ELICA KIT0179549 Installation guide

1

Use, Care, and

Installation Guide

Guide

d’utilisation,

d’entretien et

d’installation

Guía de

instalación, uso y

mantenimiento

READ AND SAVE THESE

INSTRUCTIONS

LISEZ CES

INSTRUCTIONS ET

CONSERVEZ-LES

LEA Y CONSERVE

ESTAS INSTRUCCIONES

LIB0180582

Printed in Mexico

Models: KIT0179549

2

English

APPROVED FOR RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local Electrical Inspector’s use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

Safety Warning: Turn o power circuit at service panel and lock out panel, before wiring this appliance.

Requirement: 120 V~ AC, 60 Hz. 15 or 20 A Branch Circuit.

Important Safety Notice 3

Electrical Requirements 4

Tools and parts 5

Product dimensions 6

Venting Requirements 6

Installation Instructions 7

Prepare location 7

Install In-Blower system 12

Make Electrical Connection for In-Line Blower Motor System 13

Make Electrical Connection Inside Range Hood Between In-Line Blower System and Range Hood 14

3

Important Safety Notice

I CAUTION

FOR GENERAL VENTILATING USE ONLY. DO NOT USE TO

EXHAUST HAZARDOUS OR EXPLOSIVE MATERIALS OR

VAPOURS.

IWARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

B. Before servicing or cleaning the unit, switch power o at

service panel and lock service panel disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag,

to the service panel.

C. Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable codes

& standards, including fire-rated construction.

D. Sucient air is needed for proper combustion and

exhausting of gases through the flue (Chimney) of fuel

burning equipment to prevent back- drafting.

Follow the heating equipment manufacturers guideline and

safety standards such as those published by the national

fire protection association (NFPA), the american society

for heating, refrigeration and air conditioning engineers

(ASHRAE), and the local code authorities.

E. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

F. Ducted systems must always be vented to the outdoors.

I CAUTION

To reduce risk of fire and to properly exhaust air, be sure to

duct air outside - do not vent exhaust air into spaces within

walls, ceilings, attics, crawl spaces, or garages.

IWARNING

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCT

WORK.

Install this hood in accordance with all requirements specified.

IWARNING

To reduce the risk of fire or electric shock, do not use this

hood with any external solid state speed control device.

IWARNING

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE.

a) Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

flambeing food (I.e. Crepes Suzette, Cherries Jubilee,

Peppercorn Beef Flambe’).

c) Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

d) Use proper pan size. Always use cookware appropriate for

the size of the surface element.

IWARNING

TO REDUCE THE RISK OF INJURY TO PERSONS, IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:a

a) SMOTHER FLAMES with a close-fitting lid, cookie sheet, or

other metal tray, then turn o the gas burner or the electric

element. BE CAREFUL TO PREVENT BURNS. If the flames

do not go out immediately, EVACUATE AND CALL THE

FIRE DEPARTMENT.

b) NEVER PICK UP A FLAMING PAN - you may be burned.

c) DO NOT USE WATER, including wet dishcloths or towels -

a violent steam explosion will result.

d) Use an extinguisher ONLY if:

1) You know you have a class ABC extinguisher, and you

already know how to operate it.

2)The fire is small and contained in the area where it

started.

3)The fire department is being called.

4)You can fight the fire with your back to an exit.

e) Ducted fans must always be vented to the outdoor.

aBased on “Kitchen Fire Safety Tips” published by NFPA.

I CAUTION

Automatically Operated Device - To reduce the risk of

Injury disconnect from power supply before servicing.

For double Blower Motor Models (ELN136S2, ELN142S2, ELN148SS, ELI136S2, ELI142S2, EAR134S4, EAR140S4, EAR146S4,

ECL136S4, ECL142S4, ECL148S4, ETR134S1, ETR146SS)

4

Installation requirements

Electrical Requirements

IMPORTANT

Observe all governing codes and ordinances.

It is the customer’s responsibility:

• Have a qualified technician install the in-line blower motor

system.

• All openings in the ceiling and wall where the in-line

blower motor system will be installed must be sealed.

• Ensure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA

70 (latest edition), or CSA Standards C22.1-94, Canadian

Electrical Code, Part 1 and C22.2 No. 0-M91 (latest edition)

and all local codes and ordinances.

• If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that

the ground path is adequate.

• A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

• A 120 volt, 60 Hz., AC only, 15-amp, fused electrical circuit

is required.

• If the house has aluminum wiring, follow the procedure

below:

1 Connect a section of solid copper wire to the pigtail leads.

2 Connect the aluminum wiring to the added section

of copper wire using special connectors and/or tools

designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer’s

recommended procedure. Aluminum/copper connection

must conform with local codes and industry accepted.

wiring practices.

• Save Installation Instructions for electrical inspector’s use.

• Wire sizes and connections must conform with the rating

of the appliance as specified on the model/serial rating

plate. The model/serial plate is located behind the kit on

the rear wall.

• Wire sizes must conform to the requirements of the

National Electrical Code, ANSI/NFPA 70 (latest edition), or

CSA Standards C22. 1-94, Canadian Electrical Code, Part

1 and C22.2 No. 0-M91 (latest edition) and all local codes

and ordinances.

For Mobile Home Installations

The installation of this external blower motor system must

conform to the Manufactured Home Construction Safety

Standards, Title 24 CFR, Part 328 (formerly the Federal

Standard for Mobile Home Construction and Safety, Title

24, HUD, Part 280) or when such standard is not applicable,

the standard for Manufactured Home Installation 1982

(Manufactured Home Sites, Communities and Setups) ANSI

A225.1/NFPA 501A*, or latest edition, or with local codes.

5

Tools and parts

Gather the required tools and parts before starting the

installation. Read and follow the instructions provided with

any tools listed here.

Tools/Materials required

• Drill

• 11⁄4” (3 cm) drill bit

• 3⁄16” (0.5 mm) drill bit

• Pencil

• Wire stripper or utility knife

• Tape measure or ruler

• Pliers

• Caulking gun and weatherproof caulking compound

• Vent clamps

• Jigsaw or keyhole saw

• Metal snips

• Screwdrivers

•Phillips

•Flat-blade

Parts not supplied

• 6 AWG wires, one each of the following colors: black, white,

red, blue, gray, and green/yellow (ground)

NOTE: The length of the conduit and AWG wires is

determined by the distance between the in-line blower

motor and range hood terminal boxes.

• 11 - UL listed wire connectors.

Parts supplied

Removing parts from the packages. Check that all parts are

included.

• Shell for blower motor assembly

• Hardware bag with:

Supplied Part Pieces Supplied Part Pieces

Strain relief connector (13.5)

26.5 X 3.5 mm screws 10

4.2x8 mm screws 33

Ø 12 mm strain relief

1

6-wire blower connector

1

6x13.5 mm

2

4x1.8mm at washers

4Torx adapter

(T10)1

(T20)1

Spring tab

1

Clip nuts

4

6.3 x 60 mm screws

7Strap 2.5x 95 mm 3

Support bracket

1

6 x 16 mm screws

4

10x50 mm wall anchors

7

6

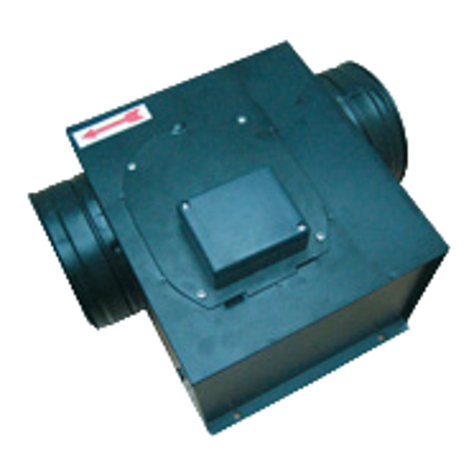

Product dimensions

14 7⁄8”

(20 cm)

TOP (OUTLET) VIEW

3 3⁄8”

(8.6 cm)

12 15⁄16”

(32.9 cm)

26 1⁄8”

(66.4 cm)

14 11⁄16”

(37.3 cm)

24 3⁄4”

(62.9 cm)

BOTTOM (INLET) VIEW

3 3⁄8”

(8.6 cm)

14 7⁄8”

(20 cm)

16 1⁄8”

(41 cm)

Venting Requirements

• The vent system must terminate to the outdoors.

• Do not terminate the vent system in an attic or other

enclosed area.

• Do not use 4” (10.2 cm) laundry-type vent or wall caps.

• Use round, metal vent only. Rigid metal vent is

recommended. Plastic or metal foil vent is not

recommended.

• The length of the vent system and number of elbows

should be kept to a minimum to provide ecient

performance.

For the most ecient and quiet operation:

• Use no more than three 90° elbows.

• Make sure there is a minimum of 24” (61.0 cm) of straight

vent between the elbows if more than 1 elbow is used.

• Do not install 2 elbows together.

• Use clamps to seal all joints in the vent system.

• The vent system must have a damper.

• Use weatherproof caulking to seal the exterior wall or roof

opening around the cap.

• The size of the vent should be uniform.

Cold weather installations

An additional backdraft damper should be installed to

minimize backward cold air flow. A thermal break should be

installed to minimize conduction of outside temperatures as

part of the vent system. The damper should be on the cold air

side of the thermal break.

The thermal break should be as close as possible to where the

vent system enters the heated portion of the house.

Typical In-line Blower System Installations

A 8” (20.32 cm) - 10” (25.4 cm) round vent system is needed

for installation (not included). The in-line blower system inlet

and outlet openings are 8” (20.32 cm) - 10” (25.4 cm) round.

The exhaust (outlet) opening on the range hood must also be

8” (20.32 cm) - 10” (25.4 cm) round.

NOTE: Flexible vent is not recommended. Flexible vent

creates back pressure and air turbulence that greatly reduce

performance.

The vent system can terminate either through the roof or wall.

NOTE: Plywood may be used as a mounting base to span

open areas between ceiling joists and rafters. If used, be sure

to use plywood capable of supporting the weight of the in-

line blower system (50 lb [22.6 kg]).

A

B

C

D

E

E

A. Mount on top of ceiling joists.

B. Mount from cross-members tied to

trusses.

C. Duct horizontal; mount to cross-mem-

bers tied to trusses.

D. Mount on underside of roof rafters.

E. Plywood

7

Installation Instructions

Prepare location

• Before making cutouts, make sure there is proper

clearance within the ceiling or wall for the exhaust vent.

• When cutting or drilling into the ceiling or wall, do not

damage electrical wiring or other hidden utilities.

• Check that all installation parts have been removed from

the shipping carton.

NOTE: For the correct performance of your In-Line Blower

System you must remove the Range Hood Internal Motor

Blower.

Remove Range Hood Internal Motor Blower

1 Remove grease filters from range hood.

2 Disconnect the blower power cord from de wire box.

B

A

A. Wire box connector

B. Power cord

3 For EAR134S4, EAR140S4, EAR146S4, ECL136S4,

ECL142S4, ECL148S4, ETR134S1 and ETR146SS range

hood models you have to remove the 4 - 6 x 16 mm screws

holding the blower motor.

4 For ELN136S2, ELN142S2, ELN148SS, ELI136S2 and

ELI142S2 models remove duct covers and the 4 - 6 x 16

mm blower motor screws.

5 Remove the motor mounting plate by setting free the

spring clip.

NOTE: The spring clip should be outside the slot in the

mounting plate.

A. Mounting plate

B. Spring Clip

A

B

A. Mounting plate

B. Spring Clip

A

B

8

6 Slide out mounting plate to the left from under the motor

mounting bracket.

A

B

A. Motor mounting plate

B. Motor mounting bracket

A

B

A. Motor mounting plate

B. Motor mounting bracket

7 Remove the range hood internal blower motor.

8 Replace the grease filters on the hood.

Prepare for Mounting the In-Line Blower System

The In-Line Blower System must be fastened to a secure

structure of the roof, ceiling, wall, floor, or new or existing

frame construction. The 4 holes on either the inlet (bottom)

side or the outlet (top) side of the blower must be used to

mount the in-line blower system to the structure.

NOTE: The mounting hole locations must span the studs.

Additional stud framing may be required. Plywood may be

used to span open areas between ceiling joists or roof rafters

to aid installation. This structure must be strong enough to

support the weight of the in-line blower system (50 lb [22.6

kg] min).

Prepare the In-line Blower System

IWARNING

Excessive Weight Hazard

Use two or more people to move and install range hood.

Failure to do so can result in back or other injury.

1 Disconnect power.

2 Determine which venting method to use: roof or wall

exhaust.

3 Remove the 6 - 6.5 x 3.5 mm screws from the front cover

of the shell and save them for later. Remove the front cover

of the shell and set it aside.

4 Remove the 6 - 4.2 x 8 mm screws from the back of the

shell.

A

B

A. Front cover

B. Back of the shell

5 Rotate the shell and place it with the back over a covered

surface.

6 Remove 4 - 4.2 x 8 mm screws from each side cover and

remove the covers.

A

B

B

B

B

A. Side covers

B. 4.2 x 8 mm screws

For models EAR134S4, EAR140S4, EAR146S4, ECL136S4,

ECL142S4, ECL148S4, ETR134S1 and ETR146SS

Fix support bracket and spring tab, support brackets to the

appropriate screw slots following the next image.

B

A

C

D

A. Support bracket

B. Spring tab

C. 3 - 4.2 x 8 mm screws

D. 2 - 4.2 x 8 mm screws

9

7 Slide halfway the mounting plate of the blower motor

assembly, from the front of the shell, gently over the

support bracket and the spring tab inside the shell with the

wiring connection pointing to the front.

A

B

C

A. Mounting plate

B. Spring tab

C. Wiring connection

8 Push the right end of the motor mounting plate up and

snap it into the spring tab.

NOTE: The spring tab should be outside the slot in the

mounting plate.

9 Place nuts over the top of the shell on the right slots.

A

A

A. Nuts

10 Align mounting holes in motor mounting plate with motor

mounting clip nuts and install 5 - 6 x 16 mm screws with

clip nuts.

A

B

C

A. Screw with lock washer

B. Mounting hole in motor mounting plate

C. Clip nut

11 Attach power cord connector from the range hood to

connector on wiring box.

B

A

A. Wiring box connector

B. Power supply connector from range hood

12 Replace side covers with the previously removed screws

and with 6 - 4.2 x 8 mm screws from the hardware bag for

each cover and tighten.

10

13 Replace the 6 screws previously retired and place the

additional 10 - 4.2 x 8 mm screws contained on the

hardware bag to the back cover of the shell.

For models ELN136S2, ELN142S2, ELN148SS, ELI136S2 and

ELI142S2

1 Remove the 4 - 6.5 x 3.5 mm top plate screws and the top

shell plate.

A

B

B

A. Top plate

B. 4 screws

2 Fix support bracket and spring tab, support brackets to the

appropriate screw slots following the next image.

A

BD

C

A. Support bracket

B. Spring tab

C. 3 - 4.2 x 8 mm screws

D. 2 - 4.2 x 8 mm screws

3 Slide halfway the mounting plate of the blower motor

assembly, from the side of the shell, gently over the

support bracket and the spring tab inside the shell with the

wiring connection pointing to the front.

A. Mounting plate

B. Spring tab

C. Wiring connection

D. Support bracket

A

B

C

D

4 Push the right end of the motor mounting plate up and

snap it into the spring tab.

NOTE: The spring tab should be outside the slot in the

mounting plate.

A

B

A. Motor mounting plate

B. Spring clip

11

5 Place clip nuts over the top of the shell on the right slots

6 Replace the 4 - 6.5 x 3.5 mm top plate screws and the top

shell plate.

A

B

B

A. Top plate

B. 4 screws

7 Align mounting holes in motor mounting plate with motor

mounting clip nuts and install 5 - 6 x 16 mm screws and clip

nuts.

A

B

C

A. Screw with lock washer

B. Mounting hole in motor mounting plate

C. Clip nut

8 Attach power cord connector from the range hood to

connector on wiring box.

B

A

A. Wiring box connector

B. Power supply connector from range hood

9 Replace side covers with the previously removed screws

and with 6 - 4.2 x 8 mm screws from the hardware bag for

each cover and tighten.

10 Replace the 6 screws previously retired and place the

additional 10 - 4.2 x 8 mm screws contained on the

hardware bag to the back cover of the shell.

12

Install In-Blower system

NOTE: The blower motor housing can be mounted using

4 holes from either the inlet side or the outlet side of the

blower.

A

A

A

A

A

A

A. Mounting holes

1 Using two or more people, move the in-line blower motor

system to the mounting location.

2 Position the in-line blower motor housing in its mounting

location and mark the 4 mounting hole locations.

3 Drill 4 mounting pilot holes using a ³⁄₁₆” (0.5 cm) drill bit.

4 Attach the in-line blower motor housing to the mounting

location with mounting 4 - 6.3 x 60 mm screws and 4 - 4

x 1.8 mm washers. Parts are included with the range hood

motor kit.

5 If removed, reinstall the blower motor assembly and secure

it with the screws previously removed.

6 If removed, reattach the motor electrical plug to the

connector on the blower motor assembly.

Complete Preparation

1 Determine and make all necessary cuts for the vent system.

IMPORTANT: When cutting or drilling into the ceiling or

wall, do not damage electrical wiring or other hidden

utilities.

2 Determine the location where the ¹⁄₂” (1.3 cm) wiring

conduit will be routed through the ceiling or wall between

the in-line blower and the range hood.

3 Drill a 1¹⁄₄” (3.2 cm) hole at this location.

4 Locate the electrical terminal boxes in the in-line blower

housing and range hood. Remove the terminal box covers

and set the covers and screws aside.

A

B

A. Terminal Box Cover

B. Knockout

5 Remove the electrical knockout from the in-line blower

housing and range hood (see the range hood installation

instructions) to prepare for the installation of the UL listed

or CSA approved ¹⁄₂” (1.3 cm) wiring conduit and conduit

connector.

6 With the range hood mounted (see the range hood

installation instructions), run the ¹⁄₂” (1.3 cm) wiring conduit

between the in-line blower motor housing and the range

hood. Pull enough ¹⁄₂” wiring conduit to allow for easy

connection to the terminal boxes in the in-line blower

housing and range hood.

A

B

C

D

F

E

A. In-Line Blower Kit

B. Range Hood Terminal Box

C. Power Supply wiring Conduit

D. In-Line Blower Wiring Conduit (not

included)

E. In-Line Blower Terminal Box

F. In-Line Motor Electrical Plug Cable

13

7 Replace the front cover of the shell and fix it with the 6

screws previously retired and place the additional 10 - 6.5 x

3.5 mm screws contained on the hardware bag.

8 Install the conduit connectors and conduit to the in-line

blower housing and range hood electrical terminal boxes.

9 Connect the vent system to the range hood and in-line

blower system and seal all joints with clamps. F

E

B

G

A

C

D

A. Vent System

B. In line Blower Motor

C. Ceiling

D. Roof rafters/ Plywood

E. In line Blower Wiring Conduit (not

included)

F. Power Supply Wiring Conduit

G.Hood Insert

Make Electrical Connection for In-Line Blower Motor System

IWARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

IWARNING

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground wire in

terminal box.

Failure to do so can result in death or electrical shock.

NOTE: The electrical diagram is attached at the end of the

document.

Electrical Connection Inside In-line Blower System

1 Disconnect power.

2 Connect the wires from the wiring conduit to the wires

from the motor electrical plug cable inside the in-line

blower housing terminal box.

3 Use UL listed wire connectors and connect the black wires

(C) together.

4 Use UL listed wire connectors and connect the white wires

(D) together.

5 Use UL listed wire connectors and connect the red wires

(E) together.

6 Use UL listed wire connectors and connect the blue wires

(F) together.

7 Use UL listed wire connectors and connect the gray wires

(G) together.

8 Connect the green (or green/yellow) ground wire from the

wiring conduit to the green (or yellow/green), ground wire

(H) in the terminal box using UL listed wire connectors.

A

B

C

D

E

F

G

H

I

A. Strain relief

B. UL listed wire connectors

C. Black wires

D. White wires

E. Red wires

F. Blue wires

G.Gray wires

H. Green (or yellow/ green) and green / yellow wires

I. Motor electrical plug cable

9 Once the connection is done, is necessary to adjust the 6

wire connector with the included strap.

A. Ground wires connection

B. 6-9 wire connector

C. Strap

D. Strain relief

A

B

C

D

10 Reinstall the in-line blower terminal box cover and screws.

11 Reinstall the front cover of the in-line blower housing and

secure it with 10 mounting screws.

14

Make Electrical Connection Inside Range Hood Between In-Line Blower System and Range Hood

1 With the range hood mounted (see the range hood

installation instructions), locate the wiring cable connector

inside the range hood.

C

D

A

B

MODELS ETR134S1, ETR146SS, EAR134S4, EAR140S4 and

EAR146S4

A. Range Hood Junction Box

B. Range Hood knockout for Wire Connector Assembly

C. Wire Connector Assembly (provided in the In-Line Blower Kit)

D. Power Supply Wiring Conduit

MODELS ELN136S2, ELN142S2, ELN148SS,

ELI136S2 and ELI142S2

A. Range Hood Junction Box

B. Range Hood knockout for Wire Connector Assembly

C. Wire Connector Assembly (provided in the External Blower Kit)

D. Power Supply Wiring Conduit

MODELS ECL136S4, ECL142S4 and ECL148S4

A. Range Hood Junction Box

B. Range Hood knockout for Wire Connector Assembly

C. Wire Connector Assembly (provided in the External Blower Kit)

D. Power Supply Wiring Conduit

2 Connect the 6 wire connector assembly supplied with the

in-line blower motor system to the mating connector from

the range hood.

B

A

A. Wire Connector Assembly (provided in the In-Line Blower Kit)

B. Hood Insert Blower Connector

3 Install UL listed or CSA approved strain reliefs. Run through

the strain reliefs the 6 wire connector and the In-Line

Blower wiring conduit (not incluided leaving enough wire

length to make the wiring connections.

4 Tighten the strain relief screws.

5 Connect the wires from the 6- wire connector assembly to

the wires from the wiring conduit inside the range hood

terminal box.

6 NOTE: Connect the green (or green/yellow) ground wire

from the wiring conduit to the green (or bare) ground wire

from the home power supply and to the and to the green/

yellow ground wire from the 6-wire connector assembly

(H) using UL listed wire connectors (see the “Make

Electrical Power Supply Connections to Range Hood”

section in the range hood installation instructions).

A

B

C

D

E

F

G

H

I

A. Strain relief

B. UL listed wire connectors

C. Black wires

D. White wires

E. Red wires

F. Blue wires

G.Gray wires

H. Green (or yellow/ green) and green / yellow wires

I. Motor electrical plug cable

7 Connect the home power supply wiring to the range hood

following the instructions that are supplied with the range

hood.

8 Reinstall the range hood terminal box cover.

9 Reconnect power.

ELICA North America

TWO-YEAR LIMITED WARRANTY

TO OBTAIN SERVICE UNDER WARRANTY

Owner must present proof of original purchase date. Please keep a copy of your dated proof of purchase (sales slip) in

order to obtain service under warranty.

PARTS AND SERVICE WARRANTY

For the period of two (2) years from the date of the original purchase, Elica will provide free of charge, non consumable

parts or components that failed due to manufacturing defects. During these two (2) years limited warranty, Elica will also

provide free of charge, all labor and in-home service to replace any defective parts.

WHAT IS NOT COVERED

• Damage or failure to the product caused by accident or act of God, such as, flood, fire or earthquake.

• Damage or failure caused by modification of the product or use of non-genuine parts.

• Damage or failure to the product caused during delivery, handling or installation.

• Damage or failure to the product caused by operator abuse.

• Damage or failure to the product caused by dwelling fuse replacement or resetting of circuit breakers.

• Damage or failure caused by use of product in a commercial application.

• Service trips to dwelling to provide use or installation guidance.

• Light bulbs, metal or carbon filters and any other consumable part.

• Normal wear of finish.

• Wear to finish due to operator abuse, improper maintenance, use of corrosive or abrasive cleaning products/pads and

• When the product has not been operated in accordance with the accompanying instructions for use.

oven cleaner products.

WHO IS COVERED

This warranty is extended to the original purchaser for products purchased for ordinary residential use in North America

(Including the United States, Guam, Puerto Rico, US Virgin Islands & Canada).

This warranty is non-transferable and applies only to the original purchaser and does not extend to subsequent owners of

the product. This warranty is made expressly in lieu of all other warranties, expressed or implied, including, but not limited

to any implied warranty of merchantability or fitness for a particular purpose and all other obligations on the part of Elica

North America, provided, however, that if the disclaimer of implied warranties is ineective under applicable law, the dura-

tion of any implied warranty arising by operation of law shall be limited to two (2) years from the date of original purchase

at retail or such longer period as may be required by applicable law.

This warranty does not cover any special, incidental and/or consequential damages, nor loss of profits, suered by the

original purchaser, its customers and/or the users of the Products.

WHO TO CONTACT

To obtain service under warranty or for any service related question:

USA & CANADA - Western Provinces

SERVICE POWER

888 732 8018

CANADA - Ontario Province

AGI Services

888 651 2534

CANADA - Quebec & Atlantic Provinces

Ateliers G. Paquette

800 463 0119

•

•

To ensure prompt after-sales service, when you call we will kindly ask you to provide the following information indicated

on the nameplate inside the hood: hood model, 12 NC and date of purchase on original invoice.To access the nameplate,

all you have to do is remove the grease filters.

•

Register your product in

elica.com

and earn a 3rd year of factory

warranty, covering all parts

plus in-home labor.

12NC:

Hood model:

Serial No:

Date of purchase on original invoice:

16

Français

APPROUVÉ POUR LES APPAREILS DE TYPE RÉSIDENTIEL

POUR UNE UTILISATION RÉSIDENTIELLE SEULEMENT

LISEZ CES INSTRUCTIONS ET CONSERVEZ-LES

VEUILLEZ LIRE CES INSTRUCTIONS AU COMPLET AVANT DE COMMENCER.

L’INSTALLATION DE L’APPAREIL DOIT RESPECTER TOUS LES CODES EN VIGUEUR.

IMPORTANT : Conservez ces instructions afin de pouvoir les remettre à l’inspecteur-électricien de votre région.

INSTALLATEUR : Veuillez laisser ces instructions avec l’appareil pour le propriétaire.

PROPRIÉTAIRE : Veuillez conserver ces instructions pour pouvoir vous y référer plus tard.

Avertissement de sécurité : Coupez l’alimentation du circuit dans le panneau électrique et verrouillez le

panneau avant de raccorder les fils de cet appareil.

Exigence : 120 V c.a., 60 Hz circuit de dérivation de 15 V c.a., 20 Hz, de 15 ou 20 A.

Avis de Sécurité Important 17

Exigences électriques 18

Outils et pièces 19

Dimension du produit 20

Exigences concernant l’évacuation 20

Instructions d’ Installation 21

Préparation de l’emplacement 21

Installer le Système de Soufflante en Ligne 26

Faire le Raccordement Électrique pour le Système de Moteur de Soufflante en Ligne 27

Raccordement électrique à l’intérieur de la hotte de cuisine entre un Système de Soufflante en ligne et une hotte de

cuisinière 28

17

Avis de Sécurité Important

I AVERTISSEMENT

POUR RÉDUIRE LES RISQUES D’INCENDIE, DE CHOC

ÉLECTRIQUE ET DE BLESSURE, RESPECTER LES DIRECTIVES

SUIVANTES:

A. Utiliser cet appareil uniquement aux fins prévues par le

fabricant. Si vous avez des questions à propos de l’appareil,

communiquez avec le fabricant.

B. Avant de faire l’entretien de l’appareil ou de le nettoyer,

coupez l’alimentation dans le panneau électrique et

verrouillez le panneau en bloquant le dispositif permettant

d’empêcher d’activer l’alimentation accidentellement. S’il

n’est pas possible de verrouiller l’accès au panneau, fixez

une étiquette très voyante au panneau électrique.

C. Une personne qualifiée doit eectuer l’installation et le

câblage des fils électriques en conformité avec tous les

codes et toutes les normes, y compris la cote de résistance

au feu.

D. Il est important de prévoir susamment d’air pour assurer

une bonne combustion de l’équipement de chaue et

l’évacuation adéquates des gaz par le conduit de cheminé

afin de prévenir les refoulements d’air. Respectez les

directives et les normes de sécurité des fabricants de

l’équipement de chauage, comme celles publiées par la

National Fire Protection Association (NFPA), la American

Society for Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE) et le code des autorités de votre

région.

E. Au moment de couper ou de percer un mur ou un plafond,

assurez-vous de ne pas endommager la filerie électrique ou

tout autre accès à un service publique.

F. Il faut toujours évacuer à l’extérieur les systèmes conduit.

I ATTENTION

Pour réduire les risques d’incendie et évacuer l’air correctement,

assurez-vous que le conduit mène à l’extérieur; il ne faut pas

évacuer l’air dans l’espace entre les murs, dans les plafonds, dans

les greniers, les vides sanitaires ou les garages.

I AVERTISSEMENT

POUR RÉDUIRE DES RISQUES D’INCENDIE, UTILISEZ UNI-

QUEMENT DES CONDUITS EN MÉTAL.

Installez cette hotte en respectant toutes les exigences

mentionnées.

I AVERTISSEMENT

POUR RÉDUIRE LES RISQUES D’INCENDIE DE GRAISSE SUR

LES CUISINIÈRES.

a) Ne laissez jamais la cuisinière sans surveillance lorsqu’elle

est réglée à une haute température. Les débordements par

bouillonnement causent de la fumée et des débordements

de gras qui peuvent s’enflammer. Faites chauer l’huile

lentement, à une température basse ou moyenne.

b) Faites toujours fonctionner la hotte lorsque vous utilisez

la cuisinière à une haute température ou que vous faites

flamber des aliments (P. ex.: crêpes Suzette, cerises

jubilées, boeuf au poivre flambé).

c) Nettoyez les hélices de ventilation fréquemment. Il ne faut

pas que la graisse s’accumule sur les filres ou les hélices.

d) Utilisez le bon format de casserole. Utilisez toujours un

chaudron de taille approprié à l’élément de la cuisinière.

e) Convient pour utilisation dans la zone de cuisson domestique.

I AVERTISSEMENT

POUR ÉVITER DE BLESSER QUELQU’UN LORS D’UN

INCENDIE DE GRAISSE SUR LA CUISINIÈRE, SUIVRE LES

CONSEILS SUIVANTS:a

a) ÉTOUFFER LES FLAMMES avec un couvercle aux

dimensions de la taque de cuisson, une tôle à biscuit

ou tout autre plateau métallique, puis couper le gaz ou

l’alimentation électrique de la cuisinière. FAIRE ATTENTION

A NE PAS SE BRÛLER. Si les flammes ne s’éteignent pas

immédiatement, QUITTER LA PIÈCE ET APPELER LES

POMPIERS.

b) NE JAMAIS PRENDRE EN MAIN UNE CASSEROLE N FEU,

vous pourriez vous blesser.

c) NE PAS UTILISER D’EAU, y compris les essuies de vaisselle

ou les serviettes humides – une violente explosion due à la

vapeur formée pourrait survenir.

d) Utiliser un extincteur SEULEMENT si:

1) Vous êtes sûr d’avoir un extincteur de classe ABC que

vous savez utiliser.

2)Le feu est petit et confiné à la zone où il s’est formé.

3)Les pompiers ont été appelés.

4)Vous pouvez lutter contre le feu avec une sortie derrière

vous.f

a Recommandations tirées des conseils de sécurité en cas d’incendie de cuisine

publiés par la NFPA..

I ATTENTION

Dispositif à fonctionnement automatique - Pour réduire le

risque de blessures, débranchez l’appareil de l’alimentation

électrique avant de le réparer.

Pour les modèles de moteurs de soufflerie double (ELN136S2, ELN142S2, ELN148SS, ELI136S2,

ELI142S2, EAR134S4, EAR140S4, EAR146S4, ECL136S4, ECL142S4, ECL148S4, ETR134S1,

ETR146SS)

18

Exigences d’ installation

Exigences électriques

IMPORTANT

Respectez tous les codes et les ordonnances en vigueur.

Le client a la responsabilité de :

• Contacter un électricien-installateur.

• Vérifier que l’installation électrique est adéquate et

conforme avec le Code national de l’électricité, ANSI/

NFPA 70 (la plus récente édition*), ou les normes C22.1-94,

Code canadien de l’électricité, Partie 1 et C22.2 No.0-M91

(La plus récente édition**) de la CSA, ainsi que tous les

codes et les ordonnances de votre région.

• Si le code le permet et que vous utilisez un fil de mise à la

tere distinct, il est recommandé de faire vérifier le chemin

du fil par un électricien.

• Une copie des normes du code ci-dessus peut être

obtenue auprès de :

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

• L’appareil doit être alimenté par un circuit de 120 V, CA

seulement, 60 Hz, 15 A, protégé par fusible.

• Si le domicile est équipé d’un câblage en aluminium, suivre

les instructions suivantes :

1 Connecter une section de câble en cuivre massif aux

conducteurs en queue de cochon.

2 Connecter le câblage en aluminium à la section ajoutée de

câblage en cuivre en utilisant des connecteurs et/ou des

outils spécialement conçus et homologués UL pour fixer le

cuivre à l’aluminium.

Appliquer la procédure recommandée par le fabricant

des connecteurs. La connexion aluminium/cuivre doit être

conforme aux codes locaux et aux pratiques de câblage

acceptées par l’industrie.

• Le calibre des conducteurs et les connexions doivent être

compatibles avec la demande de courant de l’appareil

spécifiée sur la plaque signalétique. La plaque signalétique

de l’appareil est située à l’intérieur du boîtier du moteur.

• Le calibre des conducteurs doit satisfaire aux exigences

de la plus récente édition de la norme National Electrical

Code, ANSI/NFPA 70, ou de la norme CSA C22.1-94,

Code canadien de l’électricité, partie 1 et C22.2 n° 0-M91

(dernière édition) et de tous les codes et règlements en

vigueur.

Pour les installations de maisons mobiles

L’installation de ce système de moteur soufflant externe doit

être conforme aux Manufactured Home Construction Safety

Standards, Title 24 CFR, Part 328 (anciennement Federal

Standard for Mobile Home Construction and Safety, Title 24,

HUD, Part 280) ou, si cette norme n’est pas applicable, à la

norme Manufactured Home Installation 1982 (Manufactured

Home Sites, Communities and Setups) ANSI A225.1/NFPA

501A*, ou à la dernière édition, ou aux codes locaux.

19

Outils et pièces

Rassembler les outils et composants nécessaires avant

d’entreprendre l’installation. Lire et observer les instructions

fournies avec chacun des outils de la liste ci-dessous.

Outils nécessaires

• Perceuse

• Foret de 1¼” (3 cm)

• Foret de ³⁄₁₆” (0,5 cm)

• Crayon

• Pince à dénuder ou couteau utilitaire

• Mètre-ruban ou règle

• Pince

• Pistolet à calfeutrage et composé de calfeutrage résistant

aux intempéries

• Brides de conduit

• Scie sauteuse ou scie à guichet

• Screwdrivers

•Phillips

•Lame-plate

Pièces non fournies

• 6 conducteurs de calibre 18 AWG de chacune des couleurs

suivantes : noir, blanc, rouge, bleu, gris et vert ou vert/

jaune (terre).

REMARQUE: La longueur du conduit et des cables

AWG est d.terminée par la distance entre le moteur du

ventilateur interne et les botiers de raccordement de la

hotte.

• 11 connecteurs de fils homologués UL

Pièces fournies

Retirer les pièces de leur emballage. Vérifier que toutes les

pièces sont présentes.

• Carcasse pour l’assemblage du moteur de la souante

• Sac de matériel avec :

Pièce fournie Qté Pièce fournie Qté

Décharge de traction connector (13,5)

26.5 X 3.5 mm vis de montage 10

4.2x8 mm vis de montage 33

Ø 12 mm Décharge de traction

1

6-Câble de prise

1

6x13.5 mm

2

4x1.8mm rondelles plates

4Torx adaptateur

(T10)1

(T20)1

Languette à ressort

1

Écrous de xation

4

6.3 x 60 mm vis de montage

7Bride 2.5x 95 mm 3

Support de montage

1

6 x 16 mm vis de montage

4

10x50 mm ancrages muraux

7

20

Dimension du produit

14 7⁄8”

(20 cm)

VUE DE DESSUS (SORTIE)

3 3⁄8”

(8.6 cm)

12 15⁄16”

(32.9 cm)

26 1⁄8”

(66.4 cm)

14 11⁄16”

(37.3 cm)

24 3⁄4”

(62.9 cm)

VUE DE DESSOUS (ENTRÉE)

3 3⁄8”

(8.6 cm)

14 7⁄8”

(20 cm)

16 1⁄8”

(41 cm)

Exigences concernant l’évacuation

• Le système d’évacuation doit décharger l’air à l’extérieur.

• Ne pas terminer le circuit d’évacuation dans un grenier ou

dans un autre espace clos.

• Ne pas utiliser une bouche de décharge murale de 4”

(10,2 cm) normalement utilisée pour un équipement de

buanderie.

• Utiliser un conduit métallique cylindrique uniquement. Un

conduit en métal rigide est recommandé. Ne pas utiliser de

conduit en plastique ou aluminium.

• La longueur du conduit de décharge et le nombre de

coudes doivent être réduits au minimum pour obtenir les

meilleurs résultats.

Pour un fonctionnement ecace et silencieux :

• Ne pas utiliser plus de trois coudes à 90°.

• Veiller à ce qu’il y ait une section droite de conduit d’un

minimum de 24” (61 cm) entre les raccords coudés, si on

doit en utiliser plus d’un.

• Ne pas installer 2 coudes successifs.

• Au niveau de chaque jointure du circuit d’évacuation,

assurer l’étanchéité avec les brides de serrage.

• Le circuit d’évacuation doit comporter un clapet anti-

reflux.

• À l’aide d’un produit de calfeutrage, assurer l’étanchéité

autour de la bouche de décharge à l’extérieur (à travers le

mur ou le toit).

• Le diamètre du conduit doit être uniforme.

Installations pour régions à climat froid

On doit installer un clapet anti-retour supplémentaire à l’arrièr

pour minimiser le reflux d’air froid et incorporer une résistance

thermique pour minimiser la conduction des températures

extérieures par le conduit d’évacuation. Le clapet anti-retour

doit être placé du côté air froid de la résistance thermique.

La résistance thermique doit être le plus près possible de

l’entrée du circuit d’évacuation dans la partie chauffée de la

maison.

Installations typiques d’un système de ventilation interne

Un circuit d’évacuation en conduit rond de 8” (20.32 cm) - 10”

(25,4 cm) est nécessaire pour l’installation (non fourni). Les

ouvertures d’entrée et de sortie du système de ventilation

interne ont un diamètre de 8” (20.32 cm) - 10” (25,4 cm).

L’ouverture de décharge (sortie) sur la cuisinière doit

également mesurer 8” (20.32 cm) - 10” (25,4 cm) de diamètre.

REMARQUE : On déconseille l’emploi d’un conduit flexible.

Un conduit flexible peut causer une contre-pression et

des turbulences d’air, qui réduisent considérablement la

performance. La sortie à l’extérieur du circuit d’évacuation

peut se faire à travers le toit ou un mur.

REMARQUE : Il est possible d’utiliser du contreplaqué comme

base de montage dans les zones ouvertes entre solives et

chevrons. Dans un tel cas, veiller à utiliser du contreplaqué

capable de supporter le poids du système de ventilation

interne (50 lb [22,6 kg]).

A

B

C

D

E

E

A. Montage au-dessus des solive

B. Montage sur traverses de ferme

C. Conduit horizontal, montage sur traverses

de ferme

D. Montage sous les chevrons

E. Contreplaqué

Table of contents

Languages:

Other ELICA Fan manuals

Popular Fan manuals by other brands

Addvent

Addvent AVX100QS operating instructions

Harbor Breeze

Harbor Breeze PACIFIC GROVE 40101 installation guide

Craftmade

Craftmade Pro Energy Saver 209 installation guide

AERMEC

AERMEC FCX-P Series Use and installation manual

Meltem

Meltem M-WRG-II M installation manual

Vent-Axia

Vent-Axia MVDC-MSH UniFlex Installation and wiring instructions