

adjusted. When selecting RS 485 for communication, the MODBUS slave ID must be set, and the

serial port settings must match the inverter settings.

When all settings are correct they can be send to the inverter by pressing “Save settings”. Up to ten

inverters can be programmed by pressing “Add Inverter”.

Header with status

information and menu

Main area with system

information

Daily chart with load

and PV output

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 16 of 25

5.3 elgris cloud

With the elgris cloud you can store data on the open source platform eCloud. This enables the user

to have a cloud solution where all data can be visualised and transferred on other mediums.

The eCloud software can run on the open source server, a self-hosted server or local server like

Raspberry PI.

To start logging, you must fill out the server address with its hostname, the user key for security and

optional a user name when you want to log more data under the same account.

With the interval time you can set the time between each update interval. By setting the time to

zero, the data logging to the remote sever stops.

The response of the communication is displayed as last messages. When everything is working fine,

the message ”Ok” will be displayed here.

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 17 of 25

5.4 System settings

On the settings page the main settings and parameters can be changed. To enable the advanced

settings, the checkbox must be selected.

Status information

and settings for

information

Basic settings like IP

address and date /

time

Advanced settings for

RS 485 bus and

control parameters

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 18 of 25

5.5 Multiple generators with elgris SMART METER

The elgris HYBRID controller has only one metering input which is shared for both grid mode and

generator “Fuel Saving”mode.

In case there are more than one generator in the system, or the physical location of the feeders do

not allow the use of the shared metering input, elgris SMART METERS can be used to obtain the

measurement data.

Only generators can be connected to the system as an elgris SMART METER slave. By design,

the grid is always the elgris HYBRID controller internal meter.

The maximum of single generators than can be add is 5.

Ensure that all SMART METERS are powered all the time, otherwise the communication is

delayed all the time.

To select the elgris SMART METER first select “elgris SM” in the dropdown and fill out the IP address.

MODBUS port is 502 by default.

Then press “Save Settings” to store the settings. After refreshing the page, the serial number and

load will be shown on the table.

The current used generator for control is shown as “active”. This is even active when the controller is

in grid mode but has no influence on the actual value taken for the controller as current value which

is still the measurement from the internal meter.

With the more button, detailed information can be obtained.

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 19 of 25

5.5.1 Grid and dual generator application example with optional storage

G1 G2

GCB GCB

MCCB MCB

To load

elgris

SMART METER

MCB

~=

elgris BASIC

elgris

SMART METER

GRID Generator 1

200 kVA Generator 2

50 kVA

powerline

Ethernet

MCB

~=

STORAGE

3~ meter

switch

In this example the elgris BASIC is used as the master controller. The BASIC communicates with each

generator over Ethernet and collects the load of each generator. The BASIC controller automatically

determines the optimum setpoint for each generator and sends a setpoint to the PV inverters.

When the grid is connected to the load, the grid setpoint is used.

In case that the PV energy available is higher than the possible load for the whole system, an optional

storage can be charged and discharged later.

Version: 7. Oktober 2018 12:40

www.elgrispower.com

Page 20 of 25

6 Adjusting the PID settings

The elgris HYBRID controller has a real time PID controller to adjust the amount of PV power within

the system. By setting one value to zero, P, PI or PID controllers can be set. For standard applications,

the PI controller is a good starting point.

The PID controller takes the current power value (single or three phase) as current value and the

setpoint (grid or generator setpoint) as desired value.

The settings for P, I and D can be changed according to the application. Please note the following:

The P value is the proportional gain of the error between setpoint and current value. The

higher the P value, the more the controller will react to a change of load.

When the solar system over reacts on load changes, the P factor is too high. The other way

around, when the response is not high enough, the P factor is too small.

The I value is the integrated value of the past error over time. The longer and error exist, the

more the I part will affect the output.

When the reaction time on a load change is too slow, the I factor is too low. Opposite, when

the system is unstable (oscillating around a value) the I factor is too high.

The D value is for future trends. When there are big load changes in a very small time interval

this can be compensated by adding some D factor. The D factor only has influence on load

changes and not in a steady system.

The values entered on the settings page are divided by 1000.

6.1 Manual tuning

If the system must remain online, one tuning method is to first set I and D values to zero. Increase

the P until the output of the loop oscillates, then the P should be set to approximately half of that

value for a "quarter amplitude decay" type response. Then increase I until any offset is corrected in

enough time for the process. However, too much I will cause instability.

Finally, increase D, if required, until the loop is acceptably quick to reach its reference after a load

disturbance. However, too much D will cause excessive response and overshoot. A fast PID loop

tuning usually overshoots slightly to reach the setpoint more quickly; however, some systems cannot

accept overshoot, in which case an overdamped closed-loop system is required, which will require a

P setting significantly less than half that of the P setting that was causing oscillation.

Parameter

Rise time

Overshoot

Settling time

Steady-state error

Stability

P

Decrease

Increase

Small change

Decrease

Degrade

I

Decrease

Increase

Increase

Eliminate

Degrade

D

Minor change

Decrease

Decrease

No effect in theory

Improve if small

Table of contents

Other elgris Controllers manuals

Popular Controllers manuals by other brands

Metso

Metso Neles ValvGuard VG9000F Installation maintenance and operating instructions

molitor

molitor MAD instruction manual

EUROSTER

EUROSTER 11WB user manual

Banner

Banner LC25 Pro instruction manual

Metronix

Metronix DIS-2 48/10 FB FS STO manual

Toshiba

Toshiba nv Series Operating instructions (functional manual)