1. SAFETY

The following symbols refer to

particular dangers or give advice for save

operation

Danger

Danger from electric current / high voltage!

Danger! Do not step under hanging load!

Crush danger!

Important, information

Safety advice

Wolter In line ducts are produced in

accordance with the latest technical standards

and our quality assurance programme, which

includes material and function tests, ensures

that the final product is of a high quality and

durability. Never the less these fans can be

dangerous if they are not used and installed

correctly, according to the instructions

Before installing and operating this fan

please read instructions carefully!

Only use the fan after it has been securely

mounted and fitted with protection guards and

maintenance cover to suit the application

(Tested guards can be supplied for all fans

from our programme). Installation, electrical

and mechanical maintenance and service

should only be undertaken by qualified worker!

The fan must only be used according to its

design parameters, with regard to required

performance stated in the name-plate and

mediums passing through it!

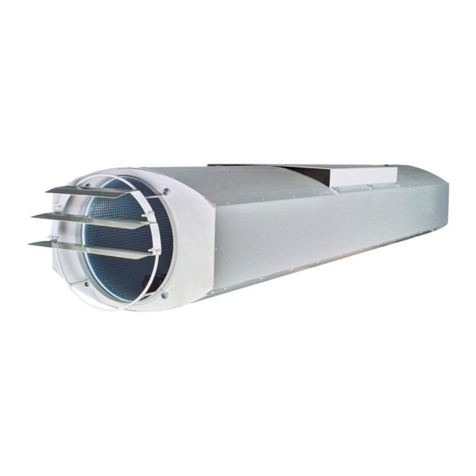

2. DESCRIPTION

Duct fans were especially developed for use in

modern ventilation systems. By using external

rotor motors there are significant technical

advantages in operation. All duct fans are 100%

speed controllable and are statically and

dynamically balanced as a composite unit in

our factory. The fans are also available with

motor/impellers to be folded out for

maintanence

3. CONDITIONSOFUSE

Duct fans can be used for ventilation of:

•Clean air

•Slightly dusty and greasy air

•Slightly aggressive gases and fumes

(please refer to our engineers)

•mediums up to an atmosheric density of

1,2 kg/m3

•Mediums passing through with a

temperature of -30°C up to + 40°C

•Mediums up to a max. Humidity of 95%

4. STORAGE & TRANSPORT

•Store the fan on a dry place and weather

protected in its original packing

•Cover open palettes with a tarpaulin and protect

the fans against influence of dirt (i.e. Stones,

splinters, wires, etc.).

•Storage temperatures between -30°C and +

40°C

•With storage times of more than 1 year, please

check the bearings on soft running before

mounting (turn by hand).

•Transport the fan with suitable loading means:.

•Do not damage casing.

•Use suitable assembling means as e.g. scaffolds

conforming to specifications.

Danger! Do not step under hanging load!

5. INSTALLATION

Installation and electric work only by skilled

and introduced workers and in accordance to

applying regulations!

Installation of fan either with mounting flange directly to

the duct system, possibly by conjunctions with a sound

attenuator or, in order to avoid noise transmission, with

flexible connectors, installed on the inlet and outlet.

The standard method of mounting is via a pre-prepared

platform or for vertical mounting channel section

brackets fixed to the fan casing. (8" weight as per chart

in enclosure

For installation on mounting flange use M8 screws and

secure properly

Avoidsoundbridges byuse ofisolation

material (i.e. sponge rubber)

Check impeller rotation by hand for soft running

For external mounting weather protection should be

used.This should be designed to suit the installation

and is supplied by others.

The duct system must not be supported by

the fan casing !