Elk Products ELK-9100 User manual

ELKPRODUCTS,INC.

PO Box 100 • 3266 US Hwy. 70 West

Hildebran, NC 28637 •USA

828-397-4200•FAX828-397-4415

http://www.elkproducts.com•Email:[email protected]

ULTRAMATE

ELK-9100

Remote Controlled Heavy Duty Switch, X-10 Activated

With Built-in Signal Bridge, and Repeater Function

05/03

Overview

The ELK-9100 is a remote controlled heavy duty switch which may be used with 220/240 Volt electrical appliances, water

heaters, pool pumps, or 110/120 branch lighting loads. It can be activated by an X-10 power line signal or contact closure

source. The unit features built-in signal bridging across both legs of the 220/240 power circuit for improved performance of

X-10 powerline signaling. It also features a selectable repeater function to provide more reliable X-10 communications over

longer distances.

Features

• Controlled Remotely from X-10 Power Line Carrier Commands.

• Optional Dry Contact Closure Activation.

• 30 Amp Long Life Double Pole Relay Contacts.

• Control One 220-240 Volts A.C. Device: Water Heater, Pool or Irrigation Pump, Heater, etc.

OR

• Control Two 115-120 Volts A.C. Devices: Lights, Motors, etc.

• Built-in signal bridging of the two 220-240 Volts A.C. legs improves X-10 signal performance in the entire building.

• Selectable X-10 signal repeater functionality.

• Single or Dual Commands may be programmed to turn the relay On/Off. Dual commands reduce false activation.

• On-site programming of X-10 signal(s).

• Manual On/Off Push Button Control.

• LED Status indicators for X-10 signal, Circuit 1(Relay 1), and Circuit 2 (Relay 2).

• EEProm Memory remembers the last relay state in the event of a power fluctuation.

• Heavy Duty PVC enclosure prefitted with 1/2" conduit connector. Not suitable for wet locations.

• Color coded 18" wire leads, #10 AWG, MTW, stranded nickel plated copper rated for 30 Amps A.C.

• Mounting hardware included.

• Lifetime Limited Warranty.

Specifications

• Operating Voltage: 220-240 Volts A.C., drawn locally from the electrical panel (line) source.*

• Nominal Current Draw: 26mA

• Relay Contact Rating: 30 Amps at 120/240 Volts A.C.

• Wire Harness: 18" wire leads, #10 AWG, MTW, stranded nickel plated copper rated for 30 Amps A.C.

• Size: 4.36" W x 6.36" H x 2" D.

* Note: The ELK-9100 cannot be powered from GFCI Ground Fault Breakers.

However, GFCI Breakers can be utilized on the output (load) side of the ELK-9100.

* Note: The ELK-9100 is not compatible with the Leviton model 6325 Telephone Transponder due to some non-standard

line signals that the Leviton transmits.

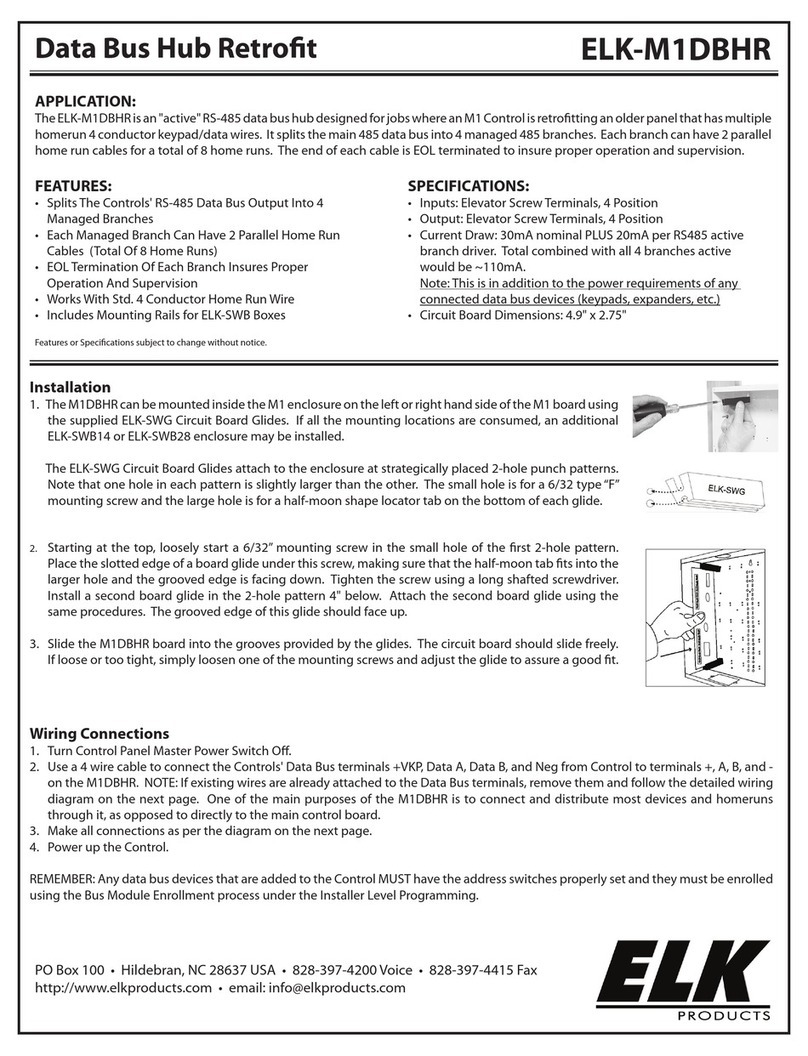

FACTORY CONFIGURATION AND JUMPER OPTIONS

TheELK-9100isfactoryconfiguredforsinglephase220/240VoltsA.C.operationtypicallyfoundinresidentialinstallations.It

containstwoRelays which are factory configuredtoactivateatonce for controlling of a220/240VoltsA.C. device. The X10

powerlinerepeaterfunctionisalsofactoryenabledforimprovedX-10communicationsoverlongdistances.

INSTALLATION

1. Locate the 220-240 Volts A.C. electrical panel circuit breaker or the manual disconnect source (line) that supplies the

equipmenttobecontrolled.

* Note: The ELK-9100 cannot be powered from GFCI Ground Fault Breakers. However, GFCI Breakers can be connected to the output

(load) side of the ELK-9100.

2. Turnofftheelectricity supplying the device to be controlled.

3. Mount the ELK-9100 adjacent to the electrical panel or the manual disconnect.

4. Removethecoveroftheelectricalpanelormanualdisconnect.

5. Unscrewand remove the twoLOADwires from thecircuitbreaker or disconnect terminals.

6. Using two wire nuts strip and connect the BLUE wire from the ELK-9100 to one of the removed LOAD wires. Connect the

ORANGEwireto the otherLOADwire.

7. StripandconnecttheREDandBLACKwiresfromtheELK-9100totheLOADterminalsofthecircuitbreakerordisconnect.

8. Replacethecover on the electricalpanelormanual disconnect.

9. Turn on the electricity.

Jumper Configuration

IMPORTANT NOTE: For safety and legal reasons the ELK-9100 should ONLY be installed by a

licensed and qualified electrician. There is an inherent risk of electrical shock or death if not

properly installed. Do not remove the cover of the unit without first turning off the electrical

supply. Except for the configuration jumpers there are no user servicable components inside.

J1 RELAYSGROUPED [Default] Bothrelaysactivate togetherforcontrolof220/240VoltsA.C.devices.

RELAYSSEPARATED Each relaycanbecommandedseparatelyforcontrolof110/120VoltsA.C.devices.

J2 1 (single phase) [Default] For typical residential installations

3 (3 phase) For commercial 208 Volts A.C. /3 P power systems this must be selected.

J3 REPEATERYES [Default] ReceivedX-10signalswillbetransmittedontobothsidesofa residentialelectri-

cal system. Signals will be amplified to 5V P-P maximum. Note: Actual signal boost is highly dependent

upon the electrical system. This feature cannot be used in the 3 phase or commercial systems.

REPEATERNO Disablestherepeaterfunctionality.

OPERATION

MANUAL CONTROL

Pressing the button on the front of the ELK-9100 sends a local signal to change the state of the relay(s). As long as

JumperJ1 is set to RELAYS GROUPED, both relays will toggle. If Jumper J1is set to RELAYS SEPARATED the relays

will toggle through the four possible states of ON/OFF, OFF/ON, ON/ON, OFF/OFF with each button press.

CONTACT CLOSURE OPERATION

Therelaysmay also be controlled from thehardwiredterminalinputs located inside the unit. In theRELAYS GROUPED

operation mode, if the "Trig 1 Relay" terminals are closed together (shorted), both relays will go to the "off" state. In the

RELAYSSEPARATEDoperationeachrelayisindividuallycontrolledbyclosure(shorting)thetheappropriatetrigger

terminals. Arelaywhich is hardwired triggered to be "OFF" cannot be turned ON via X-10.

X-10 OPERATION

TheELK-9100hasbeenfactoryprogrammedtorespondtoX-10HouseCode"C"andUnitCode"16"(ingroupedmode

only)andcanbereprogrammedbythe user to respond to other House and Unit Code(s) if desired. To restore factory

default C16 code, hold the On/Off switch pressed, power up the 9100, hold switch until Circuit 2 led flashes, release

switch and press once more, Circuit 2 led will go out and the 9100 is now programmed for House Code "C" and Unit

Code "16". Note: the same House Code must be used for both relays.

PROGRAMMING THE X-10 CODES

For GROUPED MODE,J1 must be set to RELAYS GROUPED.

Withpower applied,pressand holdtheOn/Off switchuntilthe CIRCUIT1LED beginsflashing.From anX-10transmitter,

send an ON signal of the desired House and Unit Code, then send an OFF signal to the same House and Unit Code. The

LEDwillstop blinking and both relaysarenowprogrammed.

Example: Enter program mode, send A1 ON and then A1 OFF. The LED will stop blinking. You now must send A1 ON

to activate both relays (Circuit 1 & 2 On). You must send A1 OFF to deactivate both relays (Circuit 1 & 2 Off).

TheELK-9100canalsobeprogrammedtorespondONLYtoamoresecuredoublesignaloperation.(groupedmodeonly)

This will significantly reduce the chance of a stray X-10 signal accidentally turning the ELK-9100 On or Off. This method

requiresa specific second ONorOFFsignal within atimewindowof approximately 5 seconds.Thesecond signal must be

thesameHouseCodebutadifferentUnitcode.Toprogramthisdoublesignalfeature,withpowerapplied,pressandholdthe

On/OffswitchuntiltheCIRCUIT1LEDbeginsflashing.FromanX-10transmitter,sendanONsignalofthedesiredHouseand

thefirstUnitCode,thensendanONsignaltothesameHouseCodeandadifferent2ndUnitCode.TheLEDwillstopblinking

andtherelaysarenowprogrammed.

Example: Enter program mode, send A1 ON and then A2 ON. The LED will stop blinking to indicate programming is

complete. You now must send the sequence A1 ON, then A2 ON with no other X-10 between them to activate the relays

(Circuit 1 & 2 On). You must also send the sequence A1 OFF, then A2 OFF to deactivate the relays (Circuit 1 & 2 Off).

For SEPARATED MODE, J1 must be set to RELAYS SEPARATED.

ToprogramtherelayforCIRCUIT1, withpower applied,press andholdtheOn/OffswitchuntiltheCIRCUIT1LEDstarts

toblink.From an X-10 transmitter, send anONsignalofthe desired House and Unit CodeforCIRCUIT1, then send an

OFF signal to the same House and Unit Code. The LED will stop blinking and the relay for CIRCUIT 1 is now pro-

grammed.

Example: Enter program mode, send A1 ON and then A1 OFF. The LED will stop blinking. You now must send A1 ON

toactivate relay 1(CIRCUIT1 On). You mustsendA1 OFF todeactivaterelay 1 (CIRCUIT1Off).

Toprogramtherelayfor CIRCUIT 2, you must use the same House Code that was used to program Circuit 1, with power

applied, press and hold the On/Off button until the CIRCUIT 2 LED starts to blink. From an X-10 transmitter, send an ON

signalofthedesiredHouseandUnitCodefor CIRCUIT 2, then send an OFF signal to the same House and Unit Code.

TheLEDwillstopblinking andthe relayforCIRCUIT2isnowprogrammed.

Example: Enter program mode, send A2 ON and then A2 OFF. The LED will stop blinking. You now must send A2 ON to

activaterelay 2(CIRCUIT 2On). YoumustsendA2 OFFtodeactivaterelay2 (CIRCUIT2 Off).

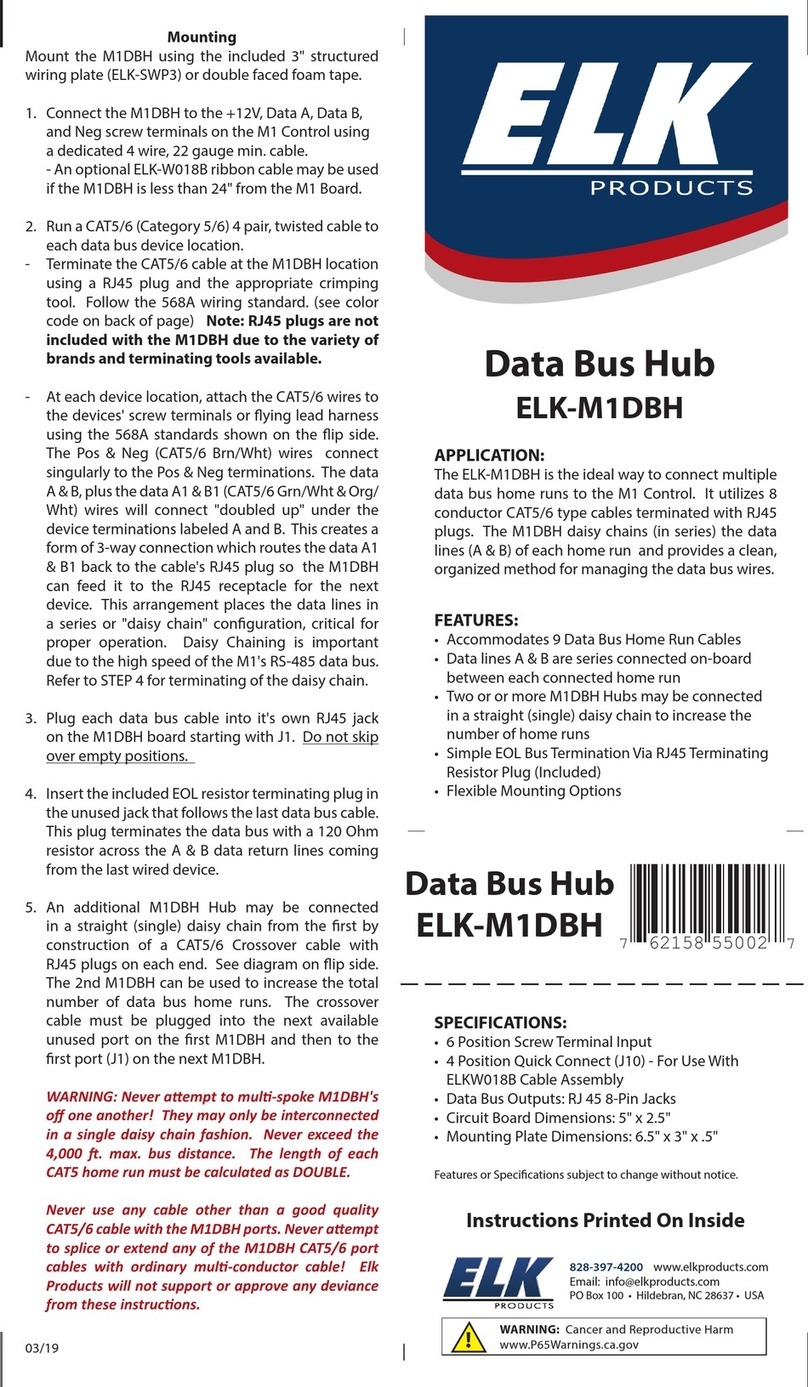

BLACK

ORANGE

MAIN

Electrical Breaker Panel

NEUTRAL/

GROUND

BLOCK

240240

240 240 120 120 120 120

120 120 120 120

WATER HEATER

Installation of ELK-9100

at the Breaker Panel

Controlling Two 120VAC

Circuit Loads

Circuit 2

120 VAC Device

LINE SIGNAL

CIRCUIT1

CIRCUIT2

PUSH ON

PUSH OFF

ELK-9100

240V - 30A

HEAVY DUTY

ULTRAMATE

PVC

CONDUIT

LOAD

LOAD

NEUTRAL

GROUND

Note: 120V Breakers Must

be Side by Side to connect

to both L1 & L2 120v legs

i.e. Lights, Heater

Black & Blue Wires = Circuit 1

Red & Orange Wires = Circuit 2

Installation of ELK-9100 at the Load

Controlling One 240 VAC Circuit Load

ELK-9100

LINE SIGNAL

CIRCUIT1

CIRCUIT2

PUSH ON

PUSH OFF

ELK-9100

240V - 30A

HEAVY DUTY

ULTRAMATE

Electrical

Junction

Box

GND

TO

LOAD

BLUE

RED

FROM

BREAKER

PANEL

L1 L2 LOAD

After disconnecting power, mount the 9100 and a 4" electrical

junction box near the load. (water heater, motor, etc.)

Disconnect the existing wiring from the load and route it into

the junction box. Add wiring from the junction box to the load

and wire according to the diagram.

Note: The ELK-9100 cannot be powered

from GFCI Ground Fault Breakers.

However, GFCI Breakers can be utilized

on the output (load) side of the ELK-9100

Note: The ELK-9100 cannot be

powered from GFCI Ground Fault

Breakers. However, GFCI

Breakers can be utilized on the

output (load) side of the ELK-9100

Electrical Circuit

Breaker Panel

Figure 1

Figure 2

4"

Electrical

Junction

Box

(or other load)

(i.e. Water Heater)

This is the preferred method when the circuit breaker panel is flush

mounted, not accessible, or far away from the load. It requires a

separate 4" electrical junction and wire connectors for safely

completing the installation.

Existing Wiring

to the Load

Remote from Load

Circuit 1

120 VAC Device

i.e. Lights, Heater

BLACK

RED

BLUE

ORANGE

NEUTRAL

GROUND

Not

Suitable

for Wet

Locations

Not

Suitable

for Wet

Locations

4

Other Elk Products Switch manuals