Elife Elife-Drive HR Series User manual

Brushless Edition - Rev. B

Elife-Drive HR Series

(ex H)

Application

Reference Manual

Elife International S.r.l.

Via del Giglio, 4 - 57037 Portoferraio - LI

Isola d’Elba - Toscana - Italy

Tel: +39 0565 944121 Fax: +39 0565 945726

email: [email protected]

This manual is copyrighted of Elife International. All rights are reserved. This manual must not be

copied in whole or in part, nor transferred to any other media or language, without express written

permission of Elife International.

Technical Manual Version: 2.4

Release Data: 07/12/2018

Contents

1 Overview 1

2 Installation and Wiring 5

2.1 Mounting Elife-Drive on-board . . . . . . . . . . . . . . . . . . . . . 5

2.2 Connections................................ 5

2.2.1 High Power Connections . . . . . . . . . . . . . . . . . . . . . 6

2.2.2 Low Power Connections . . . . . . . . . . . . . . . . . . . . . 8

2.3 Standard Wiring Diagrams and Wiring Instructions . . . . . . . . . . 11

2.3.1 StandaloneMode......................... 11

2.3.2 PLCMode............................. 16

2.3.3 CAN Network Mode . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.4 RS232Mode ........................... 24

2.4 FeedbackConnector ........................... 27

2.4.1 Resolver.............................. 29

2.4.2 SinCosEncoder.......................... 30

2.4.3 HallSensor ............................ 30

2.4.4 Fa-Coder.............................. 31

2.4.5 Digital Absolute Angle Position . . . . . . . . . . . . . . . . . 32

3 Configuration 33

3.1 SoftwareOverview............................ 33

3.2 Connect Elife-Drive to your PC . . . . . . . . . . . . . . . . . . . . . 34

3.3 Import and Export Parameter Values . . . . . . . . . . . . . . . . . . 35

3.4 Change Programmable Parameters . . . . . . . . . . . . . . . . . . . 35

3.4.1 Operating Mode and Controller Parameters . . . . . . . . . . 36

3.4.2 Motor and Acceleration Parameters . . . . . . . . . . . . . . . 38

3.4.3 Throttle Parameters . . . . . . . . . . . . . . . . . . . . . . . 39

3.4.4 CANopen®Parameters...................... 39

3.4.5 Locked Parameters . . . . . . . . . . . . . . . . . . . . . . . . 40

3.4.6 Advanced Parameters . . . . . . . . . . . . . . . . . . . . . . 43

3.5 Auto-tuning Elife-Drive Parameters . . . . . . . . . . . . . . . . . . . 46

3.5.1 Gain Parameters for closed-loop Current Control . . . . . . . 46

3.5.2 Finding the Min and Max values for SinCos Encoder . . . . . 47

3.5.3 Offset Resolver/SinCos . . . . . . . . . . . . . . . . . . . . . . 49

i

4 Monitoring Elife-Drive 51

4.1 LEDDiagnostics.............................. 51

4.2 Reading Telemetry Data from Telemetry Panel . . . . . . . . . . . . . 51

4.2.1 AlarmIndicators ......................... 54

4.2.2 Reset all Current Alarms . . . . . . . . . . . . . . . . . . . . . 56

4.2.3 Digital I/O and Drive State Indicators . . . . . . . . . . . . . . 56

4.2.4 The Target Velocity/Torque Track Bar . . . . . . . . . . . . . . 58

4.3 Plot and Log Telemetry Data in Real-Time . . . . . . . . . . . . . . . 59

5 Maintenance 61

A Troubleshooting: Alarm Messages 63

B Index of Programmable Parameters 71

List of Tables

1.1 The common features of all models of Elife-Drive H Series ....... 2

1.2 An overview of the Elife-Drive H Series Models . . . . . . . . . . . . . 3

2.1

A summary table of high-power connections, except the H4896-X-X Type.

7

2.2 Fuse size in accordance with the Elife-Drive Type. . . . . . . . . . . . . 7

2.3 The pins’ description for the J1 - COMMAND connector. . . . . . . . . . . 8

2.4 Elife-Drive I/O definitions for Standalone Mode. ............ 12

2.5 Elife-Drive I/O definitions for PLC Mode ................. 16

2.6 CAN bus address selector switch at the node set to 0. . . . . . . . . . . 17

2.7 Elife-Drive I/O definitions for Can Network Mode............ 20

2.8 Elife-Drive I/O definitions for RS232 Mode. ............... 24

2.9

Pinout Description of the

J2 - FEEDBACK

DB9 connector (

See Figure

2.11) to connect a Resolver to your Elife-Drive. . . . . . . . . . . . . . 29

2.10

Pinout Description of the

J2 - FEEDBACK

DB9 connector (

See Figure

2.11) to connect a SinCos Encoder to your Elife-Drive. . . . . . . . . . 30

2.11

Pinout Description of the

J2 - FEEDBACK

DB9 connector (

See Figure

2.11) to connect a Hall Sensor to your Elife-Drive. . . . . . . . . . . . 30

2.12

Pinout Description of the

J2 - FEEDBACK

VGA connector (

See Figure

2.12) to connect a Fa-Coder to your Elife-Drive. . . . . . . . . . . . . . 31

2.13

Pinout Description of the

J2 - FEEDBACK

VGA connector (

See Figure

2.12) to connect a Digital Absolute Angle Position to your Elife-Drive. 32

4.1 Description of Digital I/O indicators in Telemetry Panel. . . . . . . . . 57

ii

iv

1

Overview

Elife-Drive

is the new family of drivers designed to drive the various types of

low-voltage servomotors, specifically for use in battery powered devices.

The compact form was made possible thanks to the high efficiency of the design,

manufactured with state-of-art electronic components.

Elife-Drive is highly configurable, a wide range of programmable parameters allow

you to customize your system for your needs.

The main key features include:

•Designed to drive from 24 V to 96 V Brushless, Brushed and AC ServoMotors.

•

The different types of feedback are supported:

Absolute Resolver

,SinCos

Encoder,Hall Sensors,Sensorless,Incremental Encoder,Tachometer.

•Advanced algorithms for predictive speed and torque control.

•

CANopen

®

communication protocol

1

: CiA

®

DS301 and CiA

®

DSP402 (Interface

Profile Velocity, Torque Profile Mode and Profile Position Mode)

•

Electromagnetic Holding Brake Output with DPR System (Dynamic Power

Reduction)

•Telemetry of the Internal functions

•Integrated Fuse Holder (only up 80 V)

•

European Conformity

C

, and designed and tested in accordance with the

Electromagnetic compatibility (EMC) emission [EN 61000-6-4] and immunity

[EN 61000-6-2] standards.

1Elife International is a Member of CiA®- CAN in Automation

1

Specification:

Four Quadrant Regenerative Operation

Space Vector Modulation Technology

Sinusoidal and Trapezoidal Commutation Methods

Programmable Gain Setting

Fully Configurable Velocity and Position Limits

On-the-fly Mode and Gain Set Switching

Emergency Deceleration Ramp and Emergency Input

Programmable Input/Output:

Two High Powered Digital Outputs One 12-bit Analog Input 0÷10 V

Five Digital Inputs Single Ended Four Digital Outputs Singled Ended

Table 1.1: The common features of all models of Elife-Drive H Series

VALUE

PWM Operating Frequency: 6103 Hz

Digital Input Pin Voltage: up to 36 V

Electrical Insulation at Heat Sink: 500 V (minimum)

Digital Output Pin Current: up to 250 mA

Brake and Power Relay Pin Current: up to 2 A

Digital Input Pin Current: 1.0 mA @24 V

Digital Output Pin Voltage: From 6 to 30 V

Analog Input Voltage: From 0 to 10 V

Package Environmental Rating: IP 30

Weight 1.1 kg

144x100x72 mm (Electrical Box Version)

Dimensions H x W x D: 110x90x56 mm (OEM Version)

2Chapter 1 Overview

A broad range of models enable us to satisfy every requirements and to suggest the

best solution for your system.

An overview of the

Elife-Drive H

Series Models is shown in Table 1.2. For other

models, have a look at Elife-Drive S Series for lower power models or at Elife-Drive

M Series for higher power models.

Table 1.2: An overview of the Elife-Drive H Series Models

DRIVER CONTINUOUS RMS

PHASE CURRENT *

MAXIMUM

OUTPUT POWER

NOMINAL VOLTAGE SUPPLY

(Operating Range)

H2448-2-X up to 100 A 2 KW 48 V

(18 Vmin - 70 Vmax)

H2424-3-X up to 150 A 3 KW 24 V

(18 Vmin - 35 Vmax)

H2436-3-X up to 150 A 3 KW 36 V

(18 Vmin - 55 Vmax)

H2448-3-X up to 150 A 3 KW 48 V

(18 Vmin - 70 Vmax)

H4896-6-X up to 150 A 6 KW 96 V

(43 Vmin - 150 Vmax)

*The value of the maximum continuous RMS Phase current is ensured with an appropriate heat sink

(a) Electrical Box Version

Size: 144x100x72 mm

(b) OEM Version

Size: 110x90x56 mm

Figure 1.1:

Elife-Drive series H enables you to drive from 24 V to 96 V Brushless, Brushed

and AC ServoMotors. It’s available in two configurations: (a) Electrical Box with container

and in (b) OEM Version for integrating into motor housing.

3

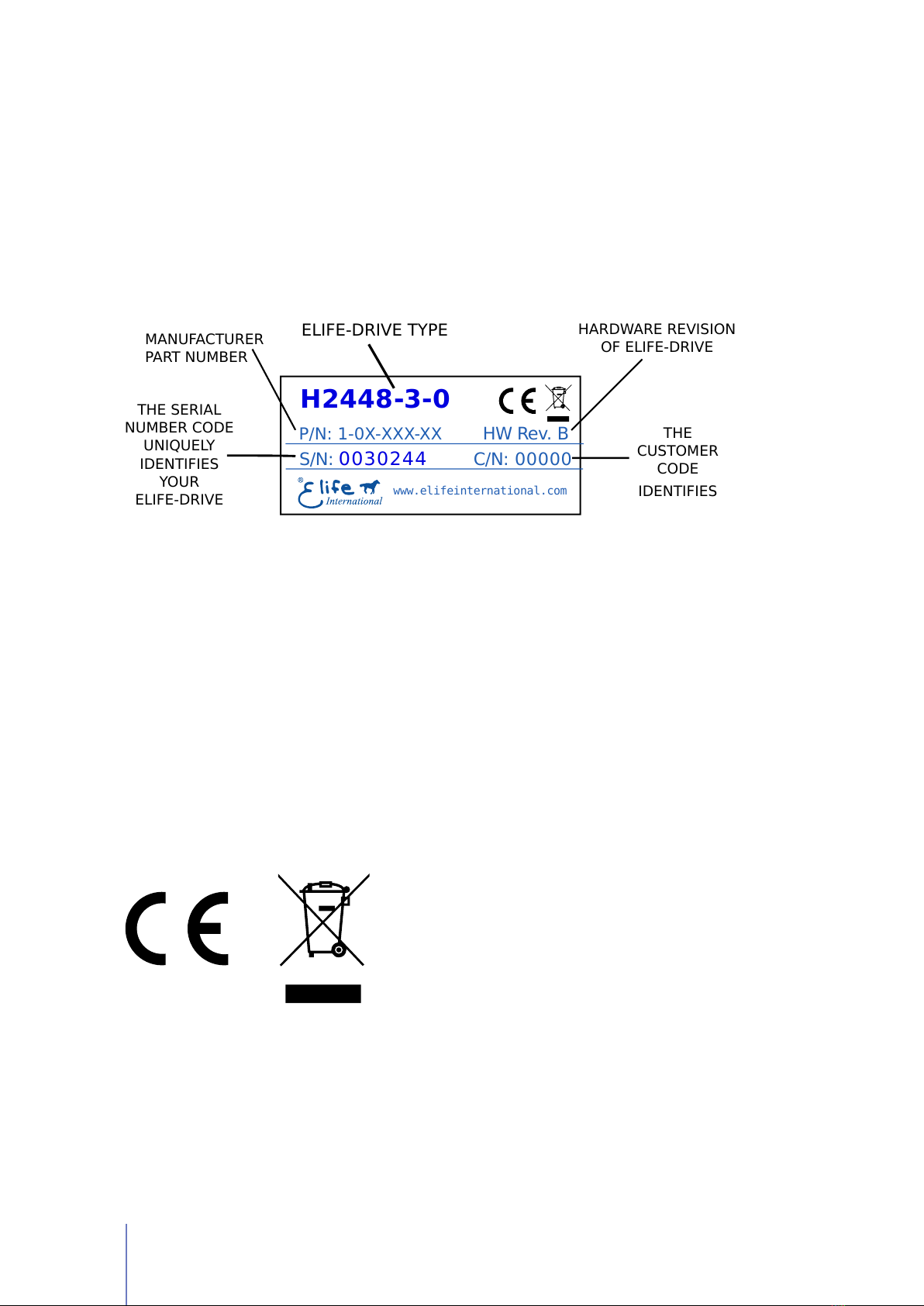

Product Identification Label

Most of information about your Elife-Drive - such as serial number, model, customer

information, etc - can be found on a label located on the front of the Elife-Drive (see

figure below). Some of these information might be requested when you contact the

technical assistance.

THE SERIAL

NUMBER CODE

UNIQUELY

IDENTIFIES

YOUR

ELIFE-DRIVE

ELIFE-DRIVE TYPE HARDWARE REVISION

OF ELIFE-DRIVE

THE

CUSTOMER

CODE

IDENTIFIES

www.elifeinternational.com

0030244 00000S/N: C/N:

HW Rev. B

P/N: 1-0X-XXX-XX

MANUFACTURER

PART NUMBER

H2448-3-0

Compliance with the EU regulatory requirement for electrical and electronic equipment.

When your Elife-Drive is no more usable, can’t be treated as generic garbage, but

must be disposed of at a collection point for recycling of electrical and electronic

equipment, in compliance with the

WEEE

regulation (Waste of Electrical and

Electronic Equipment).

4Chapter 1 Overview

2

Installation and Wiring

2.1 Mounting Elife-Drive on-board

The Elife-Drive can be mounted in any orientation, but you must choose a location

in order to keep the controller

clean

and

dry

, aways from sunlight, water and ice.

When you mount the Elife-Drive on-board you should

ensure an effective heat

dissipation between the Elife-Drive and the vehicle surface.

A thermal grease can be used on the rear side of the Elife-Drive heatsink to

improve the heat exchange between Elife-Drive and the vehicle surface.

Tips and Advice

Elife-Drive has a LED light on the front of the device that visually explains what the

driver is doing (see Section 4.1), if you want it to be visible you should take this into

consideration before choosing the location where your Elife-Drive will be mounted.

In order to ensure the proper functioning of the Elife-Drive you must keep the

controller clean and dry and ensure an effective heat exchange between the

Elife-Drive and the vehicle surface.

Warning

2.2 Connections

Elife-Drive on the front, see Figure 2.1, has different types of connectors:

High Power Connections

The three-phase alternating-current generated by Elife-Drive

is supplied through the

U

,

V

,

W

terminals. The

F+

,

B-

are the positive

1

and

negative terminals to connect to your battery.

Low Power Connections

A 24-pin male connector (

J1 - COMMAND

) for low power

logic control.

1For H4896-X-X Type you must connect an external fuse to the B+ terminal, see Section 2.2.1.

5

Feedback Connections

A 9-pin female low power connector (

J2 - FEEDBACK

) to

connect your feedback board.

Figure 2.1:

Elife-Drive has different types of connectors that can be categorized in: High

Power Connections (

U

,

V

,

W

,

F+

,

B-

,

B+

), Low Power Connections (

J1 - COMMAND

) and

Feedback Connector (J2 - FEEDBACK).

2.2.1 High Power Connections

High power connections are provided by: 3-phase supply terminals (

U

,

V

,

W

) and

two terminals for battery connections (F+ or B+,B-).

In order to connect correctly Elife-Drive, you should use the following instructions:

1.

Except the

H4896-X-X

Type, you must mount an appropriately sized fuse (See

Table 2.2) between

F+

and

B+

terminal to avoid damage to the controller.

All Elife-Drive models, except the

H4896-X-X Type

, have a fuse already

installed.

Note

2.

Connect the

battery positive

cable to the

F+

terminal and the

battery negative

cable to the B- terminal.

For

H4896-X-X

Type you must connect an external fuse to the

B+

terminal

(see Table 2.2 and the Wiring Diagrams).

6Chapter 2 Installation and Wiring

Table 2.1: A summary table of high-power connections, except the H4896-X-X Type.

TERMINAL CONNECT TO

F+ Battery positive terminal to the fuse link

B+ Fuse terminal

B- Battery negative terminal

U,V,W U, V, and W motor phases

3.

Connect the U, V, and W motor phases to the 3-phase supply terminals

(U,V,W).

The tightening torque for high-power connections must be 5.5 N·m.

Note

Make sure when you connect the high-power cables that the feedback cable

passes as far as possible from the power cables and they are not located close

to each other, in order to avoid electromagnetic interference.

Warning

Table 2.2: Fuse size in accordance with the Elife-Drive Type.

ELIFE-DRIVE TYPE FUSE RATING

H2448-2 40 A

H2424-3 100 A

H2436-3 70 A

H2448-3 50 A

H4896-6 70 A

Figure 2.2: Elife-Drive H Series - High-power connections.

2.2 Connections 7

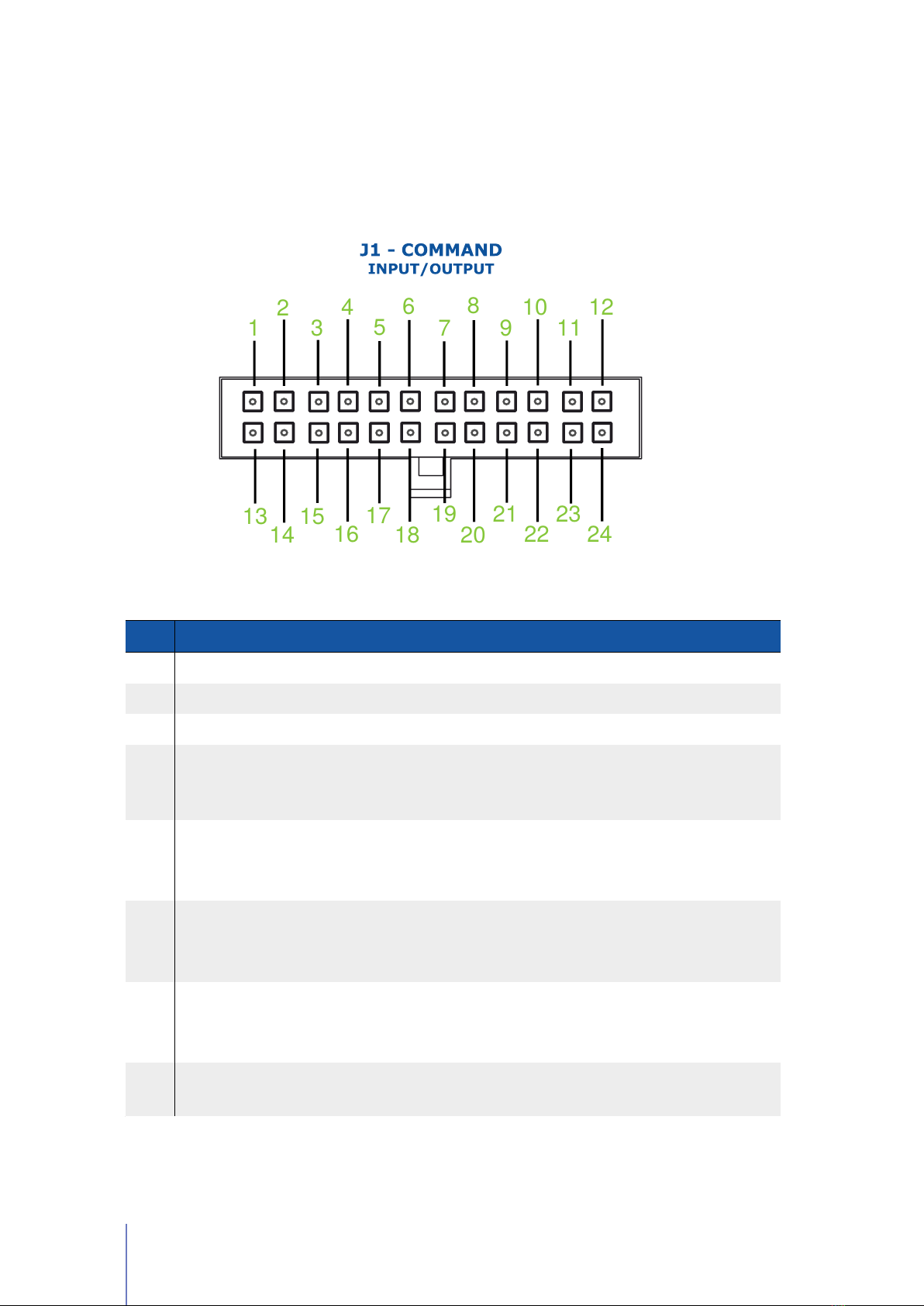

2.2.2 Low Power Connections

The low power logic control connections are provided by a 24-pin male connector

(J1 - COMMAND). The pins’ description is given in Table 2.3.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Table 2.3: The pins’ description for the J1 - COMMAND connector.

PIN I/O TYPE DESCRIPTION OPERATING RANGE

1IN1 Digital input 1 VMAX = 36 V, High > 11 V

2IN3 Digital input 3 VMAX = 36 V, High > 11 V

3IN5 Digital input 5 VMAX = 36 V, High > 11 V

4+24V INPUT

Power supply for output pins, it

should be protected with 4A

delayed fuse, type T

From 6 to 30 V

5BRAKE

Brake supply with

programmable dynamic power

reduction

Output Voltage in according

to the Input voltage on PIN 4

IMAX=2 A

6

LINE

CONTACTOR

OUT

Driver main contactor output

Output Voltage in according

to the Input voltage on PIN 4

IMAX=2 A

7OUT1 Digital output 1

Output Voltage in according

to the Input voltage on PIN 4

IMAX=250 mA

8PWR POT Speed potentiometer supply

output VOUT= 10 V IOUT=100 mA

Continued on next page . . .

8Chapter 2 Installation and Wiring

. . . continued from previous page

PIN I/O TYPE DESCRIPTION OPERATING RANGE

9ANALOG GND Analog Common /

Potentiometer Low Input /

10 CAN-

CAN_L bus line (dominant low)

Standard CAN

11 TX RS232

TX output, it is used to

communicate with RS232 in

order to realize Telemetry panel

Standard RS232

12 SERIAL GND

RS232 Common, it is used to

communicate with RS232 in

order to realize Telemetry panel

/

13 KEY (+BATT)

Internal logic circuits power

supply, it should be protected

with 1A delayed fuse, type T

From 18 to 80 V

(Only for H4896-X-X Type:

From 43 to 160 V)

14 IN2 Digital input 2 VMAX = 36 V, High > 11 V

15 IN4 Digital input 3 VMAX = 36 V, High > 11 V

16 SERVICE Do not use /

17 OUT2 Digital Output 2

Output Voltage in according

to the Input voltage on PIN 4

IMAX=250 mA

18 OUT3

Drive fault alarm output, it

changes its current state

whenever an alarm is present.

See Section 3.4.1, Pag. 37

Output Voltage in according

to the Input voltage on PIN 4

IMAX=250 mA

19 OUT4 Encoder emulator, single phase

Output Voltage in according

to the Input voltage on PIN 4

IMAX=250 mA

20 -BATT

Common ground, it should be

connected to the negative

terminal of battery

/

21 AIN /

WIPER POT

Analog input /

Wiper input for throttle

From 0 to +10 V

From 0 to +5 V

22 CAN+ CAN_H bus line (dominant

high) Standard CAN

23 GND CAN CAN bus common /

24 RX RS232

RX Input, it is used to

communicate with RS232 in

order to realize Telemetry panel

Standard RS232

Concluded

2.2 Connections 9

The digital inputs have over-voltage protection up to battery voltage and the

analog input up to 26 V.

Note

10 Chapter 2 Installation and Wiring

2.3 Standard Wiring Diagrams and Wiring

Instructions

This section contains standard wiring diagrams to be used to connect your

Elife-Drive

H Series

on your system. The following wiring diagrams cover only the standard

operating mode in which the Elife-Drive works to drive a Brushless Servomotor.

It’s also possible to connect two or more Elife-Drive together for specific application

(e.g: steering wheel control) and drive different types of servomotor. These advanced

installations will not be dealt with in the present manual.

The following wiring diagrams and operating instructions should be read

carefully and completed before wiring your Elife-Drive up on your system.

The wiring diagram must be chosen in according to the operating mode

(PLC, Standalone, CAN, RS323) that suits your needs.

Warning

For H4896-6-X Type you should mount an external fuse, see Section 2.2.1.

Note

2.3.1 Standalone Mode

The Standalone mode is designed to drive your motor with only two inputs: a throttle

and a emergency input.

Other optional inputs can be used to extend the functionality of this operating mode

(See Table 2.4).

For the correct functioning of this operating mode, special attention must be paid

to choose the correct value of Analog Input (See Section 3.4.3) in according to the

throttle characteristics.

If you’ve installed a 0-10V or 0-5V throttle the rotation direction of the motor

should be given through the FORWARD and the BACKWARD input.

Note

When

throttle is put to neutral position

- before bridge activation - you can indicate

the speed mode (FAST/SLOW input).

2.3 Standard Wiring Diagrams and Wiring Instructions 11

Table 2.4: Elife-Drive I/O definitions for Standalone Mode.

PIN I/O

TYPE NAME DESCRIPTION

1IN1 CRUISE

Rising Edge Signal = Enable/Disable

Active or Disable the Cruise Control if a

Rising Edge Signal is detected

Optional

14 IN2

FAST/SLOW

High = Slow mode, Low = Fast mode.

This input is processed only before bridge

activation

Optionala

2IN3 FORWARD High = Forward, Low = Stop

(only if BACKWARD is low) Optionalb

BACKWARD

High = Backward, Low = Stop.

This input is only processed if FORWARD

input is low.

Optionalb

15 IN4 REVERSE

High = Active, Low = Inactive.

If it’s active, invert the positive/negative

range of throttle.

Optionalc

3IN5

EMERGENCY

Emergency input should always be

supplied, otherwise Elife-Drive stops

motor rotation and unlocks motor brake.

Mandatory

7OUT1 REVERSE

It is the output to connect to buzzer, it

gets high when the rotation direction is

backward.

17 OUT2 STATUS

It gets steady high when motor is

running and blinking when motor is

stopped. It’s low when there is an alarm.

18 OUT3 ALARM

Alarm output, it changes its current state

whenever an alarm is present. See

Section 3.4.1, Pag. 37

aMandatory if you want to switch between Fast and Slow mode, see Section 3.4.2.

bMandatory only for 0–10V or 0-5V throttle, see Section 3.4.3

cOnly valid for 0–5-10V or 0-2.5-5V throttle, see Section 3.4.3

You can setup accurately the levels of your throttle in the

Tuning Tab

by the

Analog adjustment in Standalone parameters.

Tips and Advice

The Fast and Slow modes are designed to meet two different purposes:

Slow mode

It’s programmable so that the vehicle indoor moves slowly with accurate

operation.

Fast mode It allows a faster velocity for outdoor long distance path.

12 Chapter 2 Installation and Wiring

It’s scheduled both the configuration of the maximum motor velocity and the

maximum velocity at Slow mode (See Section 3.4.2).

The Standalone Mode has a

Cruise Control

. The controller - when the Cruise

Control is activated by a Rising Edge Signal on IN1 - read the actual target velocity

by the throttle state and keep this velocity stable also when the throttle is released.

The Cruise Control are disabled by the following actions:

•A Risign Edge Signal on IN1

•If the Emergency Input is unsupplied.

•For any Alarm Occours.

The

wiring diagram

for standalone mode is shown in Figure 2.3 for any Elife-Drive

H Series Type, except the H4896-X-X Type (Figure 2.4).

2.3 Standard Wiring Diagrams and Wiring Instructions 13

Standalone Mode - Wiring Diagram

BRAKE 24V

24V BUS

GND BUS

KEY

EMERGENCY

1A DELAYED

4A DELAYED

+IN -IN

+OUT -OUT

1A DELAYED

POWER

CONNECTIONS

U

V

W

F+ B+

M

3

B-

FORWARD

MAIN FUSE

24

11

12

16

10

22

23

14

21

18

7

6

20

SIGNAL CONNECTIONS

5

17

19

9

8

4

2

13

3

15

1

CAN PORT RS232

DIGITAL INPUTSDIGITAL OUTPUTS ANALOG I/O SUPPLY

BACKWARD/REVERSE

ALARM

REVERSE

CW

POT +

-

Alternative:

use a voltage source

in place of the pot.

FAST/SLOW

STATUS

RS232-2 TX

RS232-2 RX

RS232-2 GND

OPTIONAL

1A

2A

3A

4A

6A

7A

8A

9A

5A

J2 - FEEDBACK

MOTOR FEEDBACK

Elife-Drive

H Series

CONTACTOR 24V

BATTERY

24 to 48V

DC / DC

Vbatt → 24Vout

@ 6A

VENDOR SPECIFIC

Figure 2.3:

The wiring diagram to connect your

Elife-Drive H Series

- except the H4896-X-X

Type - to your system in Standalone Mode.

14 Chapter 2 Installation and Wiring

This manual suits for next models

7

Table of contents

Popular Servo Drive manuals by other brands

Parker

Parker PSD1-SW1200 installation instructions

Mitsubishi Electric

Mitsubishi Electric MR-J2S-11K Series Instructions and Cautions for Safe Use

Syntec

Syntec SVD-32C1-020 Hardware manual

Omron

Omron R88M-U03030HA user manual

Tsino Dynatron

Tsino Dynatron CoolDrive Series user manual

Estun

Estun Trio DX4 user manual

Omron

Omron OMNUC U Series user manual

Siemens

Siemens SINAMICS S210 FSA Quick installation guide

Metronix

Metronix DIS-2 310/2 FB FS STO Mounting instructions

Rockwell Automation

Rockwell Automation Allen-Bradley Ultra3000 Migration guide

THORLABS

THORLABS KBD101 user guide

Sanyo Denki

Sanyo Denki Sanmotion R manual